civil & structural engineering - Institution of Engineers Singapore

civil & structural engineering - Institution of Engineers Singapore

civil & structural engineering - Institution of Engineers Singapore

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The Magazine Of<br />

The <strong>Institution</strong> Of <strong>Engineers</strong>, <strong>Singapore</strong><br />

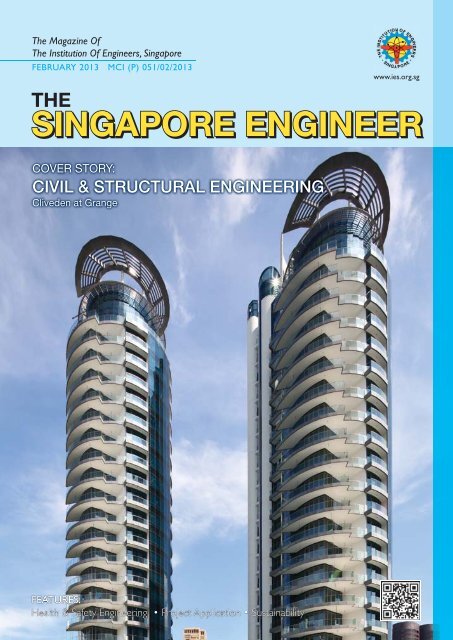

FEBRUARY 2013 MCI (P) 051/02/2013<br />

THE<br />

www.ies.org.sg<br />

SINGAPORE ENGINEER<br />

COVER STORY:<br />

CIVIL & STRUCTURAL ENGINEERING<br />

Cliveden at Grange<br />

FEATURES:<br />

Health & Safety Engineering • Project Application • Sustainability

CONTENTS<br />

FEATURES<br />

12 CIVIL & STRUCTURAL ENGINEERING: Cover Story:<br />

Cliveden at Grange<br />

The residential project received recognition also for its emphasis on design and<br />

<strong>engineering</strong> safety.<br />

16 INTERVIEW:<br />

SIT moves ahead with broadened portfolio and higher student intake<br />

<strong>Singapore</strong> Institute <strong>of</strong> Technology is proactively responding to the challenges and<br />

opportunities in tertiary education.<br />

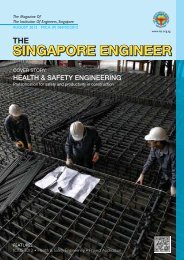

18 HEALTH & SAFETY ENGINEERING:<br />

Ergonomics at the construction sites<br />

Poor working conditions could lead to serious problems for workers over time.<br />

30 HEALTH & SAFETY ENGINEERING:<br />

Proper fi tting <strong>of</strong> hearing protection devices<br />

There is a need to eliminate problems for workers due to excessive noise.<br />

32 PROJECT APPLICATION:<br />

Two Liebherr internal climbing tower cranes build designer<br />

homes in India<br />

The machines performed well in spite <strong>of</strong> the site constraints.<br />

34 PROJECT APPLICATION:<br />

The expansion <strong>of</strong> Panama Canal<br />

Mapei is supplying high performance admixtures for the production <strong>of</strong> concrete<br />

required for this major construction project.<br />

38 PROJECT APPLICATION:<br />

Potain and Grove cranes work at the Panama Canal<br />

Lifting and installation duties are being carried out round-the-clock.<br />

40 SUSTAINABILITY:<br />

Global phosphorus and the case for phosphorus recovery<br />

The depletion <strong>of</strong> this important resource is cause for worry.<br />

REGULAR SECTIONS<br />

02 IES UPDATE<br />

Chief Editor<br />

T Bhaskaran<br />

t_b_n8@yahoo.com<br />

Director, Marketing<br />

Roland Ang<br />

roland@iesnet.org.sg<br />

Marketing & Publications Executive<br />

Jeremy Chia<br />

jeremy@iesnet.org.sg<br />

CEO<br />

Angie Ng<br />

angie@iesnet.org.sg<br />

Publications Manager<br />

Desmond Teo<br />

desmond@iesnet.org.sg<br />

Published by<br />

The <strong>Institution</strong> Of <strong>Engineers</strong>, <strong>Singapore</strong><br />

70 Bukit Tinggi Road<br />

<strong>Singapore</strong> 289758<br />

Tel: 6469 5000 Fax: 6467 1108<br />

Cover designed by Irin Kuah<br />

Cover image by City Developments Limited.<br />

The <strong>Singapore</strong> Engineer is published<br />

monthly by The <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>,<br />

<strong>Singapore</strong> (IES). The publication is<br />

distributed free-<strong>of</strong>-charge to IES members<br />

and affi liates. Views expressed in this<br />

publication do not necessarily refl ect those<br />

<strong>of</strong> the Editor or IES. All rights reserved. No<br />

part <strong>of</strong> this magazine shall be reproduced,<br />

mechanically or electronically, without the<br />

prior consent <strong>of</strong> IES. Whilst every care is<br />

taken to ensure accuracy <strong>of</strong> the content<br />

at press time, IES will not be liable for any<br />

discrepancies. Unsolicited contributions<br />

are welcome but their inclusion in the<br />

magazine is at the discretion <strong>of</strong> the Editor.<br />

Design & layout by 2EZ Asia Pte Ltd<br />

Printed by Print & Print Pte Ltd.<br />

39 PRODUCTS & SOLUTIONS<br />

44 NEWS<br />

February 2013 THE SINGAPORE ENGINEER<br />

01

IES UPDATE<br />

Message from the President<br />

On the morning <strong>of</strong> 16 January 2013, a helicopter<br />

crashed in Vauxhall, in London, UK, after it hit a crane<br />

on top <strong>of</strong> a high-rise tower under construction.<br />

The helicopter fell onto the road, hitting several<br />

vehicles and bursting into fl ames. Two people died<br />

in the accident - the pilot <strong>of</strong> the helicopter and a<br />

pedestrian. Around 12 or 13 people were injured.<br />

Some <strong>of</strong> them were treated on the spot and some<br />

were taken to hospital.<br />

The accident shows that construction activities can pose a hazard to other occupations<br />

and to the general public.<br />

In order to eliminate such tragedies, it is essential to improve the quality <strong>of</strong> safetyrelated<br />

information on projects at all times, and the effectiveness in communicating<br />

that information to all relevant parties.<br />

This should be possible, considering the tremendous progress being made in digital<br />

capture and communication <strong>of</strong> information, in real-time. These techniques can be<br />

optimised and made cost-effective, and with the necessary regulatory initiatives and<br />

coordination and collaboration among various sectors <strong>of</strong> government and industry,<br />

they can be applied.<br />

At the same time, great importance is given to design and <strong>engineering</strong> safety in the<br />

implementation <strong>of</strong> construction projects. This should reduce on-site accidents such as<br />

those involving workers and heavy objects falling from heights, as well as the toppling<br />

<strong>of</strong> large construction equipment.<br />

The challenge to ensure safety in construction is even greater today because <strong>of</strong><br />

the size and complexity <strong>of</strong> projects, the increased volume <strong>of</strong> work and the shorter<br />

completion times allotted, all set against a target <strong>of</strong> zero incidents and accidents.<br />

To attain this objective, engineers will have to play their part, along with other<br />

stakeholders.<br />

Pr<strong>of</strong> Chou Siaw Kiang<br />

President<br />

The <strong>Institution</strong> <strong>of</strong> <strong>Engineers</strong>, <strong>Singapore</strong> (IES)<br />

IES COUNCIL MEMBERS<br />

2012/2013<br />

President<br />

Pr<strong>of</strong> Chou Siaw Kiang<br />

Vice Presidents<br />

Er. Chong Kee Sen<br />

Er. Edwin Khew<br />

Dr Kwok Wai Onn, Richard<br />

Mr Neo Kok Beng<br />

Er. Ong Geok Soo<br />

Er. Ong See Ho<br />

Honorary Secretary<br />

Dr Boh Jaw Woei<br />

Honorary Treasurer<br />

Mr Kang Choon Seng<br />

Assistant Honorary Secretary<br />

Er. Koh Beng Thong<br />

Assistant Honorary Treasurer<br />

Er. Seow Kang Seng<br />

Immediate Past President<br />

Er. Ho Siong Hin<br />

Past Presidents<br />

Er. Dr Lee Bee Wah<br />

Er. Tan Seng Chuan<br />

Honorary Council Member<br />

Er. Ong Ser Huan<br />

Council Members<br />

Pr<strong>of</strong> Chau Fook Siong<br />

Er. Dr Chew Soon Hoe<br />

Ms Fam Meiling<br />

Er. Dr Ho Kwong Meng<br />

Dr Ho Teck Tuak<br />

Mr Lee Kwok Weng<br />

Mr Lim Horng Leong<br />

Mr Ng Sing Chan<br />

Mr Oh Boon Chye, Jason<br />

Er. Tan Shu Min, Emily<br />

Mr Tan Boon Leng, Mark<br />

Er. Toh Siaw Hui, Joseph<br />

Er. Wong Fee Min, Alfred<br />

Dr Zhou Yi<br />

02 THE SINGAPORE ENGINEER February 2013

IES UPDATE<br />

IES 12 th CTO Forum generates new<br />

innovative ideas<br />

Proudly organised by IES and National University <strong>of</strong> <strong>Singapore</strong><br />

