CM-B-UV - Halton Company

CM-B-UV - Halton Company

CM-B-UV - Halton Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

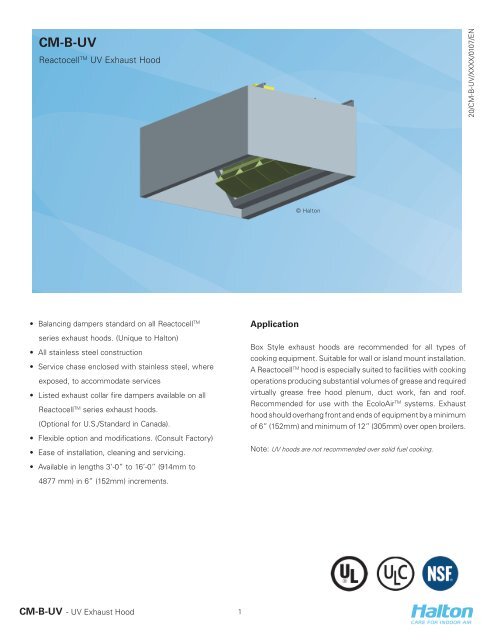

<strong>CM</strong>-B-<strong>UV</strong><br />

Reactocell TM <strong>UV</strong> Exhaust Hood<br />

20/<strong>CM</strong>-B-<strong>UV</strong>/XXXX/0107/EN<br />

© <strong>Halton</strong><br />

• Balancing dampers standard on all Reactocell TM<br />

series exhaust hoods. (Unique to <strong>Halton</strong>)<br />

• All stainless steel construction<br />

• Service chase enclosed with stainless steel, where<br />

exposed, to accommodate services<br />

• Listed exhaust collar fire dampers available on all<br />

Reactocell TM series exhaust hoods.<br />

(Optional for U.S./Standard in Canada).<br />

• Flexible option and modifications. (Consult Factory)<br />

• Ease of installation, cleaning and servicing.<br />

Application<br />

Box Style exhaust hoods are recommended for all types of<br />

cooking equipment. Suitable for wall or island mount installation.<br />

A Reactocell TM hood is especially suited to facilities with cooking<br />

operations producing substantial volumes of grease and required<br />

virtually grease free hood plenum, duct work, fan and roof.<br />

Recommended for use with the EcoloAir TM systems. Exhaust<br />

hood should overhang front and ends of equipment by a minimum<br />

of 6” (152mm) and minimum of 12” (305mm) over open broilers.<br />

Note: <strong>UV</strong> hoods are not recommended over solid fuel cooking.<br />

• Available in lengths 3’-0” to 16’-0” (914mm to<br />

4877 mm) in 6” (152mm) increments.<br />

<strong>CM</strong>-B-<strong>UV</strong> - <strong>UV</strong> Exhaust Hood<br />

1

Consultant Specification<br />

Kitchen exhaust hood shall be a <strong>Halton</strong> ______________<br />

UL/ULC listed.<br />

The exhaust hood shall be constructed of 18 gauge or<br />

heavier, 300 series stainless steel. The exhaust hood<br />

shall be provided with a stainless steel all welded exhaust<br />

duct collar with connection flange. All joints and seams<br />

are welded and/or liquid tight. All exposed welds are<br />

ground and polished to the original finish of the metal.<br />

End panels shall be hemmed to the interior. Continuous<br />

hanging brackets shall be supplied on each unit for ceiling<br />

or wall mount installations.<br />

Exhaust hood shall contain an integral 3” (76mm) rear air<br />

space.<br />

Exhaust hoods shall be listed by Underwriters Laboratories<br />

and/or Underwriters Laboratories of Canada, and meet all<br />

NFPA96 requirements.<br />

20/<strong>CM</strong>-B-<strong>UV</strong>/XXXX/0107/EN<br />

Reactocell TM series exhaust hoods will be equipped with a<br />

UL/ULC listed self closing spring loaded exhaust collar fire<br />

damper (Optional for U.S./Standard for Canada) assembly<br />

which shall be activated by a fusible link rated at 286 o F<br />

(141 o C). A UL/ULC listed exhaust collar air volume control<br />

damper shall also be provided for optimum balancing of<br />

single and multiple exhaust hood systems. All dampers<br />

shall be accessable through the exhaust hood plenum.<br />

The lower exhaust hood plenum shall be supplied with<br />

a removable high efficiency Primary Grease Extractor<br />

Cartridge (EXIII), and a Secondary “Grease Particle<br />

Separator” (GPS). The upper plenum shall contain a<br />

removable high intensity <strong>UV</strong> Cassette. The <strong>UV</strong> cassette<br />

shall be accessible through a hinged access door secured<br />

with lockable latches.<br />

Modifications & Options<br />

• LIGHTS - Exhaust hood shall contian -<br />

Quantity ________, (bulbs/lamps by others)<br />

- Flush mount fluorescent light fixtures 36”<br />

(914mm) or 48” (1219mm) long (2x40 watts).<br />

- Flush mount vapor proof incandescent light<br />

fixture (2x75 watts).<br />

- Surface mount globe type light fixtures complete<br />

with clear thermal shock proof glass with plated<br />

steel wire guard (1x100 watts).<br />

• FIRE DAMPERS - Listed exhaust collar fire dampers<br />

on Cyclo Maze Dry series hoods.<br />

(Optional for U.S./Standard for Canada)<br />

• STAINLESS STEEL MAIN BACK - Where exposed,<br />

for island applications.<br />

• DIMENSIONS - Height, length and depth can be<br />

altered as required.<br />

<strong>CM</strong>-B-<strong>UV</strong> - <strong>UV</strong> Exhaust Hood<br />

