Proceedings 2002/2003 - IRSE

Proceedings 2002/2003 - IRSE

Proceedings 2002/2003 - IRSE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

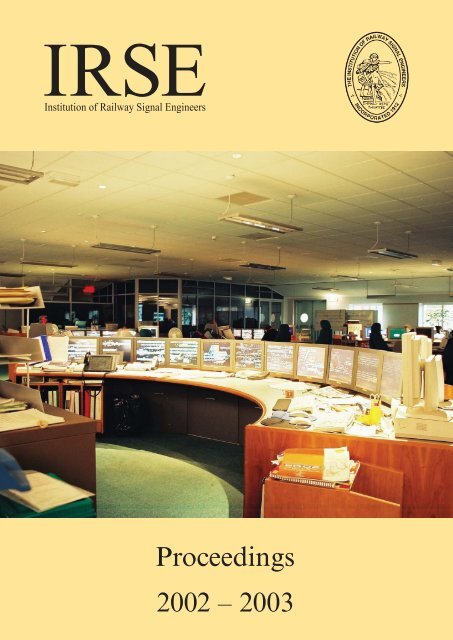

<strong>Proceedings</strong><br />

<strong>2002</strong> – <strong>2003</strong>

Kilometres flash by<br />

While she’s curled in a corner<br />

Hunting the horizon<br />

Laura, happy by rail.<br />

© - ALSTOM - <strong>2002</strong> - Bon Angle<br />

Tomorrow’s child will be on the move like never<br />

before. Thanks to advances in rail transportation now<br />

underway, travelling from one part of town to another,<br />

from city centre to suburb or from one<br />

region to another will be a mere hop, skip or jump for<br />

the 21st century’s mobile generation. ALSTOM<br />

engineers are contributing to this faster, environmentally<br />

clean rail travel, developing innovative solutions for<br />

every aspect of passenger and freight markets: rolling<br />

stock, signalling, infrastructure and maintenance.<br />

ALSTOM doesn’t stop there, the Company’s expertise<br />

extends even further in proposing financial solutions<br />

tailored to each customer. For those who will go far<br />

tomorrow, ALSTOM will be there.<br />

ALSTOM, the global specialist in energy and transport infrastructure<br />

TRANSPORT • 34 Dover Street • London W1S 4NG<br />

Tel: 020 7290 55 76 • Fax: 020 7290 5570<br />

www.transport.alstom.com

The Institution of Railway Signal Engineers<br />

INCORPORATED 1912<br />

FOR THE<br />

Advancement of the Science of<br />

Railway Signalling<br />

<strong>Proceedings</strong> <strong>2002</strong>/<strong>2003</strong><br />

(Copyright Reserved)<br />

PRICE TO NON-MEMBERS £50.00<br />

Printed by Fericon Press Ltd (Tel: 0118 945 6100)

Engineering<br />

and technology<br />

in harmony<br />

Think<br />

Rail Maintenance<br />

Track Renewals<br />

Plant<br />

Head Office: Floor 7 Buchanan House<br />

58 Port Dundas Road,<br />

Glasgow G4 0HG<br />

Tel: 0141-335 3005 Fax: 0141-335 3006<br />

www.firstengineering.co.uk<br />

Consultancy Power & Civils<br />

Signalling Technology & Facilities<br />

Head Office: Coltness House, Lark Way,<br />

Strathclyde Business Park Bellshill,<br />

North Lanarkshire ML4 3RB<br />

Tel: 01698 574200 Fax: 01698 746301<br />

www.first-projects.co.uk<br />

First Engineering and First Projects are part of Peterhouse Group plc www.peterhouse.co.uk

Contents<br />

Contents ……………………………………………………………………………………………………………………………………………………………………………………3<br />

3<br />

Page<br />

Portrait of P W Stanley ……………………………………………………………………………………………………………………………………………………………4<br />

History of President …………………………………………………………………………………………………………………………………………………………………5<br />

The Council of the Institution <strong>2002</strong>/<strong>2003</strong> ……………………………………………………………………………………………………………………………6<br />

Addresses of Officers ………………………………………………………………………………………………………………………………………………………………8<br />

Institution Announcements ……………………………………………………………………………………………………………………………………………………9<br />

Institution Sales ………………………………………………………………………………………………………………………………………………………………………11<br />

Institution Awards …………………………………………………………………………………………………………………………………………………………………13<br />

Obituaries…………………………………………………………………………………………………………………………………………………………………………………14<br />

Annual Dinner and Dance ……………………………………………………………………………………………………………………………………………………17<br />

Fourth Members’ Luncheon …………………………………………………………………………………………………………………………………………………17<br />

Presidential Address ………………………………………………………………………………………………………………………………………………………………19<br />

Technical Meeting of the Institution, Wednesday 9th October <strong>2002</strong> “Eurobalise Transmission System, ………………24<br />

A Technical Overview” by Per Lundberg with a summary of the Discussion ………………………………………………………30<br />

Technical Meeting of the Institution, Wednesday 6th November <strong>2002</strong> “EuroRadio and the RBC”…………………………31<br />

by John Harmer, Kevin Turner and C Riley with a summary of the Discussion …………………………………………………40<br />

Technical Meeting of the Institution, Tuesday 10th December <strong>2002</strong> “Eurocab and the Driver MMI – an ……………42<br />

introduction to the technology” by Christian Frerichs with a summary of the Discussion ………………………………47<br />

