Ophthalmic, Nasal and Parenteral Applications - Gerresheimer

Ophthalmic, Nasal and Parenteral Applications - Gerresheimer

Ophthalmic, Nasal and Parenteral Applications - Gerresheimer

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

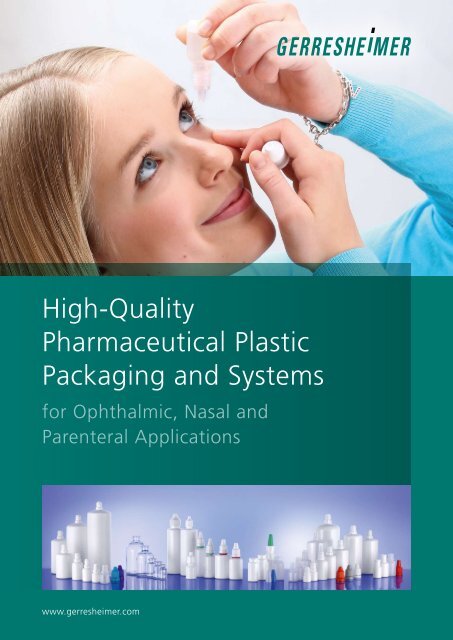

High-Quality<br />

Pharmaceutical Plastic<br />

Packaging <strong>and</strong> Systems<br />

for <strong>Ophthalmic</strong>, <strong>Nasal</strong> <strong>and</strong><br />

<strong>Parenteral</strong> <strong>Applications</strong><br />

www.gerresheimer.com

<strong>Gerresheimer</strong> Plastic Packaging<br />

Europe<br />

<strong>Gerresheimer</strong> Vaerloese | Denmark<br />

<strong>Gerresheimer</strong> Haarby | Denmark<br />

<strong>Gerresheimer</strong> Boleslawiec | Pol<strong>and</strong><br />

<strong>Gerresheimer</strong> Valencia | Spain<br />

<strong>Gerresheimer</strong> Zaragoza | Spain<br />

Asia<br />

<strong>Gerresheimer</strong> New Delhi | India<br />

<strong>Gerresheimer</strong> Kundli | India<br />

South America<br />

<strong>Gerresheimer</strong> São Paulo, Butanta | Brazil<br />

<strong>Gerresheimer</strong> São Paulo, Cotia | Brazil<br />

<strong>Gerresheimer</strong> São Paulo, Embu | Brazil<br />

<strong>Gerresheimer</strong> Buenos Aires | Argentina<br />

About <strong>Gerresheimer</strong><br />

<strong>Gerresheimer</strong> is an internationally leading manufacturer of highquality<br />

specialty products made of glass <strong>and</strong> plastic for the global<br />

pharma <strong>and</strong> healthcare industry. Our comprehensive portfolio of<br />

products extends from pharmaceutical vials to complex drug delivery<br />

systems such as syringe systems, insulin pens <strong>and</strong> inhalers for<br />

safe medication dosage <strong>and</strong> application. Together with our partners,<br />

we develop solutions which set st<strong>and</strong>ards <strong>and</strong> have role model<br />

status in their respective market sectors.<br />

Our Group realizes revenues of around one billion euros <strong>and</strong> has<br />

about 11,000 employees at 47 locations in Europe, North <strong>and</strong><br />

South America <strong>and</strong> Asia. We use first-rate technologies, convincing<br />

innovations <strong>and</strong> targeted investments to systematically consolidate<br />

our strong market position.

<strong>Gerresheimer</strong> Plastic Packaging Solutions<br />

Intelligent products for diverse pharmaceutical applications<br />

PET / Liquid & Solid<br />

Solid<br />

<strong>Ophthalmic</strong>, <strong>Nasal</strong> <strong>and</strong> <strong>Parenteral</strong> <strong>Applications</strong><br />

