FSIS Notice 20-13 - Food Safety and Inspection Service

FSIS Notice 20-13 - Food Safety and Inspection Service

FSIS Notice 20-13 - Food Safety and Inspection Service

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

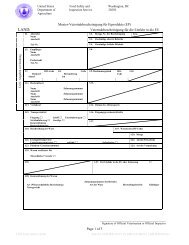

UNITED STATES DEPARTMENT OF AGRICULTURE<br />

FOOD SAFETY AND INSPECTION SERVICE<br />

WASHINGTON, DC<br />

<strong>FSIS</strong> NOTICE <strong>20</strong>-<strong>13</strong><br />

3/12/<strong>13</strong><br />

INCREASED VERIFICATION BY INSPECTION PROGRAM PERSONNEL OF SANITARY <br />

DRESSING AT VEAL SLAUGHTER ESTABLISHMENTS<br />

I. PURPOSE<br />

This notice provides inspection program personnel (IPP) assigned to veal slaughter<br />

establishments additional information to use when verifying that sanitary dressing <strong>and</strong> process<br />

control procedures are preventing contamination of carcasses <strong>and</strong> the creation of insanitary<br />

conditions. For purposes of this notice, veal slaughter establishments include all<br />

establishments that slaughter bob veal, formula-fed veal, non-formula fed veal, <strong>and</strong> heavy<br />

calves.<br />

II. BACKGROUND<br />

A. <strong>FSIS</strong> test results show that the percent positive rate for Shiga toxin-producing Escherichia<br />

coli (STEC) from trimmings produced from veal appears to be higher than that for trimmings<br />

produced from other cattle slaughter classes. Following up on these results, <strong>FSIS</strong> conducted a<br />

review of <strong>Food</strong> <strong>Safety</strong> Assessments (FSAs) <strong>and</strong> onsite visits to veal slaughter establishments to<br />

identify concerns unique to veal slaughter.<br />

The results of the review showed that:<br />

1. Many veal slaughter establishments may not have implemented sanitary dressing<br />

<strong>and</strong> process control procedures sufficient to prevent contamination of carcasses <strong>and</strong><br />

the creation of insanitary conditions.<br />

2. The amount of contamination from deficient sanitary dressing procedures likely<br />

overwhelmed the decontamination <strong>and</strong> antimicrobial intervention treatments. These<br />

sanitary dressing deficiencies contributed to the production of products contaminated<br />

with STEC.<br />

B. Based on results of the analyses, IPP need to verify that veal slaughter establishments are<br />

consistently focusing on their sanitary dressing <strong>and</strong> process control procedures, <strong>and</strong> that these<br />

establishments are preventing carcass contamination (9 CFR 310.18(a)) <strong>and</strong> the creation of<br />

insanitary conditions in their operations (9<br />

CFR 416.1). 9 CFR 416.1 through 416.5 require that establishments maintain sanitary<br />

conditions.<br />

C. <strong>FSIS</strong> issuances related to beef also apply to veal. <strong>FSIS</strong> inspection program personnel<br />

assigned to veal establishments are to follow the directions in the following issuances:<br />

DISTRIBUTION: Electronic NOTICE EXPIRES: 4/1/14 OPI: OPPD

1. <strong>FSIS</strong> Directive 10,010.1 Rev. 3, Verification Activities for Escherichia coli O157:H7 in<br />

Raw Beef Products, <strong>and</strong><br />

2. <strong>FSIS</strong> PHIS Directive 6410.1 Rev. 1, Verifying Sanitary Dressing <strong>and</strong> Process Control<br />

Procedures by Off-line <strong>Inspection</strong> Program Personnel (IPP) in Slaughter Operations of<br />

Cattle of Any Age.<br />

III. INITIAL INSPECTION PROGRAM PERSONNEL RESPONSIBILITIES<br />

A. After receipt of this notice, at the next weekly meeting, IPP assigned to veal slaughter<br />

establishments are to meet with establishment management. IPP are to inform establishment<br />

management that:<br />

1. IPP will be performing the Beef Sanitary Dressing task at an increased frequency. IPP<br />

will perform the sanitary dressing task at least twice a week for the next 90 days. IPP will<br />

follow the methodology in <strong>FSIS</strong> PHIS Directive 6410.1 Rev. 1, Verifying Sanitary<br />

Dressing <strong>and</strong> Process Control Procedures by Off-line <strong>Inspection</strong> Program Personnel<br />

