Ways to Conserve Energy on Board - DNV

Ways to Conserve Energy on Board - DNV

Ways to Conserve Energy on Board - DNV

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

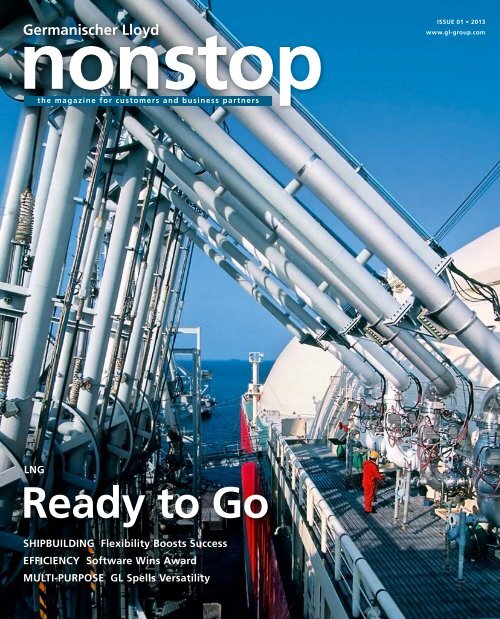

n<strong>on</strong>s<str<strong>on</strong>g>to</str<strong>on</strong>g>p<br />

Germanischer Lloyd<br />

Issue 01 • 2013<br />

www.gl-group.com<br />

the magazine for cus<str<strong>on</strong>g>to</str<strong>on</strong>g>mers and business partners<br />

LNG<br />

Ready <str<strong>on</strong>g>to</str<strong>on</strong>g> Go<br />

SHipbuilding Flexibility Boosts Success<br />

Efficiency Software Wins Award<br />

Multi-purpose GL Spells Versatility

Fuel Cost Reducti<strong>on</strong>.<br />

<str<strong>on</strong>g>Energy</str<strong>on</strong>g> Efficiency by GL.<br />

FutureShip´s maritime c<strong>on</strong>sultants and engineering experts supply energy-saving soluti<strong>on</strong>s for every ship in your fleet.<br />

For instance, the award-winning ECO-Assistant software for optimal ship trim.<br />

www.futureship.de ∙ www.efficiency-class.com ∙ www.gl-group.com

Dear Readers,<br />

EXCITING TIMES LIE AHEAD OF US: We intend <str<strong>on</strong>g>to</str<strong>on</strong>g> master the challenges of the industry, <str<strong>on</strong>g>to</str<strong>on</strong>g> the<br />

benefit of our cus<str<strong>on</strong>g>to</str<strong>on</strong>g>mers, by joining <str<strong>on</strong>g>to</str<strong>on</strong>g>gether with our Norwegian competi<str<strong>on</strong>g>to</str<strong>on</strong>g>r <strong>DNV</strong> – and are<br />

currently hard at work preparing the merger forming the <strong>DNV</strong> GL Group. For both partners,<br />

this step represents a m<strong>on</strong>umental change.<br />

Experience, competence and innovative strength have formed GL and <strong>DNV</strong> over a period<br />

of almost 150 years in<str<strong>on</strong>g>to</str<strong>on</strong>g> reliable partners for the maritime industry and the business fields of<br />

oil and gas, renewable energies and plant engineering. For all segments, the merger opens up<br />

an enormous vista of possibilities – and will offer the best of both worlds, particularly for our<br />

cus<str<strong>on</strong>g>to</str<strong>on</strong>g>mers and business partners. This is our pledge <str<strong>on</strong>g>to</str<strong>on</strong>g> you!<br />

Erik van der Noordaa<br />

SUBSTANTIATED RESULTS are being delivered by the GasPax project. This research programme<br />

is focused <strong>on</strong> LNG as a viable fuel for cruise liners, ferries and mega-yachts. The project partners<br />

are well <strong>on</strong> the way <str<strong>on</strong>g>to</str<strong>on</strong>g>wards making shipping even more efficient and ecological. “Ready<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> build!” was the message given at GL’s GasPax Forum (page 16). The technology is there –<br />

now the infrastructure for bunkering is required. A study under GL management analyses the<br />

prerequisites needed for the safe supply of gas (page 18) in German ports.<br />

ON THE OPEN SEA, ship crews often have <str<strong>on</strong>g>to</str<strong>on</strong>g> fend for themselves. High waves cause intensive<br />

sloshing within the LNG tanks, which may lead <str<strong>on</strong>g>to</str<strong>on</strong>g> loss of cargo and costly repairs (page 12).<br />

For this, GL offers the software soluti<strong>on</strong> GL SeaScout, which assists in choosing the best alternative<br />

route. On the other hand, not every ship is exposed <str<strong>on</strong>g>to</str<strong>on</strong>g> heavy seas. With a new class<br />

notati<strong>on</strong>, GL has developed loading rules for route-dependent c<strong>on</strong>tainer s<str<strong>on</strong>g>to</str<strong>on</strong>g>wage. Greater<br />

flexibility of loading is now possible without compromising safety (page 49).<br />

SAVING COSTS, reducing the probability of failure, increasing operati<strong>on</strong>al reliability: the use of<br />

digital 3D models is a proven approach. The GL Emissi<strong>on</strong>Manager, for example, analyses and<br />

prepares the relevant informati<strong>on</strong> with great precisi<strong>on</strong> <str<strong>on</strong>g>to</str<strong>on</strong>g> yield the basis for reducing pollutant<br />

emissi<strong>on</strong>s. GL is currently probing further applicati<strong>on</strong>s for 3D models (page 46).<br />

THE QUEST FOR EFFICIENCY AND ENVIRONMENTAL COMPATIBILITY remains a key driver for innovati<strong>on</strong>.<br />

In the field of hull and trim optimisati<strong>on</strong>, the GL subsidiary FutureShip is a world<br />

leader: the GL software ECO-Assistant has received the Lloyd’s List Asia Award for Envir<strong>on</strong>ment<br />

(page 42). Just as award-worthy are the new potentials for saving energy <strong>on</strong> board<br />

(page 33) that were identified by FutureShip in a study <strong>on</strong> the cooling water systems of ships.<br />

And a special commendati<strong>on</strong> for the work of the GL engineers is reported in an entirely different<br />

field: the world-renowned Volvo Ocean Race will be held with a <strong>on</strong>e-design class in future.<br />

The structural strength of the racing yachts will then be certified by GL (page 22).<br />

I wish you an interesting read!<br />

Erik van der Noordaa<br />

Chairman of the Executive <strong>Board</strong>, Germanischer Lloyd SE<br />

01/2013<br />

3

n<strong>on</strong>s<str<strong>on</strong>g>to</str<strong>on</strong>g>p<br />

c<strong>on</strong>tents<br />

Pho<str<strong>on</strong>g>to</str<strong>on</strong>g>: Volvo Ocean Race<br />

12 22<br />

Pho<str<strong>on</strong>g>to</str<strong>on</strong>g>s: Dps.fo<str<strong>on</strong>g>to</str<strong>on</strong>g>/Romanausks/Surz01 | Dreamstime.com<br />

lng market<br />

12 Str<strong>on</strong>g Forces<br />

Persistent sloshing in partly loaded LNG carrier tanks<br />

can cause extensive damage <str<strong>on</strong>g>to</str<strong>on</strong>g> the tank walls. The<br />

GL SeaScout software provides <strong>on</strong>-board assistance<br />

16 Laying the Groundwork for LNG<br />

The GasPax research project produced the desired<br />

results: fully developed designs for passenger vessels<br />

propelled by LNG<br />

18 Wanted: Reliable Gas Supply<br />

Legal stipulati<strong>on</strong>s, logistics requirements and<br />

technical challenges: a new study shows how LNG<br />

bunkering can be made a reality in German ports<br />

22 Safer Racing<br />

There’s a thin line between ultra-lightweight design and<br />

structural strength. Volvo Ocean Race has the structural<br />

design of its next-generati<strong>on</strong> racing yachts certified by GL<br />

28 “We Resp<strong>on</strong>d Flexibly <str<strong>on</strong>g>to</str<strong>on</strong>g> Cus<str<strong>on</strong>g>to</str<strong>on</strong>g>mer Requests”<br />

Successful over five generati<strong>on</strong>s: the Fassmer yard has<br />

l<strong>on</strong>g since reacted <str<strong>on</strong>g>to</str<strong>on</strong>g> the upheaval of the shipbuilding<br />

landscape and is already active in wind energy<br />

38 Licensed <str<strong>on</strong>g>to</str<strong>on</strong>g> Lift<br />

The world market leader in the classificati<strong>on</strong> of c<strong>on</strong>tainer<br />

ships is also in demand for multi-purpose cargo carriers.<br />

More than 1,100 MPVs are classed by GL<br />

extra<br />

33 More <str<strong>on</strong>g>Ways</str<strong>on</strong>g> <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>C<strong>on</strong>serve</str<strong>on</strong>g> <str<strong>on</strong>g>Energy</str<strong>on</strong>g> <strong>on</strong> <strong>Board</strong><br />

A new study c<strong>on</strong>ducted by FutureShip analyses the energy<br />

c<strong>on</strong>sumpti<strong>on</strong> of the complex cooling water circuit<br />