<strong>Gerresheimer</strong> Plastic Packaging specializes in the widely varied<br />

spectrum of pharmaceutical plastic packaging within solid, PET<br />

<strong>and</strong> ophthalmic applications, plastic vials <strong>and</strong> plastic bottles for<br />

personal care. Our leading br<strong>and</strong>s Duma ® , Dudek <strong>and</strong> Triveni for<br />

solid dosage, edp-br<strong>and</strong>ed PET bottles for liquid dosage <strong>and</strong> our<br />

ophthalmic products form part of a comprehensive <strong>and</strong> innovative<br />

product range. Our plastic vials br<strong>and</strong>ed MultiShell ® are specially<br />

designed for sensitive parenteral drug formulations.<br />

Our st<strong>and</strong>ard range includes a wide choice of different types of<br />

containers <strong>and</strong> closures, PET bottles, eye droppers, nasal sprays,<br />

nebulisers as well as numerous customized developments.<br />

Using our ideas <strong>and</strong> experience to produce intelligent, increasingly<br />

safe <strong>and</strong> user-friendly packaging solutions has enabled us to become<br />

an innovative partner to the global pharmaceutical industry.<br />

We know, underst<strong>and</strong> <strong>and</strong> reinforce our customers business.<br />

05/13 3

05/13 4

Specialist <strong>and</strong> quality leader in primary<br />

plastic packaging<br />

Our manufacturing operations use state-of-the-art technology <strong>and</strong> apply the most rigorous<br />

quality <strong>and</strong> hygiene st<strong>and</strong>ards. They cover all production technologies from injection<br />

moulding <strong>and</strong> injection blow moulding to blow moulding processes. The majority of our<br />

production operations are carried out in modern classified clean-rooms or in clean<br />

conditions. All plants apply the rules of Good Manufacturing Practice (GMP) <strong>and</strong> are certified<br />

in accordance with ISO st<strong>and</strong>ards.<br />

· Solution providing<br />

· Good Manufacturing Practice (GMP)<br />

· ISO certifications (ISO 9001, ISO 15378, ISO 14001)<br />

· Automated in-line controls<br />

· Vision-based inspection system<br />

· Class 7 (10,000) + class 8 (100,000) clean-rooms<br />

Strong regulatory approach<br />

We ensure full conformity of our products with the European Pharmacopoeia, the United States<br />

Pharmacopeia <strong>and</strong> the requirements for FDA registration with a Drug Master File as the<br />

st<strong>and</strong>ard. Knowing the extensive requirements of our customers we focus on providing a<br />

high level of documentation with our products.<br />

· High level of documentation <strong>and</strong> registration<br />

· St<strong>and</strong>ard product database<br />

· FDA <strong>and</strong> world-wide registration of all products<br />

· US <strong>and</strong> Canada Drug Master File<br />

· Product registrations in Russia, China <strong>and</strong> the Ukraine<br />

· Food approval<br />

Strong quality culture<br />

A strong quality culture supports our efforts to deliver excellent quality. The culture is defined<br />

by our shared beliefs, values <strong>and</strong> behaviour patterns.<br />

· Quality attitude <strong>and</strong> team work<br />

· Continous improvements<br />

· Systematic problem solving<br />

· Quality by design<br />

· Stable, robust, reliable <strong>and</strong> validated processes<br />

· Risk-based approach<br />

05/13 5

Innovative <strong>and</strong> trendsetting<br />

Dedication to technological advancement <strong>and</strong> product development enable <strong>Gerresheimer</strong><br />

to set benchmarks in packaging design. We offer our pharmaceutical customers the very latest<br />

developments in packaging systems.<br />

· Longer shelf-life requirements for sensitive pharmaceutical<br />

formulations<br />

· Higher compliance st<strong>and</strong>ards<br />

· Child-resistant <strong>and</strong> senior-friendly closure systems<br />

· Total solution provider<br />

· Barrier packaging<br />

· Unique, customized solutions for niche market segments<br />

<strong>Gerresheimer</strong> Plastic Packaging’s most recent innovations are the OneLiner ® <strong>and</strong> our parenteral<br />