2

Dimension: Inches<br />

mm<br />

4'-0" (1219)<br />

STD.<br />

3"<br />

(76)<br />

C L<br />

EXHAUST COLLAR<br />

20/<strong>CM</strong>-B-<strong>UV</strong>/XXXX/0107/EN<br />

VARIES<br />

3’ - 6” (1067) MIN. TO 16’ - 0” (4880) MAX.<br />

PLAN VIEW<br />

VARIES *<br />

CONTINUOUS<br />

HANGING BRACKET<br />

30.5” (775)<br />

STD.<br />

FRONT ELEVATION VIEW<br />

EXHAUST COLLAR<br />

FIRE DAMPER<br />

(OPTIONAL FOR U.S./<br />

STANDARD FOR CANADA)<br />

3.75"<br />

(95)<br />

10"<br />

(254)<br />

4.5"<br />

(114)<br />

CONTINUOUS<br />

HANGING BRACKET<br />

<strong>CM</strong>-B-<strong>UV</strong> - <strong>UV</strong> Exhaust Hood<br />

3“ (76) AIR SPACE<br />

GREASE EXTRACTOR<br />

CARTRIDGE<br />

GREASE CUP<br />

LEFT SECTION VIEW<br />

3<br />

4‘ - 0"<br />

(1219)<br />

<strong>UV</strong> PLENUM<br />

GREASE PARTICLE<br />

SEPARATOR<br />

2‘ - 2”<br />

(660)<br />

6'-6" A.F.F.<br />

(1981)<br />

Note: Not recommended for use<br />

over solid fuel cooking.