(IPP) in Slaughter Operations of Any Age.<br />

2. The purpose of this activity is to verify that veal slaughter establishments have<br />

implemented sanitary dressing <strong>and</strong> process control procedures to prevent contamination<br />

of carcasses (9 CFR 310.18(a)) <strong>and</strong> to ensure that insanitary conditions are not created<br />

(9 CFR 416.1 <strong>and</strong> 416.2-416.5, as applicable).<br />

B. IPP are to document this meeting in a Memor<strong>and</strong>um of Interview (MOI) according to <strong>FSIS</strong><br />

PHIS Directive 5000.1, Verifying an Establishment’s <strong>Food</strong> <strong>Safety</strong> System <strong>and</strong> to provide a copy<br />

of the MOI to establishment management.<br />

IV. SANITARY DRESSING VERIFICATION<br />

A. Routinely, IPP perform the Beef Sanitary Dressing task once every other week. However,<br />

IPP assigned to veal slaughter establishments are to perform the Beef Sanitary Dressing task at<br />

an increased frequency for the next 90 days.<br />

1. IPP assigned to veal slaughter establishments are to perform the Beef Sanitary<br />

Dressing task at least twice a week for the next 90 days by adding directed tasks.<br />

2. IPP are to follow the methodology <strong>FSIS</strong> PHIS Directive 6410.1 Rev. 1, Verifying Sanitary<br />

Dressing <strong>and</strong> Process Control Procedures by Off-line <strong>Inspection</strong> Program Personnel (IPP)<br />

in Slaughter Operations of Any Age.<br />

B. IPP are to follow the instructions in <strong>FSIS</strong> PHIS Directive <strong>13</strong>,000.1 Rev. 1, Scheduling In-plant<br />

<strong>Inspection</strong> Tasks in the Public Health Information System (PHIS) when scheduling their<br />

inspection tasks. IPP are to designate any unscheduled tasks that they did not complete as “not<br />

performed” as a result of the increased frequency of the Beef Sanitary Dressing task. IPP are to<br />

select “Higher priority task took precedent” as the reason code.<br />

2

C. IPP are to record any non-compliances identified on a noncompliance record (NR) according<br />

to <strong>FSIS</strong> PHIS Directive 6410.1 <strong>and</strong> <strong>FSIS</strong> PHIS Directive 5000.1, Verifying an Establishment’s<br />

<strong>Food</strong> <strong>Safety</strong> System including associating noncompliance records (NRs), where appropriate.<br />

D. Examples of situations when it is appropriate for IPP to associate NRs include:<br />

1. Two or more NRs documented while performing the Beef Sanitary Dressing task;<br />

2. One NR indicates that the establishment’s corrective actions for a previous sanitary<br />

dressing NR were not implemented or did not prevent recurrence; <strong>and</strong><br />

3. One or more NRs in response to a positive <strong>FSIS</strong> STEC result in trimmings.<br />

E. When the information gathered suggests that the establishment has lost process control, IPP<br />

are to determine whether the establishment has taken corrective actions to bring the process<br />

back under control. IPP are to verify that the establishment’s corrective actions are effective<br />

<strong>and</strong> prevent recurrence. IPP are to consult with their immediate supervisor for assistance in<br />

making this determination, if needed. IPP are to request a for-cause FSA through supervisory<br />

channels if the establishment repeatedly fails to take corrective action, or if the corrective actions<br />

the establishment takes are ineffective. Examples of the types of findings that can indicate a loss<br />

of control are provided in Section VIII of <strong>FSIS</strong> PHIS Directive 6410.1. Specific findings in FSAs<br />

that have evidenced that veal slaughter establishments were losing process control include:<br />

1. Multiple positive STEC results in raw beef manufacturing trimmings from <strong>FSIS</strong> routine<br />

<strong>and</strong> follow-up samples;<br />

2. Generic E. coli results from establishment testing that indicate increasing microbial<br />

contamination on carcasses; <strong>and</strong><br />

3. An establishment not evaluating testing results, including generic E. coli on carcasses<br />

<strong>and</strong> STEC on beef manufacturing trimmings, to help determine how the results impact<br />

veal slaughter operations.<br />

F. Attachment 1 provides information on <strong>and</strong> examples of sanitary dressing deficiencies <strong>and</strong><br />

ineffective application of interventions that have been observed at veal slaughter<br />

establishments. IPP are to use the information in Attachment 1 to assist them in verifying<br />

sanitary dressing in veal slaughter establishments.<br />

G. If the establishment’s slaughter <strong>and</strong> sanitary dressing procedures are out of control, the level<br />

of contamination may affect IPP’s ability to perform proper post-mortem inspection procedures.<br />

