230ee/300ee 230ee/300ee - Invacare

230ee/300ee 230ee/300ee - Invacare

230ee/300ee 230ee/300ee - Invacare

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

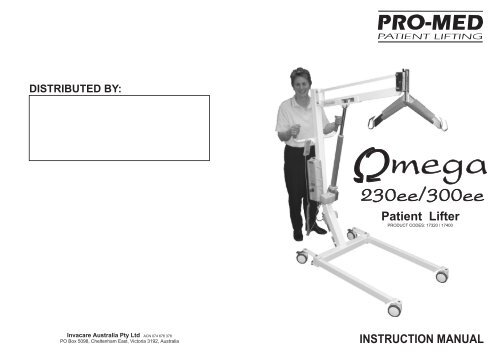

DISTRIBUTED BY:<br />

mega<br />

<strong>230ee</strong>/<strong>300ee</strong><br />

Patient Lifter<br />

PRODUCT CODES: 17320 / 17400<br />

<strong>Invacare</strong> Australia Pty Ltd ACN 074 676 378<br />

PO Box 5098, Cheltenham East, Victoria 3192, Australia<br />

INSTRUCTION MANUAL

Notes<br />

Contents<br />

Preface ................................................... 3<br />

Intended Purpose.......................... 4<br />

Pro-Med Credentials...................... 5<br />

Warranty ..................................... 6<br />

Key to Symbols........................... 7<br />

Getting Started ....................................... 9<br />

Documentation.......................... 10<br />

Assembly Instructions .............. 11<br />

Fitting Spreader or Pivot...............12<br />

Features ............................................... 13<br />

Overview ................................... 14<br />

Specifications <strong>230ee</strong> ................ 15<br />

Specifications <strong>300ee</strong> ................ 16<br />

Mechanical Features ................ 17<br />

Attachment Options .................. 18<br />

Lifting Cradle / Frame ......... 19-20<br />

Floor Lift / Frame ................. 21-22<br />

Weighing Device ...................... 23<br />

Slings ....................................... 24<br />

Lifting ................................................... 25<br />

Safety Precautions ................... 26<br />

General Purpose Slings<br />

Selecting the Sling .............. 27-29<br />

Lifting Procedures ............... 30-33<br />

Pivot Slings<br />

Selecting the Sling .............. 34-35<br />

Lifting Procedures ............... 36-40<br />

Maintenance ........................................ 41<br />

Mobilette Control Unit............ 42-45<br />

Recharging............................... 46<br />

Sling Care ................................ 47<br />

Lifter Maintenance ............... 48-50<br />

Trouble Shooting ...................... 51<br />

Spare Parts............................ 52-56<br />

Distributors .................................... 57-60<br />

Log Book ........................................ 61-67<br />

Notes .................................................... 68<br />

68<br />

1

Log Book<br />

TO BE COMPLETED AFTER EACH INSPECTION/SERVICE<br />

Service Type<br />

Condition Report<br />

Pre-Delivery<br />

Periodic<br />

Inspection<br />

Minor<br />

Major<br />

Date<br />

Inspected By<br />

Action Taken<br />

Signature<br />

Service Type<br />

Condition Report<br />

Pre-Delivery<br />

Periodic<br />

Inspection<br />

Minor<br />

Major<br />

Date<br />

Inspected By<br />

Action Taken<br />

Signature<br />

2 67

Log Book<br />

TO BE COMPLETED AFTER EACH INSPECTION/SERVICE<br />

Service Type<br />

Pre-Delivery<br />

Periodic<br />

Inspection<br />

Date<br />

Minor<br />

Major<br />

Condition Report<br />

Preface<br />

Intended Purpose............................ 4<br />

Pro-Med Credentials...................... 5<br />

Warranty...................................... 6<br />

Key to Symbols............................... 7<br />

Inspected By<br />

Action Taken<br />

Signature<br />

Service Type<br />

Condition Report<br />

Pre-Delivery<br />

Minor<br />

Periodic<br />

Inspection<br />

Major<br />

Date<br />

Inspected By<br />

Action Taken<br />

Signature<br />

66<br />

3

Preface<br />

Log Book<br />

Following intended purpose is as declared for the ARTG Listing.<br />

FLOOR LIFTERS ARTG LISTING: 98422<br />

Intended Purpose of Patient Lifting Devices:<br />

Is to be operated by a qualified carer in conjunction with an appropriate<br />

Pro Med sling and accessories to move or transfer patients with<br />

disabilities who are within the capacity indicated on the device and the<br />

carer using the device to guidelines identified in the relevant device<br />

instruction manual.<br />

TO BE COMPLETED AFTER EACH INSPECTION/SERVICE<br />

Service Type<br />

Pre-Delivery<br />

Periodic<br />

Inspection<br />

Date<br />

Minor<br />

Major<br />

Condition Report<br />

Stand up Lifters: ARTG LISTING: 98427<br />

Inspected By<br />

Action Taken<br />

Intended Purpose of Patient Stand up Lifter Devices:<br />

Is to be operated by a qualified carer in conjunction with an appropriate<br />

Pro Med sling and accessories to assist a patient with disabilities in<br />

standing from a sitting position transferring the patient to another device<br />

and assist the carer to reseat the patients who is within the capacity<br />

indicated on the device and the usage guidelines identified in the<br />

relevant device instruction manual. Other devices i.e. the walking tutor<br />

can be fitted to these devices to assist patients with walking with the<br />

assistance of a qualified carer to operate the device within its specified<br />

capabilities identified in relevant device instruction manuals.<br />

Signature<br />

Service Type<br />

Pre-Delivery<br />

Periodic<br />

Inspection<br />

Minor<br />

Major<br />

Condition Report<br />

Date<br />

Slings And Accessories: ARTG LISTING: 98421<br />

Intended Purpose of the Slings and Accessories Device:<br />

Is to be used by a qualified carer in conjunction with an appropriate Pro<br />

Med patient lifting device to support patients with disabilities who are<br />

within the capacity indicated on the sling from one device to another and<br />

the carer adhering to the usage guidelines identified in the relevant<br />

slings instruction manual.<br />

Inspected By<br />

Signature<br />

Action Taken<br />

4<br />

65

Log Book<br />

TO BE COMPLETED AFTER EACH INSPECTION/SERVICE<br />

Service Type<br />

Pre-Delivery<br />

Periodic<br />

Inspection<br />

Date<br />

Inspected By<br />

Signature<br />

Minor<br />

Major<br />

Condition Report<br />

Action Taken<br />

Preface<br />

PRO-MED Credentials<br />

• Australian Therapeutic Goods Listing, Certificate of Listing AUST L 42882<br />

• FDA Listing A804934 (USA)<br />

• FDA Registration 9613615 (USA)<br />

• CE Mark (European Union Listing)<br />

• Global operations for in-warranty and out-of-warranty service support.<br />

• Each finished lifter is individually tested in our laboratory. No lifter is<br />

delivered without a signed Quality Test Certificate bearing the serial<br />

number of that unit.<br />

• Lifting capacities 127kg/280lb to 300kg/660lb. Engineering safety factor<br />

exceeds European Standards.<br />

• Each machine is operated by leading edge electrical or hydraulic technology.<br />

• Complete range of slings and supports designed and manufactured by<br />

Pro-Med using medical quality padding and fabrics.<br />

• The Australian Government endorses <strong>Invacare</strong> Australia for its medical<br />

equipment<br />

export marketing program.<br />

Service Type<br />

Condition Report<br />

Pre-Delivery<br />

Periodic<br />

Inspection<br />

Minor<br />

Major<br />

Date<br />

Inspected By<br />

Action Taken<br />

Signature<br />

64<br />

5

Warranty<br />

Preface<br />

<strong>Invacare</strong> Australia Pty Ltd warrants its products to be free from defects in<br />

material and workmanship under normal use and service and will, within the<br />

periods stated below from the date of purchase, repair or replace, without cost<br />

to the original customer, any part, assembly, or portion thereof which shall be<br />

returned to Pro-Med and from our inspection, shows to be defective.<br />

Patient Lifter including Electronics / Hydraulics .. 2 years<br />

Weighing Devices ................................................ 1 year<br />

Accessories on Lifter ........................................... 2 years<br />

Slings ................................................................... 1 year<br />