4 n<strong>on</strong>s<str<strong>on</strong>g>to</str<strong>on</strong>g>p

28 42<br />

Pho<str<strong>on</strong>g>to</str<strong>on</strong>g>: Fassmer<br />

efficiency gl world<br />

42 Optimising Optimisati<strong>on</strong><br />

Efficient and eco-friendly: GL’s c<strong>on</strong>sultancy arm, Future-<br />

Ship, is a world leader in the complex fields of hull and<br />

trim optimisati<strong>on</strong>. Its ECO-Assistant software recently<br />

received a prestigious award<br />

46 New Dimensi<strong>on</strong>s<br />

using 3D models facilitates data acquisiti<strong>on</strong> and<br />

evaluati<strong>on</strong> for ships of any type. GL is examining the<br />

potential offered by other areas of operati<strong>on</strong><br />

49 Route-Specific Box Loading<br />

GL is preparing more flexible deck s<str<strong>on</strong>g>to</str<strong>on</strong>g>wage rules<br />

6 Perspectives: Høvik Ahead!<br />

Powerful uni<strong>on</strong>: GL Group and <strong>DNV</strong> are joining forces <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

form <strong>DNV</strong> GL Group. Corporate headquarters will be in<br />

høvik near Oslo<br />

8 News<br />

32 GL Academy: Seminars worldwide<br />

50 Service: Exhibiti<strong>on</strong>s, rules and<br />

guidelines, imprint<br />

Cover: Mayumi Terao/iS<str<strong>on</strong>g>to</str<strong>on</strong>g>ckpho<str<strong>on</strong>g>to</str<strong>on</strong>g><br />

01/2013<br />

5

perspectives<br />

Høvik Ahead!<br />

The missi<strong>on</strong> <str<strong>on</strong>g>to</str<strong>on</strong>g> merge the GL Group and <strong>DNV</strong> has been<br />

successfully started. On their way <str<strong>on</strong>g>to</str<strong>on</strong>g> build the new <strong>DNV</strong><br />

GL Group, the partners are well <strong>on</strong> track with all the necessary<br />

pre-arrangements.<br />

Announced last December, the merger will create a<br />

leading ship classificati<strong>on</strong> society and risk expert in the oil<br />

and gas, renewable energy and power sec<str<strong>on</strong>g>to</str<strong>on</strong>g>rs, and <strong>on</strong>e of<br />

the leading providers of management system certificati<strong>on</strong>.<br />

The maritime business unit will be headquartered in Hamburg,<br />

Germany, while maintaining its commitment <str<strong>on</strong>g>to</str<strong>on</strong>g> the<br />

Norwegian maritime cluster. The <strong>DNV</strong> GL Group’s global<br />

headquarters will be in Høvik near Oslo.<br />

The parties are currently involved in the merger c<strong>on</strong>trol<br />

proceedings of the competent competiti<strong>on</strong> authorities.<br />

They are c<strong>on</strong>fident that the merger c<strong>on</strong>forms <str<strong>on</strong>g>to</str<strong>on</strong>g> all<br />

relevant competiti<strong>on</strong> rules and expect <str<strong>on</strong>g>to</str<strong>on</strong>g> gain the necessary<br />

approvals.<br />

With proper planning and attenti<strong>on</strong> <str<strong>on</strong>g>to</str<strong>on</strong>g> detail throughout<br />

the merger process, from determining the strategic directi<strong>on</strong><br />

and transacti<strong>on</strong> design <str<strong>on</strong>g>to</str<strong>on</strong>g> careful executi<strong>on</strong> of the<br />

post-merger integrati<strong>on</strong> and branding, diligent adherence<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> the agreed-up<strong>on</strong> merger principles will pave the way<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> a successful merger of GL and <strong>DNV</strong> <strong>on</strong>ce all approvals<br />

have been achieved.<br />

Pho<str<strong>on</strong>g>to</str<strong>on</strong>g>: <strong>DNV</strong><br />

6 n<strong>on</strong>s<str<strong>on</strong>g>to</str<strong>on</strong>g>p

Headquarters. The future home<br />

of the merged <strong>DNV</strong> GL Group in<br />

Høvik near Oslo, Norway.<br />

01/2013 7

n<strong>on</strong>s<str<strong>on</strong>g>to</str<strong>on</strong>g>p<br />

news<br />

<str<strong>on</strong>g>Energy</str<strong>on</strong>g> Management System<br />

A Model for the<br />

Shipping Industry<br />

Pho<str<strong>on</strong>g>to</str<strong>on</strong>g>: Rickmers<br />

Audit. “Rickmers<br />

Singapore” has been<br />

certified <str<strong>on</strong>g>to</str<strong>on</strong>g> ISO 50001.<br />

Rickmers Shipmanagement becomes the<br />

first German company operating in the<br />

maritime industry and <strong>on</strong>e of <strong>on</strong>ly a handful<br />

of shipping companies in the world <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

achieve certificati<strong>on</strong> <str<strong>on</strong>g>to</str<strong>on</strong>g> the ISO 50001 Ener-<br />

Certificate handover. The GL and<br />

Rickmers audit team for ISO 50001.<br />

gy Management System standard. GL Systems<br />

Certificati<strong>on</strong> (GL) issued the accredited<br />

ISO 50001 certificati<strong>on</strong> for the Rickmers offices<br />

in Hamburg and Singapore, as well as<br />

for ten ships from their fleet. The handover<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g>ok place at the Rickmers’ head office in<br />

Hamburg last January. All audits were completed<br />

successfully by GL audi<str<strong>on</strong>g>to</str<strong>on</strong>g>rs in 2012,<br />

with plans in place <str<strong>on</strong>g>to</str<strong>on</strong>g> add nine more ships<br />

in early 2013.<br />

ISO 50001 is a voluntary internati<strong>on</strong>al<br />

standard that gives companies a framework<br />

for developing targets and implementing<br />

policies with the aim of improving energy<br />

efficiency, quality of services and reducti<strong>on</strong><br />

in emissi<strong>on</strong>s. The successful implementati<strong>on</strong><br />

of the ISO 50001 standard within a period<br />

of just six m<strong>on</strong>ths underlines the support<br />

and commitment from Rickmers’ <str<strong>on</strong>g>to</str<strong>on</strong>g>p management<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> energy efficiency. “In shipping<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g>day, making more efficient use of energy<br />

is not <strong>on</strong>ly a key fac<str<strong>on</strong>g>to</str<strong>on</strong>g>r in a company’s strategy<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> reduce its impact <strong>on</strong> the envir<strong>on</strong>ment<br />

but an essential part of remaining competitive<br />

and reducing bunker costs substantially,”<br />

said Björn Sprotte, Rickmers’ Global<br />

Head of Maritime Services.<br />

For Further Informati<strong>on</strong>:<br />

Philipp Schwarmann, Product Manager <str<strong>on</strong>g>Energy</str<strong>on</strong>g> Management<br />

Ph<strong>on</strong>e: +49 40 36149-8674<br />

E-Mail: philipp.schwarmann@gl-group.com<br />

implementati<strong>on</strong><br />

C<strong>on</strong>diti<strong>on</strong> M<strong>on</strong>i<str<strong>on</strong>g>to</str<strong>on</strong>g>ring Survey Arrangement for Engine Pis<str<strong>on</strong>g>to</str<strong>on</strong>g>ns<br />

German shipping company NSC Schifffahrtsgesellschaft<br />

has decided <str<strong>on</strong>g>to</str<strong>on</strong>g> implement<br />

a C<strong>on</strong>diti<strong>on</strong> M<strong>on</strong>i<str<strong>on</strong>g>to</str<strong>on</strong>g>ring (CM) survey<br />

arrangement <strong>on</strong> the main diesel engine<br />

pis<str<strong>on</strong>g>to</str<strong>on</strong>g>ns of 49 GL-classed vessels of its fleet.<br />

Survey. Pis<str<strong>on</strong>g>to</str<strong>on</strong>g>n<br />

with pis<str<strong>on</strong>g>to</str<strong>on</strong>g>n rings<br />

seen through<br />

scavenge ports of<br />

a large two-stroke<br />

diesel engine.<br />

“The preventi<strong>on</strong> of unnecessary openup<br />

inspecti<strong>on</strong>s and surveys is <strong>on</strong>e of the<br />

significant benefits of the CM survey arrangement,”<br />

says Dr Jörg Rebel, GL c<strong>on</strong>diti<strong>on</strong><br />

m<strong>on</strong>i<str<strong>on</strong>g>to</str<strong>on</strong>g>ring expert. “Open-up inspecti<strong>on</strong>s<br />

and surveys are<br />

costly and time-c<strong>on</strong>suming,<br />

especially in the case of<br />

pis<str<strong>on</strong>g>to</str<strong>on</strong>g>n overhauls for large<br />

diesel engines. Dismantling<br />

and re-assembling of the<br />

engines ways holds the risk<br />

of damaging a system that is running<br />

well.” GL offers the CM survey arrangement<br />

for crank-train bearings and pis<str<strong>on</strong>g>to</str<strong>on</strong>g>ns<br />

of two-stroke diesel engines, as well as<br />

for rotating auxiliary machinery, such as<br />

centrifugal pumps, electric mo<str<strong>on</strong>g>to</str<strong>on</strong>g>rs, fans<br />

and purifiers.<br />

For Further Informati<strong>on</strong>:<br />

Dr Jörg Rebel, Safety & Envir<strong>on</strong>mental Research<br />

Ph<strong>on</strong>e: +49 40 36149-940<br />

E-Mail: joerg.rebel@gl-group.com<br />

8<br />

n<strong>on</strong>s<str<strong>on</strong>g>to</str<strong>on</strong>g>p

Pho<str<strong>on</strong>g>to</str<strong>on</strong>g>: LEHNKERING<br />

Premiere.<br />

Hendrik Lorenz (l.),<br />

Head of Fleet<br />

Services, IMPERIAL<br />

Shipping Group, and<br />

Dr Ulrich Ellinghaus,<br />

Head of Regi<strong>on</strong><br />

Germany, GL Systems<br />

Certificati<strong>on</strong>.<br />

Cooperati<strong>on</strong><br />

Shipping Meets Space<br />

TankerS<br />

First-Ever Certificati<strong>on</strong> <str<strong>on</strong>g>to</str<strong>on</strong>g> TMSA<br />

