DOC - DOMO - DIWA - DN - DL SERIES

DOC - DOMO - DIWA - DN - DL SERIES

DOC - DOMO - DIWA - DN - DL SERIES

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

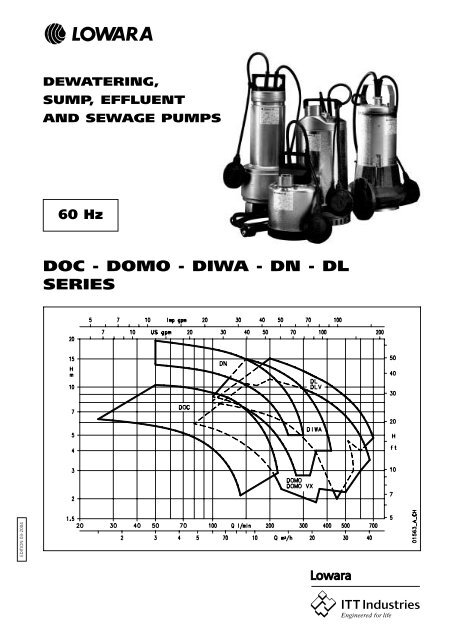

DEWATERING,<br />

SUMP, EFFLUENT<br />

AND SEWAGE PUMPS<br />

60 Hz<br />

<strong>DOC</strong> - <strong>DOMO</strong> - <strong>DIWA</strong> - <strong>DN</strong> - <strong>DL</strong><br />

<strong>SERIES</strong><br />

EDITION 03-2004

CONTENTS<br />

Typical Applications<br />

Specifications for dirty water handling pumps<br />

(not for use with large-diameter suspended solids)............................. 4<br />

5<br />

<strong>DOC</strong> Series<br />

Submersible electric pumps for dirty water .........................................<br />

10<br />

<strong>DIWA</strong> Series<br />

Submersible electric pumps for dirty water .........................................<br />

15<br />

<strong>DOMO</strong> Series<br />

Submersible electric pumps for solids-laden wastewater .....................<br />

21<br />

<strong>DN</strong> Series<br />

Submersible electric pumps for dirty water .........................................<br />

25<br />

<strong>DL</strong> Series<br />

Submersible electric pumps for solids-laden wastewater .....................<br />

Technical appendix.................................................................... 32

TYPICAL APPLICATIONS<br />

Corrosive industrial sewage<br />

Pumping of sludge, mud<br />

Emptying of residential sump pits (apartment complexes) X<br />

Emptying of residential sump pits (detached houses, Fresh water supply X X<br />

Pumping of sludge, mud<br />

Corrosive industrial sewage<br />

Fresh water supply X X X X X<br />

Irrigation X X X X X<br />

Draining of construction sites X X<br />

Draining of basements, tanks X X X<br />

Draining of basements, tanks X X X<br />

Emptying of residential sump pits (apartment complexes)<br />

Emptying of residential sump pits (detached houses,<br />

small condominiums)<br />

Handling of liquids containing abrasives (sand)<br />

Saltwater supply<br />

Fresh water supply<br />

Irrigation<br />

Draining of construction sites<br />

Handling of wastewater not containing large-diameter solids<br />

(washbasins, showers, no WC)<br />

Draining of basements, tanks<br />

<strong>DOC</strong><br />

<strong>DIWA</strong><br />

<strong>DN</strong><br />

<strong>DOMO</strong><br />

<strong>DL</strong><br />

4

Submersible<br />

Electric<br />

Pumps for<br />

Dirty Water<br />

<strong>DOC</strong> Series<br />

<strong>DOC</strong> pumps are versatile, corrosion-resistant and<br />

compact. Different versions are available with 0.25 to<br />

0.55 kW motor powers.<br />

A <strong>DOC</strong> 7VX version with Vortex impeller is also available.<br />

APPLICATIONS<br />

• Emptying of residential sump pits,<br />

rainwater tanks or laundry drainage.<br />

• Garden and lawn irrigation, with<br />

suction from rainwater tanks.<br />

• Emergency draining of flooded<br />

basements, garages and cellars.<br />

• Transfer of water from tanks,<br />

cisterns and swimming pools.<br />

SPECIFICATIONS<br />

• Maximum liquid<br />

temperature: 40°C with<br />

partially submerged pump.<br />

Dry motor.<br />

Maximum immersion depth: 5 m..<br />

Class B insulation.<br />

• The <strong>DOC</strong> 3 pump has a capacity of<br />

140 l/min, head up to 7 m, and<br />

passes suspended solids up<br />

to 10 mm in diameter. Singlephase<br />

version only.<br />

• The <strong>DOC</strong> 7 pump has a capacity of<br />

220 l/min, head up to 11 m, and<br />

passes suspended solids up<br />

to 10 mm in diameter.<br />

• The <strong>DOC</strong> 7VX pump has a<br />

capacity of 180 l/min, head up to<br />

7 m, and can handle liquids with<br />

suspended solids up to 20<br />

mm in diameter.<br />

•<br />

A “shallow-suction device”,<br />

that can be mounted on both the<br />

<strong>DOC</strong>3 and <strong>DOC</strong>7 models, is<br />

available on request. It ensures<br />

complete drainage of flooded floors<br />

(to 3 mm from floor).<br />

• Versions:<br />

Single-phase 220 V 60 Hz<br />

2 poles.<br />

Three-phase 380 V 60 Hz<br />

2 poles.<br />

60 Hz and floatless (SG) models are<br />

available on request.<br />

•<br />

The single-phase versions<br />

feature:<br />

Pre-assembled float for<br />

automatic pump operation (version<br />

without float available on request).<br />

Built-in capacitor.<br />

Thermal overload<br />

protection to stop pump supply<br />

in case of overheating.<br />

LAB-LIP SEAL SYSTEM<br />

• The electric motor is protected by<br />

three lip seals.<br />

An impeller<br />

counterbladesystem keeps solid<br />

particles away from the seal unit to<br />

prevent damage to the lip seals and<br />

ensure their long-lasting efficiency.<br />

A double labyrinth and a V-ring<br />

on the shaft have also been<br />

provided.<br />

• Other voltages available on request.<br />

TABLE OF MATERIALS<br />

PART MATERIAL<br />

Pump body<br />

Suction screen<br />

MATERIAL<br />

Handle<br />

Upper support<br />

Impeller<br />

STAINLESS STEEL<br />

Outer sleeve (AISI 304 - DIN 1.4301)<br />

Motor Casing<br />

Lower cover<br />

STAINLESS STEEL<br />

Screws and tie-rods (AISI 416 - DIN 1.4005)<br />

Shaft extension<br />

NITRILE RUBBER<br />

Elastomers<br />

(NBR)<br />

5

PUMP SECTION AND LIST OF MAIN COMPONENTS<br />

1 Upper head with handle<br />

Made of fiberglass-reinforced Noryl, it houses the capacitor<br />

and connection terminals.<br />

2 Test hole<br />

The tightness of the motor seals is tested by injecting<br />

compressed air (0.5 bar).<br />

3 Float<br />

In compliance with European standards<br />

4 Cable gland<br />

The float cable can be secured at different lengths to start the<br />

pump at the desired liquid level.<br />

5 1 /4” delivery port<br />

6 HO5RN-F type power supply cable<br />

(Version with 10-metre length of HO5RN-F cable is<br />

available on request).<br />

7 Motor casing with upper bearing housing<br />

AISI 304 stainless steel, single-piece design, no welds.<br />

The liquid circulates around the motor ensuring optimum<br />

cooling.<br />

8 Capacitor<br />

9 Dry wound motor<br />

Class F windings and built-in thermal protector<br />

(for single-phase versions).<br />

10 External jacket<br />

AISI 304 stainless steel, single-piece design,<br />

no welds.<br />

11 Pump body<br />

Made of fiberglass-reinforced Noryl.<br />

12 Triple lip seal<br />

13 Shaft<br />

AISI 416 stainless steel.<br />

14 Impeller<br />

Open centrifugal type, made of fibreglass-reinforced Noryl.<br />

The impeller’s rear counterblades (14a) centrifuge the solid<br />

particles and, together with the ring (14b), protect the seal<br />

unit from abrasion.<br />

15 Suction screen<br />

Made of reinforced Noryl, it prevents the passage of solids<br />

over 10 mm in diameter (20 mm for <strong>DOC</strong> 7VX). A low suction<br />

screen (3 mm) is also available on request.<br />

16 Lower cover<br />

• All elastomers are made of nitrile rubber (NBR).<br />

• AISI 304 stainless steel screws and tie-rods.<br />

6

<strong>DOC</strong> <strong>SERIES</strong><br />

OPERATING CHARACTERISTICS AT 3450 rpm, 60 Hz<br />

HYDRAULIC PERFORMANCE TABLE AT 60 Hz<br />

PUMP TYPE<br />

kW<br />

RATED<br />

POWER<br />

HP<br />

Q = DELIVERY<br />

l/min 0 25 50 75 100 125 140 180 220<br />

m 3 /h 0 1,5 3 4,5 6 7,5 8,4 10,8 13,2<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

<strong>DOC</strong>36 - <strong>DOC</strong>36 GT 0,25 0,33 6,8 6,3 5,7 5 4,1 3,0 2,1 - -<br />

<strong>DOC</strong>76(T) - <strong>DOC</strong>76 GT 0,55 0,75 10,6 - 10,3 9,9 9,2 8,4 7,7 5,6 2,9<br />

<strong>DOC</strong>76VX(T) - 0,55 0,75 6,7 - 6,4 6 5,4 4,6 4,1 2,5 -<br />

These performances are valid for liquids with density ρ = 1.0kg/dm and kinematic viscosity ν = 1mm/sec<br />

doc-2p60-en_a_th<br />

ELECTRICAL DATA (60Hz, 3450 rpm) <strong>DOC</strong> <strong>SERIES</strong><br />