(NUS), the 12 th CTO Forum was eagerly anticipated by the<br />

CTOs who were in attendance. Nearly 20 specially invited CTO<br />

members attended the Forum, which was held on 28 January<br />

2013, at the National Library Board building.<br />

The speaker for the evening was Dr Yves Pigneur from NUS,<br />

who presented the topic ‘Business Model Innovation and<br />

Design’. The presentation engendered discussion among the<br />

CTOs regarding the different segments <strong>of</strong> business innovations.<br />

A free fl owing Q&A session followed, where Dr Pigneur fi elded<br />

questions from the business leaders.<br />

The presentation was then followed by a networking dinner,<br />

where the attendees mingled and interacted with each other.<br />

Dr Yves Pigneur delivered his presentation on ‘Business Model Innovation and<br />

Design’ at the 12 th CTO Forum.<br />

Courtesy Visit by delegation from China<br />

Association for Science & Technology<br />

Group photo taken with CAST Executive Secretary Mr Shen Aimin (6 th from<br />

right) and IES President Pr<strong>of</strong> Chou Siaw Kiang (7 th from right).<br />

IES warmly welcomed a delegation from the China Association<br />

for Science & Technology (CAST) to its premises on 25 January<br />

2013 as part <strong>of</strong> a technical visit and to promote closer bilateral<br />

relationship between the two associations. The delegation was<br />

led by Mr Shen Aimin, Executive Secretary <strong>of</strong> CAST.<br />

The CAST representatives were received by IES President Pr<strong>of</strong><br />

Chou Siaw Kiang, IES Vice President Er. Ong See Ho, IES Past<br />

Presidents Er. Tan Seng Chuan and Er. Dr Lock Kai Sang, IES<br />

CEO Ms Angie Ng and Member <strong>of</strong> WES 2013 Ambassadorial<br />

Committee, Er. Chong Chin Hin.<br />

Both sides gave an update on their organisations’ respective<br />

activities for 2012. CAST revealed that it is actively looking at raising<br />

the quality <strong>of</strong> <strong>engineering</strong> education in China. It is also in the process<br />

<strong>of</strong> applying for accreditation under the Washington Accord.<br />

IES also informed CAST <strong>of</strong> its new annex building plans and<br />

the organisation <strong>of</strong> the inaugural World <strong>Engineers</strong>’ Summit<br />

(WES) in September this year. Pr<strong>of</strong> Chou and the WES Steering<br />

Committee Chairman, Er. Tan Seng Chuan, extended an invitation<br />

to CAST to take part in the event.<br />

The meeting ended with an exchange <strong>of</strong> tokens between the<br />

two organisations.<br />

IES wishes to extend its thanks to all who have donated or<br />

pledged an amount to the IES Building Redevelopment fund<br />

thus far.<br />

The construction <strong>of</strong> the new IES Annex Building is well underway<br />

after the ground breaking last December. The state-<strong>of</strong>-the-art<br />

building will be an iconic showpiece <strong>of</strong> <strong>engineering</strong> effort that<br />

will feature advanced green and sustainable features.<br />

We are still seeking donations and pledges from our members<br />

and the <strong>engineering</strong> fraternity to realize this new building as the<br />

‘Home <strong>of</strong> <strong>Engineers</strong>’. For those who are keen to donate/pledge,<br />

please email Siew Keow at siewkeow@iesnet.org.sg.<br />

For those who have already pledged their donation, we would<br />

appreciate it if you could mail your cheque to IES as soon as<br />

possible so as to help us get to our targeted goal. Please make a<br />

crossed cheque payable to “IES Building Fund” and indicate your<br />

name/company name behind the cheque.<br />

If you wish to help out in another way, we also have 2013 IES<br />

table calendars on sale for $10, the proceeds <strong>of</strong> which will go<br />

towards the Fund as well.<br />

Your kind support is greatly appreciated.<br />

Artist’s impression <strong>of</strong> the new IES Annex Building.<br />

04 THE SINGAPORE ENGINEER February 2013<br />

Discover ‘Innovative and Sustainable Solutions to Climate Change’ at WES 2013!<br />

For more information, visit http://www.wes2013.org

February 2013 THE SINGAPORE ENGINEER<br />

05

IES UPDATE<br />

BETC Symposium 2013 – Engineering In<br />

Medical Devices<br />

IES kicked <strong>of</strong>f the year 2013 with the inaugural Biomedical<br />

Engineering Technical Committee (BETC) Symposium 2013 –<br />

Engineering in Medical Devices. Themed ‘Engineer Your Mind<br />

Towards Excellence’, this year’s event was held at the auditorium<br />

<strong>of</strong> TÜV SÜD PSB <strong>Singapore</strong> Pte Ltd on 11 and 12 January.<br />

The two-day event was attended by about 100 participants,<br />

including representatives from the government, industry and<br />

hospitals, IES members, students from junior colleges and<br />

tertiary institutions, patients and members <strong>of</strong> the public.<br />

The Guest-<strong>of</strong>-Honour at the opening ceremony was Dr Lam<br />

Pin Min from KK Women’s and Children’s Hospital, Member <strong>of</strong><br />

Parliament for Sengkang West SMC in the Ang Mo Kio GRC,<br />

and Chairman <strong>of</strong> the Government Parliamentary Committee<br />

for Health. Later in the afternoon, Dr Intan Azura Mokhtar,<br />

Assistant Pr<strong>of</strong>essor at the National Institute <strong>of</strong> Education and<br />

Member <strong>of</strong> Parliament for Ang Mo Kio GRC, gave a moving<br />

speech, as a Special Observer, about the need to develop better<br />

medical devices for handicapped adults and children.<br />

Guest-<strong>of</strong>-Honour Dr Lam Pin Min (fourth from left) with Dr Ho Teck Tuak<br />

(fi fth from left), Chairman <strong>of</strong> BETC, and other members <strong>of</strong> the welcome entourage.<br />

A/Pr<strong>of</strong> Daniel Lim presenting his keynote speech.<br />

Ms Susan Ng, symposium emcee, welcoming delegates.<br />

Pr<strong>of</strong> Ruys Andrew presenting his keynote speech.<br />

Delegates at the Opening Ceremony.<br />

Dr Ho presenting a token <strong>of</strong> appreciation to Dr Lam.<br />

06 THE SINGAPORE ENGINEER February 2013<br />

IES Journal Part A: Civil & Structural Engineering Vol 6 is out now!<br />

For more information or to subscribe, call 6469 5000.

February 2013 THE SINGAPORE ENGINEER<br />

07

IES UPDATE<br />

At the symposium, two keynote speakers and twelve plenary<br />

speakers from key players in the medical device industry including<br />

the Agency for Science, Technology & Research (A*STAR),<br />

the Health Sciences Authority (HSA), IES, Nanyang Technological<br />

University (NTU), National University <strong>of</strong> <strong>Singapore</strong> (NUS),<br />

Stryker <strong>Singapore</strong>, TÜV SÜD PSB <strong>Singapore</strong>, University <strong>of</strong><br />

Sydney (Australia), WongPartnership, and 3M <strong>Singapore</strong><br />

presented on a variety <strong>of</strong> topics on the latest issues, challenges<br />

and solutions in medical device technology. Apart from the<br />

symposium, attendees got a rare opportunity to participate in<br />

site visits to TÜV SÜD PSB secured laboratories.<br />

The symposium was supported by the <strong>Singapore</strong> Medical<br />

Association, the <strong>Singapore</strong> Manufacturing Federation and<br />

sponsored by ANSYS (The Finite Element Method Solution),<br />

and TÜV SÜD PSB <strong>Singapore</strong>.<br />

Besides being treated to healthy and sumptuous lunches and<br />

tea breaks featuring local delights, participants also received<br />

goodie bags jointly sponsored by TÜV SÜD PSB <strong>Singapore</strong>,<br />

WongPartnership and IES as well as symposium booklets as<br />

mementoes.<br />

The BETC Committee welcomes everyone to the next BETC<br />

event which will take place in the near future.<br />

Dr Ho showing Dr Intan products <strong>of</strong> the Finite Element Method at the<br />