Batteries ............................................................... 3 months<br />

Log Book<br />

TO BE COMPLETED AFTER EACH INSPECTION/SERVICE<br />

Service Type<br />

Pre-Delivery<br />

Periodic<br />

Inspection<br />

Date<br />

Minor<br />

Major<br />

Condition Report<br />

No warranty claim shall apply where the product or any part thereof has been<br />

altered, varied, modified, or damaged either accidentally or through improper<br />

or negligent use, or repaired or serviced by any persons not accredited by the<br />

Authorised Distributor. Pro-Med Slings void warranty if not laundered as per<br />

instructions on the Sling Label.<br />

It is the responsibility of the Purchaser to train and instruct new staff on the<br />

proper use of the products. Warning: It is the responsibility of the Purchaser to<br />

select the appropriate Pro-Med Lifter and Pro-Med Sling to address the lifting<br />

needs of an individual. An incorrect selection may cause injury. If in doubt,<br />

seek input from a suitably qualified therapist.<br />

<strong>Invacare</strong> Australia disclaims any responsibility for accidents, mishaps or injury<br />

caused by the combination of Pro-Med products with another manufacturer’s<br />

equipment.<br />

Inspected By<br />

Signature<br />

Service Type<br />

Pre-Delivery<br />

Minor<br />

Action Taken<br />

Condition Report<br />

Periodic<br />

Inspection<br />

Major<br />

Date<br />

Inspected By<br />

Action Taken<br />

Signature<br />

6<br />

63

Log Book<br />

TO BE COMPLETED AFTER EACH INSPECTION/SERVICE<br />

Preface<br />

Key to Symbols<br />

The following symbols are used on lifter and attachment labels:<br />

Service Type<br />

Pre-Delivery<br />

Minor<br />

Condition Report<br />

The symbol required to be displayed on regulated products for<br />

sale on the European Market. It indicates that the product<br />

complies with applicable European Directives related to health,<br />

safety, environment and consumer protection.<br />

Periodic<br />

Inspection<br />

Date<br />

Major<br />

Safe Working Load. Represents the maximum load the lifter is<br />

SWL rated at for safe operation.<br />

The following symbols are used on sling labels and relate to washing<br />

instructions:<br />

Inspected By<br />

Action Taken<br />

Wash at maximum<br />

temperature 60 o C<br />

(140 o F) permanent<br />

press cycle.<br />

Do not dry clean.<br />

Signature<br />

Wash at maximum<br />

temperature 85 o C<br />

(198 o F) permanent<br />

press cycle.<br />

Dry cleanable.<br />

Do not tumble dry.<br />

Service Type<br />

Condition Report<br />

Do not use bleach.<br />

Do not iron.<br />

Pre-Delivery<br />

Periodic<br />

Inspection<br />

Minor<br />

Major<br />

Please refer to individual sling labels for complete instructions regarding<br />

washing and laundering.<br />

Date<br />

Inspected By<br />

Action Taken<br />

Signature<br />

62<br />

7

Log Book<br />

Customer Name<br />

Customer Address<br />

Product Name Serial No<br />

Date of Purchase Warranty Period<br />

Distributed By<br />

Owner:<br />

• Ensure the patient lifter is serviced regularly<br />

(refer Lifter Maintenance, page 33).<br />

• Contact an Authorised Pro-Med Distributor /<br />

Service Agent immediately if there are any<br />

problems with the operation of the patient<br />

lifter.<br />

• Ensure the Log Book is completed and<br />

signed.<br />

• Record any repairs required.<br />

• Withdraw the patient lifter from service if<br />

inspection reveals that user safety is<br />

jeopardised in any way from use of the<br />

patient lifter.<br />

• Ensure ongoing servicing after the Warranty<br />

Period is maintained by agreement between<br />

you and an Authorised Pro-Med Distributor /<br />

Service Agent.<br />

Check List<br />

Authorised Pro-Med Distributor /<br />

Service Agent:<br />

• Ensure the patient lifter is serviced in<br />

accordance with the Manufacturer’s<br />

recommendations.<br />

• Ensure the Log Book is completed and<br />

signed.<br />

• Record any repairs required.<br />

• Advise the Owner to withdraw the patient<br />

lifter from service if inspection reveals that<br />

user safety is jeopardised in any way from<br />

use of the patient lifter.<br />

• Ensure ongoing servicing after the Warranty<br />

Period is maintained by agreement between<br />

you and the Owner.<br />

8 61

Distributors<br />

INTERNATIONAL<br />

Canada<br />

Blue Leaf Healthcare<br />

Unit 2, 6104-82 Avenue, Edmonton, Alberta T6B OE7<br />

Tel: 1780 435 4951 Fax: 1780 468 1946<br />

Korea<br />

Pro-Med Korea Pty Ltd<br />

401 Hando Building, 942 Donopk Dong, Kangnam-GU, Seoul<br />

Tel: 822 3462 9601 Fax: 822 3462 9373<br />

Getting Started<br />

Documentation.......................... 10<br />

Assembly Instructions .............. 11<br />

Fitting Spreader or Pivot...............12<br />

New Zealand<br />

Active Rehab Equipment<br />

25 Rennie Drive, Airport Oaks, Mangere<br />

Tel: 649 256 4800 Fax: 649 256 0055<br />

Rehab Equipment Company<br />

260 King Edward Street, Dunedin<br />

Tel: 643 455 3321 Fax: 643 455 3322<br />

South Africa<br />

G.I.S. PTY LTD<br />

26 William Campbell Drive, La Lucia, KwaZulu Natal 4051<br />

Tel: (031) 5628875 Fax: (031) 5723799<br />

United Kingdom<br />

Park House Healthcare<br />

Bradford Road, Birstall, Batley West, Yorkshire WF17 9PH<br />

Tel: 44 845 0600 333 Fax: 44 845 3442 640<br />

USA<br />

Alpha Modalities<br />

700 NW 42nd Street Suite 207, Seattle, Washington 98107<br />

Tel: 1800 273 5749 Fax: 1206 374 2476<br />

60<br />

9

Getting Started<br />

Documentation<br />

With each lifter you should receive the following<br />

documents:<br />

• this Instruction Manual;<br />

• a Test Certificate; and<br />

• a Warranty / Registration Card.<br />

Victoria<br />

Linds Rehabilitation Equipment<br />

58-60 Star Crescent, Hallam VIC, 3803<br />

Tel: (03) 9796 3399 Fax: (03) 9796 3313<br />

Western Australia<br />

River Abilities<br />

29 Alexandra Place, Bentley WA, 6102<br />

Tel: (08) 9350 6600 Fax: (08) 9350 5299<br />

Distributors<br />

Warranty/Registration Card<br />

The tear-off Registration Card must be completed and<br />

returned to Pro-Med within fourteen days of purchase.<br />

10<br />

59

Distributors<br />

AUSTRALIA<br />

New South Wales / ACT<br />

Active Mobility Systems<br />

30 James Street, Lidcombe, NSW, 2141<br />

Tel: (02) 9649 2111 Fax: (02) 9649 8506<br />

Northern Territory<br />

Mobility & Rehabilitation Services (North)<br />

3/6 Beresford Road, Yarrawonga NT, 0810<br />

Tel: (08) 8932 1900 / 1966 Fax: (08) 8932 1922<br />

Mobility & Rehabilitation Services (South)<br />

6 Fogarty Street, Alice Springs, NT, 0870<br />

Tel: (08) 8952 3599 Fax: (08) 8952 4833<br />

South Australia<br />

Grajen Medical<br />

376-380 South Road, Richmond SA, 5033<br />

Tel: (08) 8344 0100 Fax: (08) 8234 8883<br />

Queensland<br />

Active Medical Supplies<br />

35 Southgate Avenue, Cannon Hill, Qld, 4170<br />

Tel: (07) 3899 8887 Fax: (07) 3899 8825<br />

Independent Living Solutions<br />

8 Keane Street, Currajong, Townsville, Qld, 4812<br />

Tel: (07) 4728 1200 Fax: (07) 4728 1201<br />

Medtech Mobility Equipment<br />

18 Prescott Street, Toowoomba, Qld, 4350<br />

Tel: (07) 4639 3977 Fax: (07) 4659 5953<br />

Tasmania<br />

Tasmanian Medical Supplies<br />

40 Brisbane Street, Hobart, Tas, 7000<br />

Tel: (03) 6234 9777 Fax: (03) 6234 8452<br />

Assembly Instructions<br />

All Pro-Med lifters are fully assembled, load tested and certified at the factory<br />