PUMP TYPE INPUT INPUT CAPACITOR PUMP TYPE INPUT INPUT INPUT<br />

POWER* CURRENT* POWER* CURRENT* CURRENT*<br />

SINGLE-PHASE 220-230 V THREE-PHASE 220-230 V 380-400 V<br />

kW A µF / 450 V kW A (1) A<br />

<strong>DOC</strong>36 - <strong>DOC</strong>36 GT 0,32 1,47 6,3 - - - -<br />

<strong>DOC</strong>76 - <strong>DOC</strong>76 GT 0,76 3,45 16 <strong>DOC</strong> 76T 0,69 - 1,27<br />

<strong>DOC</strong>76VX - 0,73 3,33 16 <strong>DOC</strong> 76VXT 0,66 - 1,24<br />

*Maximum value in specified range<br />

(1) Available on request<br />

doc-2p60-en_a_te<br />

7

<strong>DOC</strong> <strong>SERIES</strong><br />

DIMENSIONS AND WEIGHTS<br />

PUMP TYPE<br />

DIMENSIONS (mm)<br />

WEIGHT<br />

F H D X* kg<br />

<strong>DOC</strong>36 <strong>DOC</strong>36 GT 245 188 155 20 4<br />

<strong>DOC</strong>76(T) <strong>DOC</strong>76(T) GT 285 228 155 20 6<br />

<strong>DOC</strong>76VX(T) - 310 252 175 45 6<br />

* Minimum liquid level doc-2p60-en_a_td<br />

8

<strong>DOC</strong> <strong>SERIES</strong><br />

INSTALLATION EXAMPLES<br />

PUMP TYPE<br />

A B C D H<br />

<strong>DOC</strong>36 <strong>DOC</strong>36 GT 390 330 50 310 90<br />

<strong>DOC</strong>76 <strong>DOC</strong>76 GT 390 370 90 350 90<br />

<strong>DOC</strong>76VX - 390 395 115 375 -<br />

ACCESSORIES<br />

DIMENSIONS (mm)<br />

MINIMUM WATER<br />

LEVEL<br />

MAXIMUM WATER<br />

LEVEL<br />

MINIMUM WATER<br />

LEVEL<br />

docliv-2p60-en_a_td<br />

Lover suction device VRD check valve RPG pipe fitting<br />

9

Submersible<br />

Electric<br />

Pumps for<br />

Dirty Water<br />

<strong>DIWA</strong> Series<br />

Submersible pumps for dirty water manufactured in<br />

AISI 304 stainless steel. Head up to 20 metrers, capacity<br />

up to 425 l/min (25.5 m 3 /h).<br />

Four basic versions with 0.55 (0.75 HP) to 1.5 kW (2HP)<br />

rated power.<br />

DRIVELUB SEAL SYSTEM<br />

Diffuser plate coated with polyurethane elastomer for<br />

maximum abrasion resistance.<br />

Three-phase 380 V 60 Hz<br />

2 poles.<br />

Other voltages available on request.<br />

• Motor power<br />

– 0.55 to 1.1 kW for<br />

single-phase version.<br />

– 0.55 to 1.5 kW for<br />

three-phase version.<br />

The single-phase versions features:<br />

Pre-assembled float (version<br />

without float available on request).<br />

Built-in capacitor (except for<br />

<strong>DIWA</strong> 11 version with control box on<br />

cable).<br />

Thermal protector.<br />

- Floatless (SG) versions available.<br />

APPLICATIONS<br />

•<br />

basements.<br />

• Fountains.<br />

•<br />

Draining of cellars, garages,<br />

Draining of construction sites.<br />

Emptying of tanks and reservoirs.<br />

Lawn and garden irrigation.<br />

Pumping of domestic wastewater<br />

(washing machines, showers, sinks).<br />

Emptying of tanks in industrial and<br />

ecological applications.<br />

SPECIFICATIONS<br />

Liquid temperature up to 50°C.<br />

Open impeller.<br />

• Minimum level of pumped liquid:<br />

25 mm.<br />

• Suspended solids handled<br />

up to 8 mm in diameter.<br />

• Maximum immersion depth:<br />

7m.<br />

• 10 meters of HO7RN-F type<br />

neoprene power cord.<br />

• Dry motor (class F insulation)<br />

cooled by pumped liquid.<br />

• Versions:<br />

Single-phase 220 V 60 Hz 2<br />

poles with built-in thermal protector.<br />

DRIVELUB SEAL<br />

SYSTEM<br />

• Watertight electric motor protected<br />

by multiple seal system with oil<br />

chamber.<br />

A V-ring and silicon carbide<br />

mechanical seal (extremely res<br />

stant to wear and abrasion), as well<br />

as a lip seal which is conti<br />

nuously lubricated by the<br />

DRIVELUB system, provide an<br />

extremely efficient barrier against<br />

ingress.<br />

TABLE OF MATERIALS<br />

PART<br />

MATERIAL<br />

Pump body<br />

Motor casing<br />

Outer sleeve<br />

STAINLESS STEEL<br />

Impeller (AISI 304 - DIN 1.4301)<br />

Shaft extension<br />

Suction screen<br />

Nuts and bolts<br />

Front diffuser plate<br />

STAINLESS STEEL<br />

(AISI 304 - DIN 1.4301)<br />

COATED WITH<br />

POLYURETHANE<br />

ELASTOMER<br />

Lower mechanical seal<br />

SILICON CARBIDE/<br />

Upper lip seal<br />

SILICON CARBIDE<br />

Elastomers<br />

NITRILE RUBBER<br />

Handle<br />

STAINLESS STEEL<br />

(AISI 304 - DIN 1.4301)<br />

COATED WITH<br />

POLYACETAL RESINS<br />

10

PUMP SECTION AND LIST OF MAIN COMPONENTS<br />

1 Handle.<br />

Made of AISI 304 – DIN 1.4301 stainless steel<br />

coated with polyacetal resins.<br />

2 Cable gland.<br />

The float cable can be secured at different<br />

lengths to start the pump at the desired liquid<br />

level.<br />

3 Float.<br />

In compliance with European standards.<br />

4 Power supply cable.<br />

HO7RN-F type.<br />

5 Motor.<br />

With dry winding, class F insulation.<br />

6 Cooling jacket.<br />

AISI 304 – DIN 1.4301 stainless steel.<br />

7 Motor casing and pump body.<br />

AISI 304 – DIN 1.4301 stainless steel.<br />

8 Seal system.<br />

Lowara – DRIVELUB double seal with oil<br />

chamber.<br />

9 Impeller.<br />

AISI 304 – DIN 1.4301 stainless steel open<br />

impeller.<br />

10 Diffuser plate.<br />

AISI 304 – DIN 1.4301 stainless steel coated<br />

with abrasion-resistant polyurethane resin.<br />

11 Filter.<br />

AISI 304 – DIN 1.4301 stainless steel.<br />

25 mm minimum level of pumped liquid, passes<br />

solids up to 8 mm dia.<br />

The Lowara S.p.A. research laboratories have developed an<br />

original method for detecting wear through the use of fluids<br />

containing abrasive particles. When tested after 100 hours of<br />

operation, pumps with traditional coatings reveal a high degree<br />

of wear. <strong>DIWA</strong>, thanks to its novel coating, shows no sign of<br />

abrasion. The pump’s characteristic curves and performance<br />

remain unaltered for a period approximately 5 times longer than<br />

pumps with traditional coatings.<br />

11

<strong>DIWA</strong> <strong>SERIES</strong><br />

OPERATING CHARACTERISTICS AT 3450 rpm, 60 Hz<br />

HYDRAULIC PERFORMANCE TABLE AT 60 Hz<br />

PUMP TYPE<br />

kW<br />

RATED<br />

POWER<br />

HP<br />

Q = DELIVERY<br />

l/min 0 100 125 150 200 225 250 275 300 325 350 420<br />

m 3 /h 0 6 7,5 9 12 13,5 15 16,5 18 19,5 21 25,2<br />

<strong>DIWA</strong>056(T) - <strong>DIWA</strong>056 GT 0,55 0,75 11 8,7 8,1 7,3 5,6 4,7 3,8 2,8 - - - -<br />

<strong>DIWA</strong> 076(T) - <strong>DIWA</strong>076 GT 0,75 1 13,4 11 10,3 9,5 7,8 6,9 6 5 3,9 2,8 - -<br />

<strong>DIWA</strong> 116(T) - <strong>DIWA</strong>116 GT 1,1 1,5 16 - - 12 10,3 9,3 8,3 7,3 6,3 5,2 4 -<br />

<strong>DIWA</strong> 156T - 1,5 2 20 - - 15 13,4 12,5 11,6 10,7 9,7 8,6 7,5 4<br />

These performances are valid for liquids with density ρ = 1.0kg/dm and kinematic viscosity ν = 1mm/sec<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

ELECTRICAL DATA (60 Hz, 3450 rpm) <strong>DIWA</strong> <strong>SERIES</strong><br />

diwa-2p60-en_a_th<br />

PUMP TYPE INPUT INPUT CAPACITOR PUMP TYPE INPUT INPUT INPUT<br />

POWER* CURRENT* POWER* CURRENT* CURRENT*<br />

SINGLE-PHASE 220-230 V THREE-PHASE 220-230 V 380-400 V<br />

kW A µF / 450 V kW A (1) A<br />

<strong>DIWA</strong> 056 - <strong>DIWA</strong>056 GT 0,92 4,53 20 <strong>DIWA</strong> 056T 0,81 - 1,42<br />

<strong>DIWA</strong> 076 - <strong>DIWA</strong>076 GT 1,18 5,73 22 <strong>DIWA</strong> 076T 1,13 - 2,09<br />

<strong>DIWA</strong> 116 - <strong>DIWA</strong>116 GT 1,39 6,27 30 <strong>DIWA</strong> 116T 1,29 - 2,31<br />