The Public Health Veterinarian (PHV) or Inspector-in-Charge (IIC) is to determine whether this<br />

is the case. If it is, the PHV or IIC is to reduce the line speed in accordance with 9 CFR<br />

310.1(b)(1). (See Section XI. E. of <strong>FSIS</strong> PHIS Directive 6410.1 Verifying Sanitary Dressing <strong>and</strong><br />

Process Control Procedures by Off-line <strong>Inspection</strong> Program Personnel (IPP) in Slaughter<br />

Operations of Cattle of Any Age)<br />

V. SUPERVISORY PERSONNEL RESPONSIBILITIES<br />

A. “Supervisory personnel” refers to any Office of Field Operations (OFO) personnel that<br />

supervise IPP who conduct off-line verification activities in cattle (including veal) slaughter<br />

operations.<br />

B. Supervisory personnel with one or more veal slaughter establishments within their circuit are<br />

3

to conduct a work unit meeting with IPP assigned to veal slaughter establishments. Supervisory<br />

personnel are to review the inspection methodology in <strong>FSIS</strong> PHIS Directive 6410.1 <strong>and</strong> the<br />

information in this <strong>Notice</strong>.<br />

C. Supervisory personnel are to conduct an on-site visit to veal slaughter establishments in<br />

their circuit within 90 days of this issuance.<br />

D. Supervisory personnel are to ensure that IPP are correctly prioritizing inspection tasks, are<br />

correctly applying the inspection methodology, are making informed decisions, are properly<br />

documenting findings, <strong>and</strong> are taking the appropriate enforcement actions as instructed in this<br />

notice <strong>and</strong> <strong>FSIS</strong> PHIS Directive 6410.1.<br />

E. Supervisory personnel are to refer to the current version of the <strong>FSIS</strong> Guide for Conducting<br />

In-Plant Performance System (IPPS) Assessments for additional guidance <strong>and</strong> instructions.<br />

VI. DATA ANALYSIS<br />

Members of the Risk, Innovations, <strong>and</strong> Management Division (RIMD), Office of Policy <strong>and</strong><br />

Program Development, will analyze data from Shiga toxin-producing Escherichia coli (STEC)<br />

sampling programs <strong>and</strong> <strong>Food</strong> <strong>Safety</strong> Assessments (FSA) performed at veal slaughter<br />

establishments to determine whether veal slaughter establishments have adequately<br />

addressed hazards. RIMD will analyze data to determine whether the frequency of sanitary<br />

dressing verification for veal should be different than other cattle slaughter classes.<br />

Members of the Data Analysis <strong>and</strong> Integration Group (DAIG), Office of Data Integration <strong>and</strong><br />

<strong>Food</strong> Protection, will analyze PHIS data to determine whether IPP at veal slaughter<br />

establishments performed the beef sanitary dressing task at the increased frequency.<br />

VII. QUESTIONS<br />

Refer questions regarding this notice to the Risk, Innovations, <strong>and</strong> Management Division <br />

through ask<strong>FSIS</strong> or by telephone at 1-800-233-3935. When submitting a question, use the <br />

Submit a Question tab, <strong>and</strong> enter the following information in the fields provided:<br />

Subject Field: Enter <strong>FSIS</strong> <strong>Notice</strong> <strong>20</strong>-<strong>13</strong><br />

Question Field: Enter question with as much detail as possible.<br />

Product Field: Select General <strong>Inspection</strong> from the drop-down menu. <br />

Category Field: Select Sampling E. coli O157:H7 from the drop-down menu.<br />

Policy Arena: Select Domestic (U.S.) Only from the drop-down menu.<br />

When all fields are complete, press the Submit button.<br />

Assistant Administrator<br />

Office of Policy <strong>and</strong> Program Development<br />

4

Attachment 1 Observed Sanitary Dressing Deficiencies <strong>and</strong> Ineffective Application of<br />

Interventions at Veal Slaughter Establishments<br />

<strong>FSIS</strong> conducted a review of <strong>Food</strong> <strong>Safety</strong> Assessments (FSAs) <strong>and</strong> onsite visits to identify<br />

concerns unique to veal slaughter. The results of the review indicated that many veal slaughter<br />

establishments have not implemented sanitary dressing <strong>and</strong> process control procedures<br />

sufficient to prevent carcass contamination <strong>and</strong> the creation of insanitary conditions.<br />