before being partially dismantled for shipping. Follow these instructions to<br />

assemble your Omega <strong>230ee</strong> / <strong>300ee</strong>.<br />

Tools required: Spanners - 17mm AF, 16mm AF, 2 x 13mm AF<br />

Hexagon Wrench - 3.00mm AF<br />

1. Remove lifter components from packing and lay out on carpeted area.<br />

2. Fit Mast Assembly into Mast Holder of chassis. Ensure that the Mast is<br />

fully engaged in the Mast Holder. Tighten the Clamp Screw to prevent<br />

movement of the Mast.<br />

3. Attach Push Handle with M8 Screws, Nuts and Washers packed with<br />

the handle.<br />

4. Assemble Boom to Mast with M10 x 75 Bolt and Washer. Assistance<br />

may be required to support the outer end of the Boom whilst fitting.<br />

Tighten nuts to clamp inner bush to clevis.<br />

5. Attach Boom to top of Actuator with M10 Hex Bolt, Nut and Washer.<br />

Tighten, taking care not to crush top Actuator hole.<br />

6. Attach electrics Mounting Rail to the Mast if required. Loosen the three<br />

screws in the left side of the Mast, fit the Rail and re-tighten the Screws.<br />

7. Mount the Control Box by sliding it down firmly onto the lower lugs of the<br />

Mounting Rail. Secure with M5 Socket Head Cap Screw.<br />

8. Plug the Main Actuator into Port 1 on the underside of the Control Box<br />

and the Leg Spreading Actuator into Port 2<br />

9. Plug the Handset Lead into the large socket on the underside of the<br />

Control Box. Note, this socket is keyed so that the plug must be<br />

correctly orientated before it will enter. When aligned, press home<br />

firmly. A smear of Vaseline on the O-Ring may assist if the plug is tight.<br />

10. Clip Battery Pack onto Control Box and check operation of the Actuators.<br />

The Red Emergency Stop Button must be released for the Actuators to<br />

function properly. Turn the Knob 1/4 turn clockwise to release.<br />

Refer diagram overleaf.<br />

Getting Started<br />

58<br />

11

Getting Started<br />

Distributors<br />

Fitting a Spreader Bar or Pivoting Frame<br />

1. Remove the spreader bar shaft from the boom end fitting.<br />

2. Insert the spreader bar shaft through the spreader bar or Pivoting Frame.<br />

3. Attach spreader bar cover (Pivoting Frame only).<br />

4. Insert bolt through clevis and shaft.<br />

5. Fit nut and tension to allow easy movement of spreader bar shaft.<br />

12<br />

57

Maintenance<br />

SPARE PARTS<br />

Features<br />

Overview ................................... 14<br />

Specifications <strong>230ee</strong> ................ 15<br />

Specifications <strong>300ee</strong> ................ 16<br />

Mechanical Features ................ 17<br />

Attachment Options .................. 18<br />

Lifting Cradle / Frame ......... 19-20<br />

Floor Lift / Frame ................. 21-22<br />

Weighing Device ...................... 23<br />

Slings ....................................... 24<br />

56<br />

13

Features<br />

Overview<br />

The Omega range of Pro-Med lifters are designed to lift patients safely and<br />

securely in a wide range of slings.<br />

The Omega <strong>230ee</strong> / <strong>300ee</strong> are a multi-use, heavy duty patient lifter that may be<br />

supplied with the following lifting attachment options:<br />

• Spreader Bar - for use with standard slings;<br />

• Pivoting Frame - for use with Banana Slings;<br />

• Cradle - for lifting Pro-Med Lifting Frames; and<br />

• Weighing Device - for effortless, accurate, electronic weighing.<br />

The Omega <strong>230ee</strong> is an electric powered general purpose unit with a safe<br />

working load of 230kg.<br />

The Omega <strong>300ee</strong> is an electric powered general purpose unit with a safe<br />

working load of 300kg.<br />

SPARE PARTS<br />

Maintenance<br />

14<br />

55

Maintenance<br />

Features<br />

SPARE PARTS<br />

Specifications Omega <strong>230ee</strong><br />

Model Omega <strong>230ee</strong><br />

Product Code 17320<br />

Capacity 230kg (500lb)<br />

Configuration<br />

Boom Length 92.5cm (36.5in)<br />

Base size, max open<br />

13 x 126 x 115.5cm (5 x 49.5 x 45.5in)<br />

H x W x L<br />

Base size, closed<br />

13 x 70 x 115.5cm (5 x 27.5 x 45.5in)<br />

H x W x L<br />

Minimum storage space 160 x 70 x 115.5cm (63 x 27.5 x 45.5in)<br />

H x W x L<br />

Frame Material Epoxy coated steel<br />

Castors Twin Wheel<br />

Size 10cm (4in)<br />

Brakes Yes – Rear<br />

Weight 62kg (136lb)<br />

Safe for Bathroom Use Yes<br />

Lift Range<br />

Spreader Bar: Low 58cm (23in)<br />

High 170cm (67in)<br />

Pivot: Low 41cm (16in)<br />

High 153cm (60in)<br />

Other Specifications Provides rigid stretcher attachment for single carer supine lifting<br />

Floor lift possible<br />

54<br />

15

Features<br />

Maintenance<br />

Specifications Omega <strong>300ee</strong><br />

SPARE PARTS<br />

Model Omega <strong>300ee</strong><br />

Product Code 17400<br />

Capacity 300kg (660lb)<br />

Configuration<br />

Boom Length 92.5cm (36.5in)<br />

Base size, max open<br />

13 x 126 x 115.5cm (5 x 49.5 x 45.5in)<br />

H x W x L<br />

Base size, closed<br />

13 x 70 x 115.5cm (5 x 27.5 x 45.5in)<br />

H x W x L<br />

Minimum storage space 160 x 70 x 115.5cm (63 x 27.5 x 45.5in)<br />

H x W x L<br />

Frame Material Epoxy coated steel<br />

Castors Twin Wheel<br />

Size 10cm (4in)<br />

Brakes Yes – Rear<br />

Weight 62kg (136lb)<br />

Safe for Bathroom Use Yes<br />

Lift Range<br />

Spreader Bar: Low 58cm (23in)<br />

High 170cm (67in)<br />

Pivot: Low 41cm (16in)<br />

High 153cm (60in)<br />

Other Specifications Provides rigid stretcher attachment for single carer supine lifting<br />

