PUBLIC AUCTION - Hilco Industrial

PUBLIC AUCTION - Hilco Industrial

PUBLIC AUCTION - Hilco Industrial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

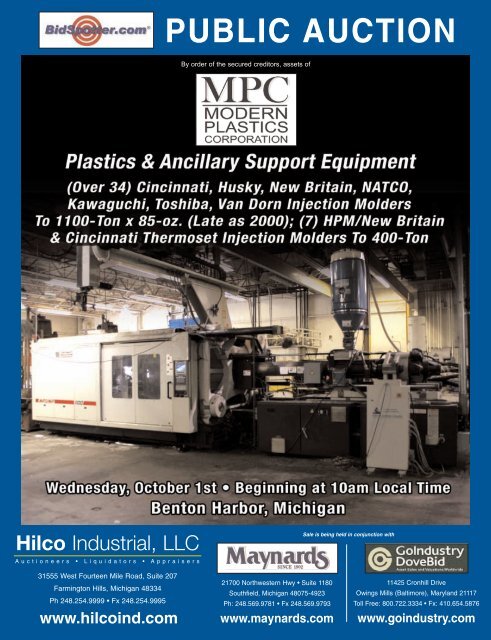

<strong>PUBLIC</strong> <strong>AUCTION</strong><br />

By order of the secured creditors, assets of<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

Auctioneers • Liquidators • Appraisers<br />

Sale is being held in conjunction with<br />

31555 West Fourteen Mile Road, Suite 207<br />

Farmington Hills, Michigan 48334<br />

Ph 248.254.9999 • Fx 248.254.9995<br />

www.hilcoind.com<br />

21700 Northwestern Hwy • Suite 1180<br />

Southfield, Michigan 48075-4923<br />

Ph: 248.569.9781 • Fx 248.569.9793<br />

www.maynards.com<br />

11425 Cronhill Drive<br />

Owings Mills (Baltimore), Maryland 21117<br />

Toll Free: 800.722.3334 • Fx: 410.654.5876<br />

www.goindustry.com

<strong>PUBLIC</strong><br />

<strong>AUCTION</strong><br />

PLASTIC INJECTION MOLDERS<br />

sale to be conducted by<br />

By order of the secured creditors, assets of<br />

WEDNESDAY, OCTOBER 1ST<br />

Beginning at 10am Local Time<br />

Preview Date<br />

Tuesday, September 30th<br />

9am to 4pm Local Time or By Appointment<br />

1999<br />

CINCINNATI<br />

MILACRON<br />

MAXIMA<br />

MM1100–85,<br />

1100–TON X<br />

85 OZ. 3–PLATEN<br />

PLASTIC<br />

INJECTION<br />

MOLDING<br />

MACHINE<br />

Auction Location<br />

489 North Shore Drive<br />

Benton Harbor, MI 49022<br />

Preview Locations<br />

489 North Shore Drive • Benton Harbor, MI 49022<br />

18300 West Hwy. US-12 (Plastic Masters)<br />

New Buffalo, MI 49117<br />

Directions to Sale<br />

Directions from Detroit Area: I–94 West to Exit #33 –<br />

Business Loop 94 West. Follow Business Loop 94<br />

West/Main St. West 3 Miles into Downtown Benton Harbor.<br />

Turn Right on 5th St, Proceed 4/10 Mile to Plant on Right.<br />

(5th St. Turns into North Shore Drive)<br />

Directions from Chicago Area: I–94 East to Exit #23 –<br />

Business Loop 94 East/Red Arrow Hwy. Proceed East on<br />

Business Loop 94 6–1/2 Miles Thru Downtown St. Joseph.<br />

Cross Over River Bridge into Benton Harbor, Continue East<br />

on Business Loop 94/Main St. 1 Mile to 5th St. Turn Left on<br />

5th St., Proceed 4/10 Mile to Plant on Right. (5th St. Turns<br />

into North Shore Drive)<br />

Travel Information<br />

Airlines:<br />

American Airlines . . . . . . . . . . . . . . . . . . . 800.433.7300<br />

Northwest Airlines . . . . . . . . . . . . . . . . . . . 800.225.2525<br />

United Airlines . . . . . . . . . . . . . . . . . . . . . . 800.241.6522<br />

Delta Airlines . . . . . . . . . . . . . . . . . . . . . . . 800.221.1212<br />

Southwest Airlines . . . . . . . . . . . . . . . . . . 800.435.9792<br />

Hotels:<br />

Hampton Inn (Stevensville) . . . . . . . . . . . . 269.429.2700<br />

Holiday Inn Express (St. Joseph) . . . . . . . 269.982.0115<br />

Courtyard by Marriott (Benton Harbor) . . . 269.925.3000<br />

Holiday Inn Express (Benton Harbor) . . . . 800.345.8082<br />

Baymont Suites (Stevensville) . . . . . . . . . 269.428.9111<br />

Further Information<br />

• All payments must be made payable to<br />

Maynards.<br />

• A buyer’s premium will be in effect. The auction<br />

will be conducted in English, accepting U.S.<br />

Currency only.<br />

• Removal Deadline is Wednesday, October 15, 2008<br />

with Hours of Removal between 8am to 4pm Monday<br />

thru Friday. After October 15th at 4pm buyer will<br />

incur a cost of $500 daily for entry into the facility.<br />

• For further information please contact<br />

Taso Sofikitis at 248.569.9781 or<br />

Email taso@maynards.com<br />

• For Payment & Customer Service please<br />

contact: Becky Kuznicki at 517.719.8134 or<br />

Email becky@maynards.com<br />

2000<br />

CINCINNATI<br />

MILACRON<br />

MAGNA<br />

MH–500–68,<br />

500–TON X<br />

68 OZ. 3–PLATEN<br />

PLASTIC<br />

INJECTION<br />

MOLDING<br />

MACHINE<br />

(34) PLASTIC INJECTION MOLDING MACHINES<br />

1 – CINCINNATI MILACRON MAXIMA MODEL MM1100–85, 1100–TON X 85 OZ. 3–PLATEN PLASTIC INJECTION MOLDING MACHINE,<br />

S/N H32A0100011 (1999), Hydraulic Clamp, Platen Size 82.7” x 61.2”, Tie Bar Spacing 60–1/2” x 45”, 78.7” Clamp Stroke, 94.5” Maximum Daylight,<br />

CAMAC 486C Microprocessor Controls (#574)<br />

1 – CINCINNATI MILACRON MAGNA MODEL MH–500–68, 500–TON X 68 OZ. 3–PLATEN PLASTIC INJECTION MOLDING MACHINE,<br />

S/N H05A0400067 (2000), Hydraulic Clamp, Platen Size 48” x 48”, Tie Bar Spacing 34” x 34”, CAMAC 486C Microprocessor Controls (#563)<br />

1 – CINCINNATI MILACRON VISTA MODEL VT–550–68, 550–TON X 68 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N T60A0398024 (1998),<br />

Toggle Clamp, Platen Size 49” x 49”, Tie Bar Spacing 34.2” x 32.5”, Core Pull, Ejector, CAMAC 486C Microprocessor Controls (#573)<br />

1 – NATCO 650–TON X 100 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 650E–70, Hydraulic Clamp, Platen Size 48” x 48”, Tie Bar Spacing<br />

31” x 31”, Screw Ram, Barber Colman 3–Zone Standard Temperature Controls, Feed Hopper (#575)<br />

1 – CINCINNATI MILACRON MODEL 500–70, 500–TON X 70 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 4025A21/87–07, Hydraulic Clamp,<br />

Tie Bar Spacing 32” x 32”, Platen Size 48” x 48”, Cincinnati Milacron Microprocessor Controls (#565)<br />

1 – CINCINNATI MILACRON MODEL VH500–54, 500–TON X 54 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 3905A21/89–20, Hydraulic<br />

Clamp, Tie Bar Spacing 34” x 34”, Platen Size 48” x 48”, CAMAC VLC Microprocessor Controls, Hydraulic Eject, Core Pull (#567)<br />

1 – CINCINNATI MILACRON MODEL 500–TON X 48 OZ. PC3 PLASTIC INJECTION MOLDING MACHINE, S/N 4005A21/80–1, Hydraulic Clamp, Tie<br />

Bar Spacing 32–1/2” x 32–1/2” Platen Size 48” x 48”, Hydraulic Ejectors, Core Pull, Relay Electrics (#564)<br />

1 – KAWAGUCHI MODEL KM450B 495–TON X 61.6 OZ, PLASTIC INJECTION MOLDING MACHINE, S/N TG–RZ0145, Toggle Clamp, Shot Volume<br />

118 Cu. In., Tie Bar Spacing 32” x 32”, Platen Size 46” x 46”, Bright 301 Microprocessor Controls, Hydraulic Eject, Core Pull (#560)<br />

1 – CINCINNATI MILACRON MODEL VT440–29, 440–TON X 29 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 4039A61/91–34, Toggle Clamp,<br />

Tie Bar Spacing 29” x 29”, Platen Size 39” x 39”, CAMAC VEL Microprocessor Controls (Not In Service, Screw Hydraulic Drive Removed) (#550)<br />

1 – CINCINNATI MILACRON MODEL VH400–41–CE 400–TON X 41 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 3904A21/90–7, Hydraulic<br />

Clamp, Tie Bar Spacing 29” x 29”, Platen Size 41” x 41”, CAMAC XTL Microprocessor Controls (Rob & Heidi Orlaske Estate)<br />

1 – HUSKY MODEL X400P 400–TON PLASTIC INJECTION MOLDING MACHINE, S/N 9027, Hydraulic Clamp, Tie Bar Spacing 24” x 24”, Platen Size<br />

38” x 38”, Shut Height 27.5mm Minimum to 800mm Maximum, 30 KW Screw Drive, CNC Controls, Feed Hopper, With Mould–Tek Additive Feeder<br />

(Rob & Heidi Orlaske Estate)<br />

1 – KAWAGUCHI MODEL KM360B 397–TON X 42.3 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N RD–RZ0347 (1994), Toggle Clamp, Platen<br />

Size 41” x 41”, Tie Bar Spacing 28” x 28”, Core Pull, Ejector, Bright 301 Microprocessor Controls (#572)<br />