This attachment includes examples of sanitary dressing deficiencies <strong>and</strong> ineffective application<br />

of interventions that <strong>FSIS</strong> observed repeatedly during on-site visits. IPP are to use this<br />

information in conjunction with the inspection methodology in <strong>FSIS</strong> PHIS Directive 6410.1 to<br />

assist them while verifying sanitary dressing in veal slaughter establishments. The attachment<br />

includes the relevant section (slaughter process step) in <strong>FSIS</strong> PHIS Directive 6410.1 to<br />

facilitate this process.<br />

Sticking<br />

In this photo, we see that the establishment uses a large cut to bleed the calf, <strong>and</strong> that ingesta is<br />

leaking from the esophagus during bleeding (yellow arrow). <strong>FSIS</strong> observed employees cutting<br />

through the weas<strong>and</strong> (esophagus) during sticking. This practice resulted in ingesta<br />

contaminating the carcass <strong>and</strong> head. <strong>FSIS</strong> also observed employees removing the head<br />

without closing the weas<strong>and</strong>. <strong>FSIS</strong> recommends that the establishment use the smallest cut<br />

possible to accomplish bleeding <strong>and</strong> not to cut the weas<strong>and</strong> during sticking <strong>and</strong> bleeding. <strong>FSIS</strong><br />

recommends that establishments close the weas<strong>and</strong> after rodding prior to head removal.<br />

Photo 1 Cutting through the weas<strong>and</strong> (esophagus) during sticking<br />

5

Hide removal<br />

Onsite visits to veal slaughter establishments <strong>and</strong> reviews of FSAs showed that<br />

establishments were cutting through the hide <strong>and</strong> further dressing the carcass without sanitizing<br />

knives, gloves, <strong>and</strong> equipment adequately to prevent the creation of insanitary conditions. An<br />

example would be an employee making a “dirty cut” (one through the hide, left photo) <strong>and</strong><br />

continuing to cut through aitchbone (yellow arrow) without sanitizing the knife after making the<br />

dirty cut. Another example (not pictured) of this would be a veal slaughter establishment further<br />

processing veal carcasses with the hide-on. Proper hide removal is a critical step in preventing<br />

carcass contamination <strong>and</strong> the creation of insanitary conditions. While opening the hide (except<br />

for the original incisions for sticking <strong>and</strong> starting the skinning operations at the poll <strong>and</strong> shanks),<br />

<strong>FSIS</strong> recommends that the employee direct the knife blade toward the hair side of the skin to<br />

prevent contaminating the flesh with cut hair (not shown). After making the “dirty cut” <strong>and</strong><br />

exiting the hide, <strong>FSIS</strong> recommends that the employee sanitize his knife <strong>and</strong> glove before<br />

making another cut (in this case, cutting through to the aitchbone, right photo).<br />

6

Bunging<br />

This concept of sanitizing after the “dirty cut” can also be seen with bunging. The employee<br />

makes the “dirty cut,” in this case cutting around the tissue surrounding the anus (yellow arrow,<br />

top left photo). The employee then sanitizes his knife <strong>and</strong> gloves before further cutting the<br />

exposed tissue ( top right photo). <strong>FSIS</strong> recommends that establishments remove the hide prior<br />

to cutting into the carcass. Tying <strong>and</strong> bagging the bung (not shown) is also an important step to<br />

preventing carcass contamination.<br />

7

Bunging<br />

These photos show the impact of the establishment failing to bag <strong>and</strong> tie the bung. The<br />

contaminated bung is contacting the exposed carcass (yellow arrows). When establishments<br />

apply hot water or antimicrobial interventions to an exposed bung, it further spreads<br />

contamination. <strong>FSIS</strong> recommends that establishments tie <strong>and</strong> bag the bung in a sanitary<br />

manner.<br />

8

Hide removal<br />

Legging<br />

9

These photos show the “legging” process, a part of the hide removal process during which the<br />

establishment personnel remove the hide from the hindlimbs. Establishment personnel may<br />

introduce contamination at the pattern lines (along the incision lines through the hide, as the<br />

arrows show in the two bottom pictures). It is important that establishments prevent<br />

contamination throughout the slaughter process <strong>and</strong> remove contamination promptly when it<br />

occurs. The establishment can do this through knife trimming or steam vacuuming.<br />