Floor lift possible<br />

16<br />

53

Maintenance<br />

SPARE PARTS<br />

Features<br />

Mechanical Features<br />

Sling Attachment<br />

Standard slings are attached to the hooks on a<br />

spreader bar via webbing straps.<br />

Pivot slings are attached via key-hole buckles to studs<br />

located on the pivoting frame.<br />

Locking Castors<br />

The Omega <strong>230ee</strong> / <strong>300ee</strong> comes with high quality<br />

locking castors at the rear. These castors are easily<br />

operated by foot and keep the lifter stationary when<br />

required.<br />

52<br />

17

Features<br />

Attachment Options<br />

The Safe Working Load (SWL) of the Omega <strong>230ee</strong> /<br />

<strong>300ee</strong> is determined by the stated SWL of the<br />

boom-end attachment.<br />

The lowest stated SWL determines the ultimate load<br />

carrying capacity.<br />

Trouble Shooting<br />

Before trouble shooting ensure that:<br />

• the actuator is not in operation<br />

• the actuator is free from load, and<br />

• that maintenance procedures have been<br />

checked and followed.<br />

Mechanical<br />

Maintenance<br />

Trouble shooting should be<br />

performed by someone that is<br />

familiar with both the use and<br />

mechanism of the lifter and<br />

general electrics. If in doubt,<br />

contact your supplier to arrange a<br />

service call.<br />

Spreader Bar<br />

The Spreader Bar is the standard attachment for<br />

general purpose lifters for use with the following<br />

slings:<br />

• General Purpose Sling;<br />

• General Purpose Sling with Head Support;<br />

• General Purpose Hygiene Sling with Head<br />

Support; and<br />

• Hammock Sling<br />

Spreader Bar Safe Working Load SWL 300kg (660lb)<br />

Pivot Frame/Pivot Sling<br />

The Pivot Frame/Pivot Sling Option allows a patient<br />

to be lifted in either a sitting or lying position. The<br />

frame spreads the sling attachment points to<br />

ensure the patient’s hips are not excessively<br />

flexed, avoiding the discomfort obese patients<br />

sometimes experience with standard slings.<br />

The ability to position a patient in the sitting<br />

posture greatly assists correct seating. The<br />

reclining position is ideal for lifting on or off a bed<br />

or off the floor. The unique additional pivot at the<br />

end of the boom allows the whole frame to be<br />

rocked back and forth.<br />

Pivot Frame Safe Working Load SWL 205kg (451lb)<br />

Symptom Possible Causes Action<br />

Actuator makes creaking noise No free movement at actuator Loosen mounting bolts slightly<br />

during lift<br />

mounting bolts<br />

Lifter tracks incorrectly Castor brakes faulty Check both castor brakes are<br />

releasing properly<br />

Electrical<br />

Symptom Possible Causes Action<br />

Buzzer sounds from within Flat battery<br />

Recharge battery<br />

control box Defective battery Replace battery<br />

Battery charger power indicator Not connected to the mains Connect to mains<br />

does not light up<br />

The fuse has blown<br />

Replace fuse or send the<br />

system for repair<br />

Battery charger is defective Send battery charger for repair<br />

Actuator does not run but relays<br />

in control box are heard clicking<br />

Actuator plug not pushed into<br />

control box properly<br />

Push plug into control box<br />

properly<br />

Actuator defective<br />

Replace actuator<br />

Control box defective<br />

Replace control box<br />

Actuator does not run and no Control box defective<br />

Replace control box<br />

relay noise is heard from Handset defective<br />

Replace handset<br />

control box<br />

Actuator cannot lift full load Motor is damaged Send actuator for repair<br />

Control box completely dead on Emergency stop button pressed Release button<br />

battery; no relay clicking is Battery completely flat<br />

Charge battery<br />

heard<br />

Battery defective<br />

Replace battery<br />

Actuator works in one direction Handset defective<br />

Send handset for repair<br />

only Control box defective Send control box for repair<br />

Actuator works with some but Handset defective<br />

Send handset for repair<br />

not all handset buttons<br />

No motor sound or movement The actuator is not connected Connect actuator to control box<br />

of piston rod<br />

to the control box<br />

Blown fuse in the control box Change fuse<br />

Cable damaged<br />

Send actuator for repair<br />

Motor runs but piston rod does Gear wheel or spindle damaged Send actuator for repair<br />

not move<br />

Piston rod will only move<br />

inwards and not outwards<br />

Safety nut has operated Send actuator for repair<br />

18<br />

51

Maintenance<br />

Features<br />

Lifting Cradle/Frame - SWL 230kg (506lb)<br />

A Major Service undertaken by an authorised service agent every<br />

12 months is a minimum requirement.<br />

Note: LOAD TEST TO SAFE WORKING LOAD (SWL) ONLY<br />

Repairs and Spare Parts<br />

Faulty components or workmanship covered by warranty will be repaired<br />

where appropriate and replaced when necessary. Defects due to mistreatment<br />

or neglect will not be covered by warranty but repair can be arranged by<br />

Pro-Med’s authorised agents at the request of the User.<br />

Spare parts are available for purchase and are itemised by part number. The<br />

list and diagrams following allow easy reference to part numbers for ordering:<br />

The cradle attachment is designed to allow the Omega<br />

<strong>230ee</strong> / <strong>300ee</strong> to lift a patient supported in the PRO-<br />

MED Lifting Frame.<br />

If the cradle is not already attached to the lifter, then the<br />

existing attachment will first have to be removed.<br />

Removing an attachment<br />

Hold the attachment firmly by one hand and with the<br />

other hand, use the thumb to pull back the release tab<br />

on the boom end of the lifter. Lift the attachment up and<br />

away from the lifter.<br />

Attaching the cradle<br />

Slide the cradle down over the<br />

boom end. The release tab will<br />

click into its location hole when<br />

properly fitted.<br />

Frame<br />

Assemble the frame by locking the two halves together<br />

and place over the patient. If the patient is attached to<br />

apparatus such as drips, monitor, etc, the<br />

unassembled frame needs to be placed around the<br />

patient before assembly.<br />

Gliders - Do not use a glider that is damaged. Pass the single hole end of a<br />

glider under the patient. If skin is exposed, apply talcum powder to the glider<br />

first. Attach to a support peg on the frame at a strategic point. Tension the<br />

glider by selecting the appropriate hole at the glider’s other end. Employ a<br />

sufficient number of gliders to provide a cradle support. It is recommended<br />

that a minimum of 9 standard gliders and 1 head glider be used for patients<br />

exceeding 70kg. Gliders can be fitted diagonally to avoid injured areas.<br />

Similarly, a glider can be left out for toileting or wound dressing.<br />

Removal of Gliders - To release a glider from a stud, pull the glider gently so<br />

that the stud clears the keyhole and lift. Should the glider be difficult to<br />

remove, employ a twising motion.<br />

50<br />

19

Features<br />

Lifting a patient supported in a Lifting Frame<br />

Wheel the lifter under the bed of the patient supported<br />

in the Lifting Frame. Lower the boom so that the<br />

elasticised cradle straps will easily stretch to the sides<br />

of the frame. Cradle straps are attached by hooking the<br />

white plastic buckle of each strap over a group of three<br />

studs located on the sides of the Lifting Frame.<br />

Because the human body is slightly top heavy, to achieve a balanced support<br />

of the lifting frame, each cradle strap must be hooked onto the first stud<br />

closest to the head end of the Lifting Frame (see diagram).<br />

For head down (Trendelenburg) lifting, reverse or other combinations can be<br />

used. Be sure that both sides of the Lifting Frame are symmetrical with regard<br />

to cradle strap-stud selection.<br />

Raise the patient with the lifter, checking that he/she is well supported and<br />

comfortable. If not, lower immediately and adjust or add more Lifting Frame<br />

Gliders.<br />

Maintenance<br />

• Inspect surfaces for scratches/chips<br />

• Retard rusting by applying spray paint (Dulux ‘Special White’ Code: 81880)<br />

• Clean surfaces with mild soap and water and remove any adhesive tape<br />

marks with eucalyptus oil<br />

• Examine all moving parts and fasteners for wear and fatigue and lubricate<br />

and/or adjust as required<br />

• Arrange repair/replacement of any faulty parts<br />

• Complete and sign log book<br />

Major Service: (After Every 6 Months of Service)<br />

• General inspection of lifter<br />

• Check castors are tightly attached to legs<br />

• Check castors for free running wheels (remove any fluff and/or hair)<br />

• Check castor brakes operate efficiently<br />

• Overhaul castors and repack with grease<br />

• Inspect surfaces for scratches/chips<br />

• Retard rusting by applying spray paint (Dulux ‘Special White’ Code: 81880)<br />