Reactocell Exhaust Air Volumes &<br />

Collar Sizing Data Chart<br />

200 cfm/ft<br />

(0.094 m3/s per 305mm)<br />

HOOD SIZE<br />

3’-6” - 5’-0”<br />

1067mm - 1524mm<br />

DUCT COLLAR<br />

10” (254mm) x _____<br />

6” (152mm)<br />

CFM<br />

(m 3 /s)<br />

700<br />

(0.33)<br />

300 cfm/ft<br />

(.142 m3/s per 305mm)<br />

HOOD SIZE<br />

3’-6” - 5’-0”<br />

1067mm - 1524mm<br />

DUCT COLLAR<br />

10” (254mm) x _____<br />

10” (254mm)<br />

CFM<br />

(m 3 /s)<br />

1050<br />

(0.496)<br />

20/<strong>CM</strong>-B-<strong>UV</strong>/XXXX/0107/EN<br />

5’-6” to 6’-6”<br />

1676mm - 1981mm<br />

10” (254mm)<br />

1100<br />

(0.519)<br />

5’-6” to 6’-6”<br />

1676mm - 1981mm<br />

16” (406mm)<br />

1650<br />

(0.779)<br />

7’-0” to 8’-6”<br />

2134mm - 2591mm<br />

2 @ 6” (152mm)<br />

1400<br />

(0.66)<br />

7’-0” to 8’-6”<br />

2134mm - 2591mm<br />

2 @ 10” (254mm)<br />

2100<br />

(0.991)<br />

9’-0” to 10’-6”<br />

2743mm - 3200mm<br />

1 @ 6” (152mm)<br />

& 1 @ 10” (254mm)<br />

1800<br />

(1.038)<br />

9’-0” to 10’-6”<br />

2743mm - 3200mm<br />

1 @ 10” (254mm)<br />

& 1 @ 16” (406mm)<br />

2700<br />

(1.274)<br />

11’-0” to 12’-0”<br />

3353mm - 3658mm<br />

2 @ 10” (254mm)<br />

2200<br />

(1.038)<br />

11’-0” to 12’-0”<br />

3353mm - 3658mm<br />

2 @ 16” (406mm)<br />

3300<br />

(1.557)<br />

12’-6” to 14’-0”<br />

3810mm - 4267mm<br />

2 @ 6” (152mm)<br />

& 1 @ 10” (254mm)<br />

2500<br />

(1.18)<br />

12’-6” to 14’-0”<br />

3810mm - 4267mm<br />

2 @ 10” (254mm)<br />

& 1 @ 16” (406mm)<br />

3750<br />

(1.77)<br />

14’-6” to 16’-0”<br />

4420mm - 4877mm<br />

1 @ 6” (152mm)<br />

& 2 @ 10” (254mm)<br />

2900<br />

(1.369)<br />

14’-6” to 16’-0”<br />

4420mm - 4877mm<br />

1 @ 10” (254mm)<br />

& 2 @ 16” (406mm)<br />

4350<br />

(2.053<br />

250 cfm/ft<br />

(.118 m3/s per 305mm)<br />

350 cfm/ft<br />

(.165 m3/s per 305mm)<br />

HOOD SIZE<br />

DUCT COLLAR<br />

10” (254mm) x _____<br />

CFM<br />

(m 3 /s)<br />

HOOD SIZE<br />

DUCT COLLAR<br />

10” (254mm) x _____<br />

CFM<br />

(m 3 /s)<br />

3’-6” - 5’-0”<br />

1067mm - 1524mm<br />

8” (203mm)<br />

875<br />

(0.4130)<br />

3’-6” - 5’-0”<br />

1067mm - 1524mm<br />

12” (305mm)<br />

1225<br />

(0.578)<br />

5’-6” to 6’-6”<br />

1676mm - 1981mm<br />

12” (305mm)<br />

1375<br />

(0.649)<br />

5’-6” to 6’-6”<br />

1676mm - 1981mm<br />

18” (457mm)<br />

1925<br />

(0.909)<br />

7’-0” to 8’-6”<br />

2134mm - 2591mm<br />

2 @ 8” (203mm)<br />

1750<br />

(0.826)<br />

7’-0” to 8’-6”<br />

2134mm - 2591mm<br />

2 @ 12” (305mm)<br />

2450<br />

(1.156)<br />

9’-0” to 10’-6”<br />

2743mm - 3200mm<br />

1 @ 8” (203mm)<br />

& 1 @ 12” (305mm)<br />

2250<br />

(1.062)<br />

9’-0” to 10’-6”<br />

2743mm - 3200mm<br />

1 @ 12” (305mm)<br />

& 1 @ 18” (457mm)<br />

3150<br />

(1.487)<br />

11’-0” to 12’-0”<br />

3353mm - 3658mm<br />

2 @ 12” (305mm)<br />

2750<br />

(1.298)<br />

11’-0” to 12’-0”<br />

3353mm - 3658mm<br />

2 @ 18” (457mm)<br />

3850<br />

(1.817)<br />

12’-6” to 14’-0”<br />

3810mm - 4267mm<br />

2 @ 8” (203mm)<br />

& 1 @ 12” (305mm)<br />

3125<br />

(1.475)<br />

12’-6” to 14’-0”<br />

3810mm - 4267mm<br />

2 @ 12” (305mm)<br />

& 1 @ 18” (457mm)<br />

4375<br />

(2.065)<br />

14’-6” to 16’-0”<br />

4420mm - 4877mm<br />

1 @ 8” (203mm)<br />

& 2 @ 12” (305mm)<br />

3625<br />

(1.711)<br />

14’-6” to 16’-0”<br />

4420mm - 4877mm<br />

1 @ 12” (305mm)<br />

& 2 @18” (457mm)<br />

5075<br />

(2.395)<br />

Note: For hoods with multiple collars please contact the factory to confirm<br />

location. Please contact factory to confirm static pressure.<br />

Exhaust Hood Static Pressure Chart<br />

Exhaust Air Volumes<br />

150 cfm/ft<br />

(0.071 m 3 /s per 305mm)<br />

200 cfm/ft<br />

(0.094 m 3 /s per 305mm)<br />

250 cfm/ft<br />

(.118 m 3 /s per 305mm)<br />

300 cfm/ft<br />

(.142 m 3 /s per 305mm)<br />

350 cfm/ft<br />

(.165 m 3 /s per 305mm)<br />

Static Pressure<br />

0.5” (.125kPa)<br />

0.75” (.187kPa)<br />

1.0” (.248kPa)<br />

1.35” (.336kPa)<br />

1.75” (.436kPa)<br />

Ventilator exhaust air volume requirements depend on type of equipment,<br />

model of ventilator, location of ventilator in relation to adjacent walls and the<br />

make-up air velocity and balance within the cooking area. Each kitchen’s<br />

air system must becalculated individually and engineerd to meet these<br />

conditions. It is essential that all air, ventilator and cooking equipment<br />

factors be established and co-ordinated by the design team to achieve proper<br />

ventilator exhausting of cooking equipment. Contact <strong>Halton</strong> for assistance<br />

to determine proper cooking equipment and ventilator exhaust air volumes.<br />

EXHAUST AIR VOLUME AND DUCT COLLAR SIZE CHART.<br />

- Duct collar sized to move air at a minimum velocity of<br />

1500 fpm (7.62 m/s)<br />

SUPPLY AIR VOLUME AND DUCT COLLAR SIZE CHART.<br />

- Duct collar sized to move air at a minimum velocity of<br />

1000 fpm (5.08 m/s)<br />

Continuous product improvement is a <strong>Halton</strong> policy, therefore specifications and designs are subject to change without notice.<br />

<strong>CM</strong>-B-<strong>UV</strong> - <strong>UV</strong> Exhaust Hood<br />

4