Partners. GL’s Dr Pierre C. Sames (l.) and<br />

Dr Dietmar Heyland of DLR Technology<br />

Marketing signing the agreement.<br />

The German Aerospace Center (DLR) and<br />

GL are expanding their strategic innovati<strong>on</strong><br />

partnership first established in 2010 <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

jointly identify and develop new technologies<br />

for the shipping industry, such as ship<br />

emissi<strong>on</strong>s, indoor navigati<strong>on</strong>, advanced materials<br />

and wave predicti<strong>on</strong> via satellite.<br />

“Following hydrodynamic optimisati<strong>on</strong>,”<br />

said Dr Pierre C. Sames, Head of GL’s Department<br />

of Research and Rule Development,<br />

“the industry is now looking in<str<strong>on</strong>g>to</str<strong>on</strong>g><br />

optimising ship structures using modern<br />

n<strong>on</strong>-steel materials, a field that can greatly<br />

benefit from this cooperati<strong>on</strong>.”<br />

Dr Dietmar Heyland, Deputy Head of<br />

DLR Technology Marketing, added: “Ensuring<br />

safe and envir<strong>on</strong>mentally sound shipping<br />

is a comm<strong>on</strong> goal of DLR and GL. The<br />

skill sets and expertise of our companies<br />

are an ideal match for joint research and<br />

development projects.”<br />

For Further Informati<strong>on</strong>:<br />

Dr Pierre C. Sames, Senior Vice President<br />

Ph<strong>on</strong>e: +49 40 36149-113, E-Mail: pierre.sames@gl-group.com<br />

Pho<str<strong>on</strong>g>to</str<strong>on</strong>g>: Shiyali | Dreamstime.com<br />

TWO COMPANIES of IMPERIAL Shipping<br />

Group, LEHNKERING Reederei and<br />

LEHNKERING Rhein-Fracht GmbH, are<br />

the world’s first shipping companies<br />

certified <str<strong>on</strong>g>to</str<strong>on</strong>g> the internati<strong>on</strong>al Tanker<br />

Management and Self Assessment<br />

(TMSA) safety standard by Germanischer<br />

Lloyd.<br />

TMSA, introduced in 2004 by the Oil<br />

Companies Internati<strong>on</strong>al Marine Forum<br />

(OCIMF), initially relied <strong>on</strong> self-assessments<br />

by tanker opera<str<strong>on</strong>g>to</str<strong>on</strong>g>rs. GL is the<br />

first certificati<strong>on</strong> body <str<strong>on</strong>g>to</str<strong>on</strong>g> offer shipping<br />

companies an opti<strong>on</strong>al, third-party audit.<br />

”The IMPERIAL Shipping Group meets all<br />

the requirements of the TMSA standard<br />

CORROSION PROTECTION<br />

New Research Results<br />

NICKEL-REDUCED STAINLESS STEELS<br />

may be a suitable replacement for<br />

standard austenite steels under certain<br />

c<strong>on</strong>diti<strong>on</strong>s. Using low-nickel<br />

alternative steels could calm some of<br />

the price turbulences in the so-called<br />

stainless-steel markets. This is the outcome<br />

of a research project presented<br />

by Mr Andreas Burkert of the German<br />

Federal Institute for Materials Research<br />

and Testing (BAM) at the 12th<br />

c<strong>on</strong>ference <strong>on</strong> corrosi<strong>on</strong> protecti<strong>on</strong> in<br />

maritime engineering, Hamburg.<br />

The c<strong>on</strong>ference, first held in 2001,<br />

is a recurring event jointly hosted by<br />

regarding pers<strong>on</strong>nel management and<br />

qualificati<strong>on</strong>, navigati<strong>on</strong>al safety and<br />

safety management, including incident<br />

investigati<strong>on</strong> and improvement measures,”<br />

c<strong>on</strong>firmed Dr Ulrich Ellinghaus,<br />

Head of Regi<strong>on</strong> Germany, GL Systems<br />

Certificati<strong>on</strong>. The audits were held at<br />

the company’s headquarters in Duisburg,<br />

Germany, as well as several other company<br />

sites and <strong>on</strong> board 17 of IMPERIAL’s<br />

tankers.<br />

For Further Informati<strong>on</strong>:<br />

Dr Ulrich Ellinghaus, Head of Regi<strong>on</strong> Germany, GL Systems Certificati<strong>on</strong><br />

Ph<strong>on</strong>e: +49 40 36149-8273<br />

E-Mail: ulrich.ellinghaus@gl-group.com<br />

Schiffbautechnische Gesellschaft e.V.,<br />

Gesellschaft für Korrosi<strong>on</strong>sschutz e.V.<br />

and Germanischer Lloyd. The c<strong>on</strong>ference<br />

featured seven additi<strong>on</strong>al presentati<strong>on</strong>s<br />

following Mr Burkert’s opening<br />

lecture. Topics included material<br />

properties of aluminium, thermoplastic<br />

powder coatings, rust ablati<strong>on</strong> rates,<br />

and corrosi<strong>on</strong> protecti<strong>on</strong> of steel<br />

structures.<br />

For Further Informati<strong>on</strong>:<br />

Michael Kühnel, Head of Department Materials and<br />

Corrosi<strong>on</strong> Protecti<strong>on</strong>, Ph<strong>on</strong>e: +49 40 36149-2235<br />

E-Mail: corrosi<strong>on</strong>@gl-group.com<br />

01/2013<br />

9

n<strong>on</strong>s<str<strong>on</strong>g>to</str<strong>on</strong>g>p<br />

news<br />

Handover: (f.l.t.r.) Christian Ulrich Diehl,<br />

Senior Vice President Group Quality, Governance<br />

& Risk, Pekka Paasivaara, Member of the<br />

GL Group’s Executive <strong>Board</strong>, Erik van der<br />

Noordaa, CEO GL Group, Götz Blechschmidt,<br />

DQS Managing Direc<str<strong>on</strong>g>to</str<strong>on</strong>g>r, Dr Joachim Segatz,<br />

Member of the GL Group’s Executive <strong>Board</strong>,<br />

Ramón Azúa, Head of Department Group QHSE<br />

Management, and Gert Krüger, DQS’s Head<br />

of Key Account Management.<br />

ENERGY EFFICIENCY<br />

EFNAV Presentati<strong>on</strong> Marks 1,000th<br />

SEEMP for GL’s FutureShip<br />

Saving Fuel, lowering CO 2 emissi<strong>on</strong>s<br />

during operati<strong>on</strong>: effective<br />

January 2013, the amended MAR-<br />

POL Annex VI requires all seagoing<br />

ships larger than 400 GT <str<strong>on</strong>g>to</str<strong>on</strong>g> carry a<br />

Ship <str<strong>on</strong>g>Energy</str<strong>on</strong>g> Efficiency Management<br />

Plan (SEEMP) <strong>on</strong> board. Future-<br />

Ship GmbH, GL’s maritime c<strong>on</strong>sulting<br />

arm, offers an SEEMP soluti<strong>on</strong><br />

and recently presented its 1,000th<br />

SEEMP certificate <str<strong>on</strong>g>to</str<strong>on</strong>g> EFNAV COM-<br />

PANY LTD (EFNAV), Athens.<br />

“Excellent service and the shortest<br />

lead time, al<strong>on</strong>gside a competitive<br />

price, were the main reas<strong>on</strong>s <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

go with FutureShip as our partner<br />

for implementati<strong>on</strong> of an SEEMP,”<br />

said EFNAV’s Technical Manager,<br />

Mr Pantelis Ch<strong>on</strong>dros.<br />

The FutureShip SEEMP soluti<strong>on</strong><br />

allows the energy manager of a<br />

shipping company <str<strong>on</strong>g>to</str<strong>on</strong>g> select appropriate<br />

measures and c<strong>on</strong>vert them<br />

in<str<strong>on</strong>g>to</str<strong>on</strong>g> vessel-specific SEEMPs. Every<br />

single SEEMP is checked by Future-<br />

Ship <str<strong>on</strong>g>to</str<strong>on</strong>g> minimise the chance of error.<br />

The SEEMP soluti<strong>on</strong> comes with<br />

a vessel-specific <str<strong>on</strong>g>Energy</str<strong>on</strong>g> Efficiency<br />

Operati<strong>on</strong>al Indica<str<strong>on</strong>g>to</str<strong>on</strong>g>r (EEOI) calcula<str<strong>on</strong>g>to</str<strong>on</strong>g>r.<br />

“Vessels with an SEEMP in place<br />

have already shown marked improvements<br />

in fuel c<strong>on</strong>sumpti<strong>on</strong>,<br />

especially so in c<strong>on</strong>juncti<strong>on</strong> with a<br />

comprehensive c<strong>on</strong>tinuous improvement<br />

system,” said Till F. Braun,<br />

Managing C<strong>on</strong>sultant with Future-<br />

Ship GmbH.<br />

On-demand energy efficiency<br />

management c<strong>on</strong>sulting support<br />

is available from FutureShip. Many<br />

cus<str<strong>on</strong>g>to</str<strong>on</strong>g>mers have already taken advantage<br />

of this service.<br />

The FutureShip SEEMP soluti<strong>on</strong><br />

is currently available in Russian,<br />

English and Spanish.<br />

For Further Informati<strong>on</strong>:<br />

Till F. Braun, Managing C<strong>on</strong>sultant FutureShip<br />

Ph<strong>on</strong>e: +49 40 36149-337<br />

E-Mail: till.braun@gl-group.com<br />

3D Model. HullManager visualises every detail.<br />

SOFTWARE<br />

Seaspan <str<strong>on</strong>g>to</str<strong>on</strong>g> Roll out GL<br />

HullManager across Fleet<br />

Seaspan Ship Management Ltd. (Vancouver), a<br />

leading c<strong>on</strong>tainer vessel manager, has chosen GL<br />

HullManager <str<strong>on</strong>g>to</str<strong>on</strong>g> upgrade its in-house hull integrity<br />

management system. The c<strong>on</strong>diti<strong>on</strong>-based<br />

m<strong>on</strong>i<str<strong>on</strong>g>to</str<strong>on</strong>g>ring software will be implemented across<br />