• Clean surfaces with mild soap and water and remove any adhesive tape<br />

marks with eucalyptus oil<br />

• Examine all moving parts and fasteners for wear and fatigue and lubricate<br />

and/or adjust as required<br />

• Check tightness of bolt in leg bushes<br />

• Check linkages are secure in leg adjuster ball joints<br />

• Check all electrical components, including battery chargers for correct<br />

operation<br />

• Actuator:<br />

• Remove dust and dirt from actuator with cloth<br />

• Repack actuator clevis’ with grease *Top actuator bolts must not be over<br />

tightened.<br />

• Wipe actuator shaft with oiled rag (DO NOT use lubricants such as WD40<br />

or RP7)<br />

20<br />

49

Maintenance<br />

Lifter Maintenance<br />

Safety Inspections<br />

Periodic inspections should be performed by a person who is suitably and<br />

properly qualified and well acquainted with the design, use and care of the<br />

hoist.<br />

Inspections should be carried out both routinely (at least as often as specified)<br />

and, as necessary. All defects and damages that have lead to corrective action<br />

should be noted in a log book (see page 45) and signed and dated by the<br />

inspector. Defects and resulting actions should be reported in writing to your<br />

supplier.<br />

If inspection reveals that the safety of the hoist is jeopardised in any way, the<br />

Owner should be notified immediately, the hoist should be taken out of service<br />

and not used again until the problem has been rectified. Contact the supplier<br />

to arrange servicing.<br />

Floor Lift / Frame<br />

USING THE FLOOR LIFT STRAP KIT* IN COMBINATION WITH THE 4 POINT<br />

SPREADER BAR ATTACHMENT<br />

PRO-MED recommends that two carers assist with a floor lift<br />

using a Floor Lift Strap Kit and 4 Point Spreader Bar Combination.<br />

1. Assemble the Pro-Med Lifting Frame:<br />

#<br />

LIFTING FRAME<br />

Assemble lifting frame by locking the two halves together<br />

(see diagram) and place over the patient. If the patient is<br />

attached to apparatus such as drips, monitors etc., the<br />

unassembled frame needs to be placed around the<br />

patient first before assembly.<br />

Features<br />

3. Lower the boom of the lifter towards the patient<br />

stopping about a metre above the patient, allowing<br />

enough space to attach the straps.<br />

4. Connect the Floor Lift Straps to the 4 Point Spreader:<br />

Place the BLUE loops over the yoke hooks at the<br />

head end of the lifting frame, and place the RED<br />

loops over the yoke hooks at the foot end of the<br />

lifting frame.<br />

A Guide to Maintenance Procedures<br />

A regular visual check of the hoist and attachments is essential.<br />

Ideally, <strong>Invacare</strong> Australia Pty Ltd recommends servicing by an authorised<br />

service agent in accordance with the following schedule of Service Types:<br />

Pre-Delivery Inspection<br />

· Confirm all components are included<br />

· Inspect parts for possible damage in transit<br />

· Ensure all components are in working order<br />

· Arrange repair/replacement of any faulty parts<br />

· Complete and sign log book<br />

Minor Service: (After Every 3 Months of Service)<br />

· General inspection of lifter<br />

· Check castors are tightly attached to legs<br />

· Check castors for free running wheels (remove any fluff and/or hair)<br />

· Check castor brakes operate efficiently<br />

· Overhaul castors and repack with grease<br />

· Inspect surfaces for scratches/chips<br />

· Retard rusting by applying spray paint (Dulux ‘Special White’ Code: 81880)<br />

· Clean surfaces with mild soap and water and remove any adhesive tape<br />

marks with eucalyptus oil<br />

· Examine all moving parts and fasteners for wear and fatigue and lubricate<br />

and/or adjust as required<br />

· Arrange repair/replacement of any faulty parts<br />

· Complete and sign log book<br />

# Pro-Med Lifting Frame Safe Working Load: 230kg.<br />

GLIDERS<br />

Caution: Do not use a glider that is damaged.<br />

Pass the single hole end of a glider under the patient. If<br />

skin is exposed, apply talcum powder to the glider first.<br />

Attach to a support peg on the frame at a strategic point.<br />

Tension the glider by selecting the appropriate hole at<br />

the glider's other end. Employ a sufficient number of<br />

gliders to provide a cradle support. It is recommended<br />

that a minimum of 9 standard gliders and 1 head glider be<br />

used for patients exceeding 70kg.<br />

Gliders can be fitted diagonally to avoid injured areas.<br />

Similarly, a glider can be left out for toileting or wound<br />

dressing etc.<br />

Assembling a lifting frame is easier with two people,<br />

one either side of the patient.<br />

2. Widen the leg base of the lifter and position the lifter<br />

around the head of the frame.<br />

5. Attach the Floor Lift Straps to the Frame<br />

Use the longest straps. Attach keyhole buckles to<br />

the inner most studs at both ends.<br />

Make sure all gliders, attachments,<br />

and straps are fitted correctly before<br />

lifting the patient.<br />

48<br />

21

Features<br />

6. Lift the frame with the brakes on the lifter ON. One<br />

person is required at the foot end of the lifting frame to<br />

pull, and guide the frame clear of the lifter legs and<br />

electrics during the lift.<br />

NB: The frame will lift on an incline so that the<br />

lifter does not over-balance (i.e. the head end of<br />

the frame will be higher than the foot end). This is<br />

unavoidable.<br />

7. Raise the lifting frame about one metre off the ground<br />

or until clear of hospital bed. With the assistance of<br />

two carers, rotate frame to 90 degrees.<br />

8. Adjust the base width of the lifter appropriately<br />

and position the frame slowly over the bed.<br />

9. Lower the lifting frame until there is no tension on<br />

the straps.<br />

• Remove the straps<br />

• Remove the patient lifter<br />

• Remove the lifting frame from the patient.<br />

REMOVAL OF GLIDERS<br />

To release a glider from a stud, pull the glider<br />

gently so that the stud clears the keyhole and lift. If<br />

the glider is difficult to remove, employ a twisting<br />

motion.<br />

HIGH LIFT MANOEUVRE<br />

A lift from bed-to-bed can be achieved by using the BLUE<br />

loops attached to all hooks on the 4 Point Spreader and the<br />

shorter keyhole buckles straps attached to the frame.<br />

When undertaking a high lift manoeuvre, make sure the<br />

head end keyhole buckles are connected to the outer<br />

most studs. The keyhole buckles at the foot end should<br />

be connected to the inner most stud.<br />

Sling Care<br />

Maintenance<br />

General External Wear - In normal use, this is unavoidable and is shown by a<br />

fluffiness of the surface fibres of fabrics.<br />

Local Abrasion - This may be caused by the passage of webbing over sharp<br />

edges or protrusions whilst under tension.<br />

Cuts, Holes or Burns in the webbing - These are potentially dangerous and<br />

must lead to instant rejection of the product.<br />

Chemical Attack - If contamination is suspected, wash out well in warm water.<br />

Avoid contact with excessive heat which is likely to affect the product.<br />

Examination of Fittings (Buckles, "D" Rings, etc)<br />

Carefully examine buckles for ease of adjustment and absence of sharp<br />

edges or burrs likely to abrade the webbing.<br />

Examination of Stitch Patterns<br />

Examine stitch patterns for broken, worn, pulled or unraveled stitches. Reject<br />

any product where the thread has become subject to excessive abrasion or<br />

broken stitches.<br />

Cleaning<br />

For normal washing and cleaning, follow the care instructions on the label of<br />

the product.<br />

Storage<br />

Slings should be stored away from direct sunlight where they are not<br />

subjected to unnecessary strain, stress or pressure or to excessive heat or<br />

humidity.<br />

Washing Instructions<br />

Mild soap solution only, temp to 85C Max. followed by rinse. Do not use<br />

bleach, cleaning solvents or harsh detergents. Do not iron. Do not dry clean.<br />

Do not tumble dry. Avoid UV light & heat. Do not dry in sunshine. Do not place<br />

on heaters or steam pipes. Do not autoclave. Dry in warm room only.<br />

IF IN DOUBT ABOUT THE CONDITION OF A SLING DO NOT USE IT.<br />

Contact your distributor for inspection of the product for advice regarding replacement.<br />

*Pro-Med Product Code: 17397<br />

22<br />

47

Maintenance<br />

Recharging<br />

Battery packs should be recharged as frequently as possible after use to<br />

maintain a healthy battery and to extend the battery life. If the lifter is used daily,<br />

recharge the Battery Pack at least daily, preferably at all times when the lifter is<br />

not in use.<br />

Please Note: The batteries utilized in this battery pack are Sealed Lead Gel<br />