- - - - <strong>DIWA</strong> 156T 1,78 - 3,21<br />

*Maximum value in specified range<br />

(1) Available on request<br />

diwa-2p60-en_a_te<br />

12

<strong>DIWA</strong> <strong>SERIES</strong><br />

DIMENSIONS AND WEIGHTS<br />

PUMP TYPE DIMENSIONS (mm) WEIGHT PUMP TYPE DIMENSIONS (mm) WEIGHT<br />

SINGLE-PHASE<br />

THREE-PHASE<br />

F H kg F H kg<br />

<strong>DIWA</strong>056 <strong>DIWA</strong>056 GT 358 340 13 <strong>DIWA</strong>056T 343 325 12<br />

<strong>DIWA</strong>076 <strong>DIWA</strong>076 GT 388 370 14,3 <strong>DIWA</strong>076T 358 340 13<br />

<strong>DIWA</strong>116 <strong>DIWA</strong>116 GT 388 370 17 <strong>DIWA</strong>116T 388 370 15<br />

- - - - - <strong>DIWA</strong>156T 388 370 16,5<br />

diwa-2p60-en_a_td<br />

13

<strong>DIWA</strong> <strong>SERIES</strong><br />

INSTALLATION EXAMPLES<br />

PUMP TYPE<br />

DIMENSIONS (mm)<br />

F L L1 H1 H2<br />

<strong>DIWA</strong>056 <strong>DIWA</strong>056 GT 358 484 395 445 175<br />

<strong>DIWA</strong>076 <strong>DIWA</strong>076 GT 388 514 425 485 175<br />

<strong>DIWA</strong>116 <strong>DIWA</strong>116 GT 388 514 425 485 175<br />

diwaliv-2p60-en_a_td<br />

14

Submersible<br />

Electric<br />

Pumps for<br />

Solid-laden<br />

Wastewater<br />

<strong>DOMO</strong> Series<br />

The <strong>DOMO</strong> series electric pumps are available with<br />

twin-channel or vortex impeller (<strong>DOMO</strong> VX).<br />

Designed to handle suspended solids up to 50 mm in<br />

diameter (35 mm for <strong>DOMO</strong> 7 and <strong>DOMO</strong> 7VX).<br />

Four basic versions with 0.55 (0.75 HP) to 1.5 kW (2HP)<br />

rated power.<br />

DRIVELUB SEAL SYSTEM.<br />

APPLICATIONS<br />

• Pumping of effluent (VX versions<br />

can also handle suspended solids).<br />

• Emptying of septic tanks and<br />

residential sumps.<br />

• Draining of flooded basements and<br />

garages.<br />

SPECIFICATIONS<br />

• Continuous duty with 35°C<br />

liquids and fully submerged pump.<br />

Dry motor (class F insulation).<br />

• HO7RN-F type neoprene power<br />

cord.<br />

•<br />

Maximum immersion depth:<br />

5 m.<br />

• Versions:<br />

Single-phase 220 V 60 Hz<br />

2 poles.<br />

Three-phase 380 V 60 Hz<br />

2 poles.<br />

Other voltages are available on<br />

request.<br />

•<br />

Motor power<br />

0.55 to 1.1 kW for<br />

single-phase versions.<br />

0.55 to 1.5 kW for<br />

three-phase versions.<br />

•<br />

The single-phase versions feature:<br />

Pre-assembled float (version<br />

without float available on request).<br />

Integrated capacitor (except<br />

for <strong>DOMO</strong> 15 and <strong>DOMO</strong> 15 VX<br />

with control box on cable).<br />

Thermal overload<br />

protection.<br />

• The <strong>DOMO</strong> 7 and <strong>DOMO</strong> 7VX<br />

versions feature:<br />

– Rp 1 1 /2” delivery port (female<br />

gas).<br />

– Handling of suspended solids<br />

up to 35 mm in diameter.<br />

– Fiberglass-reinforced<br />

nylon impeller (stainless steel<br />

impeller also available).<br />

•<br />

The <strong>DOMO</strong> 10-15-20 and<br />

<strong>DOMO</strong> 10-15-20 VX versions<br />

feature:<br />

– 2” delivery port, female gas<br />

(can be turned into a flanged<br />

version if an optional accessory<br />

is installed).<br />

– Handling of suspended solids<br />

up to 50 mm in diameter.<br />

– Stainless steel twinchannel<br />

or vortex impeller.<br />

DRIVELUB SEAL SYSTEM<br />

• Watertight electric motor protected<br />

by multiple seal system with oil<br />

chamber.<br />

A V-ring and silicon carbide<br />

mechanical seal (extremely<br />

resistant to wear and abrasion), as<br />

well as a lip seal which is<br />

continuously lubricated thanks to<br />

the DRIVELUB system, provide<br />

an extremely efficient barrier against<br />

infiltration.<br />

TABLE OF MATERIALS<br />

PART<br />

MATERIAL<br />

Pump body,<br />

STAINLESS STEEL<br />

Motor casing (AISI 304 - DIN 1.4301)<br />

<strong>DOMO</strong> 7 (VX) impeller<br />

FIBERGLASS-REINFORCED<br />

NYLON<br />

<strong>DOMO</strong> 10-15-20 (VX) impeller STANINLESS STEEL<br />

(AISI 304 - DIN 1.4301)<br />

Lower mechanical seal<br />

SILICON CARBIDE/<br />

SILICON CARBIDE<br />

Upper lip seal<br />

NITRILE RUBBER<br />

Shaft extension<br />

STAINLESS RUBBER<br />

(AISI 304 - DIN 1.4301)<br />

Handle<br />

NYLON<br />

15

PUMP SECTION AND LIST OF MAIN COMPONENTS<br />

1 Handle<br />

Made of fiberglass-reinforced nylon.<br />

2 Test hole<br />

The tightness of the motor joints is tested by<br />

injecting compressed air.<br />

3 Float<br />

In compliance with European standards<br />

4 Cable gland<br />

The float cable can be secured at different<br />

lenghts to start the pump at the desired<br />

liquid level.<br />

5 HO7RN-F type power supply<br />

cables.<br />

6 Capacitor<br />

7 Dry wound motor<br />

Class F windings and built-in thermal<br />

protector (for single-phase versions).<br />

8 Motor casing and pump body<br />

AISI 304 stainless steel.<br />

9 Seal system<br />

10 Shaft<br />

AISI 304 stainless steel.<br />

11 Delivery port<br />

2” (50 mm) diam. except for <strong>DOMO</strong> 7 (VX)<br />

that has 1 1 /4” (35 mm) ports.<br />

12 Impeller<br />

Vortex or twin-channel type, made of AISI<br />

304 stainless steel; <strong>DOMO</strong> 7 (VX) has a<br />

fibreglass-reinforced nylon impeller.<br />

A) All elastomers are made of nitrile rubber<br />

(NBR).<br />

B) All bolts and washers are made of AISI 304<br />

stainless steel.<br />

DRIVELUB SEAL SYSTEM<br />

The electric motor is protected from ingress by a double<br />

seal system with oil chamber.<br />

A V-ring (A) made of nitrile rubber adheres like a suction<br />

cup to the upper surface and constitutes a first efficient<br />

barrier that prevents solid particles from coming into<br />

contact with the mechanical seal.<br />

The mechanical seal (B) made of silicon carbide (SIC<br />

SEAL) is extremely resistant to abrasion thanks to its<br />

exceptional hardness.<br />

The second seal is a lip one (C). It is continuously<br />

lubricated thanks to the rotation of the mechanical seal<br />

spring which drives up the oil (ESSO MARCOL 82)<br />

conveyed by the pipe (D).<br />

16

<strong>DOMO</strong> <strong>SERIES</strong><br />

OPERATING CHARACTERISTICS AT 3450 rpm, 60 Hz<br />

HYDRAULIC PERFORMANCE TABLE AT 60 Hz<br />

PUMP TYPE<br />

kW<br />

RATED<br />

POWER<br />

HP<br />

Q = DELIVERY<br />

l/min 0 100 150 200 250 280 350 400 500 600 670<br />

m 3 /h 0 6 9 12 15 16,8 21 24 30 36 40,2<br />

<strong>DOMO</strong> S76(T) - <strong>DOMO</strong> S76 GT 0,55 0,75 10,5 7,5 6,4 5,1 3,5 2,4 - - - - -<br />

<strong>DOMO</strong>106(T) - <strong>DOMO</strong>106 GT 0,75 1 8,8 7,4 6,7 6,1 5,5 5,1 4,3 3,7 2,2 - -<br />

<strong>DOMO</strong>156(T) - <strong>DOMO</strong>156 GT 1,1 1,5 12,4 - 9,6 8,8 8,1 7,7 6,8 6,1 4,7 3 -<br />

<strong>DOMO</strong>206T - 1,5 2 14,5 - - 11,2 10,4 10 9 8,2 6,6 4,9 3,5<br />

These performances are valid for liquids with density ρ = 1.0kg/dm and kinematic viscosity ν = 1mm/sec<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

ELECTRICAL DATA (60 Hz, 3450 rpm) <strong>DOMO</strong> <strong>SERIES</strong><br />

domo-2p60-en_a_th<br />

PUMP TYPE INPUT INPUT CAPACITOR PUMP TYPE INPUT INPUT INPUT<br />

POWER* CURRENT* POWER* CURRENT* CURRENT*<br />

SINGLE-PHASE 220-230 V THREE-PHASE 220-230 V 380-400 V<br />

kW A µF / 450 V kW A (1) A<br />

<strong>DOMO</strong> S76 - <strong>DOMO</strong> S76 GT 0,84 4,21 20 <strong>DOMO</strong> S76T 0,73 - 1,32<br />

<strong>DOMO</strong>106 - <strong>DOMO</strong>106 GT 1,1 5,39 22 <strong>DOMO</strong>106T 1,05 - 1,97<br />

<strong>DOMO</strong>156 - <strong>DOMO</strong>156 GT 1,56 7,03 30 <strong>DOMO</strong>156T 1,45 - 2,54<br />