1 – KAWAGUCHI MODEL KM360B 396–TON X 42.3 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N RF–PZ0222, Toggle Clamp, Tie Bar<br />

Spacing 28” x 28”, Platen Size 42” x 42”, Bright 301 Microprocessor Controls (#540)<br />

1 – TOSHIBA MODEL ISE–390, 390–TON X 63 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 842470, Hydraulic Clamp, Tie Bar Spacing 28”<br />

x 28”, Platen Size 39” x 40”, Injectivisor 5000 Controls (#562)<br />

1 – TOSHIBA MODEL ISGS390, 390–TON X 41 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 83P075, Hydraulic Clamp, Tie Bar Spacing 28”<br />

x 28”, Platen Size 40” x 40”, Injectivisor V10 Microprocessor Control, Core Pull, Ejectors (#552)<br />

1 – NATCO 350–TON X 20 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 350E–305, Hydraulic Clamp, Platen Size 33” x 34”, Tie Bar Spacing<br />

21–1/2” x 21–1/2”, Screw Ram, Maco III Relay Controls (#530)<br />

1 – KAWAGUCHI MODEL KM280B 308–TON X 29 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N PA–MZ0021, Toggle Clamp, Shot Volume<br />

45.64 cu. in., Tie Bar Spacing 24” x 24”, Platen Size 35” x 35”, Bright 301 Microprocessor Controls (#541)<br />

1 – HUSKY MODEL XL300RS 300–TON PLASTIC INJECTION MOLDING MACHINE, S/N 8852, Hydraulic Clamp, Tie Bar Spacing 28” x 28”, Platen<br />

Size 41” x 41”, 75 KW Pump Motor, Relay Electrics, Approximately 50–LB. Feed Hopper, With Mould–Tek Additive Feeder & Bunting Magnetic<br />

Separator (Rob & Heidi Orlaske Estate)<br />

1 – CINCINNATI MILACRON MODEL ACT300D 300–TON PLASTIC INJECTION MOLDING MACHINE, S/N 4045A02/91–4, Toggle Clamp, Tie Bar<br />

Spacing 28”H x 24”V, Platen Size 40”H x 36”V (Not Under Power) (#571)<br />

1 – NEW BRITAIN MODEL 300–TR–30, 300–TON X 30 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 4712–P, Toggle Clamp, Tie Bar Spacing<br />

24–1/2” x 24–1/2”, Platen Size 37”H x 38”V, Command II Microprocessor Control (#542)<br />

1 – CINCINNATI MILACRON MODEL VH250–13, 250–TON X 13 OZ. SHOT PLASTIC INJECTION MOLDING MACHINE, S/N H–2A0193012,<br />

Hydraulic Clamp, Tie Bar Spacing 22” x 22”, Platen Size 31” x 31”, CAMAC VEL Microprocessor Controls (#544)<br />

1 – CINCINNATI MILACRON MODEL VH250–11, 250–TON X 11 OZ. SHOT PLASTIC INJECTION MOLDING MACHINE, S/N H02A0193004,<br />

Hydraulic Clamp, Platen Size 31” x 31”, Tie Bar Spacing 22” x 22”, CAMAC VEL Microprocessor Controls (#543)<br />

1 – STOKES 4–POST VERTICAL CLAMP PLASTIC INJECTION MOLDING MACHINE, S/N N/A, 250–TON x 12 OZ., Horizontal Screw, Distance<br />

Between Tie Bars 24”LR x 10”FB, Toggle Clamp, Relay Controls, With Feed Hopper & Receiver (#535)<br />

1 – KAWAGUCHI MODEL K180–B 198–TON X 11.97 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 1L–YY3388, Toggle Clamp, Platen Size<br />

29.5” x 27”, Tie Bar Spacing 20” x 17”, Core Pull, Ejector, Microprocessor Controls (#533)<br />

1 – CINCINNATI MILACRON MODEL VT–165–7, 165–TON X 7 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N T36A0396011 (1996), Toggle<br />

Clamp, Platen Size 26.8” x 25.6”, Tie Bar Spacing 17.9” x 16.7”, Core Pull, Ejector, CAMAC 486 Microprocessor Controls (#523)<br />

2<br />

For more information, visit www.hilcoind.com or www.maynards.com

THERMOSET INJECTION MOLDERS • PARTS ROBOTS<br />

1998<br />

CINCINNATI MILACRON VISTA VT–550–68, 550–TON<br />

X 68 OZ. PLASTIC INJECTION MOLDING MACHINE<br />

KAWAGUCHI MODEL KM450B 495–TON X 61.6 OZ,<br />

PLASTIC INJECTION MOLDING MACHINE<br />

HUSKY MODEL X400P 400–TON<br />

PLASTIC INJECTION MOLDING MACHINE<br />

CINCINNATI MILACRON ACT–150B–226, 150–TON<br />

X 8 OZ. PLASTIC INJECTION MOLDING MACHINE<br />

HPM/NEW BRITAIN MODEL 400–TS/TP 400–TON 59 OZ.<br />

THERMOSET INJECTION MOLDING MACHINE<br />

AUTOMATED ASSEMBLIES AZ560<br />

SR–M3 EXPRESS 3–AXIS SERVO<br />

DRIVE CNC ROBOT<br />

HPM MODEL T400–55–TS–BMC 400–TON X 55 OZ.<br />

THERMOSET INJECTION MOLDING MACHINE<br />

(34) PLASTIC INJECTION MOLDING MACHINES<br />

(CONTINUED)<br />

1 – CINCINNATI MILACRON MODEL VT–165–11, 165–TON X 11 OZ. PLASTIC<br />

INJECTION MOLDING MACHINE, S/N T36A0395092 (1995), Toggle Clamp,<br />

Platen Size 46.8” x 25.6”, Tie Bar Spacing 17.9” x 16.7”, Core Pull, Ejector, CAMAC<br />

486 Microprocessor Controls (#522)<br />

1 – KAWAGUCHI MODEL KM140B 154–TON X 8.67 OZ. PLASTIC INJECTION<br />

MOLDING MACHINE, S/N JC–QZ0627, Toggle Clamp, Tie Bar Spacing 18” x 18”,<br />

Platen Size 26” x 26”, Bright 301 Microprocessor Controls, Core Pull, Ejectors, Air<br />

Blow–Off (#570)<br />

1 – CINCINNATI MILACRON MODEL ACT–150B–226, 150–TON X 8 OZ. PLASTIC<br />

INJECTION MOLDING MACHINE, S/N 4043A01/88–2, Electric Clamp, Platen Size 26”<br />

x 26”, Tie Bar Spacing 18” x 18”, Fanuc Autoshot 160B Microprocessor Controls (#521)<br />

1 – CINCINNATI MILACRON/FANUC MODEL ROBOSHOT 110R 110–TON X 3.4 OZ.<br />

PLASTIC INJECTION MOLDING MACHINE, S/N 4066A02/97–42 (1997), Electric<br />

Clamp, Platen Size 24” x 25”, Tie Bar Spacing 16” x 16”, Fanuc Series 16–i CNC<br />

Control (Press #511)<br />

1 – CINCINNATI MILACRON MODEL VT–110–7, 110–TON X 7 OZ. PLASTIC<br />

INJECTION MOLDING MACHINE, S/N T35A0194045 (1994), Toggle Clamp,<br />

Platen Size 24.8” x 22.8”, Tie Bar Spacing 16.14” x 14.17”, 27.5” Daylight, 11.8”<br />

Stroke, CAMAC VEL Microprocessor Controls (#520)<br />

1 – VAN DORN MODEL 110–RS–5.5, 110–TON X 5.5 OZ. PLASTIC INJECTION<br />

MOLDING MACHINE, S/N 901100–4, Hydraulic Clamp, Platen Size 27” x 27”, Tie<br />

Bar Spacing 14” x 14”, Path Finder Microprocessor Controls, Feed Hopper (#524)<br />

1 – VAN DORN MODEL 80–RS–5.5, 80–TON X 5.5 OZ. PLASTIC INJECTION<br />

MOLDING MACHINE, S/N 9080–1 (1990), Hydraulic Clamp, Platen Size 25” x 25”,<br />

Tie Bar Spacing 17–1/2” x 13–1/2”, Path Finder Microprocessor Control (#525)<br />

1 – TRUEBLOOD 75–TON X 5 OZ. VERTICAL CLAMP C–FRAME PLASTIC<br />

INJECTION MOLDING MACHINE, S/N NA, Horizontal Injection Barrel, 4–Station<br />

42” Diameter Rotary Indexing Table, Barber Colman Analog & Digital Temperature<br />

Controls (#513)<br />

1 – NEWBURY MODEL H3–50RS 50–TON X 1.2 OZ. PLASTIC INJECTION<br />

MOLDING MACHINE, S/N 10283650S71, Hydraulic Clamp, 16” x 17” Platen Size,<br />

Tie Bar Spacing 10” x 12”, Vacuum Receiver (Press #510)<br />

HPM–NEW BRITAIN MODEL 300 TP–30/30,<br />

300–TON X 34 OZ. THERMOSET<br />

INJECTION MOLDING MACHINE<br />

AUTOMATED ASSEMBLIES<br />

MODEL AZ620 SR M3 OPTIM<br />

3–AXIS CNC SERVO ROBOT<br />

(8) THERMOSET INJECTION MOLDERS<br />

1 – HPM/NEW BRITAIN MODEL 400–TS/TP 400–TON 59 OZ. THERMOSET INJECTION MOLDING MACHINE, S/N 4647–P/R96304<br />

(Rebuilt April 1997), Toggle Clamp, Platen Size 40” x 41”, Tie Bar Spacing 26” x 28”, Screw Type Injection, Command 4500<br />

Microprocessor Controls (#623)<br />

1 – HPM MODEL T400–55–TS–BMC 400–TON X 55 OZ. THERMOSET INJECTION MOLDING MACHINE, S/N 96194 (1996), Toggle<br />

Clamp, Platen Size 43” x 43”, Tie Bar Spacing 28” x 28”, Screw Type Injector, Command 4500 Microprocessor Controls (#621)<br />