ANSYS exhibition booth<br />

Dr Ho presenting a token <strong>of</strong> appreciation to Dr Intan.<br />

Talk on <strong>Singapore</strong> BIM Guide and BCA<br />

BIM Funding<br />

On 22 January 2013, at the IES Auditorium, the IES Environment<br />

Engineering Technical Committee Chairman, Er. Alfred Wong,<br />

brought together three speakers from different industries to share<br />

their experiences in using Building Information Modelling (BIM).<br />

One hundred participants from various industries attended the<br />

evening talk to fi nd out more about the <strong>Singapore</strong> BIM Guide<br />

and BIM funding from Mr Sonny Andalis, a technical consultant<br />

and BIM specialist from the BCA Centre for Construction IT<br />

(CCIT). Ms Christina Koh, Technical Director from Beca Carter<br />

Hollings & Ferner, talked about the pros and cons <strong>of</strong> using BIM<br />

in Civil & Structural Engineering projects in <strong>Singapore</strong> while the<br />

representative from CPG Consultants, Mr Tan Guoyi, a Senior<br />

Architectural Associate, explained how BIM was implemented<br />

at the new SAFRA Toa Payoh Clubhouse.<br />

The <strong>Singapore</strong> BIM Guide, a reference that outlines the roles<br />

and responsibilities <strong>of</strong> project members at different stages <strong>of</strong><br />

a project, is available at http://www.corenet.gov.sg/integrated_<br />

submission/bim/BIM_Guide.htm<br />

From left, Ms Christina Koh from Beca Carter Hollings & Ferner, Mr Sonny<br />

Andalis from BCA, Q&A panel moderator Er. Tsang Pui Sum, Mr Tan Guoyi<br />

from CPGConsultants, and IES Environmental Engineering Technical Committee<br />

Chairman Er. Alfred Wong.<br />

After the talk, Er. Ong Ser Huan gave out Tokens <strong>of</strong> Appreciation to the speakers.<br />

08 THE SINGAPORE ENGINEER February 2013<br />

Discover ‘Innovative and Sustainable Solutions to Climate Change’ at WES 2013!<br />

For more information, visit http://www.wes2013.org

10 THE SINGAPORE ENGINEER February 2013

February 2013 THE SINGAPORE ENGINEER<br />

11

COVER STORY<br />

Cliveden at Grange<br />

At BCA AWARDS 2012, the project received a Design and Engineering Safety Excellence Award.<br />

It also won a Construction Productivity Award (Platinum) and a Universal Design Award (Silver).<br />

INTRODUCTION<br />

The BCA Design and Engineering Safety Excellence Awards<br />

were instituted as part <strong>of</strong> the efforts by BCA (Building and<br />

Construction Authority) to ensure high safety standards in the<br />

built environment and inculcate a strong safety culture in the<br />

building industry. The Award gives recognition to the efforts<br />

taken by the Qualifi ed Person for Structural Works [QP (ST)],<br />

his or her fi rm and the project team, for ingenious design<br />

processes and solutions for overcoming project challenges and<br />

ensuring safety in the design, construction, and maintenance, <strong>of</strong><br />

building and <strong>civil</strong> <strong>engineering</strong> projects, in <strong>Singapore</strong> and overseas.<br />

Through this Award, BCA hopes to encourage industry<br />

pr<strong>of</strong>essionals to make a more concerted effort to create a safe<br />

built environment for all.<br />

The assessment criteria cover two key aspects - safety in design,<br />

and safety in construction.<br />

Project overview<br />

Cliveden at Grange is nestled in a high-class residential area<br />

along Grange Road in the downtown district. Located on a<br />

12,857.4 m 2 site, the development consists <strong>of</strong> four tower blocks,<br />

24-storey high, with 110 units including three-bedroom, fourbedroom<br />

and penthouse units; as well as a basement carpark,<br />

and a swimming pool and communal facilities on the 1 st storey.<br />

The project was implemented over a period <strong>of</strong> 42 months.<br />

Three <strong>of</strong> the blocks are single tower blocks and are similar in<br />

layout, with the staircase and lift core walls in each <strong>of</strong> them<br />

located at the side <strong>of</strong> the building, while the fourth block is<br />

a twin tower block with its staircase and lift core walls at the<br />

centre <strong>of</strong> the building. The buildings are unique, with conical<br />

staircases, circular lift cores and curved external walls. This<br />

made it a challenge in terms <strong>of</strong> design and construction.<br />

Innovative solutions and features adopted to overcome the<br />

challenges in this project include the use <strong>of</strong> the jack-in piling<br />

system, precast structures including curved walls, prefabricated<br />

toilets, steel mullions and up-stand drop panels.<br />

Design processes and solutions that emphasise safety<br />

The site on which Cliveden at Grange stands is in front <strong>of</strong> a<br />

row <strong>of</strong> landed properties. There is also a 3.1 m wide drain<br />

culvert cutting across the development.<br />

The jack-in piling system was adopted as it is environmentfriendly<br />

and ensures good on-site working conditions. Jack-in<br />

piling eliminates vibration and reduces dust and noise to the<br />

surrounding environment, which was important especially since<br />

the site is surrounded by both high-rise and landed housing.<br />

Cutting across the site is a 6.1 m drainage reserve that requires<br />

a 3 m headroom clearance above it. To make sure this is met, a<br />

fl at slab post-tensioning system with up-stand drop panels was<br />

provided. The up-stand drop panels also served to increase the<br />

buildability <strong>of</strong> the 1 st storey slab.<br />

Artist’s impression <strong>of</strong> Cliveden at Grange.<br />

Jack-in piling in progress.<br />

12 THE SINGAPORE ENGINEER February 2013

COVER STORY<br />

Up-stand drop panels<br />

Section across the drainage reserve.<br />

If the structures were cast in-situ, they would have required<br />

precise construction as well as a lot <strong>of</strong> external scaffolding,<br />

because <strong>of</strong> the circular layouts, the conical shapes <strong>of</strong> the lift<br />

cores, and staircase cores with curved external walls. Instead,<br />

by adopting precast construction, it was possible to greatly<br />

reduce the number <strong>of</strong> external scaffolds and thereby provide<br />

a safer working environment. In addition, the project became<br />

more buildable and a better quality <strong>of</strong> work was achieved. Also,<br />

rectifi cations could be done prior to installation.<br />

The use <strong>of</strong> precast <strong>structural</strong> walls, along with the use <strong>of</strong> precast<br />

fi n walls and curved beams for the ro<strong>of</strong>s, made it possible to<br />

avoid in-situ casting for the higher fl oors.<br />

No need<br />

external<br />

Scaffold<br />

Precast wall<br />

Splice at<br />

1m above<br />

fl oor level<br />

The column splices do not undermine the load-carrying capacity <strong>of</strong> the columns<br />

and did not require workers to weld from height.<br />

Quality approach in design, details and specification<br />

A comprehensive design and analysis regime was introduced<br />

with the help <strong>of</strong> various s<strong>of</strong>tware such as the 3D analysis<br />

s<strong>of</strong>tware Orion, S-FRAME and ETABS. In addition to performing<br />

standard <strong>structural</strong> design in accordance with the code <strong>of</strong><br />

practice, further verifi cation and checks were also done, on<br />

the robustness and performance <strong>of</strong> the structures, which also<br />

took into account the constructability. The design <strong>of</strong> many key<br />

elements <strong>of</strong> the buildings was also evaluated. This included the<br />

design <strong>of</strong> curved transfer beams which transfer the building<br />

load and that <strong>of</strong> the household shelters to circular columns at<br />

the 2 nd storey, and the design <strong>of</strong> the steel mullions.<br />

Front view <strong>of</strong> a single tower block.<br />

Precast<br />

curved beam<br />

for the ro<strong>of</strong><br />

Lifting <strong>of</strong> a curved precast beam.<br />

Steel mullions were also introduced in this development in lieu<br />

<strong>of</strong> reinforced concrete columns. The required column size was<br />

thus smaller, which was in line with the architect’s intent. The<br />

steel mullion section was formed from a 150 mm thick steel<br />

plate and to make the construction more buildable, the design<br />

considered the details and location <strong>of</strong> the column splice such<br />

that it would not undermine the column’s load-carrying capacity<br />

and would not require workers to weld from height.<br />

3D analysis s<strong>of</strong>tware was used in the project design.<br />

In order to achieve the design intent, the required shop drawings<br />

were checked especially with respect to the joints. It was also<br />

possible to ensure quality, since the precast structures could be<br />

inspected prior to installation. In addition, coordination <strong>of</strong> M&E<br />

services would have been considered, prior to casting <strong>of</strong> the<br />

precast structures. It was also easier for the Resident Engineer to<br />

ensure quality, since the precast yard was at the site.<br />

Material specifi cations for the steel mullions strictly complied<br />

with test requirements.<br />

Design for safe operation and maintenance<br />

With the use <strong>of</strong> precast elements which could be inspected <strong>of</strong>f-<br />