Seaspan’s entire fleet of 76 vessels over the next<br />

several years.<br />

“After reviewing three different systems, we<br />

selected GL HullManager as the software most<br />

closely meeting our needs,” explained Peter<br />

Jacks<strong>on</strong>, Direc<str<strong>on</strong>g>to</str<strong>on</strong>g>r of the Projects and Technology<br />

Department at Seaspan Ship Management Ltd.<br />

GL HullManager uses a vessel-specific 3D<br />

model <str<strong>on</strong>g>to</str<strong>on</strong>g> s<str<strong>on</strong>g>to</str<strong>on</strong>g>re and visualise hull c<strong>on</strong>diti<strong>on</strong> data<br />

gathered through crew inspecti<strong>on</strong>s and thickness<br />

measurements. It enables ship owners, managers<br />

and opera<str<strong>on</strong>g>to</str<strong>on</strong>g>rs <str<strong>on</strong>g>to</str<strong>on</strong>g> spot potential problems early<br />

<strong>on</strong>, minimise downtime and streamline inspecti<strong>on</strong>s.<br />

The software integrates easily in<str<strong>on</strong>g>to</str<strong>on</strong>g> existing<br />

maintenance processes.<br />

Pho<str<strong>on</strong>g>to</str<strong>on</strong>g>: Horst Rahmelow<br />

SPITHA. One of the vessels<br />

of EFNAV Company Ltd.<br />

For Further Informati<strong>on</strong>:<br />

Ryan Bishop, Vice President Business Development Area Americas<br />

Ph<strong>on</strong>e: +1 832 320-4658, E-Mail: ryan.bishop@gl-group.com<br />

10<br />

n<strong>on</strong>s<str<strong>on</strong>g>to</str<strong>on</strong>g>p

Certificati<strong>on</strong><br />

Safer, Smarter, Greener – DQS Certificate C<strong>on</strong>firms GL Group Visi<strong>on</strong><br />

One Step ahead – The GL Group is the first<br />

technical c<strong>on</strong>sulting, assurance and classificati<strong>on</strong><br />

society <str<strong>on</strong>g>to</str<strong>on</strong>g> have its integrated management<br />

system certified. After successfully<br />

passing an integrated management system<br />

audit c<strong>on</strong>ducted by the German certificati<strong>on</strong><br />

body DQS, the GL Group received a<br />

combined certificate of compliance with the<br />

BS OHSAS 18001, ISO 9001 and ISO 14001<br />

standards.<br />

Erik van der Noordaa, CEO of the GL<br />

Group, received the certificate from DQS<br />

Managing Direc<str<strong>on</strong>g>to</str<strong>on</strong>g>r Götz Blechschmidt at<br />

the GL Group Head Office in Hamburg.<br />

“This combined certificati<strong>on</strong> reflects the GL<br />

Group’s ambiti<strong>on</strong> <str<strong>on</strong>g>to</str<strong>on</strong>g> become safer, smarter<br />

and greener. It encourages us <str<strong>on</strong>g>to</str<strong>on</strong>g> c<strong>on</strong>tinue<br />

developing our services, processes and<br />

methodologies in pursuit of this visi<strong>on</strong>.”<br />

The CEO thanked the DQS team for<br />

its dedicati<strong>on</strong> and cooperati<strong>on</strong> in working<br />

with the GL team <str<strong>on</strong>g>to</str<strong>on</strong>g> attain this certificati<strong>on</strong>.<br />

“Both companies invested several m<strong>on</strong>ths of<br />

intensive planning, training, documentati<strong>on</strong><br />

and internal audits <str<strong>on</strong>g>to</str<strong>on</strong>g> reach this successful<br />

c<strong>on</strong>clusi<strong>on</strong>.” The DQS certificate proves<br />

that the GL Group’s management systems<br />

comply with the internati<strong>on</strong>al standards for<br />

the assessment of occupati<strong>on</strong>al health and<br />

safety management systems, BS OHSAS<br />

18001, the quality standards for products<br />

and services, ISO 9001, and the envir<strong>on</strong>mental<br />

compatibility of processes, products<br />

and services, ISO 14001.<br />

For Further Informati<strong>on</strong>:<br />

Ramón Azúa, Head of Department Group QHSE Management<br />

Ph<strong>on</strong>e: +49 40 36149-126<br />

E-Mail: ram<strong>on</strong>.azua@gl-group.com<br />

partnership<br />

C<strong>on</strong>firmed Commitment <str<strong>on</strong>g>to</str<strong>on</strong>g> Wind <str<strong>on</strong>g>Energy</str<strong>on</strong>g><br />

GL Systems Certificati<strong>on</strong> has<br />

The WindMade label, which<br />

municate their commitment <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

joined WindMade as an accred-<br />

is backed by internati<strong>on</strong>al or-<br />

renewable energy.<br />

TM<br />

ited verifying partner. The<br />

ganisati<strong>on</strong>s, requires participat-<br />

GL Group’s certificati<strong>on</strong> body<br />

ing companies <str<strong>on</strong>g>to</str<strong>on</strong>g> obtain at least<br />

For Further Informati<strong>on</strong>:<br />

thereby commits <str<strong>on</strong>g>to</str<strong>on</strong>g> supporting<br />

25 per cent of their electricity<br />

Markus Weber, GL Systems Certificati<strong>on</strong><br />

Label. GL embraces<br />

the WindMade label and its c<strong>on</strong>-<br />

from wind power. It was created<br />

Ph<strong>on</strong>e: +49 40 36149-9051<br />

renewable energy.<br />

tinued development.<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> allow companies <str<strong>on</strong>g>to</str<strong>on</strong>g> com-<br />

E-Mail: markus.weber@gl-group.com<br />

01/2013<br />

11

lng sloshing<br />

Elements.<br />

Sloshing is a risk for<br />

tankers in heavy<br />

weather. Violent fluid<br />

moti<strong>on</strong> can cause<br />

hull damage.<br />

12<br />

n<strong>on</strong>s<str<strong>on</strong>g>to</str<strong>on</strong>g>p

Persistent sloshing in partly loaded LNG carrier tanks can cause extensive<br />

damage <str<strong>on</strong>g>to</str<strong>on</strong>g> the tank walls. The software soluti<strong>on</strong> GL SeaScout helps<br />

naviga<str<strong>on</strong>g>to</str<strong>on</strong>g>rs find alternative routes <str<strong>on</strong>g>to</str<strong>on</strong>g> avoid excessive sloshing<br />

Pho<str<strong>on</strong>g>to</str<strong>on</strong>g>s: Dps.fo<str<strong>on</strong>g>to</str<strong>on</strong>g>@gmail.com/Romanausks/Surz01 | Dreamstime.com<br />

In heavy seas, vessels can roll by up <str<strong>on</strong>g>to</str<strong>on</strong>g> 30 degrees. With<br />

vessels getting larger and faster and crews often lacking<br />

experience, there is a need <str<strong>on</strong>g>to</str<strong>on</strong>g> forecast ship behaviour<br />

more reliably rather than leaving it up <str<strong>on</strong>g>to</str<strong>on</strong>g> the naviga<str<strong>on</strong>g>to</str<strong>on</strong>g>r <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

assess the situati<strong>on</strong> when he, or she, is stati<strong>on</strong>ed some 50<br />

metres above the waterline. This is especially critical at night.<br />

Vessels and their cargoes are subject <str<strong>on</strong>g>to</str<strong>on</strong>g> heaving, pitching,<br />

slamming, wave loads <strong>on</strong> deck, and in certain cases, parametric<br />

roll, which can also adversely affect deck cargoes of<br />

c<strong>on</strong>tainerships. Dr Torsten Büssow, GL’s Vice President Maritime<br />

Software, explains that sloshing produces str<strong>on</strong>g forces<br />

acting against the tank wall, which could destroy or severely<br />

damage a tank; <strong>on</strong>ce started, it is often even audible <str<strong>on</strong>g>to</str<strong>on</strong>g> the<br />

crew. Repairs can be extensive, taking three or more weeks,<br />

not <str<strong>on</strong>g>to</str<strong>on</strong>g> menti<strong>on</strong> the costly offhire time. Damage induced by<br />

sloshing could also cause loss of cargo due <str<strong>on</strong>g>to</str<strong>on</strong>g> gas boil-off.<br />

“These are valuable ships and cargoes. Sloshing is a c<strong>on</strong>cern<br />

for owners,” Büssow says.<br />

Seakeeping Qualities<br />

During the voyage of a laden LNG carrier (LNGC), the cargo<br />

volume in the tank will gradually shrink due <str<strong>on</strong>g>to</str<strong>on</strong>g> gas boil-off.<br />