- - - - <strong>DOMO</strong>206T 1,79 - 3,23<br />

*Maximum value in specified range<br />

(1) Available on request<br />

domo-2p60-en_a_te<br />

17

<strong>DOMO</strong> VX <strong>SERIES</strong><br />

OPERATING CHARACTERISTICS AT 3450 rpm, 60 Hz<br />

HYDRAULIC PERFORMANCE TABLE AT 60 Hz<br />

PUMP TYPE<br />

kW<br />

RATED<br />

POWER<br />

HP<br />

Q = DELIVERY<br />

l/min 0 80 100 150 200 230 300 350 400 500<br />

m 3 /h 0 4,8 6 9 12 13,8 18 21 24 30<br />

<strong>DOMO</strong> S76VX(T) - <strong>DOMO</strong> S76VX GT 0,55 0,75 8 5,9 5,5 4,3 3,1 2,3 - - - -<br />

<strong>DOMO</strong>106VX(T) - <strong>DOMO</strong>106VX GT 0,75 1 7,4 - 6,3 5,5 4,7 4,2 2,9 1,9 - -<br />

<strong>DOMO</strong>156VX(T) - <strong>DOMO</strong>156VX GT 1,1 1,5 10 - 8,8 8,2 7,4 6,9 5,6 4,6 3,5 -<br />

<strong>DOMO</strong>206VXT - 1,5 2 11,8 - - 10,5 9,9 9,6 8,6 7,8 6,8 4,5<br />

These performances are valid for liquids with density ρ = 1.0kg/dm and kinematic viscosity ν = 1mm/sec<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

ELECTRICAL DATA (60 Hz, 3450 rpm) <strong>DOMO</strong> VX <strong>SERIES</strong><br />

domovx-2p60-en_a_th<br />

PUMP TYPE INPUT INPUT CAPACITOR PUMP TYPE INPUT INPUT INPUT<br />

POWER* CURRENT* POWER* CURRENT* CURRENT*<br />

SINGLE-PHASE 220-230 V THREE-PHASE 220-230 V 380-400 V<br />

kW A µF / 450 V kW A (1) A<br />

<strong>DOMO</strong> S76VX - <strong>DOMO</strong> S76VX GT 0,84 4,22 20 <strong>DOMO</strong> S76VXT 0,73 - 1,33<br />

<strong>DOMO</strong>106VX - <strong>DOMO</strong>106VX GT 1,1 5,40 22 <strong>DOMO</strong>106VXT 1,05 - 1,98<br />

<strong>DOMO</strong>156VX - <strong>DOMO</strong>156VX GT 1,57 7,08 30 <strong>DOMO</strong>156VXT 1,46 - 2,56<br />

- - - - <strong>DOMO</strong>206VXT 1,84 - 3,30<br />

*Maximum value in specified range<br />

(1) Available on request<br />

domovx-2p60-en_a_te<br />

18

<strong>DOMO</strong> <strong>SERIES</strong><br />

DIMENSIONS AND WEIGHTS<br />

PUMP TYPE<br />

DIMENSIONS (mm) <strong>DN</strong>M WEIGHT PUMP TYPE DIMENSIONS (mm) <strong>DN</strong>M WEIGHT<br />

SINGLE-PHASE<br />

THREE-PHASE<br />

H H1 C kg H H1 C kg<br />

<strong>DOMO</strong> S76 <strong>DOMO</strong> S76 GT <strong>DOMO</strong> S76T<br />

433 88 193 Rp1½ 11<br />

<strong>DOMO</strong> S76VX <strong>DOMO</strong> S76VX GT <strong>DOMO</strong> S76VXT<br />

386 88 193 Rp1½ 10<br />

<strong>DOMO</strong>106 <strong>DOMO</strong>106 GT <strong>DOMO</strong>106T<br />

463 111,5 198 Rp2 13<br />

D0MO106VX D0MO106VX GT D0MO106VXT<br />

433 111,5 198 Rp2 11<br />

<strong>DOMO</strong>156 <strong>DOMO</strong>156 GT <strong>DOMO</strong>156T<br />

463 111,5 198 Rp2 15<br />

<strong>DOMO</strong>156VX <strong>DOMO</strong>156VX GT <strong>DOMO</strong>156VXT<br />

463 111,5 198 Rp2 13<br />

- - - - - - -<br />

<strong>DOMO</strong>206T<br />

D0MO206VXT<br />

463 111,5 198 Rp2 14<br />

domo-2p60-en_a_td<br />

19

<strong>DOMO</strong> <strong>SERIES</strong><br />

INSTALLATION EXAMPLE<br />

PUMP TYPE<br />

DIMENSIONS (mm)<br />

H H2 L L1 A<br />

<strong>DOMO</strong> S76 - <strong>DOMO</strong> S76 GT <strong>DOMO</strong> S76VX - <strong>DOMO</strong> S76VX GT 433 375 480 335 220<br />

<strong>DOMO</strong>106 - <strong>DOMO</strong>106 GT <strong>DOMO</strong>106VX - <strong>DOMO</strong>106VX GT 463 415 495 350 250<br />

<strong>DOMO</strong>156 - <strong>DOMO</strong>156 GT <strong>DOMO</strong>156VX - <strong>DOMO</strong>156VX GT 463 415 495 350 250<br />

domoliv-2p60-en_a_td<br />

20

Submersible<br />

Electric<br />

Pumps for<br />

Dirty Water<br />

Drainage pumps with up to 21 metre head and up to<br />

18 m 3 /h capacity.<br />

This range consists of three pumps with up to 0.8 kW<br />

rated power.<br />

<strong>DN</strong> <strong>SERIES</strong><br />

APPLICATIONS<br />

• Draining of flooded excavations and<br />

marshy ground.<br />

• Irrigation from rainwater reservoirs,<br />

ditches, ponds and watercourses.<br />

SPECIFICATIONS<br />

• Open impeller with abrasionresistant<br />

rubber coating.<br />

• Handles suspended solids up to 5<br />

mm in diameter.<br />

• Squirrel cage motor 2 poles in a<br />

dielectric non-toxic oil bath,<br />

which ensures the lubrication of the<br />

ball bearings and more efficient<br />

cooling.<br />

• Mechanical seal protected by sand<br />

labyrinth.<br />

• Maximum immersion depth:<br />

5 m.<br />

•<br />

Maximum liquid<br />

temperature:<br />

50°C with fully submerged<br />

pump.<br />

25°C with partially<br />

submerged pump.<br />

• Versions:<br />

Single-phase 220 V 60 Hz.<br />

Three-phase 380 V 60 Hz.<br />

Overload protection to be provided<br />

by user and installed in the control<br />

panel.<br />

The control panel is available on<br />

request.<br />

Other voltages available on request.<br />

•<br />

5 metres of HO7RN-F cable<br />

(the single-phase versions are also<br />

equipped with a control panel<br />

housing the capacitor + 1.5 m cord<br />

with plug).<br />

Motor insulation: class F.<br />

•<br />

request (CG version).<br />

•<br />

Pre-assembled float available on<br />

Clockwise rotation when looking at<br />

pump from above.<br />

TABLE OF MATERIALS<br />

PART<br />

Pump body<br />

MATERIAL<br />

200 UNI ISO 185 CAST IRON<br />

Impeller STEEL +<br />

NITRILE RUBBER<br />

Wear flange<br />

STAINLESS STEEL<br />

Suction filter (AISI 304 - DIN 1,4301)<br />

Motor casing<br />

Mechanical seal<br />

CARBON/CERAMIC<br />

NITRILE RUBBER<br />

O-ring<br />

NITRILE RUBBER<br />

Shaft (extension)<br />

STAINLESS STEEL<br />

(AISI 303 - DIN 1.4305)<br />

* Cast iron with polybutadiene coating through<br />

electrophoresis at 180°C.<br />

21

<strong>DN</strong> <strong>SERIES</strong><br />

OPERATING CHARACTERISTICS AT 3450 rpm, 60 Hz<br />

HYDRAULIC PERFORMANCE TABLE AT 60 Hz<br />

PUMP TYPE<br />

kW<br />

RATED<br />

POWER<br />

HP<br />

Q = DELIVERY<br />

l/min 0 50 75 100 125 150 175 200 250 300<br />

m 3 /h 0 3 4,5 6 7,5 9 10,5 12 15 18<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

<strong>DN</strong>M1106 - <strong>DN</strong>1106 0,6 0,8 15 13,8 13,1 12,3 11,3 10,3 9,2 8 5 -<br />

<strong>DN</strong>M1156 - <strong>DN</strong>1156 0,8 1 21,0 19,5 18,3 17,3 16,2 14,9 13,5 12 8,9 5<br />

These performances are valid for liquids with density ρ = 1 dn-2p60-en_a_th<br />

ELECTRICAL DATA (60 Hz, 3450 rpm) <strong>DN</strong> <strong>SERIES</strong><br />

PUMP TYPE INPUT INPUT CAPACITOR PUMP TYPE INPUT INPUT INPUT<br />

POWER* CURRENT* POWER* CURRENT* CURRENT*<br />

SINGLE-PHASE 220-230 V THREE-PHASE 220-230 V 380-400 V<br />

kW A µF / 450 V kW A (1) A<br />

<strong>DN</strong>M 1106 1,08 5,12 25 <strong>DN</strong> 1106 1,00 3,19 1,84<br />

D<strong>DN</strong>M 1506 1,45 6,74 25 <strong>DN</strong> 1506 1,46 - 2,52<br />

*Maximum value in specified range<br />

(1) Available on request<br />

dn-2p60-en_a_te<br />

22

<strong>DN</strong> <strong>SERIES</strong><br />

DIMENSIONS AND WEIGHTS<br />

PUMP TYPE DIMENSIONS (mm)<br />

<strong>DN</strong>M WEIGHT<br />

C H H1 L L1 W W1 kg<br />

<strong>DN</strong>M1106 - <strong>DN</strong>1106 Ø 200 380 81 223 209 95 81 Rp 1¼ 18,5<br />