February 2013 THE SINGAPORE ENGINEER<br />

13

COVER STORY<br />

site, inspection and coordination work were made easier. Also,<br />

rectifi cation works could be done prior to installation, thereby<br />

contributing to safer operation. In addition, in-situ casting,<br />

especially for external walls, was avoided and external formwork<br />

and scaffolding were not required, thereby providing a safer<br />

work environment without the risk <strong>of</strong> scaffold overloading and<br />

working from height.<br />

Cast <strong>of</strong>f-site, prefabricated toilets are well-coordinated and <strong>of</strong>fer<br />

better quality and greater durability.<br />

early stage <strong>of</strong> construction, there was suffi cient lead time for<br />

procurement and preparation.<br />

Public safety considerations<br />

Construction <strong>of</strong> Cliveden at Grange, by conventional means,<br />

would have caused disturbance to neighbouring developments.<br />

However, the design adopted measures and approaches to<br />

make sure that the impact would be minimised. Due to the use<br />

<strong>of</strong> jack-in piling, noise and vibrations were greatly reduced.<br />

Prior to the start <strong>of</strong> work on Cliveden at Grange, contractors<br />

informed the owners and occupants <strong>of</strong> neighbouring<br />

developments <strong>of</strong> the work schedule, provided key contact<br />

numbers and briefed them about the main disturbances like<br />

vibration and noise. The dust and noise levels at the construction<br />

site were monitored every month, particularly to make sure<br />

that machinery noise levels were within limits. In addition, the<br />

Resident Engineer constantly highlighted and reported any<br />

substandard practice, so that all activities on site were safe.<br />

Installation <strong>of</strong> prefabricated toilets on-site.<br />

Construction quality and safe construction processes<br />

The site was managed effi ciently with safety as a main concern<br />

and with active participation from the Resident Engineer and<br />

Site <strong>Engineers</strong>. Bi-weekly reports by the Resident Engineer, that<br />

monitored the quality and site safety, in addition to <strong>structural</strong><br />

works, ensured smooth and safe construction. The presence <strong>of</strong> a<br />

precast yard on-site enabled better supervision and monitoring<br />

and thereby facilitated good quality control.<br />

Approval <strong>of</strong> shop drawings for the precast structures, prior<br />

to construction, ensured that all joints are workable and in<br />

accordance with the design, thereby contributing to speedier<br />

construction and fewer site issues. The use <strong>of</strong> prefabricated toilets<br />

contributed to higher quality assurance and increased buildability.<br />

Approval <strong>of</strong> the concrete body plan, prior to construction,<br />

resulted in higher accuracy and better coordination, resulting in<br />

fewer abortive works and minimum wastage.<br />

The test requirements to determine the quality <strong>of</strong> steel mullions,<br />

which are a key element, ensured that the design intent was<br />

achieved. Since these requirements were specifi ed at an<br />

PROJECT CREDITS<br />

Qualified Person<br />

Er. Lauw Su Wee<br />

C&S Consultants<br />

LSW Consulting <strong>Engineers</strong> Pte Ltd<br />

Builder<br />

Kajima Overseas Asia Pte Ltd<br />

Developer<br />

City Developments Limited<br />

Architectural Consultants<br />

ADDP Architects LLP<br />

Activities at the precast yard.<br />

14 THE SINGAPORE ENGINEER February 2013

INTERVIEW<br />

SIT moves ahead with broadened portfolio and<br />

higher student intake<br />

Pr<strong>of</strong> Tan Thiam Soon, President, <strong>Singapore</strong> Institute <strong>of</strong> Technology (SIT), highlights some <strong>of</strong><br />

SIT’s initiatives and achievements recorded last year and explains how the institution is<br />

addressing the challenge to produce value-added, work-ready graduates.<br />

Question: How would you<br />

summarise the activities <strong>of</strong> SIT<br />

in 2012? What are some <strong>of</strong> the<br />

highlights <strong>of</strong> last year, especially in<br />

terms <strong>of</strong> new programmes, student<br />

enrolment, facilities, scholarships<br />

and sponsorships, and employment<br />

opportunities?<br />

Firstly, I would like to mention that<br />

Pr<strong>of</strong> Tan Thiam Soon.<br />

in partnership with universities<br />

in the UK, USA and Ireland, SIT launched seven new degree<br />

programmes last year. They are:<br />

• Bachelor <strong>of</strong> Engineering with Honours in Aeronautical<br />

Engineering, and Bachelor <strong>of</strong> Engineering with Honours in<br />

Aerospace Systems, from University <strong>of</strong> Glasgow, UK.<br />

• Bachelor in Science (Physiotherapy), and Bachelor in<br />

Science (Occupational Therapy), awarded by Trinity College<br />

Dublin, Ireland.<br />

• Bachelor <strong>of</strong> Arts with Honours in Communication Design,<br />

and Bachelor <strong>of</strong> Arts with Honours in Interior Design, from<br />

The Glasgow School <strong>of</strong> Art, UK.<br />

• Bachelor <strong>of</strong> Science in Early Childhood Education, awarded<br />

by Wheelock College, Boston, Massachusetts, USA<br />

We were also able to increase our total student intake for<br />

all our academic programmes, which now total 26, from<br />

950 to 1,300.<br />

A particular highlight during the year was the unveiling <strong>of</strong><br />

the designs <strong>of</strong> the satellite campuses in April 2012 and the<br />

subsequent ground-breaking ceremonies held at each <strong>of</strong> the<br />

polytechnics, between July 2012 and January 2013.<br />

We are also happy to state that the fi rst batch <strong>of</strong> students<br />

from Newcastle University’s Marine / Offshore Engineering<br />

programmes graduated in 2012, and that 92% <strong>of</strong> them have<br />

already secured jobs - mostly in related fi elds. Ten percent <strong>of</strong><br />

these graduates received company sponsorships / scholarships<br />

during their course.<br />

Q: What are some <strong>of</strong> the specifi c programmes and activities<br />

in SIT, in 2013, that you would like to mention?<br />

A: SIT is <strong>of</strong>fering two new degree programmes for Academic<br />

Year 2013. One leads to the degree <strong>of</strong> Bachelor <strong>of</strong> Engineering<br />

with Honours in Electrical Power Engineering, conferred by<br />

the University <strong>of</strong> Newcastle upon Tyne, UK, while the other is<br />

the degree <strong>of</strong> Bachelor <strong>of</strong> Science with Honours in Computing<br />

Science, from the University <strong>of</strong> Glasgow.<br />

Further, SIT is preparing to transit into an autonomous university,<br />

<strong>of</strong>fering SIT’s own degree programmes. The key feature <strong>of</strong> the<br />

SIT degree programmes will be the integrated work-study<br />

programme which will require students to alternate study<br />

semesters with work attachments. Through this programme,<br />

SIT hopes to instill the SIT-DNA in every student, making them<br />

adaptable and capable <strong>of</strong> ‘learning, unlearning and relearning’.<br />

The fi rst batch <strong>of</strong> students from Newcastle University’s marine / <strong>of</strong>fshore<br />

<strong>engineering</strong> programmes graduated in 2012.<br />

The University <strong>of</strong> Newcastle upon Tyne, UK.<br />

16 THE SINGAPORE ENGINEER February 2013

INTERVIEW<br />

SIT is also considering the possibility <strong>of</strong> extending the<br />

existing two-year programmes to three or even four years.<br />

The lengthening <strong>of</strong> the course period will allow SIT to take<br />

in students from non-articulating diplomas, who would then<br />

acquire the required knowledge content. SIT would also be<br />

able to impart the s<strong>of</strong>t skills that students need for their<br />

chosen careers.<br />

Q: Could you elaborate on the SIT-DNA and on ‘learning,<br />

unlearning and relearning’?<br />

A: Many higher education institutions are looking to ensure<br />

they educate their students to be relevant and effective in a<br />

world in which change is occurring at an increasing pace and<br />

industries will need to evolve and change constantly.<br />

The work-study model, devised by SIT, encourages students<br />

to take up meaningful work stints as part <strong>of</strong> their university<br />

education.<br />

The SIT-DNA will enable its graduates to be able to boldly<br />

embrace change and to be adaptable. We also want our<br />

graduates to be thinking tinkerers - people who are hands-on,<br />

resourceful and practical.<br />

The importance <strong>of</strong> learning, unlearning and relearning becomes<br />

clear when we realise that with improving healthcare, most <strong>of</strong><br />

us will work for some 40 plus years - nearly three times longer<br />

than the duration <strong>of</strong> our formal education.<br />

So for those who want to succeed, they must be able to deal<br />

with disruption. They will need to know how to learn, unlearn<br />

and relearn, while working.<br />

Unlearning has to do with mindsets and attitudes. It is about<br />

accepting that something you have learnt is no longer useful or<br />

applicable, showing the willingness to accept reality and then<br />

having the courage and fortitude to adapt and change. This can<br />

apply to technical know-how that has become obsolete, or<br />

even when a company has to relocate in order to survive or<br />

take advantage <strong>of</strong> new business opportunities.<br />

After unlearning comes learning and relearning. We constantly<br />

add new skills during our lifetime. As industry, processes and<br />

technology change and evolve, the question is whether or not<br />

our graduates are imbued with the right mindset to adapt to<br />

this new future.<br />

A key feature <strong>of</strong> the SIT pedagogy, moving forward, will be<br />