This provides the cargo with increasing space <str<strong>on</strong>g>to</str<strong>on</strong>g> slosh in resp<strong>on</strong>se<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> the movements of the ship. Impact pressures can<br />

be very high but of short durati<strong>on</strong>, mainly affecting the tank<br />

corners, the tank dome and internal piping.<br />

Over the years, GL has gained c<strong>on</strong>siderable experience<br />

in the study of ship seakeeping qualities. “What was lacking<br />

in the past,” says Büssow, “was an <strong>on</strong>board comp<strong>on</strong>ent,<br />

such as a fleet management guide, <str<strong>on</strong>g>to</str<strong>on</strong>g> help naviga<str<strong>on</strong>g>to</str<strong>on</strong>g>rs react<br />

appropriately <str<strong>on</strong>g>to</str<strong>on</strong>g> certain sea c<strong>on</strong>diti<strong>on</strong>s: Naviga<str<strong>on</strong>g>to</str<strong>on</strong>g>rs need help<br />

in judging the seakeeping behaviour of their vessels so they<br />

can answer questi<strong>on</strong>s such as: If my ship swings ten degrees<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> port, how will this affect its rolling moti<strong>on</strong>?”<br />

Top-Performing Software Soluti<strong>on</strong><br />

To provide a <str<strong>on</strong>g>to</str<strong>on</strong>g>ol for assessing gas carrier and c<strong>on</strong>tainership<br />

behaviour patterns, Germanischer Lloyd introduced GL<br />

SeaScout, a hydrodynamic integrated software soluti<strong>on</strong> for<br />

navigati<strong>on</strong>al decisi<strong>on</strong> support. Marketed mainly <str<strong>on</strong>g>to</str<strong>on</strong>g> the LNGC<br />

sec<str<strong>on</strong>g>to</str<strong>on</strong>g>r, the new software applies computati<strong>on</strong>al fluid<br />

Tool.<br />

CFD-based<br />

simulati<strong>on</strong><br />

helps <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

predict<br />

sloshing<br />

occurrence in<br />

certain sea<br />

and sailing<br />

c<strong>on</strong>diti<strong>on</strong>s.<br />

01/2013 13

lng sloshing<br />

dynamics (CFD) <str<strong>on</strong>g>to</str<strong>on</strong>g> analyse and predict vessel behaviour<br />

under specific sea c<strong>on</strong>diti<strong>on</strong>s.<br />

Risk Identificati<strong>on</strong><br />

While it is impossible <str<strong>on</strong>g>to</str<strong>on</strong>g> predict sloshing accurately in ship<br />

operati<strong>on</strong>, CFD-based simulati<strong>on</strong> can be used <str<strong>on</strong>g>to</str<strong>on</strong>g> determine<br />

the likelihood of sloshing in certain sea and sailing c<strong>on</strong>diti<strong>on</strong>s.<br />

GL SeaScout models the underwater part of the vessel and<br />

subjects it <str<strong>on</strong>g>to</str<strong>on</strong>g> a virtual, CFD-based tank trial. The simulati<strong>on</strong><br />

result can give an opera<str<strong>on</strong>g>to</str<strong>on</strong>g>r a 360-degree view of the vessel’s<br />

behaviour. In additi<strong>on</strong>, an infinite number of parameters can<br />

be introduced in<str<strong>on</strong>g>to</str<strong>on</strong>g> the simulati<strong>on</strong> for further analysis.<br />

GL SeaScout relies exclusively <strong>on</strong> computati<strong>on</strong>al means<br />

for sloshing predicti<strong>on</strong>. “The less hardware you put <strong>on</strong> board<br />

a vessel, the less maintenance<br />

you will need <strong>on</strong><br />

board,” Büssow explains. “The CFD computati<strong>on</strong>s used by<br />

the applicati<strong>on</strong> match up well with data validated by experiments,”<br />

he adds.<br />

“It is important <str<strong>on</strong>g>to</str<strong>on</strong>g> m<strong>on</strong>i<str<strong>on</strong>g>to</str<strong>on</strong>g>r the moti<strong>on</strong> of the vessel c<strong>on</strong>tinuously,”<br />

Büssow stresses, “especially at night-time when<br />

sea c<strong>on</strong>diti<strong>on</strong>s are not so apparent <str<strong>on</strong>g>to</str<strong>on</strong>g> the naviga<str<strong>on</strong>g>to</str<strong>on</strong>g>r.” When<br />

GL SeaScout indicates c<strong>on</strong>diti<strong>on</strong>s making sloshing appear<br />

likely, a course change can quickly be planned. A weather<br />

routing system will <strong>on</strong>ly tell the crew about possible forthcoming<br />

weather c<strong>on</strong>diti<strong>on</strong>s, whereas GL SeaScout will warn<br />

of the c<strong>on</strong>sequences of wave lengths, frequencies and<br />

heights under certain sea c<strong>on</strong>diti<strong>on</strong>s at specific vessel speeds.<br />

The central display unit of the system is colour-coded for<br />

easy identificati<strong>on</strong> of risks (see picture next page).<br />

“Furthermore, the software integrates easily with weather<br />

routing systems such as Applied Weather Technology (AWT),<br />

The Future Has Started<br />

LNG shipping. Almost 80 newbuilds are <strong>on</strong> order or<br />

under c<strong>on</strong>structi<strong>on</strong>.<br />

Interest in LNG carriers (LNGCs) has ballo<strong>on</strong>ed in the<br />

past few years since the price of natural gas dropped well<br />

below that of crude oil, triggering a virtually unprecedented<br />

c<strong>on</strong>structi<strong>on</strong> boom in receiving terminals, plants and vessels<br />

Several fac<str<strong>on</strong>g>to</str<strong>on</strong>g>rs have c<strong>on</strong>tributed <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

countries are ramping up their gas pow-<br />

Yamal in the Russian Arctic. In fact, the<br />

making gas more attractive as an ener-<br />

er plants and building new <strong>on</strong>es. While<br />

world recently witnessed the first LNGC<br />

gy source, especially in Asian countries<br />

Japan and South Korea used <str<strong>on</strong>g>to</str<strong>on</strong>g> lead the<br />

travelling the Northern Sea Route (NSR)<br />

but also, if <str<strong>on</strong>g>to</str<strong>on</strong>g> a lesser extent, in Europe.<br />

way in Asian gas c<strong>on</strong>sumpti<strong>on</strong>, Chinese<br />

across the Arctic. This vessel loaded LNG<br />

Price is still a key fac<str<strong>on</strong>g>to</str<strong>on</strong>g>r, but the Fuku-<br />

energy companies have now joined the<br />

in Hammerfest (Snøhvit) in Norway for<br />

Pho<str<strong>on</strong>g>to</str<strong>on</strong>g>: Oleksandr Kalinichenko | Dreamstime.com<br />

shima earthquake and tsunami led <str<strong>on</strong>g>to</str<strong>on</strong>g> a<br />

fundamental change in the way most<br />

countries think about energy resources:<br />

nuclear power plants are losing support<br />

in favour of c<strong>on</strong>venti<strong>on</strong>al, cheaper power<br />

sources, such as gas and coal.<br />

With the US all but closed <str<strong>on</strong>g>to</str<strong>on</strong>g> LNG<br />

imports due <str<strong>on</strong>g>to</str<strong>on</strong>g> the rise of domestically<br />

produced shale gas, Asian energy c<strong>on</strong>cerns<br />

have closed that gap. A number of<br />

so-called “dash for gas”. Much of the<br />

Asian imports derive from Asian suppliers<br />

such as Ind<strong>on</strong>esia and Australia and<br />

of course Qatar, which has emerged as<br />

<strong>on</strong>e of the largest gas producers and exporters<br />

in the world.<br />

The future bodes well for LNG shipping,<br />

as Russia has started exporting<br />

gas from Sakhalin in Asia, and in a few<br />

years will commence exporting gas from<br />

delivery <str<strong>on</strong>g>to</str<strong>on</strong>g> Japan.<br />

All of this activity has galvanised<br />

interest in LNG shipping. By the turn<br />

of the year, there were almost 80 newbuilds<br />

<strong>on</strong> order or under c<strong>on</strong>structi<strong>on</strong>,<br />

each capable of carrying in excess of<br />

10,000 m 3 . Most of them are being built<br />

at South Korean, Japanese or Chinese<br />

shipyards. Today, the active fleet stands<br />

at around 360 vessels.<br />

14 n<strong>on</strong>s<str<strong>on</strong>g>to</str<strong>on</strong>g>p

■ Observati<strong>on</strong>s<br />

(e.g. weather<br />

routing data)<br />

■ Measured<br />

(e.g. via X-band<br />

■ Loading c<strong>on</strong>diti<strong>on</strong><br />

(displacement,<br />

■ Frequency of<br />

movements,<br />

Navigati<strong>on</strong>al Decisi<strong>on</strong> Support System<br />

GL SeaScout helps calculate the likeliness of sloshing for all vessel speeds<br />

and headings. In additi<strong>on</strong>, it identifies safe vs. hazardous speed and<br />

course combinati<strong>on</strong>s.<br />

M<strong>on</strong>i<str<strong>on</strong>g>to</str<strong>on</strong>g>ring.<br />