1 – HPM MODEL 400 TP–52 400–TON X 59 OZ. THERMOSET INJECTION MOLDING MACHINE, S/N 4916–P, Toggle Clamp, Platen<br />

Size 40” x 41”, Tie Bar Spacing 26” x 28”, EPCO E–4000 Microprocessor Controls, Feed Hopper (#622)<br />

1 – HPM MODEL 375, 375–TON X 32 OZ. THERMOSET INJECTION MOLDING MACHINE, S/N R87046/2423P (1969–Rebuilt 1987),<br />

Toggle Clamp, Platen Size 37” x 37”, Tie Bar Spacing 22” x 22”, Allen Bradley SLC 5/03 CPU PLC Controls (#612)<br />

1 – NEW BRITAIN MODEL 375–TP–4, 375–TON X 32 OZ. THERMOSET INJECTION MOLDING MACHINE, S/N 1641–P, Toggle Clamp,<br />

Platen Size 37.5” x 37.5”, Tie Bar Spacing 22” x 22”, Screw Type Injector, EPCO E–4440 Microprocessor Controls (#620)<br />

1 – HPM–NEW BRITAIN MODEL 300 TP–30/30, 300–TON X 34 OZ. THERMOSET INJECTION MOLDING MACHINE, S/N 5034–P,<br />

Toggle Clamp, Platen Size 37” x 37”, Tie Bar Spacing 24–1/2” x 24–1/2”, Vertical Plunger Feed Ram, Command II Microprocessor<br />

Controls (#610)<br />

1 – NEW BRITAIN MODEL 300, 300–TON X 24 OZ. THERMOSET INJECTION MOLDING MACHINE, S/N 3195P, Toggle Clamp, Platen<br />

Size 34” x 34”, Tie Bar Spacing 22” x 22”, Allen Bradley SLC 5/01 CPU PLC Controls (#611)<br />

1 – CINCINNATI MILACRON/FANUC MODEL ROBOSHOT 110R 110–TON X 4.8 OZ. THERMOSET PLASTIC INJECTION MOLDING<br />

MACHINE, S/N 4066A02/97–59 (1997), Electric Clamp, Converted, With Thermoset Injection Barrel, Platen Size 24” x 25”, Tie Bar<br />

Spacing 16” x 16” Fanuc Series 16–i CNC Control (#512)<br />

PARTS ROBOTS<br />

1 – AUTOMATED ASSEMBLIES MODEL AZ620 SR M3 OPTIM 3–AXIS CNC SERVO ROBOT, S/N 00–0117/S46542 (2000), Cutler<br />

Hammer Panel Mate Power Pro Hand Held Touch Screen Control, Optimum Servo Controller Console, S/N S–46542 (#574)<br />

1 – AUTOMATED ASSEMBLIES MODEL AZ560 SR–M3 EXPRESS 3–AXIS SERVO DRIVE CNC ROBOT, S/N 00–0512, Mfg. No.<br />

S–47870, Cutler Hammer Panel Mate Power Pro Hand Held Touch Screen Control, With Optimum Controller, S/N C–20174, (#561)<br />

1 – AUTOMATED ASSEMBLIES MODEL AZ560 EXPRESS 3–AXIS CNC SERVO ROBOT, S/N NA, With Cutler Hammer Panel Mate<br />

Power Pro Hand–Held Touch Screen Control, Optimum Servo Controller, S/N C–20240 (#573)<br />

1 – CINCINNATI MILACRON MODEL CMR–560 SR–M3, 3–AXIS CNC SERVO ROBOT, S/N 3937A01/00–51 (2000), Power Pro Panel<br />

Mate Hand Pendant Touch Screen Control (#563)<br />

1 – AUTOMATED ASSEMBLIES MODEL AZ460 SR–M3 EXPRESS 3–AXIS CNC SERVO ROBOT, S/N 00–1011, Mfg. No. S–49056,<br />

Cutler Hammer Panel Mate Power Pro Hand–Held Touch Screen Control, With Optimum Servo Controller, S/N S–49056 (#560)<br />

2 – CMP–32 SPRUE PICKER PARTS ROBOTS, S/Ns 3937A61/98–1, N/A, Hand Held Microprocessor Control (#s 511 & 512)<br />

1 – MARK II AUTOMATION EAGLE MODEL EMC 2000 SPRUE PICKER PARTS ROBOT, S/N NA (#520)<br />

To schedule an auction, please contact us at 248.254.9999 3

MATERIAL DRYERS • HOPPERS & LOADERS • TEMPERATURE CONTROLLLERS<br />

THORENSON MCCOSH<br />

THERMAL–D TECH II MODEL<br />

TD–40 DEHUMIDIFYING DRYER<br />

NOVATEC MODEL 600#<br />

HOPPER COMP. 600–LB.<br />

CAPACITY FEED HOPPER<br />

NOVATEC MODEL NPH<br />

HOPPER 400–LB. CAPACITY<br />

FEED HOPPER<br />

VIEW OF CUMBERLAND, BALL & JEWELL,<br />

IMS & RAPID GRANULATORS<br />

STERL–TRONIC, CAPITOL, CINCINNATI–MILACRON,<br />

THERMAL CARE AQUA–THERM, LOGIC SEAL, QPC &<br />

ADVANTAGE SENTRA TEMPERATURE CONTROLLERS<br />

CENTRAL PROCESS WATER<br />

CHILLING/ RECIRCULATION SYSTEM<br />

MCQUAY WGZ055AW27–ER10 WATER COOLED<br />

RECIPROCATING CHILLER/TEMPLIFIER HEAT PUMP<br />

MATERIAL DRYERS<br />

2 – NOVATEC MPC–150 MICROPROCESSOR<br />

CONTROLLED DRYERS, S/Ns 3–6523–0673<br />

(#15), NA (#5) Model MDC–3000<br />

Microprocessor Controls, Portable Base<br />

1 – NOVATEC NPD–100 MICROPROCESSOR<br />

CONTROLLED DRYER, S/N 3–3162–0982,<br />

Relay Electrics, Portable (#17)<br />

1 – NOVATEC MDM–50 MICROPROCESSOR<br />

CONTROLLED DRYER, S/N 3A095–0498,<br />

With Model MPM–Hopper Dryer Hopper,<br />

S/N 3A0951–1742, 200–LB. Capacity, Model<br />

VL–4 Proportioning Vacuum Loader Control,<br />

S/N VL 4–2720 (#21)<br />

1 – THORENSON MCCOSH THERMAL–D TECH<br />

II MODEL TD–40 DEHUMIDIFYING DRYER,<br />

S/N 961025, 9.1 KW, Microprocessor Controls<br />

1 – NOVATEC MODEL MDN–25 PORTABLE<br />

MATERIAL DRYER, S/N 3–9815–1304<br />

(1998), 2.2 KVA, Microprocessor Controls,<br />

With Model MDM 100–LB. Capacity Dryer<br />

Hopper, S/N 3–9815–1890<br />

7 – IMS MODEL MD750–50A MATERIAL DRY-<br />

ERS, S/Ns 0711, MD75050–0325 (#812),<br />

MD75050–0432, 0511, MD75050–0431, 0703,<br />

MD75050–0273, 7.5 KW<br />

1 – CINCINNATI MILACRON MODEL MC–DD–60<br />

PORTABLE MATERIAL DRYER,<br />

S/N 3933A02–97–150 (1997), Microprocessor<br />

Controls, With Approximately 100–LB.<br />

Capacity Dryer Hopper, Ametek Model<br />

CML–LS45 Vacuum Loader, Magnetic<br />

Separator<br />

1 – CINCINNATI MILACRON DD–60 PORTABLE<br />

MATERIAL DRYER, S/N 3933A02–98–1,<br />

Microprocessor Controls, With Approximately<br />

100–LB. Capacity Dryer Hopper,<br />

Model CML–MS45 Vacuum Loader,<br />

S/N 3934A01–97–184<br />

1 – UNA–DYN MODEL DS DRY SPOT MATERIAL<br />

DRYER, S/N DS–88270, With 100–LB.<br />

Capacity Dry Spot Dryer Hopper,<br />

S/N H–10088057 (Mounted on Machine 513)<br />

4 – UNA–DYN MODEL DHD–4 DEHUMIDIFYING<br />

DRYERS, S/Ns DHD–476917 (#13), NA (#14),<br />

NA (#16), DHD–476919 (#NA)<br />

Additional Dryer Units Located at Warehouse<br />

Location<br />

HOPPERS & LOADERS<br />

1 – NOVATEC MODEL 600# HOPPER COMP. 600–LB. CAPACITY FEED HOPPER, S/N 3–3031–0002 (#530),<br />

With Conair Vacuum Loader, Magnetic Separator<br />

1 – NOVATEC 600–LB CAPACITY FEED HOPPER, MODEL & S/N NA (#542), With NOVATEC Vacuum Loader,<br />

Magnetic Separator, & NOVATEC Model VL–1 Vacuum Loader Control, S/N VL–1–1574<br />

3 – NOVATEC MODEL NPH HOPPER 400–LB. CAPACITY FEED HOPPERS, S/N 10A540/0827,<br />

10A480–0820 (#552), S/N 10–480–0593 (#543), With NOVATEC Vacuum Loader, Bunting Magnetic<br />

Separator, NOVATEC VL–4 Proportioning Vacuum Loader control, S/N VL–4–2832<br />

1 – 400–LB. CAPACITY FEED HOPPER, With NOVATEC Vacuum Loader, Magnetic Separator, NOVATEC<br />

VL–4 Proportioning Vacuum Loader Control, S/N VL–4–1973 (#565)<br />

2 – NOVATEC MODEL NPH HOPPER 400–LB. CAPACITY FEED HOPPERS, S/N 1A0480–0819 (#574),<br />

1A067–0840 (BOTH 1996) (#564), With NOVATEC Vacuum Loader, VL–4 Proportioning Vacuum Loader<br />

Control, Magnetic Separator<br />

2 – NOVATEC MODEL NPH HOPPER 200–LB. CAPACITY HOPPERS, S/N 10–766–1370, S9560 (#525),<br />

NOVATEC Vacuum Loader, Bunting Magnetic Separator<br />

1 – THORENSON MCCOSH 160–LB. CAPACITY FEED HOPPER, S/N 9421 (#544), With Thorenson McCosh<br />