MultiShell ® vials.<br />

Duma ® OneLiner ®<br />

Do you believe that st<strong>and</strong>ardizing packaging <strong>and</strong> closure solutions<br />

for the international pharma markets is a good idea? Our optional<br />

liner for the otherwise identical Duma ® Twist-Off containers is one<br />

such solution – <strong>and</strong> it’s a worldwide first.<br />

In future you will be able to use the same container <strong>and</strong> closure<br />

type on your filling lines in both the USA <strong>and</strong> Europe. The only difference<br />

is the liner inside the closure. It has the necessary foil seal<br />

for the US market, is manufactured in top quality <strong>and</strong> complies<br />

with all the relevant pharmaceutical regulations. That’s what we<br />

call efficiency.<br />

· Hygienic seal<br />

· TE function<br />

· Stability / shelf life extension<br />

· Reseal after opening<br />

MultiShell ® plastic vials<br />

<strong>Gerresheimer</strong>`s MultiShell ® vials unite the best properties of plastic<br />

<strong>and</strong> glass in a new high performance packaging for liquid medications.<br />

MultiShell ® vials have a unique triple-layer structure consisting of a<br />

layer of polyamide s<strong>and</strong>wiched between two Cyclic Olefin Polymer<br />

layers. They have unique barrier properties which enhance the drug<br />

stability over shelf life. The extraordinary puncture-resistance of<br />

the multilayer structure prevents the liquid leaking, even when unusual<br />

forces are applied, <strong>and</strong> predestines MultiShell ® vials as packaging<br />

of cytotoxic drug solutions.<br />

<strong>Gerresheimer</strong> has established commercial production line <strong>and</strong> offer<br />

now 2, 5, 10, 15, 50 <strong>and</strong> 100 ml vials. The installation of a multifunctional,<br />

automated packaging line will enable the packaging of<br />

different vial finish from st<strong>and</strong>ard to ready-to-use.<br />

· Unique barrier performance<br />

· Superior break resistance<br />

· Low adsorption<br />

· No metal ions<br />

· Inert against high <strong>and</strong> low pH<br />

· Available in st<strong>and</strong>ard, RTS <strong>and</strong> RTU<br />

05/13 6

<strong>Ophthalmic</strong>, nasal <strong>and</strong> parenteral applications<br />

Our products for ophthalmic <strong>and</strong> nasal applications include bottles <strong>and</strong> droppers in LDPE,<br />

CLC bottles <strong>and</strong> nasal sprays with either nebulisers or pumps.<br />

Other materials, sizes <strong>and</strong> designs are available, as are closures with child-resistant or<br />

senior-friendly features.<br />

The innovative design of the high-performance MultiShell ® vials is based on a combination of<br />

the plastic material COP (Cyclic Olefin Polymer) <strong>and</strong> a polyamide layer which provides high barrier<br />

properties.<br />

· Dropper <strong>and</strong> CLC bottles<br />

· <strong>Nasal</strong> sprays with nebuliser<br />

· <strong>Nasal</strong> sprays with pump<br />

· Bottles in LDPE & HDPE<br />

· Bottles in PP<br />

· Droppers in LDPE<br />

· Caps in HDPE & PP<br />

· Large range of bottles & droppers<br />

· Other materials, sizes <strong>and</strong> designs<br />

available<br />

· Tamper-evident<br />

· Child-resistant & senior-friendly closures<br />

· MultiShell ® vials (st<strong>and</strong>ard, RTS <strong>and</strong> RTU)<br />

· FDA registered, DMF type III,<br />

DMF no. 22946, DMF no. 16117<br />

05/13 7

05/13 8

Content<br />

ophthalmic<br />

1<br />

2<br />

Dropper bottles –<br />

System A<br />

3<br />

Accessories<br />

4<br />

Dropper bottles –<br />

System B<br />

5<br />

Accessories<br />

6<br />

Dropper bottles –<br />

System Q<br />

7<br />

Accessories<br />

8<br />

Dropper bottles –<br />

System CL<br />

9<br />

Accessories A1ST<br />

10<br />

Dropper bottles – System PR <strong>and</strong> CT<br />

11<br />

CLC bottles<br />

nasal<br />

12<br />

Spray bottles with nebuliser – System NEB<br />

13<br />

Spray <strong>and</strong> pump systems: Snap-on bottles<br />

parenteral<br />

14<br />

MultiShell ® vials (st<strong>and</strong>ard, RTS <strong>and</strong> RTU)<br />