Rechargeable batteries and do not suffer from overcharging.<br />

Features<br />

Weighing Device<br />

The PRO-MED weighing device is rated to 300 kg (660 lb) Safe Working<br />

Load, and suits all Pro-Med and Voyager lifting systems.<br />

!<br />

WARNING: Do not flatten the battery excessively<br />

as this will dramatically reduce the battery life.<br />

Removal of Battery Pack<br />

Remove the battery pack by pulling up with the<br />

handle and then lifting away. Carry battery pack to<br />

charging station and insert in the same manner<br />

as clipping onto the Control Unit.<br />

A quick release mechanism<br />

provides easy inter-change<br />

of lifters and attachments.<br />

SPECIFICATIONS:<br />

MAX WEIGHING CAPACITY:.... 350kg<br />

DISPLAY RESOLUTION:........... 0.2kg<br />

DISPLAY TYPE:....................... Liquid Crystal with upto 15.2mm height<br />

POWER SUPPLY:..................... 9 V standard Battery<br />

BATTERY LIFE:........................ `3000 Readings.<br />

MODES:...................................... kg or lb<br />

ENCLOSURE:........................... Powder Coated Stainless Steel<br />

46<br />

23

Features<br />

Slings<br />

Sizing<br />

Each lifter unit has a sling identification colour code sticker prominently<br />

displayed. Sling straps colour match these for quick selection. Standard<br />

sizes are available for most slings. Each label states the SWL (Safe Working<br />

Load).<br />

Please refer to sling brochure for detailed specifications.<br />

Materials<br />

All PRO-MED slings are manufactured from the highest quality materials<br />

available. Both the mesh and solid fabrics are 100% polyester and are woven<br />

specifically for the application.<br />

Labels<br />

Every Pro-Med sling comes with a sewn on label. Refer to this label if you are<br />

unsure of the style of sling you have. Washing instructions are also detailed<br />

on the label.<br />

EMERGENCY STOP function<br />

Pressing the EMERGENCY STOP button interrupts the power supply to the<br />

actuators<br />

and causes the actuator to stop immediately. The EMERGENCY OFF switch<br />

should only be used in cases of immediate danger.<br />

Pressing the EMERGENCY STOP<br />

Press the red button (A). The button<br />

engages. The actuator stops and<br />

can no longer be controlled by the<br />

control device while the EMER-<br />

GENCY STOP button is locked in<br />

position.<br />

Unlocking the EMERGENCY STOP<br />

Maintenance<br />

Turn the red button in the direction of the arrow (B). The EMERGENCY STOP<br />

button is unlocked. The actuator can be controlled as before.<br />

EMERGENCY LOWERING<br />

In contrast to the EMERGENCY STOP button,<br />

the EMERGENCY LOWERING option is<br />

intended for when faults occur. A faulty<br />

control unit can be bypassed using the<br />

EMERGENCY LOWERING button. This<br />

allows electrical lowering (retraction) of<br />

the actu-ator. This is only possible for<br />

actuators on channel 1.<br />

Custom Slings<br />

PRO-MED design and manufacture a comprehensive range of lifting and<br />

support slings. PRO-MED can also make custom slings to meet specific<br />

requirements.<br />

Pressing EMERGENCY LOWERING<br />

Press the yellow button (1).<br />

24<br />

45

Maintenance<br />

Instructions for use<br />

Controlling an actuator<br />

The actuator is controlled using the UP and DOWN buttons on the control<br />

device.<br />

When the button is pressed, the LED on the control device lights up green.<br />

The battery status can be checked as follows during any motor movement via<br />

an LED on the control unit (1).<br />

Lifting<br />

Safety Precautions ................... 26<br />

General Purpose Slings<br />

Selecting the Sling .............. 27-29<br />

Lifting Procedures ............... 30-33<br />

Pivot Slings<br />

Selecting the Sling .............. 34-35<br />

Lifting Procedures ............... 36-40<br />

LED unlit..........................Batteries are ready for operation.<br />

LED flashes yellow..........Batteries must be charged, since they are currently<br />

only charged to around 20%<br />

A beep is heard................The battery capacity is less than 20%, but there is<br />

still sufficient capacity for at least a double stroke.<br />

The batteries must be charged immediately, other<br />

wise the actuator’s deep-discharge protection will<br />

block further use (See also Troubleshooting).<br />

44<br />

25

Lifting<br />

Maintenance<br />

!<br />

Safety Precautions<br />

Connecting the actuator(s)<br />

Insert the actuator plug into the corresponding<br />

socket (2) on the control unit.<br />

Please read and understand the following<br />

before using a PRO-MED patient lifter:<br />

• PRO-MED patient lifters are designed to<br />

transfer people distances spanning no more<br />

than a few metres - typically bed to chair or<br />

chair to chair, i.e. transfers occurring in the<br />

same room. To transport a patient distances<br />

further than a few metres, PRO-MED advises<br />

the user to transfer the patient to a wheelchair<br />

or trolley first.<br />

• PRO-MED patient lifters are designed to be<br />

operated on level surfaces. Operating a<br />

PRO-MED patient lifter on an incline can be<br />

very dangerous as the lifter becomes<br />

difficult to handle and the load unstable.<br />

• Do not use Pro-Med products with other<br />

brands of patient lifters / slings unless<br />

specified.<br />

Then proceed as follows:<br />

(1) Insert the plug (the sealing<br />

rings must not be visible).<br />

Ensure that the groove on the<br />

plug is aligned with the mark on<br />

the control unit.<br />

(2) Use the special plug disassembling<br />

tool to turn the plug<br />

approx. 30° to the right up against<br />

the stop in order to lock it in<br />

position.<br />

Repeat steps (1) to (2) if you wish to connect an (optional) second actuator.<br />

Otherwise, the actuator output which is not used is closed with a watertight<br />

blanking plug at the factory. This plug must not be removed.<br />

Ensure that the groove on the plug is aligned with the<br />

mark on the housing. Otherwise, the plug cannot be<br />

connected properly.<br />

26<br />

43

Maintenance<br />

MOBILETTE Mobil Control Unit<br />

General Purpose Slings<br />

Lifting<br />

Inserting the battery pack<br />

Insert the battery pack into the mounted<br />

control unit as shown in diagram below.<br />

Ensure that the cams (1) are pushed right into<br />

the guides (2). A locking spring on the rear of<br />

the system carrier fixes the battery pack to the<br />

control unit.<br />

Pro-Med General Purpose and Hygiene Range Slings are designed to be simple<br />

and safe to use for both home and institutional patient lifting. The slings are<br />

manufactured from polyester fabric or mesh (suitable for bathing) with internal<br />

padding in pressures areas and utilises webbing attachment loops instead of<br />

chains and hooks. The webbing loops are colour coded for sizing to allow easy<br />

sling selection and identification.<br />

Webbing loops of varying lengths are provided at each connection point to allow<br />

a lay back posture for the patient or, by using the shortest loops, a higher lift.<br />