Model VM–1BR Vacuum Loader, S/N 9610321, Bunting Magnetic Separator<br />

1 – APPROXIMATELY 150–LB. CAPACITY PORTABLE HOPPER, With IMS Model 1500 PLVP Whisper<br />

Loader Vacuum Loader, S/N 2586<br />

2 – APPROXIMATELY 100–LB. CAPACITY FEED HOPPERS, With Plastic Process Equipment Vacuum Loader,<br />

Maguire MCP–8–34 Concentrate Feeder, S/N 18372, Magnetic Separator (#561), With IMS Model 1500<br />

PLVP Whisper Loader Vacuum Loader, S/N 3193 (Mounted on Machine #570)<br />

4 – APPROXIMATELY 75–LB. CAPACITY FEED HOPPERS, With IMS Model 1250 PLVPA Vacuum Loader,<br />

S/N 6404, Magnetic Separator (#541), With IMS Vacuum Loader (#533), (Mounted on Machine #523), (#522)<br />

5– AUTO LOAD PLASTI–QUIP VACUUM LOADERS, With Maguire Model MCP–8–34 Concentrate Feeder,<br />

S/N 23446 (#572), 18371 (#563), NA (#573), (#560), (#562)<br />

1 – PLASTI–QUIP VACUUM LOADER, S/N NA, With Magnetic Separator (#540)<br />

Additional Hoppers & Loaders at Warehouse Location<br />

GRANULATORS<br />

1 – CUMBERLAND SIZE 684–GRAN–6KN GRANULATOR, S/N 91000–782, Opening Size 26” x 16”, 40–HP<br />

1 – CUMBERLAND MODEL 12 X 20 GRANULATOR, S/N 399683 (1997), 15–HP, Enclosures (#13)<br />

4 – CUMBERLAND SIZE 14 X 20 GRANULATORS, S/Ns 35055–6651 (#2), 35055–685 (#7), NA (#4),<br />

35055–6447 (#14), Approximately 10–HP<br />

1 – BALL & JEWELL MODEL MC300 GRANULATOR, S/N 6662, MWT 15–HP, 12” x 16” Opening<br />

1 – CUMBERLAND MODEL 1215 GRANULATOR, S/N 93450–97506, 12” x 15” Opening, 15–HP<br />

3 – IMS MODEL 3144–SP GRANULATORS, S/Ns 341440349 (#9), 341440350 (#21), 341440200 (#1), 10–HP,<br />

12” x 12” Opening<br />

1 – RAPID MODEL GK3026K GRANULATOR, S/N 100393, Opening Size 12” x 12”<br />

2 – CUMBERLAND SIZE 10 X 12 GRANULATOR, S/N 25086–6638 (#11), 25086–64175<br />

1 – IMS MODEL 3144SP 10–HP GRANULATOR, S/N 341440355, 12” x 11” Opening (#6)<br />

1 – RAPID MODEL 912C GRANULATOR, S/N 305127 (1990), Opening Size 9” x 12” Approximately 7–1/2–HP<br />

1 – 10” X 8” GRANULATOR, MFG'R NA, Approximately 5–HP (#566)<br />

1 – RAPID MODEL 79K PLASTIC GRANULATOR, S/N 20–1871 (1998), 7” x 8” Opening, HP–NA<br />