to ingrain into each and every one <strong>of</strong> our students that life is<br />

going to be about learning on the job, from the job and during<br />

the job.<br />

Q: From an overall perspective, in an uncertain world<br />

economic situation, what are some <strong>of</strong> the challenges<br />

faced by institutions <strong>of</strong> higher learning and how is SIT<br />

addressing them?<br />

A: Challenges faced by institutions <strong>of</strong> higher learning include<br />

having to meet the needs <strong>of</strong> the domestic economy against<br />

an ever-changing world economic situation. As one such<br />

institution, SIT will need to remain nimble and fl exible in terms<br />

<strong>of</strong> programme <strong>of</strong>ferings and, at the same time, be able to train<br />

students to willingly embrace change and be adaptable.<br />

In order to address these challenges, SIT will not have the<br />

traditional faculty/school structures but will create multi-varied<br />

skills clusters to encourage cross-fertilisation.<br />

Our programmes will build on the skills and hands-on<br />

orientation <strong>of</strong> the polytechnic graduates, so that they become<br />

‘thinking doers’. Also, with our industry-driven programmes,<br />

we hope to ensure that SIT graduates have the skills necessary<br />

for the future.<br />

Another challenge is that since industries expect graduates<br />

to be work-ready, there is therefore a need for a different<br />

programme structure to create value-added graduates.<br />

The University <strong>of</strong> Glasgow, UK.<br />

Accordingly, SIT will be working closely with industries to<br />

shape the teaching pedagogy via integrated work-study<br />

learning, project-oriented learning, IT-enhanced self-learning,<br />

and integrated global learning environments.<br />

February 2013 THE SINGAPORE ENGINEER<br />

17

HEALTH & SAFETY ENGINEERING<br />

Ergonomics at the construction sites<br />

by Dr N Krishnamurthy, Safety Consultant and Trainer, <strong>Singapore</strong><br />

The right working conditions should be created, in order to prevent workers from suffering<br />

pain and injury.<br />

INTRODUCTION<br />

Most fatalities and injuries at construction<br />

sites can be traced to the worker not<br />

working in a safe position, using the wrong<br />

tool for the job, or using the right tool<br />

the wrong way. Workers are provided<br />

Personal Protective Equipment (PPE)<br />

<strong>of</strong> various types for different hazardous Dr N Krishnamurthy<br />

tasks, but inadequate understanding and unsafe conditions result<br />

in workers adopting wrong work postures. The article discusses<br />

the contributing factors to workplace ergonomic problems in<br />

relation to <strong>Singapore</strong>’s Workplace Safety and Health Act <strong>of</strong> 2006;<br />

identifi cation, assessment and management <strong>of</strong> Work-related<br />

Musculo-Skeletal Disorders (WMSDs); the benefi ts <strong>of</strong> a proactive<br />

approach to ergonomics planning; and feasible solutions.<br />

Examples and case studies <strong>of</strong> ergonomic improvements in<br />

construction <strong>engineering</strong>, and safety gear are presented. The<br />

focus is on construction workplace ergonomic issues such as<br />

manual handling, and consequences <strong>of</strong> PPE misuse.<br />

ERGONOMICS<br />

The word ‘ergonomics’ is derived from two Greek words -<br />

‘ergon’, meaning work, and ‘nomos’, meaning natural laws.<br />

Today, the word is used to describe the science <strong>of</strong> ‘designing<br />

the job to fi t the worker, not forcing the worker to fi t the job<br />

- thus the science <strong>of</strong> adapting work and working conditions<br />

to suit the worker’, according to Rwamamara and Smallwood<br />

(Ref 1), whose comments on ergonomic problems and solution<br />

recommendations in industrially developing countries are cited<br />

frequently in this article.<br />

Employees’ abilities to perform physical tasks may depend on age,<br />

physical condition, strength, gender, stature etc. The science <strong>of</strong><br />

ergonomics examines how to improve the fi t between physical<br />

demands <strong>of</strong> the workplace and employees who perform the<br />

work, or in other words, how to protect the workers from strain.<br />

Effective and successful fi tting <strong>of</strong> the workplace conditions to the<br />

capabilities <strong>of</strong> the workforce assures high productivity, avoidance<br />

<strong>of</strong> illness and injury risks, and increased satisfaction among the<br />

workforce. Although the scope <strong>of</strong> ergonomics is much broader,<br />

the term here refers to assessing those work-related factors<br />

that may pose a risk <strong>of</strong> Musculo-Skeletal Disorders (MSDs) and<br />

recommendations to alleviate them.<br />

Common examples <strong>of</strong> ergonomic risk factors are found in<br />

jobs requiring repetitive, forceful, or prolonged exertions <strong>of</strong><br />

the hands; frequent or heavy lifting, pushing, pulling, or carrying<br />

<strong>of</strong> heavy objects; and prolonged awkward postures. Vibration<br />

and excessive heat or cold may also add risk to these work<br />

conditions. The level <strong>of</strong> risk depends on the intensity, frequency,<br />

and duration <strong>of</strong> the exposure to these conditions.<br />

Ergonomic problems may also be culture- and technologyrelated.<br />

For instance, repetitive movements are more likely in a<br />

country which makes predominant use <strong>of</strong> masonry materials for<br />

walls, than in a country that makes use <strong>of</strong> prefabricated framing<br />

and panels such as the USA, and recently <strong>Singapore</strong>. Climbing<br />

and descending are more likely problems in a country which<br />

makes limited use, if any, <strong>of</strong> vertical transportation <strong>of</strong> people<br />

with the help <strong>of</strong> personnel hoists, than in a country that does.<br />

Presently, squatting on the fl oor or ground for many hours may<br />

not be a problem in many Asian countries, but modern youth<br />

may not retain such habits for long.<br />

CONSTRUCTION ERGONOMICS<br />

Construction, by its very nature, is a problem for ergonomists,<br />

as it requires work above shoulder level and below knee height.<br />

Materials may also be heavy and/or inconveniently sized and<br />

shaped, thus presenting manual material handling problems.<br />

Numerous construction tasks pose signifi cant risks to workers.<br />

To eliminate or mitigate the risks, it would be necessary to<br />

identify work risks in construction and assess the impact <strong>of</strong> even<br />

minimal ergonomics on the construction process.<br />

The most important safety-, health-, and ergonomics- related<br />

problems involving construction tools, leading to construction<br />

accidents, have been identifi ed as follows:<br />

• Manual handling, lifting, and carrying<br />

• Tripping and falling<br />

• Noise<br />

• Vibration<br />

• Dust exposure<br />

• Poor design <strong>of</strong> tool interfaces<br />

Of the job factors which caused major ergonomics-related<br />

problems, the following were assessed in a 2003 US study, to<br />

be the top four:<br />

• Bending or twisting the back<br />

• Staying in the same position for long periods<br />

• Working in the same position for long periods<br />

• Handling heavy materials or equipment<br />

Certain problems peculiar to Asian (and certain African nations)<br />

may be highlighted, in addition to bending and twisting <strong>of</strong> the body:<br />

• Reaching away from the body and reaching overhead<br />

• Working in awkward positions<br />

• Lifting and manually handling heavy and irregularly sized and<br />

shaped materials and components<br />

18 THE SINGAPORE ENGINEER February 2013

HEALTH & SAFETY ENGINEERING<br />

• Working below knee level<br />

• Working while kneeling<br />

A study <strong>of</strong> non-traumatic injuries in India indicated the<br />

predominance <strong>of</strong> repetitive movements, followed by awkward<br />

postures, heavy lifting, and lack <strong>of</strong> breaks.<br />

MAGNITUDE OF THE PROBLEM<br />

According to Wellsphere (Ref 2), Dr J D Miller, retired Director <strong>of</strong><br />