<strong>DN</strong>M1156 - <strong>DN</strong>1156 Ø 200 380 81 223 209 95 81 Rp 1¼ 19,5<br />

dn-2p60-en_a_td<br />

23

PUMP SECTION AND LIST OF MAIN COMPONENTS<br />

RIF. N.<br />

DESCRIPTION<br />

1 Pump body<br />

* 2 Impeller<br />

3 Wear flange<br />

4 Suction filter<br />

5 Flange/filterfastening screw<br />

6 Float cable gland<br />

* 7 Mechanical seal<br />

8 Insert and plug for coupling<br />

* 9 O-ring<br />

10 Motor casing with wound<br />

stator<br />

11 Shaft with rotor<br />

* 12 Lower bearing<br />

13 Impeller lock washer<br />

* 14 Upper bearing<br />

15 Plug with washer<br />

16 Supply cable gland<br />

17 Supply cable<br />

18 Control box base<br />

19 Control box cover<br />

20 Capacitor<br />

21 Cord with plug<br />

22 Float<br />

23 Switch with cap<br />

24 Cable fastener with base<br />

25 Mechanical seal spacer<br />

26 Seal shoulder washer<br />

27 Labyrint cap<br />

28 Labyrint insert<br />

29 Cable gland (pump cable)<br />

30 Cable gland (cable with<br />

plug)<br />

* Recommended spare parts<br />

24

Submersible<br />

Electric<br />

Pump for<br />

Solids-laden<br />

Wastewater<br />

<strong>DL</strong> Series<br />

The <strong>DL</strong> series electric pumps come with single-channel or<br />

Vortex impeller (<strong>DL</strong>V), and are designed to handle solidsladen<br />

wastewater, with up to 22 m head and 42 m 3 /h<br />

capacity.<br />

0.6 kW to 1.5 kW rated power.<br />

Solids handled up to 50 mm in diameter.<br />

APPLICATIONS<br />

• Pumping of sewage with suspended<br />

solids and filaments.<br />

• Emptying of sumps, septic tanks<br />

and wastewater discharge tanks.<br />

• Draining of flooded excavations and<br />

marshy ground.<br />

SPECIFICATIONS<br />

Maximum immersion depth: 5 m.<br />

• Maximum temperature of<br />

pumped liquid:<br />

50°C with fully submerged<br />

pump.<br />

25°C with partially<br />

submerged pump.<br />

• Passes solids up to:<br />

45 mm (<strong>DL</strong> 806, 906,<br />

Vortex).<br />

50 mm (<strong>DL</strong> 1096, 1256,<br />

<strong>DL</strong>V 1006, 1156).<br />

• Squirrel cage motor in a dielectric<br />

non-toxic oil bath, which ensures<br />

the lubrication of the ball bearings<br />

and more efficient cooling.<br />

Class F insulation.<br />

•<br />

2-pole (0.6 to 1.5 kW) motors.<br />

Mechanical seal protected by<br />

sand labyrinth.<br />

• Versions:<br />

Single-phase 220 V 60 Hz<br />

Three-phase 220 or 380 V<br />

60 Hz.<br />

Other voltages available on request.<br />

Overload protection to be provided<br />

by the user (in the control panel).<br />

5-metre cable for 2-pole <strong>DL</strong>-<strong>DL</strong>V<br />

•<br />

Pre-assembled float available on<br />

request for single-phase versions<br />

(<strong>DL</strong>…CG, <strong>DL</strong>V…CG).<br />

TABLE OF MATERIALS<br />

2-POLE ELECTRIC PUMPS:<br />

<strong>DL</strong>806, 906, 1096, 1256<br />

and VORTEX, <strong>DL</strong>V 1006,<br />

1156<br />

PART<br />

MATERIAL<br />

Pump body<br />

200 UNI ISO 185 CAST IRON*<br />

Impeller<br />

STAINLESS STEEL<br />

(AISI 304 - DIN 1.4301)<br />

200 UNI ISO 185 CAST IRON* FOR<br />

MINIVORTEX AND VORTEX<br />

Suction flange,<br />

Supporting feet,<br />

STAINLEES STEEL<br />

Shaft (extension), (AISI 304 - DIN 1.4301)<br />

Motor casing<br />

O-ring<br />

Mechanical sealCARBON/CERAMIC/<br />

Delivery elbow<br />

(<strong>DL</strong> 109,125 e <strong>DL</strong>V 100, 115)<br />

NITRILE RUBBER<br />

NITRILE RUBBER<br />

200 UNI ISO 185 CAST IRON*<br />

25

<strong>DL</strong> <strong>SERIES</strong><br />

OPERATING CHARACTERISTICS AT 3450 rpm, 60 Hz<br />

HYDRAULIC PERFORMANCE TABLE AT 60 Hz<br />

PUMP TYPE<br />

kW<br />

RATED<br />

POWER<br />

HP<br />

Q = DELIVERY<br />

l/min 0 100 150 200 300 350 400 450 500 600 700<br />

m 3 /h 0 6 9 12 18 21 24 27 30 36 42<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

<strong>DL</strong>M806 - <strong>DL</strong>806 0,6 0,8 10,2 8,2 7,4 6,7 5,3 4,6 - - - - -<br />

<strong>DL</strong>906 - 1,1 1,5 13,1 10,7 9,8 8,9 7,4 6,6 5,9 5,2 - - -<br />

<strong>DL</strong>M1096 - <strong>DL</strong>1096 1,1 1,5 18,2 - - 11 9 8,2 7,5 6,7 5,9 4 -<br />

<strong>DL</strong>1256 - 1,5 2 22,1 - - 15,1 12,6 11,5 10,6 9,6 8,7 6,9 4,8<br />

These performances are valid for liquids with density ρ = 1.0kg/dm and kinematic viscosity ν = 1mm/sec<br />

dl-2p60-en_a_th<br />

ELECTRICAL DATA (60 Hz, 3450 rpm) <strong>DL</strong> <strong>SERIES</strong><br />

PUMP TYPE INPUT INPUT CAPACITOR PUMP TYPE INPUT INPUT INPUT<br />

POWER* CURRENT* POWER* CURRENT* CURRENT*<br />

SINGLE-PHASE 220-230 V THREE-PHASE 220-230 V 380-400 V<br />

kW A µF / 450 V kW A A<br />

<strong>DL</strong>M806 1,13 5,31 25 <strong>DL</strong>806 1,05 3,32 1,92<br />

- - - - <strong>DL</strong>906 1,33 4,02 2,32<br />

<strong>DL</strong>M1096 1,72 7,93 35 <strong>DL</strong>1096 1,63 4,92 2,84<br />

- - - - <strong>DL</strong>1256 1,95 5,77 3,33<br />

*Maximum value in specified range<br />

dl-2p60-en_a_te<br />

26

<strong>DL</strong>V <strong>SERIES</strong><br />

OPERATING CHARACTERISTICS AT 3450 rpm, 60 Hz<br />

HYDRAULIC PERFORMANCE TABLE AT 60 Hz<br />

PUMP TYPE<br />

kW<br />

RATED<br />

POWER<br />

HP<br />

Q = DELIVERY<br />

l/min 0 100 150 200 250 300 350 400 450 500 550<br />

m 3 /h 0 6 9 12 15 18 21 24 27 30 33<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

VORTEX6 - 1,1 1,5 9,2 8 7,3 6,6 5,8 4,8 3,9 - - - -<br />

<strong>DL</strong>VM1006 - <strong>DL</strong>V1006 1,1 1,5 10,2 - 8 7,1 6,2 5,4 4,4 3,4 2 - -<br />

<strong>DL</strong>V1156 - 1,5 2 13,2 - - 10,2 9,5 8,7 7,8 7 6,1 5 3<br />

These performances are valid for liquids with density ρ = 1.0kg/dm and kinematic viscosity ν = 1mm/sec<br />

dlv-2p60-en_a_th<br />

ELECTRICAL DATA (60 Hz, 3450 rpm) <strong>DL</strong>V <strong>SERIES</strong><br />

PUMP TYPE INPUT INPUT CAPACITOR PUMP TYPE INPUT INPUT INPUT<br />

POWER* CURRENT* POWER* CURRENT* CURRENT*<br />

SINGLE-PHASE 220-230 V THREE-PHASE 220-230 V 380-400 V<br />

kW A µF / 450 V kW A A<br />

- - - - VORTEX6 1,65 4,85 2,8<br />

<strong>DL</strong>VM1006 1,71 7,91 35 <strong>DL</strong>V1006 1,62 4,90 2,83<br />

- - - - <strong>DL</strong>V1156 2,23 6,49 3,75<br />

*Maximum value in specified range<br />

dlv-2p60-en_a_te<br />

27

<strong>DL</strong>(V) <strong>SERIES</strong><br />

DIMENSIONS AND WEIGHTS<br />

PUMP TYPE<br />

<strong>DL</strong>806-<strong>DL</strong>M806<br />

<strong>DL</strong>906<br />

VORTEX6<br />

WEIGHT<br />

kg<br />

20,5<br />

21<br />

21<br />

dl-vortex-2p60-en_a_td<br />

PUMP TYPE<br />

<strong>DL</strong>1096-<strong>DL</strong>M1096<br />

<strong>DL</strong>1256<br />

<strong>DL</strong>V1006-<strong>DL</strong>VM1006<br />

<strong>DL</strong>V1156<br />

WEIGHT<br />

kg<br />

27<br />

27<br />

27<br />

27<br />

dl-dlv-2p60-en_a_td<br />

28

LIFTING AND LOWERING DEVICE<br />

Used for pump inspection and maintenance without going down the well.<br />

It consists of a support foot with built-in delivery elbow, a sliding adaptor and a bracket for fastening the guide tubes<br />