Additional Granulators Located at Warehouse Location<br />

TEMPERATURE CONTROLLERS<br />

1 – MFG'R N/A MODEL TMWH4250 TEMPERATURE<br />

CONTROLLER, S/N 1882059 (#TH555)<br />

1 – STERL–TRONIC MODEL S6422A TEMPERATURE<br />

CONTORLLER, S/N 29031<br />

1 – STERL–TRONIC MODEL 6422S TEMPERATURE<br />

CONTROLLER, S/N 19088<br />

1 – CAPITOL MODEL 300A/H TEMPERATURE CON-<br />

TROLLER, S/N 11881790<br />

1 – CINCINNATI–MILACRON MODEL MFCL–75<br />

TEMPERATURE CONTROLLER, S/N<br />

3931A04–97–513<br />

1 – STERLCO MODEL 6422E TEMPERATURE<br />

CONTROL UNIT, S/N 16745, 9000 Watts Per<br />

Heater<br />

2 – THERMAL CARE AQUA–THERM MODEL<br />

RA090803 TEMPERATURE CONTROL UNITS,<br />

S/Ns 4655009961, 4655010961<br />

1 – STERLCO MODEL 6211DX TEMPERATURE<br />

CONTROL UNIT, S/N 9382, 9000 Watt Heater<br />

1 – STERL–TRONIC MODEL S6422A TEMPERATURE<br />

CONTROLLER, S/N 28608, 9000 Watts Per Heater<br />

1 – CINCINNATI MILACRON MODEL MFCL–75<br />

TEMPERATURE CONTROLLER, S/N<br />

3931A04–98–9 (1998), 3931A04–98–10 (1998)<br />

1 – LOGIC SEAL MODEL LS–200 TEMPERATURE<br />

CONTROLLER, S/N 02347<br />

1 – STERL–TRONIC MODEL G412–A TEMPERATURE<br />

CONTROLLER, S/N 14972, 9000 Watt<br />

2 – QPC MODEL QMC–1110 TEMPERATURE<br />

CONTROLLER, S/Ns 339909, 070005<br />

1 – ADVANTAGE SENTRA SK–1075–21C1<br />

TEMPERATURE CONTROLLER, S/N 29828<br />

1 – STERL–TRONIC MODEL F–6026–BX PORTABLE<br />

TEMPERATURE CONTROLLER, S/N 41177, Watts<br />

Per Heater 18,000<br />

1 – PORTABLE TEMPERATURE CONTROLLER,<br />

MFG'R N/A, OMRON Digital Temperature Controller<br />

Additional Temperature Controllers Located at<br />

Warehouse Location<br />

All payments must be made<br />

payable to Maynards.<br />

4 For more information, visit www.hilcoind.com or www.maynards.com

PROCESS WATER COOLING SYSTEM • MILLS • LATHES • GRINDERS<br />

VIEW OF BRIDGEPORT & LAGUN<br />

VERTICAL MILLING MACHINES<br />

GIDDINGS & LEWIS/BICKFORD<br />

CHIPMASTER 4 ARM X 9”<br />

COLUMN RADIAL DRILL<br />

GALLMEYER & LIVINGSTON<br />

35, 8” X 24” HYDRAULIC<br />

SURFACE GRINDER<br />

COVEL MODEL 7A 6” X 12”<br />

HAND FEED SURFACE GRINDER<br />

LEBLOND MAKINO REGAL SERVO SHIFT<br />

19” X 54” GEARED HEAD ENGINE LATHE<br />

LEBLOND REGAL SERVO SHIFT TOOL & DIE<br />

MAKER 19” X 54” GEARED HEAD ENGINE LATHE<br />

WARNER & SWASEY/NORTON 14X36S–1,<br />

14” X 36” HYDRAULIC SURFACE GRINDER<br />

HOT RUNNER TEMPERATURE<br />

CONTROLLERS<br />

2 – D–M–E MODEL MFPR–26 2–ZONE ELECTRIC HOT RUNNER<br />

TEMPERATURE CONTROLS, S/Ns NA (Missing (1) Zone<br />

Panel Each)<br />

1 – D–M–E 8–ZONE ELECTRIC HOT RUNNER TEMPERATURE<br />

CONTROL, S/N NA (#HT006) (Missing (1) Zone Panel)<br />

1 – D–M–E 15–ZONE ELECTRIC HOT RUNNER TEMPERATURE<br />

CONTROL, S/N NA (#HT008) (Note: Missing (5) Zone Panels)<br />

1 – D–M–E 12–ZONE ELECTRIC HOT RUNNER TEMPERATURE<br />

CONTROLLER, MODEL & S/N NA (Note: Missing (4)<br />

Zone Panels)<br />

1 – IMS 2–ZONE ELECTRIC HOT RUNNER TEMPERATURE<br />

CONTROLLER, S/N 1328, With D–M–E & Athena Circuit Panels<br />

1 – D–M–E MODEL MFP–166 16–ZONE ELECTRIC HOT RUNNER<br />

TEMPERATURE CONTROLLER, S/N N/A (Note: Missing (5) Zone Panels)<br />

1 – D–M–E SINGLE ZONE ELECTRIC HOT RUNNER<br />

TEMPERATURE CONTROLLER, S/N NA (#HT004)<br />

1 – 10–ZONE ELECTRIC HOT RUNNER TEMPERATURE<br />

CONTROLLER, MFG'R NA<br />

BELT CONVEYORS<br />

1 – DYNA CON MODEL 48S2806B0 48” WIDE X 14' LONG<br />

HINGED PLASTIC BELT CONVEYOR, S/N 20693701 (1999),<br />

Motorized, Reversing, Horizontal Transfer Type, Caster<br />

Mounted, Partial Plexiglass Enclosure<br />

1 – PLASTIC PROCESS EQUIPMENT MODEL FIC189,<br />

18” X 10' PORTABLE INCLINED BELT CONVEYOR,<br />

S/N FTC1890VA2921196<br />

1 – 18” X 7' PORTABLE INCLINED BELT CONVEYOR, MFG'R<br />

NA, Plastic Cleated Belt<br />

1 – CINCINNATI–MILACRON MODEL TL–18–10–20, 18” X 10'<br />

PORTABLE POWER BELT CONVEYOR, S/N 3939A01–0023,<br />

Plastic Belt, Dayton Variable Speed Drive Control<br />

1 – PMI 24” X 9' PORTABLE INCLINED MOTORIZED BELT<br />

CONVEYOR, S/N 88016–1–72, Plastic Cleated Belt<br />

1 – 18” X 8' PORTABLE INCLINED BELT CONVEYOR, MFG'R<br />

NA, Cleated Belt<br />

1 – PMI 18” X 8' PORTABLE INCLINED BELT CONVEYOR,<br />

S/N NA, Cleated Belt<br />

1 – PMI 24” X 8' PORTABLE INCLINED BELT CONVEYOR,<br />

S/N NA, Cleated Belt<br />

1 – EMI CORP. MODEL RMC 12–5–20, 12' X 5' PORTABLE BELT<br />

CONVEYOR, S/N M9861, With Receiver Hopper, Cleated Belt,<br />

Adjustable Incline<br />

1 – EMI MODEL RMC–18–5–20, 18” X 5' PORTABLE BELT<br />

CONVEYOR, S/N M–9372, Receiver Hopper, Cleated Belt,<br />

Adjustable Incline<br />

PROCESS WATER COOLING SYSTEM<br />

1 – CENTRAL PROCESS WATER CHILLING/<br />

RECIRCULATION SYSTEM, With:<br />

• (1) McQuay Model WGZ055AW27–ER10 Water Cooled<br />

Reciprocating Chiller/Templifier Heat Pump,<br />

S/N STNU010900062 (2002), 300–Ton, McQuay<br />

Micro–Tech II PLC Controls<br />

• (1) Process Engineering & Equipment Holding &<br />

Recirculation System, With (1) 3' x 8' x 6' High Holding<br />

Tank, (1) 10' x 8' x 6' High Holding Tank, (1) Support<br />

Tower, (2) 10–HP Recirculation Pumps, (2) 3–HP<br />

Recirculation Pumps, (2) 25–HP Recirculation Pumps,<br />

(2) 40–HP Recirculation Pumps, (1) Mueller<br />

Accu–Therm Model AT80–B20 Plate Type Heat<br />

Exchanger, S/N G28516, (1) Central Control Panel,<br />

With Relay Electrics<br />

• (1) Marley Roof Mounted Water Cooling Tower<br />

MILLING MACHINES<br />

1 – BRIDGEPORT SERIES I 2–HP PROGRAMMABLE<br />

VERTICAL MILLING MACHINE, S/N 12BR–193860,<br />

Anilam Crusader II Microprocessor Controls, 48” Table<br />

1 – LAGUN MODEL FTV–1 2–HP VARIABLE SPEED<br />

VERTICAL MILLING MACHINE, S/N SE 36541, 42”<br />

Table, With Servo 140 Power Feed, 4200 RPM,<br />

Acu–Rite Mill–Mate 2– Axis Readout<br />

3 – BRIDGEPORT 1–HP 8–SPEED VERTICAL MILLING<br />

MACHINES, S/Ns 12BR–83209, 12BR–71978 with<br />

Pathfinder 2–Axis Readout, 12BR–139573, 80 – 2720<br />

RPM, 42” Table, 4” Column Riser, Acu–Rite 2–Axis<br />

Readout<br />

1 – BRIDGEPORT 1/2–HP ROUND RAM VERTICAL<br />

MILLING MACHINE, S/N 1872, 32” Table, Shaper<br />

Attachment<br />

1 – TREE VERTICAL TRACER MILLING MACHINE,<br />

S/N 8633, (10) Speeds 60 – 3300 RPM, 48” Table,<br />

Scan–O–Matic 3D Hydraulic Tracer Attachment<br />

1 – KEARNEY & TRECKER MILWAUKEE MODEL D #2<br />

ROTARY HEAD MILLING MACHINE, S/N 1–6612, (15)<br />

Spindle Speeds 250 – 4000 RPM, Power Feeds, 16” x<br />

30” Table, Coolant<br />

1 – LAGUN MODEL FTV–1 2.2 KW VARIABLE SPEED<br />

VERTICAL MILLING MACHINE, S/N NA, 42” Table,<br />

With Servo 140 Power Feed<br />

1 – KEARNEY & TRECKER MILWAUKEE MODEL<br />

10HP–3CH PLAIN HORIZONTAL MILLING MACHINE,<br />

S/N 26–7288, 15 – 1500 RPM Spindle Speeds, 13–1/2”<br />

x 64” Table, Right Angle Attachment<br />

1 – BRIDGEPORT VERTICAL MILLING MACHINE,<br />

S/N 12BR–146531, 42” Table, 7” Riser (Missing Motor)<br />

DRILLS<br />

1 – GIDDINGS & LEWIS/BICKFORD CHIPMASTER 4 ARM X 9” COLUMN RADIAL DRILL,<br />

S/N 2R69, (9) Spindle Speeds 90 – 1800 RPM, 20” x 40” T–Slotted Base, Power Clamp<br />

& Elevate, Plain Box Table<br />

1 – AMERICAN HOLE–WIZARD 4' ARM X 11” COLUMN RADIAL DRILL, S/N 1002, (12)<br />

Spindle Speeds 70 – 2100 RPM, 36” x 57” T–Slotted Base, Plain Box Table<br />

1 – AVEY MODEL 3, 24” SLIDING HEAD BOX COLUMN DRILL, S/N 32376,<br />

(6) Spindle Speeds 95 – 1130 RPM, Power Feed, 25” x 32” Table<br />

1 – ROCKWELL 20” FLOOR TYPE DRILL PRESS, S/N 1740124, Variable Speeds 230 – 4250 RPM<br />

1 – DELTA MODEL 20 CAT. NO. 70 – 230, 20” FLOOR TYPE DRILL PRESS,<br />

S/N 86D72004, (8) Step Pulley Speeds 125 – 1400 RPM, Rockwell Pneumatic Power Down Feed<br />

1 – ROCKWELL MODEL 17–600, 17” FLOOR TYPE DRILL PRESS, S/N 1445883<br />

1 – POWERMATIC 1150, 15” FLOOR TYPE DRILL PRESS, S/N 5–5476–1, Variable Speeds<br />

238 – 4800 RPM<br />

1 – ROCKWELL 15–097, 15” FLOOR TYPE DRILL PRESS, S/N GU 521173 A85<br />

2 – MANHATTAN MODEL 951225, 14” FLOOR TYPE DRILL PRESSES,<br />

S/Ns 238905, 238921<br />

1 – ROCKWELL MODEL 15–017, 15” FLOOR TYPE DRILL PRESS, S/N 1428666<br />

1 – SUN MODEL SF–15, 15” FLOOR TYPE DRILL PRESS, S/N 40147<br />

1 – CUSTOM BUILT SINGLE SPINDLE VERTICAL PRODUCTION DRILLING MACHINE,<br />

With Hy–Pneumat Model D036E–16508–B Drill Head (#34)<br />

LATHES<br />

1 – LEBLOND MAKINO REGAL SERVO SHIFT 19” X 54” GEARED HEAD ENGINE<br />

LATHE, S/N 14E–449, Spindle Speeds 40 – 1600 RPM, Quick Change Threading, 3”<br />

Hole–Thru Spindle, 2–Axis Readout, Coolant, 3 & 4 Jaw Chucks<br />

1 – LEBLOND REGAL SERVO SHIFT TOOL & DIE MAKER 19” X 54” GEARED HEAD<br />

ENGINE LATHE, S/N 5HD206, Spindle Speeds 20 – 2010 RPM, Quick Change<br />

Threading, Taper Attachment, 1–5/8” Hole–Thru Spindle, 3–Jaw Chuck<br />

1 – MONARCH MODEL 18CBB 20.5” X 72” GEARED HEAD ENGINE LATHE,<br />

S/N 25555, (16) Spindle speeds 12 – 487 RPM, Quick Change Threading, Taper<br />

Attachment, 1–1/2” Hole–Thru Spindle, 4–Jaw Chuck<br />

1 – HENDEY MACHINE CO. 14” X 30” GEARED HEAD ENGINE LATHE,<br />

S/N 30846/8–64, (18) Spindle Speeds 19 – 1000 RPM, Quick Change Threading, 1–1/2”<br />

Hole–Thru Spindle, 3–Jaw Chuck<br />

1 – HARDINGE DV–59 DOVETAIL BED TOOLROOM LATHE, S/N DV–59–11471, Variable Speed<br />

1 – HARDINGE DV–59 DOVETAIL BED SECONDARY TOOLROOM LATHE, S/N DV59–4160–3<br />

SURFACE GRINDERS<br />

1 – WARNER & SWASEY/NORTON MODEL 14X36S–1, 14” X 36” HYDRAULIC SURFACE<br />

GRINDER, S/N N–229, Electromagnetic Chuck, Coolant<br />

1 – ABRASIVE MODEL 1218, 12” X 18” HYDRAULIC SURFACE GRINDER, S/N 1218–163,<br />

Electromagnetic Chuck, Coolant<br />

1 – GALLMEYER & LIVINGSTON MODEL 35, 8” X 24” HYDRAULIC SURFACE GRINDER,<br />

S/N S35783, Electromagnetic Chuck (Located in New Buffalo, MI)<br />

1 – GALLMEYER & LIVINGSTON GRAND RAPIDS MODEL 260, 8” X 18” HYDRAULIC<br />

SURFACE GRINDER, S/N 260227, Electromagnetic Chuck, Coolant, Dresser<br />

1 – KENT MODEL KGS–200, 6” X 12” HAND FEED SURFACE GRINDER, S/N 86106,<br />

Electromagnetic Chuck, With Variable Control, Manual Overhead Dresser, External Coolant Unit<br />

1 – COVEL MODEL 7A 6” X 12” HAND FEED SURFACE GRINDER, S/N 7A–6405,<br />

Permanent Magnetic Chuck<br />

To schedule an auction, please contact us at 248.254.9999 5

SAWS • EDMS • QUALITY CONTROL • AIR COMPRESSORS<br />

2001<br />

DOALL C916M SEMI–AUTOMATIC<br />

HORIZONTAL BANDSAW<br />

DAKE 27–121, 50–TON<br />

4–POST HYDRAULIC DIE<br />

TYROUT PRESS<br />

ELOX HRP102C RAM TYPE<br />

ELECTRICAL DISCHARGE<br />

MACHINE<br />

HANSVEDT SM–150B BENCH<br />

TYPE ELECTRICAL<br />

DISCHARGE MACHINE<br />

JONES & LAMSON<br />

CLASSIC 120, 20”<br />

OPTICAL COMPARATOR<br />

2002<br />

INGERSOLL RAND MODEL SSR–EP125, 125–HP<br />

ROTARY SCREW AIR COMPRESSOR<br />

BROWN & SHARPE MICROVAL BENCH<br />

TYPE COORDINATE MEASURING MACHINE<br />

MISCELLANEOUS GRINDERS<br />

1 – NORTON 10” X 24” OD/ID UNIVERSAL GRINDER, S/N P2420, Motorized Work Head, With 6” 4–Jaw<br />