National Institute for Occupational Safety and Health (NIOSH),<br />

USA, said “that by any epidemiological criteria, occupational<br />

musculo-skeletal injures represent a pandemic problem in the<br />

United States with gigantic effects on the quality <strong>of</strong> millions <strong>of</strong><br />

peoples’ lives every year”.<br />

The US Bureau <strong>of</strong> Labor Statistics reports that MSDs amounted<br />

to 56% <strong>of</strong> all occupational illnesses in 1991 and continued<br />

to increase. Though cost estimates vary greatly, medical and<br />

workers’ compensation costs for these disorders may exceed<br />

US$ 100 billion annually. All over the world, the construction<br />

industry is worst hit with accidents and fatalities. Among<br />

accidents, ergonomics is a leading cause.<br />

CPWR (Ref 3) provides copious statistics on American<br />

construction ergonomics. Figure 1 shows non-fatal injuries and<br />

illnesses with days away from work, in the US construction<br />

industry, in 2005. It highlights that ergonomic problems such as<br />

sprains and strains (dominated by back pain and herniated disc)<br />

are the most common.<br />

Figure 1: Non-fatal injuries and illnesses.<br />

Figure 2 shows risk factors for work-related MSDs with days<br />

away from work, in the US construction industry, in 2005,<br />

indicating that common causes for work-related MSDs are<br />

bending, twisting, and over-exertion.<br />

Figure 3 clearly shows that next to transportation, the rate <strong>of</strong><br />

back injuries and illnesses with days away from work is highest<br />

in construction.<br />

Figure 3: Rate <strong>of</strong> back injuries and illnesses, 2005.<br />

ERGONOMICS IN SPECIFIC<br />

CONSTRUCTION TRADES<br />

Ergonomic hazards <strong>of</strong> common trades in construction and some<br />

solutions (shown as bullet points) are as follows:<br />

Concreting<br />

Shovelling and smoothing the surface <strong>of</strong> concrete are strenuous<br />

on the lower back. Vibration <strong>of</strong> cast concrete can have cumulative<br />

deleterious effects on the human system.<br />

Concrete uses cement and this usually involves moving cement<br />

bags, which <strong>of</strong>ten weigh 50 kg. This problem is discussed in detail<br />

elsewhere in the article.<br />

• The addition <strong>of</strong> plasticisers improves concrete workability.<br />

• <strong>Singapore</strong> and other countries still using larger than 25 kg<br />

loads must proactively reduce the loads or provide human or<br />

mechanical aids.<br />

• Vibration cushioning gloves should be used and such tasks<br />

should be rotated among the workers.<br />

Reinforcement<br />

The fi xing and tying <strong>of</strong> reinforcement bars require bending and<br />

a great deal <strong>of</strong> rapid repetitive twisting <strong>of</strong> the wrist, the latter<br />

resulting in the development <strong>of</strong> ganglion cysts. Most on-site<br />

rebar binding with wire is done in a squatting position in many<br />

Asian countries including <strong>Singapore</strong> (Figure 4, left). Although one<br />

may consider this as culturally acceptable, especially since the<br />

immigrant labour originates from under-developed countries, it<br />

still is an adverse practice, ergonomically.<br />

• Even if one does not go to the extent <strong>of</strong> providing mechanical<br />

aids to do binding from a standing position, as in Western<br />

countries (Figure 4, right), employers should try to provide<br />

relief by job rotation, rest periods and so on.<br />

Fig. 2. Risk factors for work-related MSDs.<br />

Figure 4: Binding re-bars with wire. The image on left shows a worker binding bars<br />

while in a squatting position while the image on right shows a worker standing and<br />

performing the task with the help <strong>of</strong> a mechanical aid.<br />

February 2013 THE SINGAPORE ENGINEER<br />

19

HEALTH & SAFETY ENGINEERING<br />

Steel is heavy. A 15 m long, 32 mm diameter bar will weigh 95<br />

kg and it is not unusual to see two workers carry it. If done on a<br />

regular basis, this would be an invitation to MSDs.<br />

• More workers may not always help because <strong>of</strong> the uneven<br />

distribution <strong>of</strong> the continuous load on a number <strong>of</strong> workers <strong>of</strong><br />

unequal height (and enthusiasm!) Mechanical aids are a must<br />

in this context.<br />

• The use <strong>of</strong> fabric, in lieu <strong>of</strong> bar reinforcement, reduces the<br />

amount <strong>of</strong> time spent fi xing and tying reinforcement for each<br />

concrete element, and reduces the amount <strong>of</strong> bending and<br />

rapid repetitive twisting <strong>of</strong> the wrist.<br />

• Using trestles also enables steel fixers to fix cages at ‘worktop’ level.<br />

Formwork<br />

The erection and striking <strong>of</strong> falsework (support structure) and<br />

formwork require large amounts <strong>of</strong> bending, twisting, and use<br />

<strong>of</strong> body force.<br />

• Designers can facilitate the use <strong>of</strong> composite systems through<br />

the simplifi cation <strong>of</strong> design, table forms, and wall forms which<br />

can be handled by craneage, thereby reducing the manual<br />

aspect <strong>of</strong> the activity.<br />

• The use <strong>of</strong> precast concrete also reduces the amount <strong>of</strong> falsework<br />

and formwork as well as on-site fi xing and tying <strong>of</strong> reinforcement<br />

required. Prestressed concrete elements, particularly slabs, also<br />

reduce the amount <strong>of</strong> reinforcement bars.<br />

Structural steelwork<br />

Problems with steel erection include awkward postures,<br />

occasional high force requirements, static postures, repetitive<br />

movements, use <strong>of</strong> pneumatic tools, and lifting. The high risk<br />

nature <strong>of</strong> the activity which entails straddling beams several<br />

metres in the air while aligning and bolting them to columns<br />

compounds the problems.<br />

• Pre-assembly, simple joints, and integral safety features can<br />

reduce hazards.<br />

Masonry<br />

Block- and brick- laying represent major work hazards in building.<br />

Lifting an average <strong>of</strong> 1000 bricks a day is equivalent to lifting<br />

2300 kg to 4000 kg, and 1000 trunk-twist fl exions.<br />

• A suitable intervention may be provision <strong>of</strong> waist-high material<br />

platforms.<br />

• Design improvements include the incorporation <strong>of</strong> handholds<br />

in blocks to facilitate lifting.<br />

• Alternative wall systems such as drywalls constitute the<br />

optimum solution.<br />

Ro<strong>of</strong>i ng<br />

Ro<strong>of</strong>i ng poses many different hazards due to minimal ergonomic<br />

input, but the prime one is material handling. Of the three<br />

types <strong>of</strong> ro<strong>of</strong>i ng (unit and sheet materials and waterpro<strong>of</strong>i ng<br />

membranes), unit materials require considerably more bending,<br />

twisting, and handling <strong>of</strong> mass per square metre <strong>of</strong> covered area,<br />

than sheet materials.<br />

• Use <strong>of</strong> ‘ladder type’ tile lifts facilitates the lifting <strong>of</strong> unit materials<br />

to ro<strong>of</strong> level.<br />

Building facades<br />

Differing systems and materials pose differing problems.<br />

Concrete surface fi nishes such as bush-hammering present a<br />

risk <strong>of</strong> hand-arm vibration and health problems such as silicosis.<br />

Natural stone claddings require a lot <strong>of</strong> lifting and hoisting <strong>of</strong><br />

heavy panels as well as adopting <strong>of</strong> awkward postures and handarm<br />

vibration as a result <strong>of</strong> fi xing. These present a risk <strong>of</strong> back<br />

injury and hand/wrist problems.<br />

• Design alternatives include light-weight sheet metal claddings<br />

and prefabricated, unitised curtain walling, which will minimise<br />

the risk factors.<br />

Plumbing and drainage/pipe-fi tting<br />

Piping is <strong>of</strong>ten laid at odd angles and in cramped spaces. Specifi c<br />

piping materials have specifi c jointing methods, not all <strong>of</strong> which<br />

are complementary to basic ergonomic principles. A number<br />

<strong>of</strong> installations are suspended and require extensive overhead<br />

work. The fi xing <strong>of</strong> the suspension hangers results in substantial<br />

stretching and twisting, and consequently a high level <strong>of</strong> stress<br />

on the neck and shoulders <strong>of</strong> workers.<br />

• Designers should consider the ergonomic implications <strong>of</strong><br />

jointing methods when specifying materials, the feasibility <strong>of</strong><br />

prefabricated stacks, and horizontal and vertical service ducts<br />

for piping.<br />

Electrical work<br />

Electricians <strong>of</strong>ten work in cramped postures and their work<br />

entails a large amount <strong>of</strong> wrist action, resulting in stress on the<br />

arms and shoulders. Making connections requires extensive use<br />

<strong>of</strong> hand-tools, <strong>of</strong>ten in cramped spaces such as ceilings above<br />

and between ducting and other piping.<br />

• Designers should make adequate provision for access during<br />

both design and coordination <strong>of</strong> services during design.<br />

Floor fi nishes<br />

All fl oor fi nishes require constant kneeling and bending. Ceramic<br />

and similar tile and terrazzo work entail additional risk. Often<br />

the weight <strong>of</strong> the tiles to be set can be substantial, particularly<br />

in the case <strong>of</strong> natural stone. Terrazzo and similar fi nishes require<br />