(tubes not included).<br />

One model is available:<br />

• DS 2 for <strong>DL</strong> 1096-1256, <strong>DL</strong>V 1006-1156 and <strong>DL</strong> 806-906-1056 VORTEX pumps with flange.<br />

DS 2<br />

3/4” BSP<br />

29

PUMP SECTIONS AND LIST OF MAIN COMPONENTS<br />

<strong>DL</strong>-<strong>DL</strong>M 806-906 - VORTEX<br />

REF. N.<br />

DESCRIPTION<br />

1 Pump body<br />

* 2 Impeller<br />

3 Suction flange<br />

4 Supporting foot<br />

5 Impeller lock washer<br />

* 6 O-Ring<br />

* 7 Mechanical seal<br />

* 8 Lower bearing<br />

9 Shaft and rotor<br />

10 Motor casing and wound<br />

stator<br />

* 11 Upper bearing<br />

12 Plug end washer<br />

13 Supply cable gland<br />

14 Suplly cable<br />

15 Control box base<br />

16 Control box cover<br />

17 Capacitor<br />

18 Cord with plug<br />

19 Switch with cup<br />

20 Float<br />

21 Float cable gland<br />

22 Insert and plug for coupling<br />

23 Cable fastener with base<br />

24 Mechanical seal spacer<br />

25 Mechanical seal shoulder<br />

washer<br />

26 Labyrint cap<br />

27 Labyrint insert<br />

28 Cable gland (for pump<br />

cable)<br />

29 Cable gland (for plug cable)<br />

* Recommended spare parts<br />

Reference number indicate spare parts as<br />

per relevant catalogue<br />

Reference numbers indicate spare parts as per relevant catalogue<br />

30

PUMP SECTION AND LIST OF MAIN COMPONENTS<br />

<strong>DL</strong> 1096-1256 / <strong>DL</strong>V 1006-1156<br />

REF. N.<br />

DESCRIPTION<br />

1 Pump body<br />

* 2 Impeller<br />

3 Suction flange<br />

4 Supporting foot<br />

5 Impeller lock washer<br />

* 6 O-Ring<br />

* 7 Mechanical seal<br />

* 8 Lower bearing<br />

9 Shaft an rotor<br />

10 Motor casing and wound<br />

stator<br />

* 11 Upper bearing<br />

12 Plug and washer<br />

13 Supply cable gland<br />

14 Supply cable<br />

15 Control box base<br />

16 Control box cover<br />

17 Capacitor<br />

18 Cord with plug<br />

19 Switch with cap<br />

20 Float<br />

21 Float cable gland<br />

22 Insert and plug for coupling<br />

23 Cable fastener with base<br />

* 24 Wear ring<br />

25 Gasket for delivery union<br />

26 Delivery union<br />

27 Cable gland (for pump<br />

cable)<br />

28 Cable gland (for plug cable)<br />

* Recommended spare parts<br />

Reference numbers indicate spare parts as<br />

per relevant catalogue<br />

Reference numbers indicate spare parts as per relevant catalogue<br />

31

TECHNICAL<br />

APPENDIX<br />

32

TECHNICAL APPENDIX<br />

EXAMPLE OF INSTALLATION OF SINGLE-PUMP SYSTEM<br />

LEGEND<br />

Submersible electric pump<br />

Cast iron quick coupling foot<br />

Polyethylene delivery pipe<br />

Counterflange<br />

Ball check valve, threaded up to 2” and<br />

flanged for higher <strong>DN</strong><br />

Gate valve<br />

Polyethylene delivery pipe<br />

Electric pump power cable<br />

Stainless steel guide tube<br />

Stainless steel extraction chain<br />

Level floats<br />

Inlet sluice gate<br />

Inlet pipe<br />

Electric panel<br />

Alarm siren<br />

Alarm light<br />

Allarm<br />

Pump<br />

33

TECHNICAL APPENDIX<br />

EXAMPLE OF INSTALLATION OF TWO-PUMP SYSTEM WITH<br />

THREE FLOATS<br />

LEGEND<br />

Submersible electric pump<br />

Cast iron quick coupling foot<br />

Polyethylene delivery pipe<br />

Counterflange<br />

Ball check valve, threaded up to 2” and<br />

flanged for higher <strong>DN</strong><br />

Gate valve<br />

Polyethylene delivery pipe<br />

Electric pump power cable<br />

Stainless steel guide tube<br />

Stainless steel extraction chain<br />

Level floats<br />

Inlet sluice gate<br />

Inlet pipe<br />

Electric panel<br />

Alarm siren<br />

Alarm light<br />

Allarm<br />

Start of<br />

2nd pump<br />

Start of<br />

1st pump<br />

34

TECHNICAL APPENDIX<br />

EXAMPLE OF INSTALLATION OF TWO-PUMP SYSTEM WITH<br />

FOUR FLOATS<br />

LEGEND<br />

Submersible electric pump<br />

Cast iron quick coupling foot<br />

Polyethylene delivery pipe<br />

Counterflange<br />

Ball check valve, threaded up to 2” and<br />

flanged for higher <strong>DN</strong><br />

Gate valve<br />

Polyethylene delivery pipe<br />

Electric pump power cable<br />

Stainless steel guide tube<br />

Stainless steel extraction chain<br />

Level floats<br />

Inlet sluice gate<br />

Inlet pipe<br />

Electric panel<br />

Alarm siren<br />

Alarm light<br />

Allarm<br />

Start of 2nd<br />

Start of 1st<br />

Stop<br />

35

TECHNICAL APPENDIX<br />

LEVEL CONTROL FLOAT<br />

SMALL MODEL<br />

KEY MODEL<br />

MC MATIC MODEL<br />

For single function (draining)<br />

cable length 1.5, 5, 10 m.<br />

Counterweight available on request for<br />

version with 5, 10 m cable.<br />

For dual function<br />

(draining/filling)<br />

cable length 1.5, 5, 10 m.<br />

Counterweight available on request for<br />

version with 5, 10 m cable.<br />

Version with plug and socket for<br />

single-phase pumps up to 1 kW.<br />

For solids-laden water (without<br />

mercury).<br />

Cable length: 15 m.<br />

BALL CHECK VALVES FOR<br />

SOLIDS-LADEN WATER<br />

No-clog, maximum reliability, low flow resistance.<br />

Maximum operating pressure: 10 bar.<br />

Maximum temperature: 85°C.<br />

Horizontal or vertical operating position.<br />

MODEL DIMENSIONS (mm) WEIGHT<br />

BALL Ø L H kg<br />

Rp 1” 1 /4 48 140 80 2<br />

Rp 1” 1 /2 50 140 80 4<br />

Rp 2” 60 200 98 5,5<br />

<strong>DN</strong> 80 95 260 163 13<br />

<strong>DN</strong> 100 120 300 210 18<br />

<strong>DN</strong> 150 175 400 250 37<br />

<strong>DN</strong><br />

<strong>DN</strong><br />

MODEL 1” 1 /4 - 1” 1 /2 - 2” MODEL 80 - 100 - 150<br />

36

TECHNICAL APPENDIX<br />

FLOW RESISTANCE<br />

TABLE OF FLOW RESISTANCE IN 100 m OF A NEW AND STRAIGHT CAST<br />

IRON PIPELINE<br />

FLOW PORTATA RATE<br />

NOMINAL DIAMETRO DIAMETER NOMINALE mm IN mm AND E IN INCHES POLLICI<br />

m 3 /h l/min. 15 20 25 32 40 50 65 80 100 125 150 175 200 250 300 350 400<br />

1<br />

/2” 3<br />

/4” 1” 1 1 /4” 1 1 /2” 2” 2 1 /2” 3” 4” 5” 6” 7” 8” 10” 12” 14” 16”<br />

0,6 10<br />

0,9 15<br />

1,2 20<br />

1,5 25<br />

1,8 30<br />

2,1 35<br />

2,4 40<br />

3 50<br />

3,6 60<br />

4,2 70<br />

4,8 80<br />

5,4 90<br />

6 100<br />

7,5 125<br />

9 150<br />

10,5 175<br />

12 200<br />

15 250<br />

18 300<br />

24 400<br />

30 500<br />

36 600<br />

42 700<br />

48 800<br />

54 900<br />

60 1000<br />

75 1250<br />

90 1500<br />

105 1750<br />

120 2000<br />

150 2500<br />

180 3000<br />

300 5000<br />

600 10000<br />

1200 20000<br />

1800 30000<br />

3000 50000<br />

4500 75000<br />

6000 100000<br />

V V = WATER VELOCITÀ SPEED DELL’ACQUA (m/sec) (m/sec) Hr = hr FLOW = PERDITA RESISTANCE DI CARICO (m/100 m m OF DI PIPELINE) TUBAZIONE)<br />

V 0,94 0,53 0,34 0,21<br />

hr 11,8 2,82 1 0,25<br />

V 1,42 0,8 0,51 0,31<br />

THE FLOW RESISTANCE MUST BE MULTIPLIED BY:<br />

hr 25,1 6,04 2,16 0,55<br />

• 0.8 LE for PERDITE stainless DI steel CARICO pipes DEVONO ESSERE MOLTIPLICATE PER:<br />

V 1,89 1,06 0,68 0,41 0,27<br />

• 1.25 • for 0,8 slightly per tubi rusted in acciaio steel inox pipes<br />

hr 43,1 10,4 3,72 0,95 0,31<br />

• 1.7 • for 1,25 pipes per with tubi in deposits acciaio that leggermente reduce the arrugginiti flow section<br />