Chuck, Swing–Down Belt Driven ID Spindle, Coolant<br />

1 – FAMCO MODEL 375–LG CUTTER GRINDER, S/N 91E–76907<br />

1 – DECKEL SO SINGLE LIP TOOL GRINDER, S/N 59–1748<br />

1 – COVEL MODEL FP–PT–A YANKEE DRILL POINT GRINDER, S/N 2034<br />

1 – K.O. LEE MODEL B300 X TOOL & CUTTER GRINDER, S/N 15185CL, Double–End Wheel Head,<br />

Cabinet Base<br />

1 – MFG'R NA MODEL SM6015 SINGLE LIP TOOL & CUTTER GRINDER, S/N 010404<br />

SAWS<br />

1 – DOALL MODEL C916M SEMI–AUTOMATIC HORIZONTAL BANDSAW, S/N 527–011478 (2001),<br />

Manual Clamp, Coolant<br />

1 – W.F. WELLS MODEL F–15, 12” X 16” HORIZONTAL METAL CUTTING BANDSAW, S/N 811729,<br />

2–Post Frame, Manual Clamp, Coolant<br />

1 – DOALL 26” VERTICAL METAL CUTTING BANDSAW, S/N 26441119, Blade Speeds 0 – 1600 FPM,<br />

Blade Welder/Grinder, Power Table Feed<br />

1 – WALKER TURNER MODEL 3210, 14” VERTICAL BANDSAW, S/N NA<br />

1 – CRAFTSMAN 10” TABLE SAW, S/N NA, Adjustable Fence<br />

PARTS CLEANING MACHINES<br />

1 – JET WHEEL BLAST EQUIPMENT MODEL DB21A CONVEYORIZED THRU–FEED ABRASIVE<br />

BLAST CLEANING MACHINE, S/N JW90195 (1995), 7–1/2”–HP Shot Wheel, 18” Wide Wire Mesh<br />

Conveyor, Shot Reclaim System, Floor Standing<br />

1 – HUNZIKER MODEL SBS–1502 TUMBLE TYPE PARTS DEFLASHING MACHINE, S/N 832031210,<br />

650 Parts/Hour Rating, 6” x 8' Inclined Power Infeed Conveyor, 12” Diameter Finished Parts Rotary<br />

Outfeed Conveyor, Dust Collector<br />

1 – WHEELABRATOR TUMBLAST BLAST CLEANING MACHINE, S/N A83180, Chamber Size 28” x 19”<br />

Diameter, Rubber Belt, Manual Door, Single Wheel, Self–Contained Media Reclaim System<br />

1 – WHEELABRATOR CENTRALIZED DUST COLLECTOR, S/N NA, 2–Hopper Bottom Discharge<br />

(Outside)<br />

1 – WHEELABRATOR TUMBLAST ABRASIVE BLAST CLEANING MACHINE, S/N NA, 26” Wide x 20”<br />

Diameter Chamber, Rubber Belt, Shot Reclaim System, Dust Collector (Located in New Buffalo, MI)<br />

HYDRAULIC TRYOUT PRESS<br />

1 – DAKE MODEL 27–121, 50–TON 4–POST HYDRAULIC DIE TYROUT PRESS, S/N 141387, 30” x 30”<br />

Between Posts, 32”LR x 26”FB Bolster, Top–Mounted Hydraulics<br />

ELECTRICAL DISCHARGE MACHINES<br />

1 – ELOX MODEL HRP102C RAM TYPE ELECTRICAL DISCHARGE MACHINE,<br />

S/N 293, Work Tank Size 21” x 36” x 12”, Travels 12” X, 18” Y, 12” Z, Futaba 3–Axis Readout, Xermac<br />

HP30 Power Supply<br />

1 – HANSVEDT MODEL SM–150B BENCH TYPE ELECTRICAL DISCHARGE MACHINE, S/N B05187,<br />

6” x 12” Worktable, System 3R Rotary Work Head, SM–150B 30 Amp Power Supply, Acu–Rite 3–Axis<br />

Readout<br />

SHEFFIELD CORDAX MODEL 1808 MEA<br />

COORDINATE MEASURING MACHINE<br />

QUALITY CONTROL<br />

1 – BROWN & SHARPE MICROVAL BENCH TYPE COORDINATE MEASURING MACHINE, S/N NA, 22” x 30”<br />

Granite Table, Renishaw TP–ES Probe<br />

1 – SHEFFIELD CORDAX MODEL 1808 MEA COORDINATE MEASURING MACHINE, S/N 5997–1089 (1989), 30”<br />

x 54” Black Granite Surface Plate, Renishaw Probe, 4–Axis Readout, Computer Control<br />

1 – JONES & LAMSON CLASSIC 120, 20” OPTICAL COMPARATOR, S/N EC5061, Power Table Travel/Elevation,<br />

Nova Light Projection Unit, 2–Axis Readout<br />

1 – SUBURBAN TOOL MASTER VIEW 14” OPTICAL COMPARATOR, S/N 1425–9707M<br />

1 – COVEL 14” OPTICAL COMPARATOR, S/N 14–1192<br />

1 – TINIUS OLSEN EXTRUSION PLASTOMETER, S/N 147605, Model UE–4–78 Digit Set Controller, Model DS–5<br />

Data System<br />

1 – TINIUS OLSEN MODEL 5000 TENSILE TESTER, S/N 156181<br />

1 – COMPUTRAC MAX–2000 PROGRAMMABLE MOISTURE ANALYZER<br />

1 – OMNIMARK MARK 2 HIGH PERFORMANCE PROGRAMMABLE MOISTURE ANALYZER<br />

2 – BLUE M MODEL OV–490A–2 STABIL–THERM ELECTRIC LAB OVENS, S/N OV3–23243, OV3–23236, 600<br />

Degrees Fahrenheit, 1600 Watt, 19” x 15” x 18”, Power–O–Matic 70 Control<br />

1 – THERMOLYNE MODEL 1400–FB1415M ELECTRIC LAB OVEN, S/N 34800750, 1500 Watt, 4–1/2” x 6” x 4–1/2”<br />

1 – NEY MODEL 2–525 BENCH TOP ELECTRIC LAB OVEN, S/N NA, 9” x 9” x 6”<br />

1 – HIPTRONICS HIGH VOLTAGE AC DIELECTRIC TEST SYSTEM, S/N NA, Electrostatic Voltmeter<br />

1 – 24” X 36” X 4” BLACK GRANITE SURFACE PLATE<br />

1 – WILSON MODEL 4JR–PL ROCKWELL HARDNESS TESTER, S/N 4JR–PL3285<br />

Miscellaneous Inspection Equipment Including: Pin Gages, Gage Blocks, Indicators, Level, Calipers, Micrometers, etc.<br />

WELDERS<br />

1 – MILLER SYNCROWAVE 250 DX WELDING POWER SUPPLY, S/N LF076337 (2005), Built–In Water Cooler, Tig<br />

Welding Leads<br />

1 – MILLER DIALARC HF CONSTANT CURRENT AC/DC WELDING POWER SUPPLY, S/N JG089628, 250 Amp<br />

Maximum Output, With Radiator 1 Water Cooling System, Tig Welding Leads<br />

1 – MILLER MODEL 330A/BP WELDING POWER SUPPLY, S/N U481610<br />

1 – MILLER RAMROD 200 AMP DC SHIELDED METAL ARC WELDING POWER SUPPLY, S/N JB475798<br />

2 – LINCOLN IDEALARC 250 DC ARC WELDERS, S/Ns AC245073, AC114700<br />

1 – LINCOLN SAE 600, 600 AMP GENERATOR TYPE ARC WELDER, S/N A386752<br />

1 – TAYLOR WINFIELD 20 KVA ROCKER ARM SPOT WELDER, S/N NA<br />

AIR COMPRESSORS & RELATED EQUIPMENT<br />

1 – INGERSOLL RAND MODEL SSR–EP125, 125–HP ROTARY SCREW AIR COMPRESSOR, S/N F38610U02340<br />

(2002), Water Cooled, 571 CFM, 125 PSIG, Sound Enclosure Panels, Intellisys Microprocessor Controls<br />