05/13 9

Pharmaceutical Plastic Packaging<br />

Packaging for ophthalmic applications<br />

1<br />

2<br />

Dropper bottles –<br />

System A (LDPE)<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

Specifications<br />

10<br />

11<br />

ref ml ml mm<br />

mm<br />

mm<br />

12<br />

13<br />

14<br />

35034 2 3 17 34,5 11 x 2<br />

35036 5 7,5 21 42 14 x 2<br />

35035 10 12,5 24 52 14 x 2<br />

35048 10 12 24 52 14 x 2<br />

35037 15 18,5 25 63 14 x 2<br />

35030 25 28 31 65 14 x 2<br />

35038 30 35 31 75 14 x 2<br />

35080 50 60 39 81 14 x 2<br />

32266 60 68 39 88 14 x 2<br />

32293 115 124 45 107 14 x 2<br />

32295 135 140 45 121 14 x 2<br />

32271 280 314,5 60 148 14 x 2<br />

· Material: LDPE<br />

· Available in other materials, sizes <strong>and</strong> designs<br />

· Radiation or ETO sterilisation on request<br />

· Accessories: see page 12 <strong>and</strong> 13<br />

05/13 10

Pharmaceutical Plastic Packaging<br />

Packaging for ophthalmic applications<br />

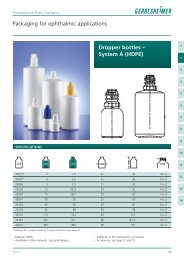

Dropper bottles –<br />

System A (HDPE)<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

Specifications<br />

10<br />

ref ml ml mm<br />

mm<br />

mm<br />

11<br />

35073* 5 7,5 21 42 14 x 2<br />

35047* 5 7,5 21 42 14 x 2<br />

35046 5 7,5 21 42 14 x 2<br />

35003 10 12,5 24 52 14 x 2<br />

35037 15 18,5 25 63 14 x 2<br />

35041 30 35 25 63 14 x 2<br />

32333 60 62 39 81 14 x 2<br />

32334 65 68 39 88 14 x 2<br />

32331 115 124 45 107 14 x 2<br />

32327 250 301 58 147,5 14 x 2<br />

33067 360 382 58 181 14 x 2<br />

12<br />

13<br />

14<br />

* Material: PP – Limited availability (further information upon request)<br />

· Material: HDPE<br />

· Available in other materials, sizes <strong>and</strong> designs<br />

· Radiation or ETO sterilisation on request<br />

· Accessories: see page 12 <strong>and</strong> 13<br />

05/13 11

Pharmaceutical Plastic Packaging<br />

Packaging for ophthalmic applications<br />

1<br />

2<br />

Dropper bottles –<br />

System A: Accessories<br />

3<br />

4<br />

5<br />

Dropper<br />

Nozzle<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

Tamper-evident<br />

screw cap<br />

Tamper-evident<br />

wing screw cap<br />

Child-resistant<br />

tamper-evident<br />

screw cap<br />

13<br />

14<br />

05/13 12

Pharmaceutical Plastic Packaging<br />

Packaging for ophthalmic applications<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

Specifications<br />

10<br />

ref Drops/ml +/- 20%<br />

ref<br />

11<br />

Dropper<br />

14110 21<br />

14166 23<br />

Tamper-evident screw cap<br />

15190<br />

15197<br />

12<br />

14182 24<br />

14213 22<br />

15233<br />

15255<br />

13<br />

14214 28<br />

Tamper-evident screw cap for nozzle<br />

15207<br />

14216 24<br />

14219 14<br />

Tamper-evident wing screw cap<br />

Child-resistant tamper-evident screw cap<br />

15250<br />

91176<br />

14<br />

Nozzle<br />

14180 –<br />

14222 –<br />

· Material: dropper LDPE, nozzle LDPE<br />

· Available in other materials, sizes <strong>and</strong> designs<br />

· Droppers <strong>and</strong> nozzles fit bottle sizes on page 10 <strong>and</strong> 11<br />

