REIS SPOTTING AND TRY-OUT PRESSES - Reis Robotics

REIS SPOTTING AND TRY-OUT PRESSES - Reis Robotics

REIS SPOTTING AND TRY-OUT PRESSES - Reis Robotics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

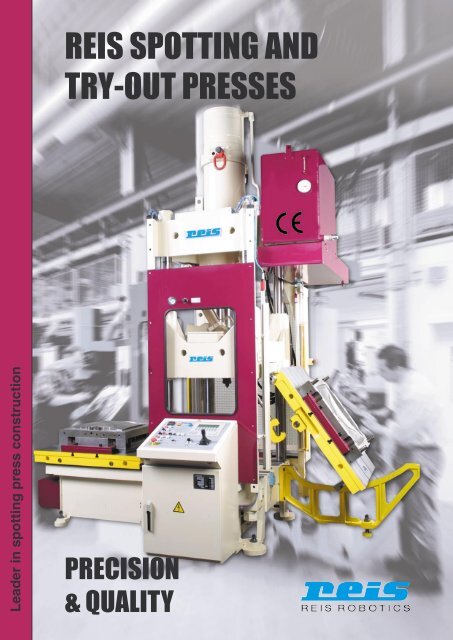

Leader in spotting press construction<br />

<strong>REIS</strong> <strong>SPOTTING</strong> <strong>AND</strong><br />

<strong>TRY</strong>-<strong>OUT</strong> <strong>PRESSES</strong><br />

PRECISION<br />

& QUALITY

Optimum mold handling<br />

Universal and fast movement of both mold halves, even for large molds with weight of 100<br />

tons. The machine is controllable in a sensitive way accurate to 1/10 mm.<br />

Spotting and Try-out Press TUS 200. Pressure force<br />

2000 KN. Upper mold half can be swiveled up to 180°.<br />

Spotting and Try-out Press TUS 200. Pressure force<br />

2000 KN. Free accessibility to mold halves.<br />

Spotting and Try-out Press TUS 80. Pressure force<br />

1000 KN. Optimum working position.<br />

YOUR ADVANTAGES:<br />

Due to the opposed movement of two<br />

clamping platens, the clamping of oversized<br />

molds is possible<br />

Optimum handling, free working positions<br />

All movements hydraulically controlled<br />

Upper mold half can be freely swiveled out<br />

up to 180 o<br />

Lower mold half can be swiveled hydraulically<br />

at the push of a button<br />

Lower mold half is tiltable to two sides<br />

Any intermediate position of all movements<br />

is possible<br />

Since all functions are electrically locked<br />

against each other, a faulty operation is<br />

excluded.

Checking, testing – cost cutting<br />

Simple checking of the molds with our reusable special injection compound PARAFORM. No<br />

time-consuming set-up on the injection or die casting machine.<br />

Quick test by means of Paraform.<br />

Sliding injection nozzle, displaceable ejector.<br />

Easy filling of the injection container.<br />

YOUR ADVANTAGES:<br />

No downtime of production machines<br />

Fast and safe checking of mold tightness,<br />

offset, wall thickness, flow behavior, surface,<br />

air entrapments, inserts and ejectors<br />

No warming up of the mold necessary<br />

Easy set-up of the injection unit due to sliding<br />

nozzle even for excentric cast<br />

Automatic temperature control of injection<br />

compound<br />

Easy filling of the injection container due to<br />

its lateral mounting to the machine<br />

After 30 sec. you will know the “secrets” of<br />

the mold

Solid – Exact - Precise<br />

First class mechanical engineering guarantees high precision and quality for product’s<br />

lifetime - even at highest stress.<br />

High plane parallelism due to center input of force<br />

from central main cylinder.<br />

Guaranteed precision, even after years, due to ribbed<br />

rams and platens, made from stress-free cast.<br />

Precision and accuracy are the basis for an optimum<br />

result.<br />

YOUR ADVANTAGES:<br />

Constant distribution of force and pressure<br />

at the ram due to cast, ribbed box profile<br />

Clamping platens free from distortion from<br />

stress-free cast<br />

Press frame optimized by finite element<br />

method<br />

Highest positioning accuracy of upper<br />

clamping platen due to hydraulic pre-tension<br />

and locking<br />

Exact positioning and centering of the lower<br />

clamping platen on spotted guide rails<br />

High rigidity against jamming due to extra<br />

long guides<br />

Simple readjustment of the press parallelism<br />

by respotting of the table supports, without<br />

dismounting the machine

Advantages due to performance and comfort<br />

Low operating costs due to efficient, state-of-the-art hydraulics and operator-friendly<br />