V 2,36 1,33 0,85 0,52 0,33<br />

• 0.7<br />

•<br />

for<br />

1,7<br />

aluminium<br />

per tubi con<br />

pipes<br />

incrostazioni che riducono la sezione di passaggio<br />

• 1.3<br />

•<br />

for<br />

0,7<br />

fibre-cement<br />

per tubi di alluminio<br />

pipes<br />

hr 64,5 15,8 5,68 1,47 0,47<br />

• 1,3 per tubi in fibra di cemento<br />

V 2,83 1,59 1,02 0,62 0,4<br />

hr 92 22,3 8 2,09 0,66<br />

V 3,3 1,86 1,19 0,73 0,46 0,3<br />

hr 123 29,8 10,8 2,81 0,89 0,31<br />

V 3,77 2,12 1,36 0,83 0,53 0,34<br />

hr 164 38,2 13,8 2,65 1,15 0,4<br />

V 4,72 2,65 1,7 1,04 0,66 0,42<br />

hr 246 58,2 21,5 5,6 1,75 0,61<br />

V 3,18 2,04 1,24 0,8 0,51<br />

hr 82 30 8 2,48 0,86<br />

V 3,72 2,38 1,45 0,93 0,59<br />

hr 110 40 10,8 3,33 1,14<br />

V 4,25 2,72 1,66 1,06 0,68<br />

hr 141 51,5 13,9 4,3 1,46<br />

V 3,06 1,87 1,19 0,76 0,45<br />

hr 64 17,5 5,4 1,82 0,46<br />

V 3,4 2,07 1,33 0,85 0,5<br />

hr 79 21,4 6,6 2,22 0,56<br />

V 4,25 2,59 1,66 1,06 0,63<br />

hr 120 33 10 3,4 0,86<br />

V 3,11 1,99 1,27 0,75 0,5<br />

hr 47 14,2 4,74 1,21 0,43<br />

V 3,63 2,32 1,49 0,88 0,58<br />

hr 63 19 6,3 1,63 0,57<br />

V 4,15 2,65 1,7 1,01 0,66<br />

hr 82 24,5 8,1 2,1 0,74<br />

V 5,18 3,32 2,12 1,26 0,83 0,53<br />

hr 126 37,5 12,3 3,2 1,12 0,36<br />

V 3,98 2,55 1,51 1 0,64<br />

hr 53 17,3 4,5 1,58 0,51<br />

V 5,31 3,4 2,01 1,33 0,85<br />

hr 92 29,5 7,8 2,7 0,89<br />

V 6,63 4,25 2,51 1,66 1,06 0,68<br />

hr 140 44,8 12 4,13 1,36 0,48<br />

V 5,1 3,02 1,99 1,27 0,82<br />

hr 63 16,9 5,8 1,93 0,68<br />

V 5,94 3,52 2,32 1,49 0,95<br />

hr 84 22,6 7,8 2,6 0,9<br />

V 6,79 4,02 2,65 1,70 1,09 0,75<br />

hr 108 29 10 3,35 1,16 0,43<br />

V 7,64 4,52 2,99 1,91 1,22 0,85<br />

hr 134 36 12,5 4,2 1,45 0,54<br />

V 5,03 3,32 2,12 1,36 0,94<br />

hr 44,5 15,2 5,14 1,76 0,66<br />

V 6,28 4,15 2,65 1,70 1,18 0,87<br />

hr 68 23 7,9 2,68 1 0,48<br />

V 7,54 4,98 3,18 2,04 1,42 1,04<br />

hr 96 32,6 11,2 3,77 1,42 0,68<br />

V 8,79 5,81 3,72 2,38 1,65 1,21 0,93<br />

hr 129 43,5 15 5,04 1,9 0,91 0,45<br />

V 6,63 4,25 2,72 1,89 1,39 1,06 0,68<br />

hr 56 19,4 6,5 2,43 1,18 0,58 0,16<br />

V 8,29 5,31 3,40 2,36 1,73 1,33 0,85<br />

hr 85 30 9,8 3,75 1,79 0,89 0,25<br />

V 9,95 6,37 4,08 2,83 2,08 1,59 1,02 0,71<br />

hr 120 42 13,8 5,3 2,53 1,25 0,35 0,15<br />

V 10,62 6,79 4,72 3,47 2,65 1,70 1,18 0,87 0,66<br />

hr 124,9 41,3 16,74 7,81 4,03 1,34 0,54 0,25 0,13<br />

V 13,59 9,44 6,93 5,31 3,4 2,36 1,73 1,33<br />

hr 161 65 30,2 15,6 5,16 2,09 0,97 0,5<br />

V 6,79 4,72 3,47 2,65<br />

hr 20,1 8,13 3,8 1,95<br />

V 7,7 5,2 4,0<br />

hr 18,07 8,39 4,32<br />

V 11,8 8,67 6,63<br />

hr 49,5 23 11,8<br />

V 17,7 13 9,9<br />

hr 110,5 51,3 26,4<br />

V 17,33 13,27<br />

hr 90,6 46,6<br />

37

TECHNICAL APPENDIX<br />

FLOW RESISTANCE<br />

TABLE OF FLOW RESISTANCE IN BENDS, VALVES AND GATES IN cm OF<br />

COLUMN OF WATER<br />

VELOCITÀ WATER<br />

CURVE SHARP AD ANGOLO BENDSVIVO SMOOTH CURVE NORMALI BENDS STANDARD SARACI- VALVO- FOOT VALVO- CHECK<br />

DELL’ACQUA SPEED<br />

NESCHE GATE VALVES LE DI VALVES LE DI<br />

NORMALI VALVES FONDO RITEGNO<br />

m/sec a = 30° a = 40° a = 60° a = 80° a = 90°<br />

d = 0,4<br />

d = 0,6<br />

d = 0,8<br />

d = 1<br />

d = 1,5<br />

R R R R R<br />

0,10 0,03 0,04 0,05 0,07 0,08 0,007 0,008 0,01 0,0155 0,027 0,030 30 30<br />

0,15 0,06 0,07 0,10 0,14 0,17 0,016 0,019 0,024 0,033 0,06 0,033 31 31<br />

0,2 0,11 0,13 0,18 0,26 0,31 0,028 0,033 0,04 0,058 0,11 0,058 31 31<br />

0,25 0,17 0,21 0,28 0,4 0,48 0,044 0,052 0,063 0,091 0,17 0,090 31 31<br />

0,3 0,25 0,30 0,41 0,6 0,7 0,063 0,074 0,09 0,13 0,25 0,13 31 31<br />

0,35 0,33 0,40 0,54 0,8 0,93 0,085 0,10 0,12 0,18 0,33 0,18 31 31<br />

0,4 0,43 0,52 0,71 1,0 1,2 0,11 0,13 0,16 0,23 0,43 0,23 32 31<br />

0,5 0,67 0,81 1,1 1,6 1,9 0,18 0,21 0,26 0,37 0,67 0,37 33 32<br />

0,6 0,97 1,2 1,6 2,3 2,8 0,25 0,29 0,36 0,52 0,97 0,52 34 32<br />

0,7 1,35 1,65 2,2 3,2 3,9 0,34 0,40 0,48 0,70 1,35 0,70 35 32<br />

0,8 1,7 2,1 2,8 4,0 4,8 0,45 0,53 0,64 0,93 1,7 0,95 36 33<br />

0,9 2,2 2,7 3,6 5,2 6,2 0,57 0,67 0,82 1,18 2,2 1,20 37 34<br />

1,0 2,7 3,3 4,5 6,4 7,6 0,7 0,82 1,0 1,45 2,7 1,45 38 35<br />

1,5 6,0 7,3 10 14 17 1,6 1,9 2,3 3,3 6 3,3 47 40<br />

2,0 11 14 18 26 31 2,8 3,3 4,0 5,8 11 5,8 61 48<br />

2,5 17 21 28 40 48 4,4 5,2 6,3 9,1 17 9,1 78 58<br />

3,0 25 30 41 60 70 6,3 7,4 9 13 25 13 100 71<br />

3,5 33 40 55 78 93 8,5 10 12 18 33 18 123 85<br />

4,0 43 52 70 100 120 11 13 16 23 42 23 150 100<br />

4,5 55 67 90 130 160 14 21 26 37 55 37 190 120<br />

5,0 67 82 110 160 190 18 29 36 52 67 52 220 140<br />

1) Le Flow perdite resistance di carico in bends nelle curve is due sono to the soltanto contraction quelle of dovute the liquid alla contrazione threads resulting dei filetti from liquidi the change per cambiamento of direction: direzione: the development sviluppo of the delle bends curve must deve therefore<br />

quindi<br />

be compreso included nella in the lunghezza length of della the pipeline. tubazione.<br />

essere<br />

2) Le Flow perdite resistance di carico in valves nelle valvole and gates e saracinesche was determined sono state on the determinate basis of practical in base tests. a prove<br />