10

Hide Removal<br />

Sanitize <strong>and</strong> Remove Debris from<br />

Steam Vacuum<br />

Steam vacuuming is a useful intervention for establishments to apply along the pattern lines <strong>and</strong><br />

for removing incidental contamination. <strong>FSIS</strong> observed (not shown) employees applying heavily<br />

contaminated steam vacuums to carcasses. The purpose of these photos is to remind IPP of<br />

the importance of cleaning <strong>and</strong> sanitizing equipment as often as necessary to prevent the<br />

creation of insanitary conditions <strong>and</strong> cross contamination.<br />

11

Hide Removal<br />

These photos show hide <strong>and</strong> hair touching the carcass when being removed, potentially allowing<br />

the dirty exterior side to touch the carcass. In the bottom left photo, the leg hide flaps are<br />

contacting the carcass. The bottom right photo shows hide flaps that have curled under after<br />

hide removal (as seen inside the yellow oval) <strong>and</strong> are contacting the carcass. <strong>FSIS</strong><br />

recommends that establishments prevent the hide from contacting the carcass during hide<br />

removal. The photo below shows the use of hide clips as one method of preventing hide from<br />

contacting the carcass.<br />

12

Evisceration<br />

These photos show the establishment puncturing the paunch <strong>and</strong> intestines during evisceration<br />

(top photo, at blue arrow) causing carcass contamination with ingesta (bottom photo, inside<br />

yellow oval). <strong>FSIS</strong> recommends that establishments perform proper sanitary dressing<br />

procedures during evisceration to prevent puncturing the paunch <strong>and</strong> intestines.<br />

14

Hide removal (wash cabinets)<br />

This photo shows cross contamination of heads from a spray applied to the carcass (water<br />

sprayed onto carcass in the direction of the arrows, water spray seen within the yellow oval).<br />

The establishment failed to take measures (e.g., adequate distance or shields) to prevent cross<br />

contamination of adjacent heads. Cross contamination (not shown) can also occur while<br />

employees spray equipment, the floor, <strong>and</strong> other surfaces if the establishment does not take<br />

appropriate precautions to prevent overspray from contacting carcasses. Also, it is important<br />

that carcasses are free of visible contamination prior to entering wash cabinets or the manual<br />

application of water or antimicrobial sprays. Otherwise, the intervention could further spread the<br />

contamination.<br />

15

Establishment Interventions<br />

Failure to Implement Interventions<br />

Effectively<br />

These photos show the practice of suspending a carcass from a single hook, which prevents<br />

antimicrobial <strong>and</strong> hot water interventions from achieving carcass/product coverage. Carcass<br />

coverage –ensuring that the entire carcass surface is treated -- is necessary for the intervention<br />

to operate effectively <strong>and</strong> as intended. Additional information is included in <strong>FSIS</strong> <strong>Notice</strong> 17-12<br />

Verification of Antimicrobial Intervention Coverage of Carcass or Product at Veal Slaughter <strong>and</strong><br />

Beef Fabrication Establishments. IPP verify that establishments are implementing their<br />

interventions effectively (i.e., according to the establishment’s scientific support) during the<br />

observation component of the appropriate Hazard Analysis <strong>and</strong> Critical Control Point (HACCP)<br />

verification task.<br />

16

Establishment Interventions<br />

These photos show the establishment’s failure to implement its trim antimicrobial intervention<br />

spray effectively. The intervention did not achieve full product coverage. Product coverage is<br />

essential for the intervention to be effective. Both pictures show that the establishment only<br />

applies the intervention to the top side of the trim. These pictures also show product that is<br />

folded on top of itself so that not all product surfaces received the intervention (in the left picture<br />

each piece has a single fold, <strong>and</strong> in the right picture the trim is piled up). The picture on the<br />

right shows clearly that the arc of the spray nozzles (inside each yellow line) is not sufficient to<br />

reach product on the sides of the conveyor belt (yellow arrows).<br />

17

Results of Sanitary Dressing<br />

Deficiencies <strong>and</strong> Ineffective<br />

Application of Interventions<br />

18

In these photos, we see contamination in the bung area (top left photo), boneless veal legs (top<br />

right photo under arrow), breast <strong>and</strong> shank areas (middle photos under arrow <strong>and</strong> within ovals),<br />

<strong>and</strong> along the thigh (bottom photo). This contamination resulted from the establishment’s failure<br />

to implement sanitary dressing procedures to prevent the creation of insanitary conditions <strong>and</strong><br />

contamination of carcasses, <strong>and</strong> its failure to implement antimicrobial interventions effectively.<br />

Positive STEC test results are a reflection of an establishment’s slaughter controls <strong>and</strong> provide<br />

evidence that the establishment is not implementing its slaughter controls effectively to produce<br />

safe, unadulterated products.<br />

19