considerable hand and wrist motion.<br />

• When specifying fi nishes, designers should consider the nature<br />

<strong>of</strong> the pertaining processes.<br />

• Using trestle type work benches reduces the need for tilers to<br />

cut at fl oor level.<br />

Suspended ceilings<br />

Most suspended ceilings require signifi cant overhead work<br />

although the components are not particularly heavy. It is<br />

necessary to suspend primary tracks from hangers and<br />

secondary tracks between the primary tracks. Screw-up<br />

suspended ceilings require considerably more overhead work<br />

than lay-in tile ceilings.<br />

• Consequently, designers should specify lay-in tile ceilings<br />

where possible.<br />

20 THE SINGAPORE ENGINEER February 2013

HEALTH & SAFETY ENGINEERING<br />

• The use <strong>of</strong> mobile tower scaffolds with full work platforms is<br />

more complementary to ergonomics than the use <strong>of</strong> ladders.<br />

Painting and decorating<br />

Overhead painting <strong>of</strong> ceilings places considerable stress on the<br />

arms and shoulders, as well as the neck.<br />

• Designers should consider self-fi nishes where possible.<br />

Paving and other external work<br />

Brick paving requires work similar to that <strong>of</strong> tiling. In addition,<br />

pavers <strong>of</strong>ten have to be cut with an electrically powered masonry<br />

saw which requires working at ground level, and consequently<br />

requires the workers to bend a great deal.<br />

• The use <strong>of</strong> work-bench type masonry saws does reduce the<br />

hazard. Although asphalt paving exposes workers to wholebody<br />

and hand-arm vibration, workers are not exposed to<br />

the volume <strong>of</strong> repetitive movements and other work-related<br />

postures as in the case <strong>of</strong> brick paving.<br />

CAUSES AND IMPACTS<br />

Environmental factors associated with the workplace can cause<br />

many workplace problems. Below are some examples:<br />

• Extreme high temperatures can increase fatigue rate.<br />

• Exposure <strong>of</strong> hands and feet to cold can decrease blood fl ow,<br />

muscle strength etc.<br />

• Excessive or awkward grip force for tool handles or objects<br />

can cause injuries.<br />

• Exhaust cold or hot air directly from tools or equipment can<br />

cause discomfort.<br />

• Inadequate or too bright lighting in a workplace causes<br />

employees to assume awkward postures to accomplish work<br />

tasks, resulting in a loss <strong>of</strong> product quality.<br />

Other sources <strong>of</strong> ergonomic problems in a construction<br />

project are:<br />

1. Contractor’s awareness <strong>of</strong> ergonomics<br />

2. Standard <strong>of</strong> site house-keeping<br />

3. Degree <strong>of</strong> planning by contractor<br />

4. Amount <strong>of</strong> work during project<br />

5. Degree <strong>of</strong> mechanisation<br />

6. Format <strong>of</strong> materials<br />

7. Specifi cations<br />

8. Details<br />

9. Type <strong>of</strong> procurement system<br />

10. General design<br />

Rwamamara and Smallwood (Ref 1) list the impact <strong>of</strong><br />

ergonomics on various stages <strong>of</strong> a building construction project,<br />

as shown below, in decreasing order <strong>of</strong> importance:<br />

1. Structural steel structure<br />

2. Reinforced concrete structure<br />

3. Installation <strong>of</strong> services (structure)<br />

4. Ro<strong>of</strong><br />

5. External works<br />

6. Ceilings<br />

7. Cladding/external fabric<br />

8. Site clearance and earthworks<br />

9. Finishes<br />

10. Walling/partitions<br />

MANUAL HANDLING<br />

The problem<br />

Almost all construction activities involve lifting and shifting<br />

objects by hand, which can lead to many ergonomic problems,<br />

mostly MSDs, causing considerable human misery and costing<br />

massive amounts <strong>of</strong> money for compensation and cure. Manual<br />

handling thus rates a special focus.<br />

More than a third <strong>of</strong> all over-three-day injuries reported each year<br />

to the Health and Safety Executive (HSE) and local authorities,<br />

in the UK, are caused by manual handling - the transporting or<br />

supporting <strong>of</strong> loads by hand or by bodily force. The pie chart<br />

(Figure 5) from HSE (Ref 4), shows the pattern for over-threeday<br />

injuries reported in 2001/2002. In the US, over-exertion,<br />

when lifting, caused 42% <strong>of</strong> the WMSDs with days away from<br />

work in construction as already shown in Figure 2.<br />

This is the single most vexing and most costly defi ciency in<br />

worksites, although many nations might not have identifi ed it or<br />

addressed it as such.<br />

Figure 5: Accidents causing over-three-day injuries.<br />

The biomechanics <strong>of</strong> manual lifting is very simple but worrisome.<br />

The simple fact is that when a person bends down and picks up 1<br />

kg, his vertebral column (backbone) experiences a compression<br />

force <strong>of</strong> 10 kg to 15 kg [Figure 6 (Ref 5)].<br />

It may be shown from principles <strong>of</strong> simple mechanics that,<br />

allowing for the pressure from the weight <strong>of</strong> the person’s torso,<br />

the limit for the weight that an Asian male can bend and lift<br />

routinely is slightly less than 25 kg. Canada recommends 23<br />

kg as the limit (Ref 6). Lifting anything larger than that, except<br />

occasionally, will affect the spine adversely, leading to chronic<br />

back pain and irreversible damage. In the construction industry,<br />

workers <strong>of</strong>ten carry routinely much more than 25 kg.<br />

February 2013 THE SINGAPORE ENGINEER<br />

21

HEALTH & SAFETY ENGINEERING<br />

The problem does not end there. While 25 kg may be the upper<br />

load limit for normal carrying <strong>of</strong> a load straight up and down in<br />

front, any twisting <strong>of</strong> the torso with respect to the hips worsens<br />

the stress on the backbone and reduces the safe weight that can<br />

be carried. For instance, rotating the body 45° can reduce the<br />

carrying limit by about 15%.<br />

Frequent lifting and carrying <strong>of</strong> 50 kg cement bags will lead to<br />

permanent spinal injuries. Only some countries like Australia and<br />

UK have mandated worker maximum loads to 20 kg to 25 kg.<br />

<strong>Singapore</strong> has recommended that worker loads be limited to<br />

25 kg, in CP92 (replaced with SS 569), BOWEC, Construction<br />

Regulations (Jan 2008) etc. The limit is mentioned as desirable<br />

in risk control for hazardous industries, and in design for<br />

safety, DO2RAS, CONQUAS, and other documents issued by<br />

authorities.<br />

But in the present safety culture context, many simply do not<br />

know that there are guidelines on this topic, and even those<br />

who know may not adopt the recommendations because they<br />

are not mandatory.<br />

Figure 6: Forces on the vertebral column..<br />

The solution right now<br />

1. Highlighting existing guidelines through publicity materials,<br />

advisories etc. WSHC (Workplace Safety and Health Council)<br />

and MOM (Ministry <strong>of</strong> Manpower) have recently been doing<br />

a lot in this regard.<br />

2. Educating stakeholders on the real dangers to workers<br />

handling heavy loads, and how in the long run, they can affect<br />

the health <strong>of</strong> workers. This means:<br />

(a) Educating the worker on why he should not carry heavy loads.<br />

(b) Educating the supervisor on how and why he should<br />

watch out for workers impulsively handling heavy loads.<br />

- Safety <strong>of</strong>fi cers and supervisors must avoid this risk, through<br />

(i) imparting training for proper lifting, and (ii) adopting<br />

mechanical assist devices.<br />

(c) Educating the management so that it understands that<br />

adverse impact on workers can reduce productivity and<br />

cause a lot <strong>of</strong> compensation claims and court cases,<br />

thereby affecting business.<br />

(d) Educating inspectors on what to watch out for, and how<br />

to deal with violations.<br />

(e) Educating the public so that it does not expect or allow<br />

workers to carry heavy loads, and will be on the lookout<br />

for, and report, violations <strong>of</strong> these guidelines.<br />

3. Doing what can be done at workplaces, within the existing<br />

system, to alleviate the problem. Trying the standard<br />

hierarchy <strong>of</strong> controls put forward by Krishnamurthy (Ref 7),<br />