· Material: tamper-evident<br />

screw cap HDPE, tamper-evident wing<br />

screw cap HDPE, child-resistant<br />

tamper-evident screw cap HDPE<br />

· Available in other materials, sizes <strong>and</strong> designs<br />

· Caps fit bottle sizes on page 10 <strong>and</strong> 11<br />

05/13 13

Pharmaceutical Plastic Packaging<br />

Packaging for ophthalmic applications<br />

1<br />

2<br />

Dropper bottles –<br />

System B<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

Specifications<br />

10<br />

11<br />

ref ml ml mm<br />

mm<br />

mm<br />

12<br />

38005 5 7,1 19 44 16 x 2<br />

38010 10 14,2 25 53 16 x 2<br />

13<br />

14<br />

· Material: LDPE<br />

· Available in other materials, sizes <strong>and</strong> designs<br />

· Radiation or ETO sterilisation on request<br />

· Accessories: see page 15<br />

05/13 14

Pharmaceutical Plastic Packaging<br />

Packaging for ophthalmic applications<br />

Dropper bottles –<br />

System B: Accessories<br />

1<br />

2<br />

3<br />

Tamper-evident<br />

screw cap<br />

Dropper<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

Specifications<br />

10<br />

Tamper-evident<br />

screw cap<br />

Dropper<br />

ref Drops/ml +/- 20%<br />

15015 –<br />

15016 –<br />

14004 21<br />

14002 18<br />

11<br />

12<br />

13<br />

· Material: dropper LDPE, tamper-evident screw cap HDPE<br />

· Available in other materials, sizes <strong>and</strong> designs<br />

· Droppers <strong>and</strong> caps fit bottle sizes on page 14<br />

14<br />

05/13 15

Pharmaceutical Plastic Packaging<br />

Packaging for ophthalmic applications<br />

1<br />

2<br />

Dropper bottles –<br />

System Q<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

Specifications<br />

10<br />

11<br />

ref ml ml mm<br />

mm<br />

mm<br />

12<br />

13<br />

14<br />

200 5 9 22 44 Q<br />

201 10 13 22 56 Q<br />

726 15 16 23 65 Q<br />

· Material: LDPE<br />

· Accessories: see page 17<br />

05/13 16

Pharmaceutical Plastic Packaging<br />

Packaging for ophthalmic applications<br />

Dropper bottles –<br />

System Q: Accessories<br />

1<br />

2<br />

3<br />

Dropper<br />

Tamper-evident<br />

screw cap<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

Specifications<br />

10<br />

ref<br />

mm<br />

11<br />

· Material: dropper LDPE, cap PP<br />

· Dropper <strong>and</strong> cap fit bottle sizes<br />

on page 16<br />

Dropper<br />

Tamper-evident screw cap<br />

10054 Q<br />

10055 Q<br />

12<br />

13<br />

14<br />

05/13 17

Pharmaceutical Plastic Packaging<br />

Packaging for ophthalmic applications<br />

1<br />

2<br />

Dropper bottles –<br />

System CL<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

Specifications<br />

10<br />

11<br />

ref ml ml mm<br />

mm<br />

mm<br />

12<br />

13<br />

14<br />

141 5 10 25 42 A1ST<br />

142 10 14 25 50 A1ST<br />

143 15 20 25 66 A1ST<br />

528 25 31 31 66 A1ST<br />

144 45 53 31 96 A1ST<br />

195 60 65 35 96 A1ST<br />

059 120 140 42 133 A1ST<br />

· Material: 5 – 45ml bottle LDPE, 60 – 120ml bottle HDPE<br />

· Radiation or ETO sterilisation on request<br />

· Accessories: see page 19<br />

05/13 18

Pharmaceutical Plastic Packaging<br />

Packaging for ophthalmic applications<br />

Dropper bottles –<br />

System CL:<br />

Accessories A1ST<br />

1<br />

2<br />

3<br />

Dropper<br />

Cap<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

Specifications<br />

10<br />

ref<br />

mm<br />

11<br />

· Material: dropper LDPE, cap PP<br />

· Dropper <strong>and</strong> cap fit bottle sizes<br />

on page 18<br />

Dropper<br />

Cap<br />

10008 A1ST<br />

10005 A1ST<br />

12<br />

13<br />

14<br />

05/13 19

Pharmaceutical Plastic Packaging<br />

Packaging for ophthalmic applications<br />

1<br />

2<br />

Dropper bottles –<br />

System PR <strong>and</strong> CT<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