Sling SWL: XS - M = 205kg SWL & L - XXL = 300kg SWL<br />

Sling Options - Standard Range<br />

General Purpose Sling<br />

Available in in six sizes in choice of fabric or mesh.<br />

The slings provide easy fitting and good support for<br />

patients with some upper body control. Recommended<br />

for general lifting.<br />

Colour: Navy<br />

Connecting the actuator and the control device<br />

Connecting the control device<br />

Insert the D-SUB plug of the control device into<br />

the corresponding socket (1) on the control<br />

unit. The cables are strain-relieved and sealed<br />

by means of the cast cams when plugged into<br />

the socket. The cams engage in the retaining<br />

clips.<br />

General Purpose with Head Support Sling<br />

Available in six sizes in choice of fabric or mesh The<br />

Sling provides easy fit to a patient in bed or a chair,<br />

providing excellent upper body and head support.<br />

Recommended for lifting from the floor and general<br />

lifting of the less secure patient.<br />

Colour: Navy<br />

Ensure that the plugs are<br />

inserted with the correct<br />

alignment, otherwise the<br />

device socket can be<br />

damaged. Ensure the plug<br />

type is correct (arrows<br />

must be on top).<br />

General Purpose Hygienie Sling With Head Support<br />

Available in six sizes in choice of fabric or mesh. The<br />

slings provide easy removal of clothing for toilet<br />

transfers. Recommended for general toilet transfers<br />

for the less secure patient.<br />

Colour: Navy<br />

42<br />

27

Lifting<br />

Paediatric Sling<br />

Available in three sizes in mesh only. The slings<br />

provide easy fitting and good support for children or<br />

small adults. Recommended for general lifting with<br />

children or small adults.<br />

Colour: Navy<br />

Maintenance<br />

The Quick Fit Sling<br />

Available in three sizes in fabric only. The slings are<br />

perfectly suited for bariatric patients with large hips or<br />

thighs. Recommended for general lifting for the larger<br />

patient.<br />

Colour: Green<br />

Mobilette Control Unit............ 42-45<br />

Recharging............................... 46<br />

Sling Care ................................ 47<br />

Lifter Maintenance ............... 48-50<br />

Trouble Shooting ...................... 51<br />

Spare Parts............................ 52-56<br />

Hammock Sling<br />

Available in two sizes in choice of fabric or mesh with<br />

commode hole. The sling provides ultimate support<br />

and security for lifting from a bed or the floor. The<br />

patient must roll on to, and off, the sling. When fitted<br />

full head support is provided. Recommended for<br />

single or double lower limb amputees and lifting from<br />

the floor, and because weight is not taken by the<br />

patient's thighs.<br />

Colour: Navy<br />

The Hammock Sling<br />

Available in three sizes in fabric only. The sling incorporates<br />

a head support and a unique strap system that<br />

keeps the patient secure, which helps to reduce friction<br />

and allows for easy placement and removal around a<br />

person in a sitting, semi-reclined or fully reclined<br />

position, without having to lift manually.<br />

Recommended for general lifting including bathing<br />

Colour: Green<br />

28<br />

41

Lifting<br />

Hygiene Range<br />

Lifting<br />

Warning: Supreme Hygiene and The Hygienic Sling should only be used if the<br />

patient has sufficient trunk and upper limb control to maintain balance. The top of<br />

the sling must pass below the armpits to maximise stability. Excessive pressure<br />

under the armpits should be avoided.<br />

Hygiene Sling<br />

Available in three sizes and comes in fully quilted<br />

fabric only. This sling is excellent for transfers onto a<br />

toilet as it provides an open area from the middle of<br />

the back to the middle of the thigh. This sling has a<br />

buckle waist strap and features generous padding<br />

around the patient's midsection and under arms.<br />

Recommended for general toilet transfers.<br />

Colour: Green<br />

40<br />

29

Lifting<br />

Lifting Procedures<br />

Fitting the Sling<br />

Warning: Please refer to your local Physiotherapist or Occupational Therapist for<br />

advice regarding suitability of sling/hoist/and specific attachment requirements to<br />

suit patient needs.<br />

Three Ways to Fit a General Purpose Sling<br />

1... Leg straps<br />

passing under<br />

each thigh and<br />

back to the<br />

hook on the<br />

same side.<br />

This provides<br />

a “legs apart”<br />

posture which<br />

is suitable for<br />

Hygiene and<br />

washing.<br />

2... Leg straps<br />

passing under<br />

both thighs<br />

and onto opposite<br />

hooks.<br />

The “seat”<br />

formed with<br />

this technique<br />

provides a<br />

comfortable,<br />

dignified posture<br />

suitable for<br />

general lifting<br />

and transferring.<br />

3... Leg straps<br />

passing under<br />

each thigh and<br />

onto the opposite<br />

hooks. This<br />

is the safest<br />

technique, the<br />

patient is well<br />

supported and<br />

prevented from<br />

tipping forward<br />

by the crossing<br />

straps. Suitable<br />

for general lifting<br />

and transferring.<br />

Lowering the Patient<br />

<br />

Position the patient over chair/bed correctly and slowly lower. Make<br />

sure the patient remains comfortable during descent. Handles on back<br />

allow the carer to pull the patient back into the correct position for<br />

seating while maintaining an ergonimically sound posture.<br />

Removing the Sling<br />

<br />

Sling removal is reverse of fitting. In some cases, the patient may be<br />

rolled, but usually the sling can be slid out from under the patient.<br />

Monitor patients legs, feet and head when lifting so they cannot come<br />

into contact with the mast and yoke of the lifter.<br />

The Pro-Med Pivot Sling is compatible only with the<br />

Pro-Med Pivoting Frame. An incorrect selection may cause injury.<br />

DO NOT USE PIVOT SLINGS WITH THE PRO-MED YOKE.<br />

Lifting<br />

Hygiene Sling Usage<br />

Warning:<br />

Supreme Hygiene and The Hygienic Sling should<br />

be used only if the patient has sufficient trunk and<br />

upper limb control to maintain balance. The top of<br />

the sling must pass below the armpits to<br />

maximise stability. Excessive pressure under the<br />

armpits should be avoided.<br />

See sling drawing<br />

30<br />

39

Lifting<br />

Lifting the Patient<br />

<br />

Understand workings of lifter: Be confident/familiar with equipment,<br />

and the patient will feel safer and likely to cooperate with you.<br />

Monitor patients legs, feet and head when lifting so they cannot come<br />

into contact with the mast and pivot frame of the lifter.<br />

Be aware of any patient apprehension toward the lifting procedure: By<br />

reassuring the patient during the transfer.<br />

Manoeuvring the lifter carefully not to bump the head with the yoke.<br />

Watch for toes and property when wheeling lifter towards a patient.<br />

Never leave patient in the lifter unattended<br />

Ensure that the brakes of the chair, bed or trolley the patient is being<br />

lifted from are locked. The brakes of the lifter must be OFF to allow the<br />

lifter to establish its own centre of gravity over the weight of the patient.<br />

This may result in the lifter moving slightly when the patient is first lifted.<br />

Before raising the patient, check that the sling attachments are still in<br />

place on the pivot frame. Slings must be properly positioned and aligned<br />

under the patient.<br />

When using Pivot Toileting Slings, ensure the upright positioning buck<br />

les are fastened around the vertical white bar of the pivoting frame.<br />

If the patient looks uncomfortable or unbalanced, stop immediately.<br />

Lower the patient and adjust the sling. It usually takes only a matter of<br />

seconds to correct a poorly positioned sling and the patient will gain<br />

confidence from your care and the transfer will be far safer.<br />

Once the patient is clear of the chair or bed he/she may be rotated to the<br />

correct position to complete the transfer.<br />

Moving the Patient<br />

If you must move a patient while supported in a lifter follow these rules:<br />

Lower the patient so the feet are just off the ground, this makes him/her<br />

feel more secure.<br />

When manoeuvring in a small area, two carer's will make the job much<br />

easier.<br />

Changing direction or steering around corners, walk the back of the<br />

machine around so that it is heading in the new direction.<br />

Always look at the patient during the transfer, be aware that some<br />

patients who are new to the sling lifting may become distressed.<br />

38<br />

Fit the sling to the patient before wheeling the lifter into position to carry out the<br />

lift.<br />

Patient in Chair<br />

<br />

<br />

<br />

<br />

Hold up sling with handles away from<br />

patient.<br />

Slide sling down patient’s back until<br />

base of sling is level with base of spine.<br />

If possible have the patient lean away<br />

from you to work the leg section under<br />

the patients hips and upper thigh. Posi<br />

tion leg sections of the sling under each<br />

thigh. Under each thigh allowing as<br />

much support to both legs and hips as<br />

possible. To achieve this pull each<br />

strap firmly under the leg.<br />

Leg Section<br />

To achieve proper leg strap positioning, kneel on one knee in front of<br />

patient placing patient’s foot on carer’s thigh. Sling then passes freely under<br />

patient’s leg/hip for greater comfort.<br />

Warning: Preparing lift from a chair, position the lifter by approaching from the<br />

front Take care to ensure not to push the yoke into the patient’s head or face.<br />