pratiche.<br />

38

TECHNICAL APPENDIX<br />

VOLUMETRIC CAPACITY<br />

litres<br />

per minute<br />

cubic metres<br />

per hour<br />

Portata Volumetrica<br />

cubic feet<br />

per hour<br />

cubic feet<br />

per minute<br />

imp. gal. per<br />

minute<br />

US gal. per<br />

minute<br />

l/min m³/h ft³/h ft³/min imp. gal./min US gal./min<br />

1,0000 0,0600 2,11890,0353 0,2200 0,2640<br />

16,6670 1,0000 35,3147 0,5886 3,6660 4,4030<br />

0,4720 0,0283 1,0000 0,0167 0,1040 0,1250<br />

28,3170 1,6990 60,0000 1,0000 6,2290 7,4800<br />

4,5460 0,2728 9,6326 0,1605 1,0000 1,2010<br />

3,7850 0,2271 8,02090,1337 0,8330 1,0000<br />

0,1100 0,0066 0,23390,00390,0240 0,0290<br />

PRESSURE AND HEAD<br />

Newton per square<br />

metre<br />

Pressione e Prevalenza<br />

kiloPascal bar pound force per<br />

square inch<br />

metre of water<br />

millimetre of<br />

mercury<br />

N/m² kPa bar psi m H 2 O mm Hg<br />

1,0000 0,0010 1 x 10 5 1,45 x 10 -4 1,02 x 10 -4 0,0075<br />

1.000,0000 1,0000 0,0100 0,1450 0,1020 7,5000<br />

100.000,0000 100,0000 1,0000 14,5000 10,2000 750,1000<br />

98.067,0000 98,0700 0,9810 14,2200 10,0000 735,6000<br />

6.895,0000 6,8950 0,0690 1,0000 0,7030 51,7200<br />

2.984,0000 2,9840 0,0300 0,4330 0,3050 22,4200<br />

9.789,0000 9,7890 0,0980 1,4200 1,0000 73,4200<br />

133,3000 0,1330 0,0013 0,0190 0,0140 1,0000<br />

3.386,0000 3,3860 0,0338 0,4910 0,3450 25,4000<br />

LENGTH<br />

Lunghezza<br />

millimetre centimetre metre inch foot yard<br />

mm cm m in ft yd<br />

1,0000 0,1000 0,0010 0,0394 0,0033 0,0011<br />

10,0000 1,0000 0,0100 0,3937 0,0328 0,0109<br />

1000,0000 100,0000 1,0000 39,3701 3,2808 1,0936<br />

25,4000 2,5400 0,0254 1,0000 0,0833 0,0278<br />

304,8000 30,4800 3,0480 12,0000 1,0000 0,3333<br />

914,4000 91,4400 0,9144 36,0000 3,0000 1,0000<br />

VOLUME<br />

Volume<br />

cubic metre litre millilitre imp. gallon US gallon cubic foot<br />

m³ l ml imp. gal. US gal ft³<br />

1,0000 1.000,0000 1 x 10 6 220,0000 264,2000 35,3147<br />

0,0010 1,0000 1.000,0000 0,2200 0,2642 0,0353<br />

1 x 10 -6 0,0010 1,0000 2,2 x 10 -4 2,642 x 10 -4 3,53 x 10 -5<br />

0,0045 4,5460 4.546,0000 1,0000 1,2010 0,1605<br />

0,0038 3,7850 3.785,0000 0,8327 1,0000 0,1337<br />

0,0283 28,3170 28.317,0000 6,2288 7,4805 1,0000<br />

39

®<br />

RECYCLED<br />

PAPER<br />

Do it 100%<br />

RETE COMMERCIALE ITALIANA “WATER TECHNOLOGY GROUP - EMEA”<br />

“WATER TECHNOLOGY GROUP - EMEA” ITALIAN SALES NETWORK<br />

BARI<br />

70026 Modugno Bari<br />

Via X Marzo, 110 P<br />

Tel. 080 5327453 - 5353808<br />

Fax: 080 5327926<br />

e-mail: bari@lowara.ittind.com<br />

BOLOGNA<br />

40132 Bologna - Via Panigale, 74/C<br />

Tel. 051 6415666<br />

Fax: 051 6415527<br />

e-mail: bologna@lowara.ittind.com<br />

BRESCIA<br />

25124 Brescia - Via Volta, 37<br />

Tel. 030 3531909<br />

Fax: 030 3534661<br />

e-mail: brescia@lowara.ittind.com<br />

CAGLIARI<br />

09100 Cagliari - Via Dolcetta, 19<br />

Tel. 070 287762 - 292192<br />

Fax: 070 280946<br />

e-mail: cagliari@lowara.ittind.com<br />

CATANIA<br />

95027 S. Gregorio - Catania<br />

Via XX Settembre, 75<br />

Tel. 095 7123226 - 7123987<br />

Fax: 095 498902<br />

e-mail: catania@lowara.ittind.com<br />

CHIETI<br />

66020 Sambuceto di S. Giovanni<br />

Teatino<br />

Via Aldo Moro, 125<br />

Tel. 085 4461360 - 4460231 - 4460449<br />

Fax 085 4460630<br />

e-mail: pescara@lowara.ittind.com<br />

MILANO<br />

20090 Trezzano sul Naviglio Milano<br />

Via Goldoni, 29<br />

Tel. 02 48464476 - Fax: 02 4451634<br />

e-mail: milano@lowara.ittind.com<br />

NAPOLI<br />

80017 Melito di Napoli - Napoli<br />

Corso Europa, 369 - Scala “A” int. 11-12<br />

Tel. 081 7113065 - 7113631<br />

Fax: 081 7115761<br />

e-mail: napoli@lowara.ittind.com<br />

PADOVA<br />

35020 Albignasego - Via A. Volta, 56<br />

Zona Mandriola<br />

Tel. 049 8801110 - 8801408<br />

Fax: 049 8801408<br />

e-mail: bassano@lowara.ittind.com<br />

PERUGIA<br />

06100 Perugia<br />

Via Settevalli, 133C, Torre 2 - 3° Piano<br />

Centro Direzionale Piazza Settevalli<br />

Tel. 075 5057126 - Fax: 075 5051242<br />

e-mail: perugia@lowara.ittind.com<br />

PISA<br />

56025 Località Gello di Pontedera - Pisa<br />

Via di Gello, 55<br />

Tel. 0587 296264 - 296286<br />

Fax: 0587 296410<br />

e-mail: pisa@lowara.ittind.com<br />

PORDENONE<br />

33082 Azzano Decimo Pordenone<br />

Viale 1° Maggio, 65/1 Area 53<br />

Tel. 0434 633243<br />

Fax: 0434 632729<br />

e-mail: pordenone@lowara.ittind.com<br />

ROMA<br />

00173 Roma - Via Frascineto, 8<br />

Tel. 06 7235890 (2 linee)<br />

Fax: 06 7234617<br />

e-mail: roma@lowara.ittind.com<br />

TORINO<br />

Via Torre Pellice, 17 - 10156 Torino<br />

Tel. 011 2979022 - 2979046<br />

Fax: 011 2979001<br />

e-mail: torino@lowara.ittind.com<br />

VICENZA<br />

36061 Bassano del Grappa - VI<br />

Via Pigafetta, 6<br />

Tel. 0424 566776 (R.A. 3 Linee)<br />

Fax: 0424 566773<br />

e-mail: bassano@lowara.ittind.com<br />

RETE COMMERCIALE EUROPEA “WATER TECHNOLOGY GROUP - EMEA”<br />

“WATER TECHNOLOGY GROUP - EMEA” EUROPEAN SALES NETWORK<br />

LOWARA DEUTSCHLAND GmbH<br />

Biebigheimer Straße 12<br />

63762 Großostheim - (OT Wenigumstadt) - D<br />

Tel. 0 60 26 9 43 - 0<br />

Fax: 0 60 26 9 43 - 2 10<br />

e-mail: info.de@lowara.ittind.com<br />

http://www.lowara.de<br />

LOWARA FRANCE S.A.S.<br />

BP 7311 - 37073 TOURS CEDEX 2 - F<br />

Tel. (0033) 02 47 88 17 17<br />

Fax: (0033) 02 47 88 17 00<br />

e-mail: info.fr@lowara.ittind.com<br />

http://www.lowara.fr<br />

LOWARA FRANCE SAS Agence Sud<br />

Z.I. La Sipière<br />

BP 23<br />

13730 Saint Victoret - F<br />

Tél. (0033) 04 42 10 02 30<br />

Fax (0033) 04 42 10 43 75<br />

LOWARA NEDERLAND B.V.<br />

POSTBUS 54 - 4180 BB Waardenburg<br />

Tel. 0031 - (0)418 - 65 50 60<br />

Fax: 0031 - (0)418 - 65 50 61<br />

e-mail: info.nl@lowara.ittind.com<br />

http://www.lowara.nl<br />

LOWARA PORTUGAL, Lda<br />

Praceta da Castanheira, 38<br />

4475-019 Barca Portugal<br />

Tel. 00351 22 9478550<br />

Fax: 00351 22 9478570<br />

e-mail: info.pt@lowara.ittind.com<br />

http://www.lowara.pt<br />

LOWARA UK Ltd.<br />

Main office<br />

Millwey Rise Industrial Estate - Axminster, Devon EX 13 5HU - GB<br />

Tel. 01297 630200 - Fax: 01297 630270<br />

e-mail: uksales@lowara.ittind.com - http://www.lowara.co.uk<br />

LOWARA UK Ltd. Regional sales office<br />

Unit 1, Byram Industrial Park - Low Street<br />

Brotherton, Knottingley - West Yorkshire WF11 9HS<br />

Tel. 01977 607267 - Fax 01977 607226<br />

e-mail: salesuknorth@lowara.ittind.com<br />

http://www.lowara.co.uk<br />

LOWARA IRELAND Ltd.<br />

59 Broomhill Drive - Tallaght Industrial Estate<br />

Tallaght - DUBLIN 24 - EIRE<br />

Tel. (1) 4520266 - Fax: (1) 4520725<br />

e-mail: sales-irl@lowara.ittind.com<br />

http://www.lowara.ie<br />

PUMPENFABRIK ERNST VOGEL GMBH<br />

ERNST VOGEL-STRASSE 2 - 2000 STOCKERAU AT<br />

Tel. 0043 2266 604 0 - Fax 0043 2266 65311<br />

http://www.vogel-pumpen.com<br />

VOGEL PUMPEN KFT<br />

BAKONY UT.8 - HU - 8000 SZEKESFEHERVAR<br />

Ph. 0036 22 512 645 - Fax 0036 22 512 642<br />

LOWARA VOGEL POLSKA Sp. z o.o.<br />

UL. WORCELLA 16 - PL - 40-652 KATOWICE<br />

Ph. 0048 32 202 8904 - Fax 0048 32 202 5452<br />

LOWARA S.r.l. - 36075 Montecchio Maggiore - Vicenza - Italy - Tel. +39 0444/707111 - Telefax +39 0444/492166 - e-mail: mkt@lowara.ittind.com - http://www.lowara.com<br />

LOWARA si riserva il diritto di apportare modifiche senza obbligo di preavviso — LOWARA reserves the right to make modifications without prior notice<br />

cod. 191014421 03/04