GL SeaScout<br />

mitigates the<br />

risks of vessel<br />

and cargo<br />

damages.<br />

WAVES<br />

■ Measured<br />

(e.g. via X-band<br />

wave radar)<br />

■ Forecasted<br />

(e.g. weather<br />

routing data)<br />

■ Observati<strong>on</strong>s<br />

SHIP<br />

■ Hydrodynamic<br />

properties<br />

■ Tank geometries<br />

■ Loading c<strong>on</strong>diti<strong>on</strong><br />

(displacement,<br />

tank filling levels)<br />

SHIP<br />

DYNAMICS<br />

■ Large movements<br />

■ Frequency of<br />

movements,<br />

fluids in tank<br />

■ Risk assessment<br />

wave radar)<br />

■ Forecasted<br />

■ Tank geometries<br />

properties<br />

■ Hydrodynamic<br />

There has been very little scrapping<br />

SHIP<br />

WAVES<br />

of older units down the years, with<br />

owners preferring <str<strong>on</strong>g>to</str<strong>on</strong>g> c<strong>on</strong>vert their redundant<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g>nnage in<str<strong>on</strong>g>to</str<strong>on</strong>g> s<str<strong>on</strong>g>to</str<strong>on</strong>g>rage units,<br />

including the fitting of regasificati<strong>on</strong><br />

plants <strong>on</strong> board in some cases.<br />

Charter rates <str<strong>on</strong>g>to</str<strong>on</strong>g>ok off a couple of<br />

years ago, hitting 200,000 dollars per<br />

day at their peak. However, they have<br />

since dropped back <str<strong>on</strong>g>to</str<strong>on</strong>g> around 100,000<br />

dollars and higher per day, which is still<br />

allowing a healthy return <strong>on</strong> investment.<br />

The revival of interest in this niche<br />

sec<str<strong>on</strong>g>to</str<strong>on</strong>g>r will no doubt spur more technological<br />

innovati<strong>on</strong>s in the future as new<br />

challenges arise, not least with the LNG<br />

floating producti<strong>on</strong> s<str<strong>on</strong>g>to</str<strong>on</strong>g>rage and offloading<br />

(FPSO) units planned for Australian<br />

and Brazilian waters. A key questi<strong>on</strong><br />

remaining is that of ice navigati<strong>on</strong>,<br />

as the Arctic LNG exporting terminals<br />

will come <strong>on</strong>-stream in a few years.<br />

■ Risk assessment<br />

X-band.<br />

tank in fluids<br />

These radars<br />

are used for<br />

Large movements<br />

■<br />

studies <strong>on</strong><br />

cloud development<br />

because<br />

SHIP<br />

DYNAMICS<br />

they can detect<br />

the tiny water<br />

particles.<br />

X-band radars<br />

provide very<br />

short-term<br />

weather<br />

informati<strong>on</strong>.<br />

as weather routing technology plays an important part in<br />

avoiding sloshing,” Büssow says. For example, GL SeaScout<br />

will use weather forecasting during an entire voyage for ship<br />

behaviour and safety assessments <str<strong>on</strong>g>to</str<strong>on</strong>g> support route planning.<br />

X-band wave radar informati<strong>on</strong> and other <strong>on</strong>-board measurement<br />

systems may also be integrated in<str<strong>on</strong>g>to</str<strong>on</strong>g> the system <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

provide a broader informati<strong>on</strong> basis and improve accuracy.<br />

Two Trends<br />

As the interest in LNG as a ship fuel c<strong>on</strong>tinues <str<strong>on</strong>g>to</str<strong>on</strong>g> grow, sloshing<br />

is likely <str<strong>on</strong>g>to</str<strong>on</strong>g> become a more comm<strong>on</strong> c<strong>on</strong>cern with <strong>on</strong>board<br />

fuel gas tanks gradually emptying in the course of each<br />

voyage. GL expert Büssow says there has been wide-spread<br />

interest in GL SeaScout, especially from Greek owners who<br />

have been active in the LNGC newbuilding market recently.<br />

“GL’s software business grew substantially in the past<br />

three years, and was mainly driven by two trends,” Büssow<br />

adds: Quality-minded shipping companies c<strong>on</strong>tinued <str<strong>on</strong>g>to</str<strong>on</strong>g> invest<br />

in new technology <str<strong>on</strong>g>to</str<strong>on</strong>g> stay ahead of the competiti<strong>on</strong>;<br />

and while there were many software systems available during<br />

the boom years, there has been significant c<strong>on</strong>solidati<strong>on</strong><br />

in the shipping software sec<str<strong>on</strong>g>to</str<strong>on</strong>g>r since, which will likely<br />

c<strong>on</strong>tinue. “Small companies cannot invest in their future,”<br />

Büssow c<strong>on</strong>cludes.<br />

IC<br />

For Further Informati<strong>on</strong>:<br />

Dr Torsten Büssow, Vice President Maritime Software<br />

Ph<strong>on</strong>e: +49 40 36149-5237, E-Mail: <str<strong>on</strong>g>to</str<strong>on</strong>g>rsten.buessow@gl-group.com<br />

tank filling levels)<br />

01/2013<br />

15

lng gaspax<br />

RoPax Ferry C<strong>on</strong>cept. Equipped<br />

with dual-fuel engines, this vessel<br />

could transport 600 passengers.<br />

Laying the Groundwork for LNG<br />

The GasPax project has shown that the time is right for shipowners <str<strong>on</strong>g>to</str<strong>on</strong>g> adopt LNG as<br />

a fuel for future cruise ships, RoPax ferries and other types of passenger vessel<br />

The message from the speakers at GL’s GasPax forum was<br />

clear: “If you are ready <str<strong>on</strong>g>to</str<strong>on</strong>g> order it, we are ready <str<strong>on</strong>g>to</str<strong>on</strong>g> build<br />

it!” The event was held <str<strong>on</strong>g>to</str<strong>on</strong>g> celebrate the completi<strong>on</strong> of<br />

the GasPax project and award approval-in-principle certificates.<br />

Sp<strong>on</strong>sored by the German government (BMWi), GasPax<br />

was designed <str<strong>on</strong>g>to</str<strong>on</strong>g> get German shipyards and manufacturers<br />

ahead of the game in terms of LNG-fuelled vessels. The project<br />

partners set out <str<strong>on</strong>g>to</str<strong>on</strong>g> examine the technical challenges associated<br />

with the use of this fuel in three types of passenger<br />

vessels – a cruise ship, a mega yacht, and a RoPax ferry – and<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> come up with market-ready designs. The forum in Hamburg<br />

was organised and chaired by GL’s Hans-Günther Albers.<br />

Short Payback Time<br />

LNG is already a well-established fuel in the ferry industry in<br />

Norway, with a growing infrastructure and uptake from many<br />

opera<str<strong>on</strong>g>to</str<strong>on</strong>g>rs. Rolf Nagel from Flensburger Schiffbau-Gesellschaft<br />

presented the company’s RoPax design for a dual-fuel, 199 m<br />

vessel designed for 600 passengers. Utilising LNG requires adjustments<br />

due <str<strong>on</strong>g>to</str<strong>on</strong>g> the size of the tanks, Nagel said, but the<br />

design succeeded in minimising the impact <strong>on</strong> the cargo hold,<br />

engine room and endurance of the vessel.<br />

Although passenger ferries are not yet subject <str<strong>on</strong>g>to</str<strong>on</strong>g> the<br />

incoming EEDI (<str<strong>on</strong>g>Energy</str<strong>on</strong>g> Efficiency Design Index) regulati<strong>on</strong>s,<br />

Nagel pointed out that LNG enjoyed a significant advantage<br />

over fuel oil in the formula’s c<strong>on</strong>versi<strong>on</strong> fac<str<strong>on</strong>g>to</str<strong>on</strong>g>r – some 26 per<br />

cent in attained EEDI. The extra costs of an LNG installati<strong>on</strong><br />

had a payback time of <strong>on</strong>e and a half <str<strong>on</strong>g>to</str<strong>on</strong>g> two years, he c<strong>on</strong>tinued,<br />

and the reduced emissi<strong>on</strong>s <str<strong>on</strong>g>to</str<strong>on</strong>g> air saved c<strong>on</strong>siderable<br />

external costs compared <str<strong>on</strong>g>to</str<strong>on</strong>g> using c<strong>on</strong>venti<strong>on</strong>al fuels – an<br />

important fac<str<strong>on</strong>g>to</str<strong>on</strong>g>r in an increasingly stringent regula<str<strong>on</strong>g>to</str<strong>on</strong>g>ry envir<strong>on</strong>ment.<br />

The cruise industry is also likely <str<strong>on</strong>g>to</str<strong>on</strong>g> move <str<strong>on</strong>g>to</str<strong>on</strong>g>wards LNG,<br />

with newbuilds planned for the near future. With a North<br />

American Emissi<strong>on</strong> C<strong>on</strong>trol Area (ECA) entered in<str<strong>on</strong>g>to</str<strong>on</strong>g> force last<br />

year, LNG offers cruise lines a cleaner fuel both in protected<br />

marine envir<strong>on</strong>ments and during port visits. Gerhard Untiedt,<br />

Meyer Werft, presented a mid-sized, 2,000-passenger cruise<br />

ship design with dual-fuel engines (see next page).<br />

Unlike the cruise ship and RoPax designs, the mega yacht<br />

from the Lürssen shipyard uses vertical tanks: two 180 m 3<br />

type C tanks situated amidships in fr<strong>on</strong>t of the engine room<br />

with a cofferdam in-between and behind the accommodati<strong>on</strong>.<br />

Lürssen’s Dr Bernhard Urban presented the c<strong>on</strong>cept,<br />

16 n<strong>on</strong>s<str<strong>on</strong>g>to</str<strong>on</strong>g>p

LNG-Fuelled Cruise Ship<br />

Meyer Werft’s cruise ship c<strong>on</strong>cept with a dual-fuel engine includes two 618 m 3 tanks that would<br />

enable the vessel <str<strong>on</strong>g>to</str<strong>on</strong>g> undertake a typical <strong>on</strong>e-week cruise running <strong>on</strong> LNG al<strong>on</strong>e.<br />