as shown below:<br />

(a) Elimination: Just not letting people handle<br />

loads. Using mechanical aids to move everything, if more<br />

than, say, 5 kg. This may not be easy.<br />

(b) Substitution: Substituting with loads smaller than 25 kg.<br />

Either getting smaller weight packages, absorbing the<br />

extra cost as insurance against health impacts, or, breaking<br />

up the larger loads delivered to site into smaller packages<br />

for shifting.<br />

(c) Engineering Controls: Providing mechanical aids operated<br />

by the workers, to ease their load, such as push carts, lever<br />

grips, hand-operated dollies, etc. The author once<br />

proposed a simple, low-cost swing arm mechanical device,<br />

to eliminate repetitive twisting by the worker, by letting<br />

the device do the twisting, leaving the worker to do only<br />

the pushing, as in Figure 7 (Ref 5).<br />

(d) Administrative Controls: With low wages being paid,<br />

immigrant construction labour is cheap. The simple<br />

expedient <strong>of</strong> putting two people to carry loads from<br />

25 kg to 50 kg, and proportionately more workers<br />

for heavier loads, will be adequate in the short term. This<br />

will require a little more supervision, and a little smarter<br />

management to ensure that the workers share the load<br />

nearly equally.<br />

(e) PPE: Although PPE will not reduce the load, gloves and<br />

safety shoes will protect hands and feet in gripping the<br />

load and if the load should fall.<br />

Figure 7: Case study <strong>of</strong> an ergonomic intervention.<br />

22 THE SINGAPORE ENGINEER February 2013

The IES Journal Part A: Civil & Structural Engineering<br />

Vol. 6 is finally available with new cover design!<br />

Early Bird Promotion: 10–15% Off!<br />

Volume 6, Number 1, February 2013 ISSN: 1937-3260<br />

THE IES JOURNAL PART A:<br />

Civil & Structural Engineering<br />

Contents<br />

Technical papers<br />

Effects <strong>of</strong> coordinated crowd motion on dynamic responses <strong>of</strong> composite floors<br />

in buildings<br />

Arash Behnia, Hwa Kian Chai, Navid Ranjbar, Nima Behnia, Amir Fateh and Nima Mehrabi 1<br />

Anti-seismic reliability analysis <strong>of</strong> continuous rigid-frame bridge based on numerical<br />

simulations<br />

Z.H. Li, Y.L. Jin, Y.F. Chen and R. Chen 18<br />

Analogy <strong>of</strong> TE waveguide and vibrating plate with sliding edge condition<br />

and exact solutions<br />

C.M. Wang, C.Y. Wang and Z.Y. Tay 32<br />

Geothermal desalination in <strong>Singapore</strong><br />

Lee Siu Zhi Michelle, Andrew Palmer, Grahame Oliver and Hendrik Tjiawi 42<br />

Buckling and vibration <strong>of</strong> stepped rectangular plates by element-based differential<br />

transform method<br />

S. Rajasekaran 51<br />

Essay<br />

Supreme structures: reflections on the IStructE <strong>structural</strong> awards<br />

David A. Nethercot 65<br />

The IES Journal Part A: Civil & Structural Engineering Volume 6, Number 1, February 2013<br />

Volume 6, Number 1, February 2013 ISSN: 1937-3260<br />

THE IES JOURNAL PART A<br />

Civil & Structural Engineering<br />

EDITOR-IN-CHIEF<br />

C. M. Wang<br />

National University <strong>of</strong> <strong>Singapore</strong><br />

Dear Members<br />

TIEA_06_01-Cover.indd 1<br />

1/17/13 10:26:37 PM<br />

Now indexed by SCOPUS and Compendex, the IES Journal is written by world<br />

renowned researchers and practitioners. The Journal provides a forum for the<br />

dissemination <strong>of</strong> original research and developments in <strong>civil</strong> & <strong>structural</strong> <strong>engineering</strong>.<br />

The papers cover a wide range <strong>of</strong> <strong>engineering</strong> issues in <strong>structural</strong>, geotechnical, water<br />

resources, environmental and infra<strong>structural</strong> fields, and <strong>of</strong>fer a focused, vibrant and<br />

timely communication tool for researchers, consultants and industry practitioners.<br />

From now till 28 June 2013, subscribe to the IES Journal Part A: Civil and Structural<br />

Engineering Vol. 6 and get 10% <strong>of</strong>f for one year‘s subscription (S$72) and 15% <strong>of</strong>f<br />

for two years‘ subscription (S$136). The usual price for a year‘s subscription is S$80.<br />

The 2013 volume <strong>of</strong> the IES Journal Part A is published on a quarterly basis. Visit the<br />

publisher’s website at http://www.tandf.co.uk/journals/tiea for more information<br />

as well as a sample copy.<br />

Call 64695000 for any further queries!<br />

Email jeremy@iesnet.org.sg for the order form.<br />

February 2013 THE SINGAPORE ENGINEER<br />

23

HEALTH & SAFETY ENGINEERING<br />

PROCEDURE FOR ERGONOMICS<br />

MANAGEMENT<br />

Basic steps<br />

A formal procedure for ergonomics management has been<br />

described in detail by Cohen et al (Ref 8). The basic steps are:<br />

1. Looking for Signs <strong>of</strong> Work-related MSD Problems<br />

2. Setting the Stage for Action<br />

3. Training and Building in-house expertise<br />

4. Gathering/Examining WMSD Evidence<br />

5. Developing Controls<br />

6. Health Care Management<br />

7. Proactive ergonomics<br />

While the fi rst six steps are straight-forward and more in<br />

the nature <strong>of</strong> administrative procedures and controls, the last,<br />

proactive ergonomics, deserves special emphasis.<br />

The proactive approach<br />

• Proactive programmes focus on prevention <strong>of</strong> WMSDs and<br />

other ergonomic risks by identifying, assessing, and controlling<br />

risk factors at the planning stage.<br />

• Design steps should ensure proper selection and use <strong>of</strong>:<br />

- Equipment and tools<br />

- Job methods<br />

- Workstation layouts<br />

- Materials<br />

• Risks should be addressed at source.<br />

• The decision must be made on which functions should be<br />

handled by machines and which by people.<br />

• The decision must be made on which task can be accomplished<br />

by whom, particularly avoiding strenuous tasks with loads that<br />

are too large, too heavy, placed too high etc.<br />

• Questions must be asked before anything harmful happens:<br />

- Are employees working in uncomfortable postures?<br />

- Do they show signs <strong>of</strong> fatigue and discomfort?<br />

- Are there other warning signs such as reports <strong>of</strong> problems,<br />

high levels <strong>of</strong> absenteeism etc?<br />

- Do employees have ideas about how to improve products<br />

and make their jobs less physically demanding and more<br />

effi cient, and apply them?<br />

Benefi ts <strong>of</strong> proactive action<br />

• Reduced absenteeism<br />

• Increased effi ciency and productivity<br />

• Improved quality<br />

• Decreased fatigue<br />

• Improved employee morale<br />

• Increased cost savings within short payback periods from:<br />

- Greater output over a given time period<br />

- Reduced wastage <strong>of</strong> raw materials<br />

- Higher quality output and fewer mistakes<br />

- Savings in wage costs from jobs which were made less<br />

manually intensive<br />

- Reduced future compensation claims and recruitment<br />

PPE AND ERGONOMICS<br />

PPE and ergonomics are closely related because the way a<br />

worker wears and uses his PPE will have a large infl uence on his<br />

comfort and well-being. The following are a few instances:<br />

1. The wrong size <strong>of</strong>, or wrongly worn ear-plugs, which are<br />

meant to alleviate workplace noise problems, may cause<br />

earache and infection.<br />

2. Helmet straps and chin straps, badly adjusted, may give a<br />

head/neck ache. Loose-fi tting helmets will expose the<br />

worker to injury.<br />

3. If gloves are not worn, due to a lack <strong>of</strong> insistence by the<br />

supervisor, it will lead to damage <strong>of</strong> hands.<br />

4. Loosely worn full-body safety harnesses may damage<br />

the genitals <strong>of</strong> wearers. The use <strong>of</strong> body harnesses<br />

without appropriate anchors, falling clearance, and rescue<br />

system, will expose the worker to greater danger than<br />

without such PPE.<br />

BENEFITS OF ERGONOMIC SOLUTIONS<br />

According to MacLeod (Ref 9), among the numerous benefi ts <strong>of</strong><br />

ergonomic solutions, the ones that directly favour the economics,<br />

are as follows:<br />

1. Dramatic reductions in workers’ compensation costs<br />

2. Improved productivity<br />

3. Fewer mistakes and less scrap<br />

4. Improved effi ciency with better working posture<br />

5. Improved effi ciency with less exertion<br />

6. Improved effi ciency with fewer motions<br />

7. Improved effi ciency with better heights and reaches<br />

8. Less fatigue<br />

9. Reduced maintenance downtime<br />

10. Protecting human resources<br />

11. Identifying waste<br />

12. Fresh insights on the operations<br />

13. Offsetting the limitations <strong>of</strong> an ageing workforce<br />

14. Reduced turnover<br />

15. Reduced absenteeism<br />

16. Improved morale<br />

17. Promoting employee involvement<br />

18. Improved labour relations<br />

19. Revival <strong>of</strong> basic ‘Methods Engineering’<br />

20. Ability to optimise the Lean (Toyota) Process<br />

21. Ability to make things more human compatible, and<br />

improve the human-system interface<br />

24 THE SINGAPORE ENGINEER February 2013