controls. CE-conformity with high safety.<br />

The hydraulic components correspond to the latest<br />

EC standards. They are arranged clearly in block design<br />

and easy-to-service.<br />

Operation independent from language due to graphical<br />

symbols. Error message and analysis in plain<br />

text<br />

Sensitive pressure and speed regulation via joystick<br />

at an ergonomic designed operating panel.<br />

YOUR ADVANTAGES:<br />

Freely regulation of the speed via joystick<br />

Freely regulation of the pressure<br />

All movements hydraulically controlled<br />

Parallel measurement between the platens<br />

Lower and upper mold half can be swiveled<br />

out hydraulically and freely by push of a<br />

button<br />

Lapping, filing and grinding function<br />

Any intermediate position of all movements<br />

is possible<br />

Faulty operation is excluded, error message<br />

in plain text on the large display

Important additional functions<br />

Well thought-out accessories increase the benefit and the profitability. Our machines offer<br />

indispensable advantages for every mold builder.<br />

Spotting and Try-out Press TUS 130. Pressure force<br />

2000 KN with rotary table.<br />

Tilting table for an optimum working position of the<br />

lower mold half.<br />

Testing of deep-draw tools due to integration of a<br />

hydraulic draw cushion.<br />

YOUR ADVANTAGES:<br />

Connections for core pulls and other<br />

hydraulic outlets<br />

Exact detection of friction in core pulls and<br />

ejectors<br />

Hydraulic ejector in lateral table, central or<br />

sliding from the center<br />

Ejector swivels along in the lateral tilting table<br />

For low ceiling room the main cylinder is<br />

available in a telescopic design<br />

Electronic/hydraulic control unit for automatic,<br />

pre-selectable ram positioning accurate<br />

to 1/10 mm

Series and references<br />

Worldwide more than 3000 first class references. For more than 40 years.<br />

AE Formen- und Werkzeugbau GmbH, D-Schortens . AUMA S.A., Mexiko . AWEBA Werkzeug GmbH . Bajaj Auto Ltd., IND-<br />

Pune . BBP Kunststoffwerk, D-Marbach . Mercedes-Benz AG, D-Essingen-Mettingen . BMW AG, D-München . Robert Bosch,<br />

D-Stuttgart . Brabant Alucast Prod. B. V., NL-AN Oss . Citroën, F-Paris . Otto Deuschle, D-Wendlingen . Eckel & Co GmbH,<br />

D-Biedenkopf-Wallau . Heinrich Grimm, D-Hildesheim . Felix Grunewald KG, D-Bocholt . Ford Motor Limited, GB-Belfast . Ford<br />

Company Werke AG, D-Berlin, D-Köln . Fonderie de Precision, F-Nauterre . Wilhelm Funke, Modell- und Formenbau, D-Alfeld .<br />

Grunewald-Modellbau KG, D-Bocholt . Heck Becker, D-Dautphetal . Helphos GmbH, D-Bad Harzburg . Siegfried Hofmann GmbH,<br />

D-Lichtenfels . Metallurgie Hoboken, B-Overpelt . Honsel-Werke AG, D-Meschede . H.S. Die & Engineering, USA-Grand Rapids .<br />

Wilhelm Karmann, D-Osnabrück . Preßwerk Köngen GmbH, D-Köngen . Sepp Misslbeck, D-Ingolstadt . Chigago Mold, Enginee-<br />

ring Co., USA-Hillside . Accurate Mould Co. Ltd., Rexdale, Ontario . Müller KG, D-Biedenkopf-Wallau . Herbert Olbrich GmbH &<br />

Co. KG, D-Bocholt . Paragon Tools, CDN-Windsor, Ontario . Paschold OHG, D-Hochstadt . Peguform Werke GmbH, D-Göttingen<br />

. Peugeot Automobiles, F-Mulhouse . Phoenix AG, D-Hamburg . Proper Mold & Engineering Inc., Center Line, USA-Mi . PWB,<br />

D-Großdubrau . Rampsperger, D-Delmhorst . Quality Machines Inc., USA-IL-Elmwood Park . Riesselmann & Sohn, D-Lohne .<br />

Fritz Schäfer, D-Neunkirchen . Schaufler Werkzeugbau OHG, D-Leichingen . Scherer & Trier OHG, D-Michelau . Schütz-Werke<br />

GmbH & Co. KG, D-Selters . Schwarzfärber & Co. GmbH, D-Nürnberg . Seeber S.p.A., Leifers (BZ) . Chr. Karl Siebenwurst OHG,<br />

