WEENER PLASTIC INTERNATIONAL EAST KFT in Hungary was ...

WEENER PLASTIC INTERNATIONAL EAST KFT in Hungary was ...

WEENER PLASTIC INTERNATIONAL EAST KFT in Hungary was ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

EXPANDING<br />

HORIZONS<br />

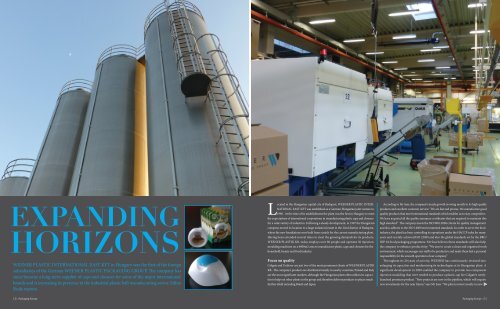

<strong>WEENER</strong> <strong>PLASTIC</strong> <strong>INTERNATIONAL</strong> <strong>EAST</strong> <strong>KFT</strong> <strong>in</strong> <strong>Hungary</strong> <strong>was</strong> the first of the foreign<br />

subsidiaries of the German <strong>WEENER</strong> <strong>PLASTIC</strong> PACKAGING GROUP. The company has<br />

s<strong>in</strong>ce become a long-term supplier of caps and closures for some of the major <strong>in</strong>ternational<br />

brands and is <strong>in</strong>creas<strong>in</strong>g its presence <strong>in</strong> the <strong>in</strong>dustrial plastic ball manufactur<strong>in</strong>g sector. Ed<strong>in</strong>a<br />

Beale reports.<br />

Located <strong>in</strong> the Hungarian capital city of Budapest, <strong>WEENER</strong> <strong>PLASTIC</strong> INTER-<br />

NATIONAL <strong>EAST</strong> <strong>KFT</strong> <strong>was</strong> established as a German-Hungarian jo<strong>in</strong>t venture <strong>in</strong><br />

1990. At the time of its establishment the plant <strong>was</strong> the first <strong>in</strong> <strong>Hungary</strong> to meet<br />

the expectations of <strong>in</strong>ternational corporations <strong>in</strong> manufactur<strong>in</strong>g plastic caps and closures<br />

for a wide variety of <strong>in</strong>dustries. Follow<strong>in</strong>g a steady development, <strong>in</strong> 1997 the Hungarian<br />

company moved its location to a large <strong>in</strong>dustrial estate <strong>in</strong> the 22nd district of Budapest,<br />

where the new foundations were built from scratch for the current manufactur<strong>in</strong>g plant.<br />

Hav<strong>in</strong>g been extended several times to meet the grow<strong>in</strong>g demands for its products,<br />

<strong>WEENER</strong> PLASTIK Kft. today employs over 80 people and operates 30 <strong>in</strong>jection<br />

mould<strong>in</strong>g mach<strong>in</strong>es on a 6000m2 area to manufacture plastic caps and closures for the<br />

household, beauty and food <strong>in</strong>dustry.<br />

Focus on quality<br />

Colgate and Unilever are just two of the most prom<strong>in</strong>ent clients of <strong>WEENER</strong> PLASTIK<br />

Kft.. The company’s products are distributed ma<strong>in</strong>ly <strong>in</strong> nearby countries; Poland and Italy<br />

are the most significant markets, although the Hungarian plant often utilises its capacities<br />

to help out other plants <strong>in</strong> the group and therefore delivers products to places much<br />

further afield <strong>in</strong>clud<strong>in</strong>g Brazil and Japan.<br />

Accord<strong>in</strong>g to Mr Sass, the company’s steady growth is ow<strong>in</strong>g mostly to its high quality<br />

products and excellent customer service: “We are fast and precise. We manufacture good<br />

quality products that meet <strong>in</strong>ternational standards which enables us to stay competitive.<br />

We have acquired all the quality assurance certificates that are required to ma<strong>in</strong>ta<strong>in</strong> this<br />

high standard.” The company meets the ISO 9001:2008 criteria for quality management<br />

and also adheres to the ISO 14000 environmental standards. In order to serve the food<br />

<strong>in</strong>dustry, the plant has been controll<strong>in</strong>g its operations under the HACCP rules for many<br />

years and recently achieved ISO 22000 and also the global standards set by the BRC/<br />