Patient Lying on Floor or Bed<br />

Sling must be placed under the patient’s back. If the patient is in bed he/she<br />

must be rolled or sat up to allow positioning. To assist, some patients may lean<br />

forward or you may adjust back of bed.<br />

If patient must be rolled, process is similar to changing sheets with patient in<br />

bed.<br />

<br />

<br />

Roll patient toward you, easing sling underneath so<br />

evenly spaced under the back.<br />

Bend patient’s knees up, one at a time, pass leg straps<br />

underneath each leg.<br />

Lifting<br />

Warning: Preparing a lift from the floor. Spread base of lifter bending patient’s<br />

knees so one leg of lifter can pass under the bent knees. If patient has fragile skin<br />

protect this with a towel/pillow. Also placing a pillow at patient’s head for comfort so<br />

to prevent injury from accidentally bumping the leg of the lifter.<br />

31

Lifting<br />

Attaching the Sling<br />

Lower the yoke. Attach straps of sling over the hooks of the yoke.<br />

Lifting the Patient<br />

<br />

Understand workings of lifter: Be confident/familiar with equipment,<br />

and the patient will feel safer and likely to cooperate with you.<br />

Monitor patients legs, feet and head when lifting so they cannot come<br />

into contact with the mast and yoke of the lifter.<br />

Be aware of any patient apprehension toward the lifting procedure: By<br />

reassuring the patient during the transfer.<br />

Manoeuvring the lifter carefully not to bump the head with the yoke.<br />

Watch for toes and property when wheeling lifter towards a patient.<br />

Never leave patient in the lifter unattended<br />

<br />

<br />

Ensure that the brakes of the chair, bed or trolley the patient is being<br />

lifted from are locked. The brakes of the lifter must be OFF to allow the<br />

lifter to establish its own centre of gravity over the weight of the patient.<br />

This may result in the lifter moving slightly when the patient is first lifted.<br />

<br />

Before raising the patient, check that the sling attachments are still in<br />

place on the yoke. Slings must be properly positioned and aligned the<br />

patient.<br />

If the patient looks uncomfortable or unbalanced, stop immediately.<br />

Lower the patient and adjust the sling. It usually takes only a matter of<br />

seconds to correct a poorly positioned sling and the patient will gain<br />

confidence from your care and the transfer will be far safer.<br />

Once the patient is clear of the chair or bed he/she may be rotated to the<br />

correct position to complete the transfer.<br />

Moving the Patient<br />

If you must move a patient while supported in a lifter follow these rules:<br />

Lower the patient so the feet are just off the ground, this makes him/her<br />

feel more secure.<br />

When manoeuvring in a small area, two carer's will make the job much<br />

easier.<br />

Changing direction or steering around corners, walk the back of the<br />

machine around so that it is heading in the new direction.<br />

Always look at the patient during the transfer, be aware that some<br />

patients who are new to the sling lifting may become distressed.<br />

32<br />

Attaching the Sling<br />

Lower the Pivot Frame and attach keyhole buckles of sling over the hooks of the<br />

pivot frame<br />

Hygiene Sling Usage<br />

Warning: This sling provides buckles<br />

which must be fastened around the vertical<br />

white bar of the pivoting frame to ensure<br />

the patient remains in an upright position.<br />

See drawing<br />

Tips for Lifting with a Pivot Frame & Pivot Sling<br />

Push down on<br />

handle when<br />

lowering a patient<br />

into a chair.<br />

The patient’s centre<br />

of gravity ensures a<br />

comfortable, reclined<br />

position during<br />

Lifting<br />

Lifting the legs will<br />

swing a patient into<br />

a reclining position<br />

for lowering onto a<br />

bed.<br />

37

Lifting<br />

Lifting Procedures<br />

Fitting the Sling<br />

Fit the sling to the patient before wheeling the lifter into position to carry out the lift.<br />

Patient in chair<br />

Hold up sling with handles away from patient.<br />

Slide sling down patient’s back until base of<br />

sling is level with base of spine.<br />

If possible have the patient lean away from you<br />

to work the leg section under the patients hips<br />

and upper thigh. Position leg sections of the<br />

sling under each thigh. Under each thigh<br />

allowing as much support to both legs and hips<br />

as possible. To achieve this pull each strap<br />

firmly under the leg.<br />

To achieve proper leg strap positioning, kneel on one knee in front of<br />

patient placing patient’s foot on carer’s thigh. Sling then passes freely<br />

under patient’s leg/hip for greater comfort.<br />

Warning: Preparing lift from a chair, position the lifter by approaching from<br />

the front Take care to ensure not to push the pivot frame into the patient’s<br />

head or face.<br />

Patient Lying on Floor or Bed<br />

Sling must be placed under the patient’s back. If the patient is in bed he/she<br />

must be rolled or sat up to allow positioning. To assist, some patients may lean<br />

forward or you may adjust back of bed.<br />

If patient must be rolled, process is similar to changing sheets with patient in<br />

bed.<br />

<br />

Roll patient toward you, easing sling<br />

underneath so evenly spaced under the<br />

back.<br />

Bend patient’s knees up, one at a time,<br />

pass leg straps underneath each leg.<br />

Lowering the Patient<br />

<br />

Position the patient over chair/bed correctly and slowly lower. Make<br />

sure the patient remains comfortable during descent.<br />

Handles on back allow the carer to pull the patient back into the correct<br />

position for seating while maintaining an ergonimically sound posture.<br />

Removing the Sling<br />

<br />

Lifting<br />

Sling removal is reverse of fitting. In some cases, the patient may be<br />

rolled, but usually the sling can be slid out from under the patient.<br />

Monitor patients legs, feet and head when lifting so they cannot come<br />

into contact with the mast and yoke of the lifter.<br />

Warning: Preparing a lift from the floor. Spread base of lifter bending patient’s<br />

knees so one leg of lifter can pass under the bent knees. If patient has fragile skin<br />

protect this with a towel/pillow. Also placing a pillow at patient’s head for comfort so<br />

to prevent injury from accidentally bumping the leg of the lifter.<br />

36<br />

33

Lifting<br />

Pivot Slings<br />

Special slings known as Pivot Slings are required for use with the Pivot Frame<br />

and Hi Lift Pivot Frame. The slings are manufactured from polyester fabric or<br />

mash (suitable for bathing). These slings allow the patient to be lifted in either a<br />

sitting or lying position, ideal for lifting on and off a bed or the floor.<br />

The unique pivot with anti-lock at the end of the boom allows the whole frame to<br />

be rocked back and forward to assist correct positioning of the patient. The frame<br />

spreads the sling attachment points to ensure the patients hips are not excessively<br />

flexed, avoiding the discomfort obese patients sometimes experience<br />

with standard slings.<br />

Sling SWL: XS - XXL = 205kg SWL<br />

Sling Options<br />

- Standard Range<br />

Lifting<br />

Pivot Sling<br />

Pivot Sling is available in six sizes in choice in fabric<br />

or mesh. The sling allows a patient to be lifted in<br />

either a sitting or lying position. The ability to position<br />

a patient in the sitting posture greatly assists correct<br />

seating.<br />

A more open lift. Recommended for general lifting<br />

including floor lifting.<br />

Colour: Navy<br />

- Hygiene Range<br />

Warning: The Pivot Hygiene Sling should only be used if the patient has sufficient<br />

trunk and upper limb control to maintain balance. The top of the sling must pass<br />

below the armpits to maximise stability. Excessive pressure under the armpits<br />

should be avoided.<br />

Pivot Hygiene Sling<br />

Pivot Hygiene Sling is available in six sizes in choice<br />

in fabric or mesh. The slings provide easy removal of<br />

clothing for toilet transfers and bathing.<br />

Recommended for general toilet transfers and<br />

bathing.<br />

Colour: Navy<br />

Important Note: This sling provides<br />

buckles which must be fastened<br />

around the vertical white bar of the<br />

pivoting frame to ensure the patient<br />

remains in an upright position.<br />

34<br />

35