D-Dietfurt . Theysohn Formenbau GmbH, D-Langenhagen . Triangle Tool Corp., USA-Milwaukee . Volkswagen AG, Wolfsburg, D-<br />

Braunschweig . YMOS AG, D-Obertshausen . J. Zimmermann Nachf., D-Erdhausen . Tecnifreza, P-2431 Marinha Grande Codex<br />

. Alzfar & Company, PAK-Lahore . Romchim, R-Bukarest . IBM, RA-Buenos Aires . Technoproimport, SU-Moskau . United Nations<br />

Industrial Development Org., TN . American Optimal Company, USA-Southbridge . Alphaform-Claho GmbH, D-Grainau . Babilon<br />

GmbH, D-Breuberg-Hainstadt . Balda Werkzeug- und Vorrichtungsbau GmbH . GIRA Giersiepen GmbH & Co. KG, D-Radevorm-<br />

wald . Horstmann & Thienelt GmbH, D-Hille-Unterlübbe . Iform GmbH, D-Köln . Jacoby GmbH & Co., D-Löhne . Jonscher Alfred<br />

GmbH, D-Velbert . Büttner GmbH, D- Sonneberg . Coko-Werk, D-Bad Salzuflen . Daimler Chrysler AG, D-Stuttgart . FER Fahr-<br />

zeugelektrik GmbH, D-Eisenach . Korf & Co. Nachfolger H. Stallmeister, D-Warstein . Krahl + Reiche Werkzeugbau, D-Kronach .<br />

Hua de Plastics Corp. Ltd., CN-Shanghai . Yau Lieng May Fair Ind. Co. Ltd, CN-Hong Kong . USA Proper Mold and Engineering,<br />

Anderson, S. C. 29625 . Reitter & Schefenacker, USA-Selmer TN . Schefenacker Vision Systems, USA . Heidenauer Formen- und<br />

Werkzeugbau GmbH, D-Dohna/Dresden . Peguform Bohemia k.s., 460 78 CZ-Liberec . Koller GmbH, D-Dietfurt . uvm.<br />

THE COMPLETE SERIES<br />

The perfect model for all molds and dies:<br />

TYPE Clamping<br />

platen size [mm]<br />

TUS 60 560 x 670<br />

TUS 80 800 x 1100<br />

TUS 100 1000 x 1300<br />

TUS 130 1300 x 1600<br />

TUS 160 1600 x 2000<br />

TUS 180 1800 x 2500<br />

TUS 200 2000 x 3000<br />

TUS 300 3000 x 3000<br />

TUS 400 4000 x 3000

<strong>Reis</strong> <strong>Robotics</strong> USA, Inc.<br />

1320, Holmes Road<br />

USA-Elgin, IL 60123<br />

Phone: ++1-847-741-95 00<br />

Fax: ++1-847-888-27 62<br />

<strong>Reis</strong> <strong>Robotics</strong> España S.L.<br />

Dr. Manuel Riera, 90<br />

E-08950 Esplugas<br />

Phone: ++ 34-93-473 72 25<br />

Fax: ++ 34-93-473 72 59<br />

<strong>REIS</strong> - Worldwide<br />

<strong>Reis</strong> GmbH & Co. Maschinenfabrik<br />

Industriegebiet an der B 426<br />

D-63785 Obernburg<br />

Tel: ++ 49 (0) 60 22-5 03-0<br />

Fax: ++ 49 (0) 60 22-5 03-110<br />

Internet: www.reisrobotics.de<br />

<strong>Reis</strong> France E.u.r.l.<br />

44 Rue du Pré des Aulnes<br />

Parc d'Activités des Arpents<br />

F-77340 Pontault-Combault<br />

Phone: ++ 33-1-60 28 22 22<br />

Fax: ++ 33-1-60 28 35 47<br />

<strong>Reis</strong> <strong>Robotics</strong> Italia S.r.l.<br />

Via del Lavoro 42<br />

I-20040 Bellusco<br />

Phone: ++ 39-039-6 06 70 20<br />

Fax: ++ 39-039-6 06 70 12<br />

<strong>Reis</strong> <strong>Robotics</strong> CR spol. s r.o.<br />

Cernovice 173<br />

CZ-430 01 Chomutov<br />

Phone: ++42 (0) 474-6385-0<br />

Fax: ++42 (0) 474-6385-20<br />

<strong>Reis</strong> <strong>Robotics</strong> do Brasil Ltda.<br />

Rua Dr. Ribeiro de Almeida 286<br />

01137-020 - Sao Paulo - SP<br />

Phone: ++55 (0 xx 11) 3612-2154<br />

Fax: ++55 (0 xx 11) 3612-2047<br />

tus_03_03