Specifications<br />

10<br />

11<br />

ref ml ml mm<br />

mm<br />

mm<br />

12<br />

13<br />

069* 30 35 31 73 PR<br />

247 15 19 23 73 PR<br />

249 30 35 28 89 PR<br />

* Available in LDPE<br />

14<br />

· Material: bottle HDPE, dropper LDPE, cap HDPE<br />

· Supplied with droppers <strong>and</strong> tamper-evident bicolour caps<br />

· Reference to spray / pump supplier on request<br />

accessories<br />

ref<br />

Dropper<br />

10040<br />

Tamper-evident bicolour cap<br />

01432<br />

05/13 20

Pharmaceutical Plastic Packaging<br />

Packaging for ophthalmic applications<br />

CLC bottles<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

Specifications<br />

10<br />

ref ml ml mm<br />

mm<br />

mm<br />

11<br />

058 120 140 41 133 ST2<br />

12<br />

13<br />

· Material: bottle HDPE, dropper LDPE, cap HDPE<br />

· Supplied with droppers <strong>and</strong> caps<br />

accessories<br />

14<br />

ref<br />

Dropper<br />

Cap<br />

10039<br />

10034<br />

05/13 21

Pharmaceutical Plastic Packaging<br />

05/13 22

Pharmaceutical Plastic Packaging<br />

Packaging for nasal applications<br />

Spray bottles<br />

with nebuliser –<br />

System NEB<br />

Front view Side view Nebuliser Tamperevident<br />

biocolour<br />

cap<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

Specifications<br />

10<br />

ref ml ml mm<br />

mm<br />

mm<br />

11<br />

138 20 23 31 x 22 68 NEB<br />

139 30 40 39 x 26 77 NEB<br />

12<br />

accessories<br />

· Material: bottle LDPE, nebuliser LDPE, cap HDPE<br />

· Supplied with two different nebulisers <strong>and</strong> tamper-evident<br />

bicolour caps 14<br />

ref<br />

13<br />

Nebuliser<br />

Tamper-evident bicolour cap<br />

10009<br />

10050<br />

10051<br />

10006<br />

10047<br />

10049<br />

01356<br />

05/13 23

Pharmaceutical Plastic Packaging<br />

05/13 24

Pharmaceutical Plastic Packaging<br />

Packaging for nasal applications<br />

Spray <strong>and</strong> pump systems:<br />

Snap-on bottles<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

Specifications<br />

10<br />

ref<br />

ml ml mm<br />

mm<br />

mm<br />

11<br />

35022 10 16,1 24 53 20<br />

35023 15 18 24 58 20<br />

35014 20 23 29 53 20<br />

· Material: bottle HDPE<br />

· Available in other materials, sizes <strong>and</strong> designs<br />

· Reference to spray / pump supplier on request<br />

12<br />

13<br />

14<br />

05/13 25

Pharmaceutical Plastic Packaging<br />

Packaging for parenteral applications<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

Product characeristics<br />

· Unique barrier properties<br />

· Superior break resistance<br />

· Inert against high <strong>and</strong> low pH<br />

· no metal ions<br />

· Low absorption<br />

Product offering<br />

· MultiShell ® st<strong>and</strong>ard<br />

· MultiShell ® ready-to-sterilise<br />

(includes certified Bioburden, Endotoxin <strong>and</strong> particle level)<br />