1 – KAESER MODEL BS61, 50–HP ROTARY SCREW AIR COMPRESSOR, S/N 5103197, 240 CFM, 110 PSIG,<br />

Sound Enclosure Panels<br />

1 – GARDNER DENVER MODEL EJBRFA 25–HP HORIZONTAL TANK MOUNTED ROTARY SCREW AIR<br />

COMPRESSOR, S/N M48659<br />

1 – INGERSOLL RAND T30 MODEL 223X5, 5–HP TWO–STAGE AIR COMPRESSOR HEAD & MOTOR, S/N 30T<br />

908112, Base Mounted (No Tank)<br />

1 – ARROW PNEUMATICS MODEL A–100–1 REFRIGERATED COMPRESSED AIR DRYER, S/N LH214, 100 SCFM<br />

1 – SULLAIR MODEL SRD 105 REFRIGERATED COMPRESSED AIR DRYER, S/N 003–D5417<br />

1 – ULTRA AIR MODEL NA REFRIGERATED COMPRESSED AIR DRYER, S/N U00859<br />

6 For more information, visit www.hilcoind.com or www.maynards.com

FORKLIFTS • VEHICLES • CRANES & HOISTS<br />

VIEW OF CLARK & DAEWOOO FORKLIFTS<br />

TO 15,000-LBS.<br />

3–TON X 10–1/2' SPAN<br />

UNDERSLUNG BRIDGE CRANE<br />

5–TON X 28' SPAN TOP RIDING<br />

SINGLE GIRDER BRIDGE CRANE<br />

FORKLIFTS & ACCESSORIES<br />

1 – CLARK MODEL CGC70, 15,000–LB. CAPACITY<br />

FORKLIFT, S/N CGC470L–0019–6886FB, LPG, Solid<br />

Tires, 189” Lift, Genesis Series 3–Stage Clear–View<br />

Mast, Side Shift, Overhead Tilt Cylinders, 48” Forks<br />

(Approximately 0460 Hrs.)<br />

1 – DAEWOO MODEL GC–18S–2, 3500–LB, CAPACITY<br />

FORKLIFT, S/N C2–00020, LPG, Solid Tires, 189” Lift,<br />

3–Stage Mast, Side Shift, 48” Forks (@ 4500 Hrs.)<br />

1 – CLARK MODEL ECS 27 SIT–DOWN RIDER TYPE<br />

ELECTRIC FORKLIFT, S/N NA, APPROXIMATELY<br />

3000–LB. Capacity, 3–Stage Mast, Side Shift, 48” Forks<br />

1 – CLARK MODEL TM15, 2800–LB. CAPACITY<br />

SIT–DOWN RIDER ELECTRIC FORKLIFT, S/N<br />

TM247–0516–684, 3–Wheel Chassis, 170” Lift,<br />

3–Stage Mast, 42” Forks, 36–Volt<br />

1 – CLARK MODEL TM15, 2575–LB. CAPACITY<br />

SIT–DOWN RIDER ELECTRIC FORKLIFT,<br />

S/N TM247–0268–7875FB, 3–Wheel Chassis, 170” Lift,<br />

3–Stage Mast, Side Shift, 42” Forks, 36–Volt<br />

1 – CLARK MODEL CMC 15L 2200–LB. CAPACITY<br />

FORKLIFT, S/N CMC158L–1196–6853KF, LPG, Solid<br />

Tires, 189” Lift, 3–Stage Mast, Side Shift, 42” Forks<br />

(7570 Hrs.)<br />

1 – CLARK MODEL TM15, 2150–LB. CAPACITY<br />

SIT–DOWN RIDER ELECTRIC FORKLIFT,<br />

S/N TM247–0101–6840FA, 3–Wheel Chassis, 170” Lift,<br />

3–Stage Mast, 36–Volt<br />

1 – CLARK MODEL C20, 2000–LB. CAPACITY FORK-<br />

LIFT, S/N C20B–764–2080, LPG, Solid Tires, 130” Lift,<br />

2–Stage Mast, 42” Forks<br />

1 – CLARK MODEL ST20, 2000–LB. CAPACITY<br />

WALK–BEHIND ELECTRIC FORKLIFT, S/N<br />

ST245–152–2224, 108” Lift, 24–Volt<br />

1 – LEWIS SHEPARD JACK STACKER TYPE E4SST–36,<br />

4000–LB. CAPACITY WALK–BEHIND ELECTRIC<br />

FORKLIFT, S/N JS5674<br />

1 – HERTNER AUTO 5000 MODEL 3TD18–865,<br />

36–VOLT/195 AMP INDUSTRIAL FORKLIFT BAT-<br />

TERY CHARGER, S/N 0H34541<br />

1 – CALDWELL MODEL PB–40, 4000–LB. CAPACITY<br />

TELESCOPIC FORKLIFT JIB BOOM ASSEMBLY,<br />

S/N 83919, 1500–LB. Capacity at 12'<br />

1 – TELESCOPIC BOOM FORKLIFT JIB ATTACHMENT<br />

SCISSORS LIFT WORK PLATFORM<br />

1 – ECONOMY CUB XT MODEL CS–2033XT BATTERY<br />

POWERED SCISSORS LIFT WORK PLATFORM, S/N<br />

GJ–74563, 20' Maximum Lift Height, 500–LB. Capacity,<br />

24–Volt, Built–In Charger, 28” x 90” Platform, 36”<br />

Platform Extension<br />

VEHICLES<br />

1 – 2000 FORD F650 XLT SUPER DUTY SINGLE AXLE<br />

BOX VAN TRUCK, VIN: 3FDNF65YXYMA42170,<br />

Cummins 1SB 240 Diesel, 6–Speed, 26,000–LB.<br />

GVWR, 8500–LB. Front/17,500–LB. Rear, Hydraulic<br />

Brakes, Supreme 26' FRP Box Van Body, Roll–Up Door,<br />

Landing Gear Support Legs, 10:00 R22.5 Tires, Air<br />

Conditioning (343,173 Miles)<br />

1 – 1996 FORD F700 SINGLE ANLE BOX VAN TRUCK,<br />

VIN: 1FDNF70JXTVA16800, V–8 Gas, 6–Speed,<br />

26,000 GVWR, 7000–LB. Front/19,000–LB. Rear<br />

Hydraulic Brakes, Supreme 22' FRP Van Body, Roll–Up<br />

Door, Air Conditioning, 10R22.5 Tires (203,815 Miles)<br />

1 – 1985 GMC 7000 SINGLE AXLE BOX VAN TRUCK,<br />

VIN: 1GDL7D1E3FV501997, V–8 Gas, 5–Speed,<br />

28,000 GVWR, 9000–LB. Front/19,000–LB. Rear,<br />

Hydraulic Brakes, Supreme 20' Aluminum Van Body,<br />

Roll–Up Door<br />

1 – 1995 FORD F150 XL PICK UP TRUCK,<br />

VIN: 1FTDF15Y6SLA16628, 4.9 L–6 Gas Engine,<br />

5–Speed, Standard Cab, Dual Tanks, Air Conditioning<br />

1 – 1997 FORD TAURUS GL 4–DOOR SEDAN, S/N 1FAL<br />

P520XV G140454<br />

WAREHOUSE & PACKAGING EQUIPMENT<br />

1 – RACK ENGINEERING ADJUSTABLE PALLET RACKING, (12) SECTIONS, Boltless Shelf<br />

Type 100” Wide x 40” Deep x 10' High, 2–Tier, Drop Hock Type Cross Beams, Structural<br />

Channel Steel Cross Beams, Plywood Decks<br />

1 – LANTECH LAN–WRAPPER V–SERIES MODEL SVGSS06501601 PALLET SHRINK WRAP<br />

MACHINE, S/N 17355, 48” x 48” Table, 60” Vertical<br />

1 – HIGHLIGHT INDUSTRIES SYNERGY 3–SEMI AUTOMATIC PALLET SHRINK WRAP<br />

MACHINE, S/N K294–009–4465A1, Allen Bradley SLC500 PLC Control, 72” Vertical, 48” x 48”<br />

Table<br />

1 – BEST PACK 1AS–75R CARTON SEALER, S/N 941065 (1994), Top & Bottom Tape Applicators,<br />

Roller Conveyor, With Adjustable Power Belt Side Conveyors, 18” Maximum Width (Rob & Heidi<br />

Orlaske Estate)<br />

1 – LITTLE DAVID CARTON SEALER, MODEL & S/N NA, Top & Bottom Tape Applicators,<br />

Motorized Conveyor<br />

1 – STANLEY BOSTITCH MODEL FC95EC ELECTRIC FLOOR TYPE CARTON STAPLER, S/N<br />

M–11483,<br />

2 – ACME FLOOR TYPE ELECTRIC CARTON STITCHERS, S/Ns N/A<br />

1 – TOLEDO FLOOR STANDING ELECTRONIC PLATFORM SCALE, Converted Mechanical, 48”<br />

x 60” Platform, 5000–LB. Capacity, 1–LB. Increments, With B–Tek Bullseye Programmable<br />

Readout/Counting Scale, Counting Scale Capacity 50–LB. x .005–LB.<br />

1 – METTLER TOLEDO ELECTRONIC BENCH SCALE<br />

2 – METTLER TOLEDO MODEL 1938, 50–LB. CAPACITY ELECTRONIC BENCH SCALES,<br />

S/Ns 2692577–2RV, 2762373–2RV<br />

1 – TOLEDO MODEL 2181, 1000–LB. CAPACITY MECHANICAL PLATFORM/COUNTING<br />

SCALE, S/N 17233, Dial Face, Portable<br />

1 – METTLER TOLEDO MODEL C–30 ELECTRONIC BENCH SCALE, S/N 5003130–5NZ,<br />

Capacity 60 x 0.01–LB., With Remote Keyboard Type Programmable Readout<br />

1 – TOLEDO MODEL 8582, 50–LB. CAPACITY ELECTRONIC BENCH SCALE, S/N 2483081–20R<br />

1 – TOLEDO MODEL 8582, 100–LB. CAPACITY ELECTRONIC BENCH SCALE,<br />

S/N 2765392–2SV<br />

1 – METTLER TOLEDO MODEL 1938, 50–LB. CAPACITY ELECTRONIC BENCH SCALE,<br />

S/N 2940602–2QY, Portable Steel Cart Mounted<br />

1 – DATAMAX I CLASS BAR CODE LABEL PRINTER<br />

MISCELLANEOUS MACHINERY<br />

1 – RIDGID MODEL 400 POWER PIPE THREADER, S/N NA<br />

1 – RIDGID MODEL 300 POWER PIPE THREADER<br />

1 – COLL–O–CRIMP MODEL T–400 HYDRAULIC HOSE CRIMPING PRESS, S/N NA, With<br />

Hydraulic Unit, Beverly Hand Shear, Cut–Off Saw, Cart<br />

1 – PEXTO MODEL 137L 36” X 16 GAUGE FOOT SHEAR, S/N 17931182<br />

1 – PEXTO MODEL 390–P 36” 16–18 GAUGE SLIP ROLLS, S/N 12760<br />

1 – DRIES & KRUMP CHICAGO MODEL L–30, 36” FINGER TYPE HAND BENDING BRAKE, S/N<br />

96966<br />

1 – 20–TON H–FRAME HYDRAULIC SHOP PRESS<br />

1 – ATLAS NO. 4 ARBOR PRESS<br />

1 – DEE–BLAST 44” X 36” ABRASIVE BLAST CABINET, S/N DB10854, 3–Bag Dust Collection<br />

1 – HUPPERT MODEL ST ELECTRIC BOX FURNACE, S/N 83, 2000 Degree Fahrenheit, 14” x 16”<br />

x 24”, 15 KW, Honeywell Digital Heat Controls<br />

1 – HUPPERT MODEL ST ELECTRIC BOX FURNACE, S/N 143, 1500 Degrees Fahrenheit, 8” x<br />