Ventilati<strong>on</strong> system<br />

All rooms c<strong>on</strong>taining gas equipment<br />

are ventilated using a<br />

double-walled duct<br />

Vent mast<br />

Outlet 10 m above<br />

uppermost deck<br />

Bunkering stati<strong>on</strong><br />

Engine Installati<strong>on</strong><br />

Dual-fuel engines (4 × 9MW),<br />

Propulsi<strong>on</strong> (2 × 12,5MW)<br />

LNG Tanks<br />

Capacity: 2 × 618 m³<br />

Pho<str<strong>on</strong>g>to</str<strong>on</strong>g>s/Illustrati<strong>on</strong>s: FSG, Lürssen, Meyer Werft<br />

based <strong>on</strong> the c<strong>on</strong>versi<strong>on</strong> of an existing 110 m, 3,600 t mo<str<strong>on</strong>g>to</str<strong>on</strong>g>r<br />

yacht, as well as the results of a CFD-analysis related <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

the air circulati<strong>on</strong> in the engine room. The dual-fuel system<br />

gives the yacht owners the same flexibility and usability as<br />

the c<strong>on</strong>venti<strong>on</strong>al-fuel design. The vessel can run <strong>on</strong> LNG for<br />

2,000-3,000 nm, with a <str<strong>on</strong>g>to</str<strong>on</strong>g>tal range of 6,000 nm between<br />

bunkering.<br />

Various Tank Soluti<strong>on</strong>s<br />

The gas fuel systems in all of the GasPax project’s designs<br />

were developed by TGE Marine Gas Engineering. Hans-Christian<br />

Haarmann-Kühn examined the fuel gas systems,which<br />

present a variety of soluti<strong>on</strong>s for different ship types. Existing<br />

Norwegian Ferries typically use very similar systems with<br />

a highly efficient vacuum tank operating at 6 – 8 bar, with<br />

a design pressure of typically 10 bar, he said. This was a potential<br />

soluti<strong>on</strong> for tanks up <str<strong>on</strong>g>to</str<strong>on</strong>g> 1,000 m³, although it would<br />

not fit perfectly <str<strong>on</strong>g>to</str<strong>on</strong>g> any vessel c<strong>on</strong>figurati<strong>on</strong>.<br />

All of the LNG c<strong>on</strong>tainment systems used by LNG carriers<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g>day could be used as fuel s<str<strong>on</strong>g>to</str<strong>on</strong>g>rage under current regulati<strong>on</strong>s,<br />

Haarmann-Kühn said, from small high-pressure tanks<br />

Celebrati<strong>on</strong>.<br />

GL’s Dr Pierre<br />

C. Sames<br />

(left) presents<br />

the GasPax<br />

project<br />

partners<br />

with<br />

approval-inprinciple<br />

certificates.<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> massive 50,000 m 3 membrane tanks – a theoretical possibility<br />

for the largest c<strong>on</strong>tainer vessels. The type C tanks<br />

used in the GasPax designs offered the advantage of being<br />

c<strong>on</strong>sidered inherently safe under the IGC code, he noted,<br />

and cylindrical, 8 – 10 bar type C tanks could easily hold up<br />

3,500 and more m³.<br />

Bunkering remains a key c<strong>on</strong>cern for a more widespread<br />

use of LNG as a ship fuel. GL has also been active in the c<strong>on</strong>current<br />

BunGas project. The hose c<strong>on</strong>necti<strong>on</strong>s and procedures<br />

for bunkering c<strong>on</strong>venti<strong>on</strong>al fuels can be diversified which require<br />

multiple adapters. LNG's different handling requirements<br />

require a soluti<strong>on</strong> enabling the daily operati<strong>on</strong> of the ship type<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> proceed as they would coventi<strong>on</strong>ally while ensuring safety.<br />

An overview of the growing bunkering infrastructure and<br />

the c<strong>on</strong>tinuing development of safety standards and guidelines<br />

was offered by Henning Pewe, GL’s Lead for Gas Technology<br />

(see also page 18). Despite there not being any import<br />

terminals <str<strong>on</strong>g>to</str<strong>on</strong>g> facilitate small-scale LNG distributi<strong>on</strong> in Asia at<br />

present, he said, there were plans for an LNG bunker facility<br />

in Singapore, and work was c<strong>on</strong>tinuing <strong>on</strong> the development<br />

of ship c<strong>on</strong>nec<str<strong>on</strong>g>to</str<strong>on</strong>g>rs for bunkering, crew training standards, and<br />

required procedures and regula<str<strong>on</strong>g>to</str<strong>on</strong>g>ry safeguards for harbours.<br />

GL’s Dr Pierre C. Sames, Head of Research and Rule Development,<br />

presented the four project partners with approval-in-principle<br />

certificates, recognising the technical feasibility<br />

of the designs. Dr Sames noted that presenting the certificates<br />

showed <strong>on</strong>ce again that there were market-ready<br />

designs available for owners <str<strong>on</strong>g>to</str<strong>on</strong>g> take the next step and move<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> LNG. SA<br />

For further Informati<strong>on</strong>:<br />

Dr Pierre C. Sames, Senior Vice President, GL Research and Rule Development<br />

Ph<strong>on</strong>e: + 49 40 36149-113, E-Mail: pierre.sames@gl-group.com<br />

01/2013<br />

17

lng infrastructure<br />

Fuel Logistics. Natural-gas-powered ships such as the GL-classed „Bit Viking“ will so<strong>on</strong> become more comm<strong>on</strong>, helped by stricter<br />

envir<strong>on</strong>mental and efficiency requirements. But ports such as Hamburg have yet <str<strong>on</strong>g>to</str<strong>on</strong>g> create an appropriate infrastructure for LNG bunkering.<br />

Wanted: Reliable Gas Supply<br />

Legal stipulati<strong>on</strong>s, logistics requirements and technical challenges:<br />

a new study clarifies how LNG bunkering can be made a reality in German ports<br />

Pho<str<strong>on</strong>g>to</str<strong>on</strong>g>s: Hbbolten/Peresanz | Dreamstime.com Tarbit Shipping<br />

Boosting energy efficiency while lowering noxious<br />

emissi<strong>on</strong>s <str<strong>on</strong>g>to</str<strong>on</strong>g> air: with bunker oil prices <strong>on</strong> a steady<br />

rise and stricter exhaust gas emissi<strong>on</strong> limits in force,<br />

propulsi<strong>on</strong> systems using liquefied natural gas (LNG) as fuel<br />

are more attractive than ever. Even as a transiti<strong>on</strong>al technology,<br />

natural gas is moving in<str<strong>on</strong>g>to</str<strong>on</strong>g> focus as a key enabler of the<br />

global energy turnaround. Anticipating a growing global demand<br />

for natural gas, the German government c<strong>on</strong>siders it<br />

a strategic necessity <str<strong>on</strong>g>to</str<strong>on</strong>g> diversify its natural gas sources and<br />

the associated means of transport.<br />

With this in mind, the German Ministry of Transport<br />

commissi<strong>on</strong>ed a safety and feasibility study <str<strong>on</strong>g>to</str<strong>on</strong>g> explore LNG<br />

bunkering of oceangoing ships in German sea and inland<br />

ports using special LNG bunkering vessels.<br />

The study investigates the existing liquefied natural<br />

gas infrastructure in northern Europe and Germany, proposes<br />

an LNG bunkering logistics c<strong>on</strong>cept, and examines<br />

a specific ship-<str<strong>on</strong>g>to</str<strong>on</strong>g>-ship bunkering interface design <str<strong>on</strong>g>to</str<strong>on</strong>g> assess<br />

the risks. Finally the study presents a draft safety c<strong>on</strong>cept,<br />

which accounts for legislative and competency c<strong>on</strong>siderati<strong>on</strong>s,<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> provide the resp<strong>on</strong>sible authorities with a basis for<br />

further acti<strong>on</strong>.<br />

Infrastructure Analysis<br />

To enable LNG bunkering in German ports, the country<br />

needs <str<strong>on</strong>g>to</str<strong>on</strong>g> build a supply infrastructure. One opti<strong>on</strong> would<br />

be <str<strong>on</strong>g>to</str<strong>on</strong>g> adopt the Norwegian method of distributing LNG via<br />

small-scale LNG carriers (capable of carrying 12,000 m 3 ),<br />

with short-term LNG s<str<strong>on</strong>g>to</str<strong>on</strong>g>rage provided by suitable in-port<br />

terminals. The small LNG carriers would serve as bunkering<br />

ships distributing the LNG within each port. A standard<br />

LNG carrier, or an appropriately designed bunkering carrier,<br />

could provide the necessary s<str<strong>on</strong>g>to</str<strong>on</strong>g>rage capacity for a transiti<strong>on</strong>al<br />

period.<br />

18 n<strong>on</strong>s<str<strong>on</strong>g>to</str<strong>on</strong>g>p

LNG Infrastructure<br />

in Northern Europe<br />

Overview of existing and planned LNG<br />

producti<strong>on</strong> and terminal sites<br />

Existing LNG producti<strong>on</strong> plants<br />

Planned LNG producti<strong>on</strong> plants<br />

Proposed LNG producti<strong>on</strong> plants<br />

Existing small-scale export/bunkering facilities<br />

Proposed small-scale export/bunkering facilities<br />

Existing LNG terminals<br />

Planned and decided LNG terminals<br />

Planned and not decided LNG terminals<br />

SECA AREA<br />

01/2013<br />

19

lng infrastructure<br />

Truck-<str<strong>on</strong>g>to</str<strong>on</strong>g>-ship bunkering<br />

Bunkering via pipeline<br />

LNG-fuelled ship<br />

LNG Bunkering Methods<br />

The three liquefied-gas fuelling methods<br />

are most likely <str<strong>on</strong>g>to</str<strong>on</strong>g> succeed in the market.<br />