· MultiShell ® ready-to-use<br />

(includes validated gamma sterilisation)<br />

13<br />

14<br />

05/13 26

Pharmaceutical Plastic Packaging<br />

Packaging for parenteral applications<br />

MultiShell ® vials<br />

(st<strong>and</strong>ard, RTS <strong>and</strong> RTU)<br />

1<br />

2<br />

3<br />

4<br />

Specifications<br />

5<br />

6<br />

ref ml ml mm<br />

mm<br />

mm mm mm g<br />

7<br />

2R EN ISO 8362-1 2 3,5 16 35 3,6 13 7 2,7<br />

6R EN ISO 8362-1 5 9,1 22 40 3,6 20 12,6 4,9<br />

10R EN ISO 8362-1 10 12,5 24 45 3,6 20 12,6 6,1<br />

15R EN ISO 8362-1 15 17 24 60 3,6 20 12,6 8,2<br />

50H EN ISO 8362-4 50 67 42,5 73 3,8 20 12,6 16<br />

100H EN ISO 8362-4 100 132,2 51,6 94,5 3,8 20 12,6 26,5<br />

8<br />

9<br />

10<br />

product packaging <strong>and</strong> finish description<br />

Specification MultiShell ®<br />

St<strong>and</strong>ard<br />

MultiShell ®<br />

RTS<br />

MultiShell ®<br />

RTU<br />

11<br />

Production environment ISO 7<br />

Packaging processing<br />

Fully automated<br />

12<br />

Packaging environment ISO 7<br />

Packaging materials in Produced in ISO 7<br />

direct contact with vials<br />

13<br />

Dimensions<br />

Defects<br />

Accord. to st<strong>and</strong>ard specification<br />

Accord. to st<strong>and</strong>ard specification<br />

14<br />

Cleanliness<br />

Accord. to st<strong>and</strong>ard specification<br />

Endotoxin<br />

Certified per batch; limit: EU<br />

Particles<br />

Certified per batch; limit:<br />

Bioburden<br />

Certified per batch; limit: cfu<br />

Gamma radiation<br />

Validated sterilisation dose<br />

Sterilisation<br />

Certified per batch / parametric release<br />

Endotoxin test post sterilisation<br />

Certified per batch<br />

05/13 27

Europe<br />

South America<br />

Asia<br />

<strong>Gerresheimer</strong> Bolesławiec S.A.<br />

ul. Boleslawa Chrobrego 15<br />

59-700 Bolesławiec – Pol<strong>and</strong><br />

Tel. +48 75 735 04 00<br />

<strong>Gerresheimer</strong> Valencia, S.L.U.<br />

Avda. Conchin Ferrer 1<br />

46292 Masalavés – Valencia – Spain<br />

Tel. +34 976 817 408<br />

<strong>Gerresheimer</strong> Plásticos São Paulo Ltda<br />

Rodovia Raposo Tavares 25.599 – Km 25,6<br />

06708-000 Cotia – São Paulo – Brazil<br />

Tel. +55 11 4613 1000<br />

Fax +55 11 4613 1009<br />

<strong>Gerresheimer</strong> Plásticos São Paulo Ldta<br />

Rua Mario Regalo Pereira 160 / 170<br />

05550-060 Butantã – São Paulo – Brazil<br />

Triveni Polymers Pvt. Ltd.<br />

Plant Kundli<br />

G.T. Road, Piao Maniyari<br />

Kundli-131028 Distt. Sonepat<br />

Haryana, India<br />

<strong>Gerresheimer</strong> Zaragoza, S.A.<br />

P.I. Valdemuel – Camino del Sabinar, s/n<br />

50290 Epila – Zaragoza – Spain<br />

Tel. +34 976 817 408<br />

<strong>Gerresheimer</strong> Vaerloese A/S<br />

Walgerholm 2 – 8 – 3500 Vaerloese<br />

Denmark<br />

Str<strong>and</strong>gade 87 – 5683 Haarby<br />

Denmark<br />

Tel. +45 4477 7888<br />

<strong>Gerresheimer</strong><br />

Tampas Herméticas Ltda<br />

Rua da Congregação 56<br />

06816-902 Embu – São Paulo – Brazil<br />

Tel. +55 11 2133 1212<br />

Fax +55 11 2133 1299<br />

<strong>Gerresheimer</strong> Buenos Aires S.A.<br />

Mercedes 2153<br />

C1417AUA Buenos Aires – Argentina<br />

Tel. +54 11 4639 0771<br />

Fax +54 11 4639 1041<br />

Sales office New Delhi<br />

2-B, IInd Floor, DCM Building<br />

Barakhamba Road, Connaught Place<br />

New Delhi-110001, India<br />

More Information<br />

info-plasticpackaging@gerresheimer.com<br />

Pharmaceutical Plastic Packaging <strong>and</strong> Systems for South America is to be found in a separate catalogue.<br />

www.gerresheimer.com