IOP 04 food packag<strong>in</strong>g programme. Mr Sass believes these standards will also help<br />

the company to enhance productivity: “We aim to create a clean and organised work<br />

environment, which encourages our staff to be productive and make them feel a personal<br />

responsibility for the smooth operation of our company.”<br />

Throughout its 20 years of activity, <strong>WEENER</strong> has cont<strong>in</strong>uously <strong>in</strong>vested <strong>in</strong>to<br />

enlarg<strong>in</strong>g its capacities and modernis<strong>in</strong>g its technologies at its Hungarian plant. A<br />

significant development <strong>in</strong> 2009 enabled the company to provide two component<br />

<strong>in</strong>jection mould<strong>in</strong>g that were needed to produce a plastic cap for Colgate’s newly<br />

launched premium product. “New projects are now <strong>in</strong> the pipel<strong>in</strong>e, which will require<br />

new <strong>in</strong>vestments for the near future,” says Mr Sass. “We plan to <strong>in</strong>vest mostly <strong>in</strong> new<br />

| 2 | Packag<strong>in</strong>g Europe<br />

Packag<strong>in</strong>g Europe | 3 |

“We are fast and precise. We manufacture good quality products that<br />

meet <strong>in</strong>ternational standards which enables us to stay competitive.”<br />

mach<strong>in</strong>ery for the next couple of years, but also hope to turn our tool repair<strong>in</strong>g plant<br />

<strong>in</strong>to a tool manufactur<strong>in</strong>g plant.”<br />

New dimensions<br />

S<strong>in</strong>ce a Danish acquisition made by <strong>WEENER</strong> <strong>in</strong> 2006, the Hungarian subsidiary has<br />

also been produc<strong>in</strong>g hollow <strong>in</strong>dustrial plastic balls that require a special manufactur<strong>in</strong>g<br />

technology. “These plastic balls have a great variety of usage,” expla<strong>in</strong>s Mr Ákos Sass,<br />

manag<strong>in</strong>g director of <strong>WEENER</strong> PLASTIK Kft. “Apart from be<strong>in</strong>g widely popular <strong>in</strong><br />

children’s play areas they are a suitable tool for therapies and can be used for many different<br />

<strong>in</strong>dustrial applications as well as <strong>in</strong> sewage systems or galvanis<strong>in</strong>g plants. This new<br />

element of the company’s product portfolio today contributes a significant €1.4 million to<br />

our total annual turnover of €9 million.”<br />

The company’s strategic plan is to strengthen their presence and operations <strong>in</strong> the<br />

plastic ball manufactur<strong>in</strong>g sector. “We believe there are many unexploited opportunities<br />

<strong>in</strong> this market,” claims Mr Sass. “The environmental usages of these plastic technical balls<br />

are extremely extensive; therefore we are currently focus<strong>in</strong>g on modernis<strong>in</strong>g our facilities<br />

<strong>in</strong> this area so we are prepared to take on these possible future projects.” The company<br />

expects 20 per cent growth for this year, and hope to achieve similar results for next year.<br />

After open<strong>in</strong>g the Hungarian plant, the <strong>in</strong>ternational expansion of the <strong>WEENER</strong> Plastic<br />

Packag<strong>in</strong>g Group has cont<strong>in</strong>ued. The company has established itself <strong>in</strong> Spa<strong>in</strong>, Ireland,<br />

Egypt and Russia. In 2004 a str<strong>in</strong>g of acquisitions began and as a result of that, today the<br />

group has operations <strong>in</strong> 21 countries.<br />

The <strong>WEENER</strong> Plastic Packag<strong>in</strong>g Group <strong>was</strong> first taken over <strong>in</strong> early 2012 by an<br />

American <strong>in</strong>vestor, L<strong>in</strong>dsay Goldberg, LLC, represented by L<strong>in</strong>dsay, Goldberg Vogel<br />

GmbH <strong>in</strong> Düsseldorf, and then, as a follow-up acquisition <strong>in</strong> the plastic packag<strong>in</strong>g<br />

<strong>in</strong>dustry, <strong>PLASTIC</strong>UM Group B.V., based <strong>in</strong> Tilburg, Netherlands <strong>in</strong> September 2012.<br />

“The recent change <strong>in</strong> the ownership structure br<strong>in</strong>gs significant growth potential for<br />

the group and therefore good future prospects for the Hungarian subsidiary too,” says<br />

Mr Sass. “Our long-term goal is to become a significant element <strong>in</strong> the entire <strong>WEENER</strong><br />

Plastic Packag<strong>in</strong>g Group.”<br />

Visit: www.wppg.co.uk<br />

| 4 | Packag<strong>in</strong>g Europe<br />

Packag<strong>in</strong>g Europe | 5 |