Operational Manual - DCU

Operational Manual - DCU

Operational Manual - DCU

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

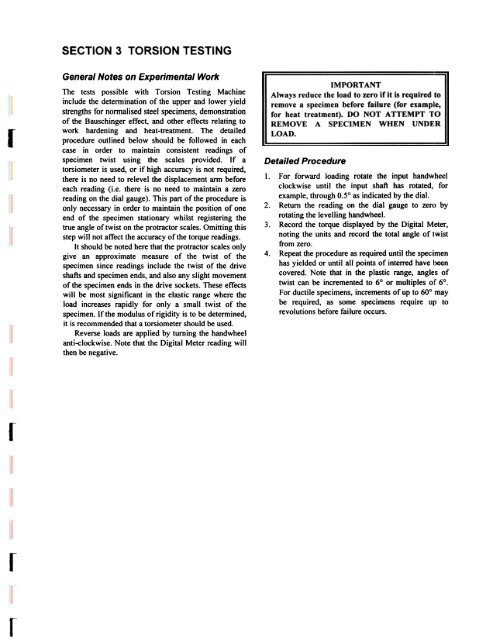

SECTION 3 TORSION TESTING<br />

r<br />

General Notes on Experimental Work<br />

The tests possible with Torsion Testing Machine<br />

include the determination of the upper and lower yield<br />

strengths for nonnalised steel specimens, demonstration<br />

of the Bauschinger effect, and other effects relating to<br />

work hardening and heat-treatment. The detailed<br />

procedure outlined below should be followed in each<br />

case in order to maintain consistent readings of<br />

specimen twist using the scales provided. If a<br />

torsiometer is used, or if high accuracy is not required,<br />

there is no need to relevel the displacement arm before<br />

each reading (i.e. there is no need to maintain a zero<br />

reading on the dial gauge). This part of the procedure is<br />

only necessary in order to maintain the position of one<br />

end of the specimen stationary whilst registering the<br />

true angle of twist on the protractor scales. Omitting this<br />

step will not affect the accuracy of the torque readings.<br />

It should be noted here that the protractor scales only<br />

give an approximate measure of the twist of the<br />

specimen since readings include the twist of the drive<br />

shafts and specimen ends, and also any slight movement<br />

of the specimen ends in the drive sockets. These effects<br />

will be most significant in the elastic range where the<br />

load increases rapidly for only a small twist of the<br />

specimen. If the modulus of rigidity is to be determined,<br />

it is recommended that a torsiometer should be used.<br />

Reverse loads are applied by turning the handwheel<br />

anti-clockwise. Note that the Digital Meter reading will<br />

then be negative.<br />

IMPORTANT<br />

Always reduce the load to zero if it is required to<br />

remove a specimen before failure (for exam pIle,<br />

for heat treatment). DO NOT ATTEMPT TO<br />

REMOVE A SPECIMEN WHEN UNDER<br />

LOAD.<br />

Detailed<br />

Procedure<br />

1. For forward loading rotate the input handwheel<br />

clockwise until the input shaft has rotated, for<br />

example, through 0.5° as indicated by the dial.<br />

2. Return the reading on the dial gauge to zero by<br />

rotating the levelling handwheel.<br />

3. Record the torque displayed by the Digital Meter,<br />

noting the units and record the total angle of twist<br />

from zero.<br />

4. Repeathe procedure as required until the specimen<br />

has yielded or until all points of interred have l)een<br />

covered. Note that in the plastic range, angles of<br />

twist can be incremented to 6° or multiples of 6°.<br />

For ductile specimens, increments of up to 60° may<br />

be required, as some specimens require up to<br />

revolutions before failure occurs.<br />

r<br />

r<br />

r