Mobile tank units are another opti<strong>on</strong>.<br />

Ship-<str<strong>on</strong>g>to</str<strong>on</strong>g>-ship bunkering<br />

The study includes an in-port LNG infrastructure c<strong>on</strong>cept<br />

using Hamburg as a reference port, and accounting for<br />

the relevant legal c<strong>on</strong>diti<strong>on</strong>s. As a general c<strong>on</strong>clusi<strong>on</strong> the<br />

authorities will face c<strong>on</strong>siderable challenges finding appropriate<br />

in-port locati<strong>on</strong>s for a short-term s<str<strong>on</strong>g>to</str<strong>on</strong>g>rage terminal, the<br />

standby berth for the bunkering vessel and additi<strong>on</strong>al water<br />

areas for maintaining and commissi<strong>on</strong>ing gas-handling systems,<br />

or making the necessary water traffic safety arrangements<br />

during bunkering. Current restricti<strong>on</strong>s do not permit<br />

LNG transfer outside gas terminals.<br />

The analysis of existing regulati<strong>on</strong>s applicable in<br />

Germany found that pursuant <str<strong>on</strong>g>to</str<strong>on</strong>g> MSC.285(86) as incorporated<br />

in<str<strong>on</strong>g>to</str<strong>on</strong>g> the German Ship Safety Act, a valid legal<br />

framework for operating and approaching an LNG-fuelled<br />

ship is already in existence. Operating LNG-powered ships<br />

is therefore legal. Similarly the German regula<str<strong>on</strong>g>to</str<strong>on</strong>g>ry situati<strong>on</strong><br />

for transporting hazardous goods by oceangoing<br />

vessel (LNG carrier) is relatively clear, c<strong>on</strong>trary <str<strong>on</strong>g>to</str<strong>on</strong>g> fuel bunkering.<br />

However, there are significant differences am<strong>on</strong>g<br />

German ports.<br />

It would therefore seem advisable <str<strong>on</strong>g>to</str<strong>on</strong>g> define specific requirements<br />

for the “Transfer of Fuels with Flashing Points below<br />

60 °C”, and <str<strong>on</strong>g>to</str<strong>on</strong>g> treat LNG bunkering and LNG transport<br />

as separate processes. Furthermore, a set of general safety<br />

criteria should be defined <str<strong>on</strong>g>to</str<strong>on</strong>g> help the resp<strong>on</strong>sible authorities<br />

develop a c<strong>on</strong>sistent nati<strong>on</strong>-wide set of rules.<br />

Technical C<strong>on</strong>cept<br />

The study includes a technical c<strong>on</strong>cept for ship-<str<strong>on</strong>g>to</str<strong>on</strong>g>-ship<br />

bunker ing of liquefied natural gas based <strong>on</strong> an LNG bunkering<br />

ship designed by TGE (see illustrati<strong>on</strong>s <strong>on</strong> the right). The<br />

c<strong>on</strong>cept reveals the basic engineering challenges inherent in<br />

bunkering liquefied gases.<br />

One of the core assumpti<strong>on</strong>s was that the system should<br />

be designed <str<strong>on</strong>g>to</str<strong>on</strong>g> allow simultaneous bunkering and cargo<br />

loading/unloading. In additi<strong>on</strong>, it was decided for ec<strong>on</strong>omic<br />

and logistical reas<strong>on</strong>s that it should be possible <str<strong>on</strong>g>to</str<strong>on</strong>g> refuel<br />

a ship with both gas and c<strong>on</strong>venti<strong>on</strong>al liquid bunker oil simultaneously.<br />

A hard arm was designed, placing particular<br />

emphasis <strong>on</strong> avoiding possible leakage. The system calls for<br />

suitable QC/DC coupling systems that minimise the potential<br />

for opera<str<strong>on</strong>g>to</str<strong>on</strong>g>r errors. An emergency quick-disc<strong>on</strong>nect system<br />

further enhances safety.<br />

An evaluati<strong>on</strong> of the technical feasibility of LNG bunkering<br />

showed that the required technology as well as comprehensive<br />

LNG handling experience are available now. From a<br />

C<strong>on</strong>cepts for Bunkering Vessels<br />

TGE Marine Gas Engineering and FKAB Marine<br />

Design are developing c<strong>on</strong>cepts for<br />

ship-<str<strong>on</strong>g>to</str<strong>on</strong>g>-ship bunkering.<br />

TGE. This design is<br />

intended for simultaneous<br />

transport of LNG and MGO.<br />

Total tank volume<br />

3,000 m 3 (LNG), 400 m 3 (MGO)<br />

Number of tanks 2 (2 ×1,500 m 3 )<br />

LNG discharge rate 1,000 m 3 /h<br />

LNG intake rate 900 m 3 /h<br />

Length over all<br />

93.6 m<br />

Beam<br />

14.8 m<br />

Height <str<strong>on</strong>g>to</str<strong>on</strong>g> main deck<br />

8.2 m<br />

Draught (LNG full, at departure)<br />

5.05 m<br />

Draught (empty, following bunkering)<br />

3.5 m<br />

20 n<strong>on</strong>s<str<strong>on</strong>g>to</str<strong>on</strong>g>p

Pho<str<strong>on</strong>g>to</str<strong>on</strong>g>: The Linde Group<br />

Terminal.<br />

A tanker<br />

vessel taking<br />

in LNG from a<br />

local s<str<strong>on</strong>g>to</str<strong>on</strong>g>rage<br />

facility in<br />

Sweden.<br />

technical viewpoint, there is no reas<strong>on</strong> <str<strong>on</strong>g>to</str<strong>on</strong>g> oppose the implementati<strong>on</strong><br />

of LNG bunkering.<br />

Risks Inherent in LNG Bunkering<br />

An analysis of hazards involved in refuelling an LNG-powered<br />

ship from a bunkering vessel revealed a number of potential<br />

errors that could increase the associated risk. These mainly<br />

include inadequate communicati<strong>on</strong> between the two ships,<br />

pers<strong>on</strong>nel falling over board, and LNG leakage while bunkering.<br />

A ship collisi<strong>on</strong> might cause the refuelling hose <str<strong>on</strong>g>to</str<strong>on</strong>g> break<br />

FKAB. This vessel will be equipped with two engines<br />

capable of burning either LNG or biogas.<br />

Length over all<br />

67.6 m<br />

Beam<br />

11.6 m<br />

Draught<br />

3.5 m<br />

LNG tank volume 800 m 3<br />

LNG intake rate 300 m 3 /h<br />

Top speed<br />

12.5 kn<br />

Engine output<br />

2 × 675 kW<br />

Pho<str<strong>on</strong>g>to</str<strong>on</strong>g>s: TGE Marine Gas Engineering, FKAB Marine Design<br />

or a tank <str<strong>on</strong>g>to</str<strong>on</strong>g> suffer damage. In the event of hose breakage,<br />

the amount of leakage could be minimised effectively by a<br />

fast-acting safety chain that would keep the hazardous effects<br />

within c<strong>on</strong>trollable limits.<br />

However, in the event of a ship collisi<strong>on</strong> potentially damaging<br />

the LNG s<str<strong>on</strong>g>to</str<strong>on</strong>g>rage tank, such a system would not be able <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

c<strong>on</strong>tain the leakage. Therefore the study investigates the probability<br />

of a collisi<strong>on</strong> in the given situati<strong>on</strong>. The analysis showed<br />

that a collisi<strong>on</strong> with a ship at berth (whether for bunkering or<br />

otherwise) is highly unlikely. Imposing appropriate limitati<strong>on</strong>s<br />

of the manoeuvring space around ships being bunkered would<br />

further mitigate the collisi<strong>on</strong> risk. The study c<strong>on</strong>cluded that the<br />

likeliness of a collisi<strong>on</strong> with a bunkering vessel in transit from<br />

its berth <str<strong>on</strong>g>to</str<strong>on</strong>g> a cus<str<strong>on</strong>g>to</str<strong>on</strong>g>mer is the same as for any other ship moving<br />

within a port. Careful m<strong>on</strong>i<str<strong>on</strong>g>to</str<strong>on</strong>g>ring and c<strong>on</strong>trol of in-port traffic<br />

by the port z<strong>on</strong>e authority can help minimise the collisi<strong>on</strong> risk.<br />

This includes specific measures such as safety distances, closestpoint-of-approach<br />

rules, z<strong>on</strong>e limitati<strong>on</strong>s or tug support.<br />

The outcome of the study and its safety analyses served<br />

as a basis for the development of a safety c<strong>on</strong>cept for bunkering<br />

liquefied gas. The resulting draft c<strong>on</strong>cept is intended<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> provide the resp<strong>on</strong>sible authorities with guidance in taking<br />

further steps <str<strong>on</strong>g>to</str<strong>on</strong>g>wards harm<strong>on</strong>ised rules for all of Germany.<br />

The safety c<strong>on</strong>cept makes a distincti<strong>on</strong> between portspecific<br />

and general requirements. The requirements were<br />

generally defined <strong>on</strong> a functi<strong>on</strong>al basis wherever possible so<br />

as <str<strong>on</strong>g>to</str<strong>on</strong>g> ensure safety while excluding technical soluti<strong>on</strong> variants.<br />

The draft guideline was amended <str<strong>on</strong>g>to</str<strong>on</strong>g> c<strong>on</strong>tain a list of compulsory<br />

items <str<strong>on</strong>g>to</str<strong>on</strong>g> include in a bunkering procedure, and a corresp<strong>on</strong>ding<br />

bunkering check list.<br />

The study closes with recommendati<strong>on</strong>s for adapting the legal<br />

basis as well as for building the necessary infrastructure.<br />

For further Informati<strong>on</strong>:<br />

Henning Pewe, Gas Technology Expert<br />

Ph<strong>on</strong>e: +49 40 36149-653, E-Mail: henning.pewe@gl-group.com<br />

01/2013<br />

21

market volvo ocean race<br />

Safer Racing<br />

Modern racing yachts walk a thin line between ultra-lightweight design and<br />