10” x 20”, 10 KW<br />

1 – DAKE MODEL 25H 25–TON H–FRAME HYDRAULIC SHOP PRESS, S/N 147655, Manual<br />

1 – GORTON MODEL P2–3, 3D PANTOGRAPH ENGRAVER, S/N 37843<br />

1 – NATCO 4–POST VERTICAL 500–TON HYDRAULIC COMPRESSION MOLDING PRESS, S/N<br />

NA, Bed Size 30”LR x 26”FB, Floor Standing, Self–Contained (Located in New Buffalo, MI)<br />

1 – EVANS STEWART & CO. MODEL 00 1/4” CAPACITY ROTARY FINE BRUSHER/SAMPLER,<br />

S/N 1285 (#10)<br />

3 – LOGAN MODEL D–2500, 125–TON CAPACITY PRE–FORM BRIQUETTING PRESSES, S/Ns<br />

NA, 2–1/4” Diameter Puck Size<br />

2 – COTTERMANN DRUMASTER BATTERY POWERED HYDRAULIC DRUM TILTERS, S/Ns NA,<br />

Portable<br />

1 – LOCTITE MODEL 400mi PNEUMATIC APPLICATOR GUN, P/N 983439, With Assembly Bench<br />

1 – DUKANE MODEL 43A175 ULTRA 1000 AUTO TRAC ULTRASONIC WELDER POWER SUP-<br />

PLY, S/N US 80093, With Hand Held Spot Type Welding Gun, S/N US 146538<br />

1 – SERVICE TECTRONICS INC. PAT–A–PRINT MODEL 802 PAD PRINTER, S/N 5144–684, With<br />

10” Vibratory Bowl Feeder<br />

1 – 8' X 16' X 8–1/2' HIGH FREE–STANDING MODULAR OFFICE ALL–AROUND WINDOWS, (1)<br />

Access Door, Window A/C Unit<br />

1 – 8' X 20–1/2' X 8' HIGH FREE–STANDING 2 OFFICE MODULAR OFFICE STRUCTURE,<br />

Windows, (1) 8' x 9–1/2' Office, (1) 8' x 10' Office, Each, With Window A/C Unit<br />

1 – 20–HP PORTABLE ELECTRIC HYDRAULIC POWER UNIT, With Control Valves & Hoses<br />

1 – 15–HP PORTABLE ELECTRIC HYDRAULIC POWER UNIT, With Control Valves & Hoses<br />

2 – 10–HP PORTABLE ELECTRIC HYDRAULIC POWER UNITS, With Control Valves & Hoses<br />

PROCESS STEAM BOILERS<br />

1 – VA POWER MODEL TRG–5901–Y2HJ–300 STEAM<br />

BOILER, S/N 17385, Natural Gas or Oil Fired, 300–HP,<br />

25 PSI W.P.<br />

1 – CYCLOTHERM MODEL 300G–06N–23A NATURAL<br />

GAS FIRED STEAM BOILER, S/N NA, 300–HP, 300<br />

PSI W.P.<br />

1 – STEAM CONDENSATE SYSTEM<br />

CRANES & HOISTS<br />

1 – LOAD LIFTER 8–TON X 12' SPAN UNDERSLUNG<br />

SINGLE GIRDER BRIDGE CRANE, With CM Cyclone<br />

8–Ton Manual Chain Fall, Manual Bridge & Trolley<br />

Travels, Approximately 70' Suspended Runway Rails<br />

1 – TM 5–TON X 20' SPAN TOP RIDING SINGLE GIRDER<br />

BRIDGE CRANE, S/N 14826, CM Powerstar 5–Ton<br />

Electric Chain Hoist, 6–Way Power Travel, Pendant<br />

Control<br />

1 – BUDGIT 3–TON MANUAL CHAIN FALL, With<br />

Approximately 20' Long 2–Post Free–Standing I Beam<br />

Monorail, 13–1/2' Under Rail<br />

1 – 5–TON X 28' SPAN TOP RIDING SINGLE GIRDER<br />

BRIDGE CRANE, S/N 911735, Shaw Box Electric<br />

Cable Hoist, 6–Way Power Pendant Controls, Class B,<br />

Single Speed, 90' Runway Rails (Located in New<br />

Buffalo, MI)<br />

1 – 5–TON X 28' SPAN TOP RIDING SINGLE GIRDER<br />

BRIDGE CRANE, Budgit 5–Ton Manual Chain Fall,<br />

Manual Travels (Located in New Buffalo, MI)<br />

1 – 3–TON X 10–1/2' SPAN UNDERSLUNG SINGLE GIRD-<br />

ER BRIDGE CRANE, S/N 911705, Class B, Budgit<br />

Electric Chain Hoist, Manual Bridge & Trolley Travel, 15'<br />

Under Rail, 20' Free Standing Runway Structure<br />

(Located in New Buffalo, MI)<br />

1 – JET 5–TON MANUAL CHAIN FALL, With<br />

Approximately 30' I Beam Monorail<br />

1 – JET 2–TON MANUAL CHAIN FALL, With<br />

Approximately 60' I Beam Monorail<br />

1 – BUDGIT 3–TON ELECTRIC CHAIN HOIST (Located in<br />

New Buffalo, MI)<br />

1 – BUDGIT 2–TON ELECTRIC CHAIN HOIST, With Power<br />

Trolley (Located in New Buffalo, MI)<br />

2 – BUDGIT & CM 2–TON ELECTRIC CHAIN HOISTS<br />

(Located in New Buffalo, MI)<br />

1 – BUDGIT 1–TON ELECTRIC CHAIN HOIST, With 40'<br />

Suspended I Beam Monorail<br />

1 – JET 2–TON CHAIN FALL<br />

1 – CM 2–TON CHAIN FALL<br />

3 – BUDGIT 2–TON CHAIN FALLS<br />

1 – 3–TON X 20' SPAN UNDERSLUNG SINGLE GIRDER<br />

BRIDGE CRANE, Budgit 3–Ton Electric Chain Hoist,<br />

Manual Travels<br />

1 – 2–TON X 20' SPAN UNDERSLUNG SINGLE GIRDER<br />

BRIDGE CRANE, Budgit 2–Ton Manual Chain Fall,<br />

Manual Travels<br />

2 – 2–TON X APPROXIMATELY 18' SPAN UNDERSLUNG<br />

SINGLE GIRDER BRIDGE CRANES, With Budgit<br />

2–Ton Manual Chain Falls, Manual Travels<br />

SHOP & FACTORY<br />

Large Quantity Maintenance & Repair Parts, Storeroom Crib,<br />

General Shop & Factory Equipment, Double–End Grinders,<br />

Hand & Power Tools, etc.<br />

MATERIAL INVENTORY & MOLDS<br />

Over (50) Gaylord Boxes of Assorted Plastic Material<br />

Over (100) Assorted Molds<br />

OFFICES<br />

Quantity of Office Equipment Including: Computers, Printers,<br />

Copiers, Fax, Plotters, General Business Machines, Office<br />

Furniture<br />

To schedule an auction, please contact us at 248.254.9999 7

Atlanta • Birmingham • Boston • Charlotte • Chicago • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong • Irapuato (MX) • Leeds (UK)<br />

London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York • San Francisco • Southampton (UK) • Toronto • Villahermosa (MX)<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

Auctioneers • Liquidators • Appraisers<br />

Headquarters<br />

31555 W. Fourteen Mile Road, Suite 207<br />

Farmington Hills, MI 48334<br />

Ph: 248.254.9999<br />

Fx: 248.254.9995<br />

www.hilcoind.com<br />

Presorted<br />

First Class Mail<br />

U.S. Postage<br />

PAID<br />

Detroit, Mich.<br />

Permit No. 100<br />

Forwarding Service Requested<br />

<strong>PUBLIC</strong> <strong>AUCTION</strong><br />

By order of the secured creditors, assets of<br />

HILCO <strong>Industrial</strong>, LLC is a division of <strong>Hilco</strong> Trading, Co. • Headquarters 5 Revere Drive, Ste. 430 • Northbrook, IL 60062<br />

All rights reserved • Printed in USA • MODE3342 • IL License #444000215<br />

Please visit our website at www.hilcoind.com to review our complete terms and conditions.<br />

Terms of Sale<br />

A buyer’s premium of 13.5% for onsite sales & 16%<br />

for webcast sales is in effect. Everything will be sold<br />

to the highest bidder for cash, in accordance with the<br />

Auctioneer’s customary “Terms of Sale”, copies of<br />

which will be posted on the premises of the sale and<br />

subject to additional terms announced the day of<br />

sale. All items will be sold “as is, where–is”<br />

without any warranties, express or implied. Although<br />

obtained from sources deemed reliable, the<br />

Auctioneer makes no warranty or guarantee to the<br />

accuracy of the information herein contained. Bidders<br />

are encouraged to thoroughly inspect the items on<br />

which they intend to bid prior to sale. Absolutely no<br />

items will be removed until the day after the conclusion<br />

of the sale and payment is made in full. Subject<br />

to additions, deletions and prior sale. For full terms<br />

and conditions please go to www.maynards.com<br />

Payment: ALL PURCHASES MUST BE PAID IN<br />

FULL ON THE DAY OF THE <strong>AUCTION</strong>. If you intend<br />

to pay by wire transfer, we will accept payment the<br />

day after the sale ONLY IF a deposit of 25% of total<br />

purchases is made on the day of the sale. Contact<br />

our office for wire transfer instructions. Only cash,<br />

wire transfer or certified check, payable to Maynards<br />

will be accepted. Company checks payable to<br />

Maynards will be accepted only if accompanied by a<br />

bank letter of guarantee, (see sample letter below).<br />

All sales are subject to sales tax. Purchasers<br />

claiming exemptions from taxes must provide proof<br />

satisfactory to the Auctioneer of their entitlement to<br />

claim such exemptions.<br />

Sample Bank Letter<br />

(Bank Name) unconditionally guarantees<br />

payment to Maynards from (Company Name).<br />

This guarantee will be valid for purchases<br />

made at the Auction of Modern Plastics<br />

Corporation on October 1, 2008