Technical Meeting of the Institution, Tuesday 15th January <strong>2003</strong> “Signalling Control Centres Today …………………49<br />

and Tomorrow” by I H Mitchell with a summary of the Discussion ………………………………………………………………………61<br />

Technical Meeting of the Institution, Tuesday 12th February <strong>2003</strong> “Migration to ERTMS on Existing …………………63<br />

Lines” by Jacques Poré with a summary of the Discussion …………………………………………………………………………………71<br />

Technical Meeting of the Institution, Tuesday 12th March <strong>2003</strong> “CTRL Signalling and Communications” …………72<br />

by Gilbert Moens and Richard Stokes with a summary of the Discussion …………………………………………………………82<br />

International Convention, 29th April – 3rd May <strong>2002</strong> “‘Cerberus’ Level Crossing Monitor and Test<br />

System – a ‘black box recorder’ for Railway Level Crossings” by Paul Szacsvay ……………………………………………84<br />

Ninetieth Annual Report ………………………………………………………………………………………………………………………………………………………92<br />

Ninetieth Annual General Meeting ……………………………………………………………………………………………………………………………………109<br />

39th Annual Dinner ………………………………………………………………………………………………………………………………………………………………111<br />

Sydney Hosts <strong>2002</strong> Convention ………………………………………………………………………………………………………………………………………112<br />

Membership Manager Appointed ……………………………………………………………………………………………………………………………………116<br />

Staff Organisation Chart ……………………………………………………………………………………………………………………………………………………117<br />

Staff Boost ……………………………………………………………………………………………………………………………………………………………………………117<br />

Much Better Engineer …………………………………………………………………………………………………………………………………………………………118<br />

Exam Study Group Facilitators …………………………………………………………………………………………………………………………………………118<br />

<strong>2002</strong> Examination Results …………………………………………………………………………………………………………………………………………………120<br />

Australasian Section ……………………………………………………………………………………………………………………………………………………………123<br />

Hong Kong Section ……………………………………………………………………………………………………………………………………………………………127<br />

Midland & North-Western Section ……………………………………………………………………………………………………………………………………128<br />

Plymouth Section …………………………………………………………………………………………………………………………………………………………………128<br />

Scottish Section……………………………………………………………………………………………………………………………………………………………………129<br />

Southern African Section ……………………………………………………………………………………………………………………………………………………130<br />

Western Section……………………………………………………………………………………………………………………………………………………………………132<br />

York Section …………………………………………………………………………………………………………………………………………………………………………135<br />

Younger Members’ Section ………………………………………………………………………………………………………………………………………………138<br />

Advertisers ……………………………………………………………………………………………………………………………………………………………………………139

4<br />

P W STANLEY<br />

PRESIDENT <strong>2002</strong>/<strong>2003</strong><br />

Photo: Colin Porter

5<br />

PETER STANLEY BSc CEng FIEE F<strong>IRSE</strong><br />

Peter was born in Stroud, Gloucestershire, in 1942 and took an early interest<br />

in music, studying the piano, trumpet and organ. At Marling Grammar School<br />

he was introduced to engineering and became so fascinated by trains and<br />

boats and planes that he decided to study engineering and chose an electrical<br />

engineering course at Manchester University that covered computer engineering<br />

and linear motors.<br />

After graduating in 1964 he entered a two-year engineering graduate training<br />

scheme with British Rail Western Region, followed by positions in the maintenance<br />

and new works design offices, working on the resignalling of the Bristol<br />

area.<br />

In 1968 Peter was appointed to his first management position at Manchester,<br />

dealing with electronic equipment in marshalling yards, remote control systems<br />

and jointless track circuits. After several years’ further experience as Assistant<br />

Divisional S&T Engineer Birmingham and Signal Maintenance Engineer for LM<br />

Region, he took a year out of engineering in 1980 to become Consultancy<br />

Services Manager, SR, dealing with cost reduction in the wider railway.<br />

In 1981 Peter returned to Reading as Signal Engineer, Western Region, then<br />

became heavily involved in the resignalling of the Exeter and Westbury areas.<br />

In 1987 he was seconded to BR HQ to lead a small team developing an IT<br />

strategy for the S&T function, then became Assistant Director Resources for the<br />

S&T function in charge of financial planning, engineering training and materials.<br />

In 1989 he was appointed as Assistant Director (Signalling) with responsibility<br />

for all BR signalling design, development, standards and equipment approval.<br />

When the rail privatisation process started in 1992, Peter was asked to take<br />

on a wider management role that, in addition to signalling projects and maintenance<br />

engineering covered much of the BR’s civil engineering manufacturing<br />

workshops and fabrication depots, traction and rolling stock technical services<br />

and vehicle assessment services, plus the position of MD of BR Telecommunications<br />

Ltd.<br />

From 1994 his responsibilities widened further as BR’s Managing Director<br />

Business & Engineering Services, with responsibilities that included setting up<br />

companies in preparation for the privatisation of research, computing, project<br />

management, signalling projects, signalling technical support, trains engineering<br />

and infrastructure testing and gauging services, whilst continuing to deliver<br />

contracted services to the newly organised UK rail network.<br />

At the end of 1996, with privatisation being almost complete, Peter left BR to<br />

work as a consultant, firstly in the role of Project Director with Eurosig, the<br />

consortium responsible for the specification and prototype trialling of the<br />

ERTMS/ETCS system, and then as an engineering advisor to Virgin Trains and<br />

LUL. He has also been a non-executive member of the Board of AEA<br />

Technology Rail since 1997.<br />

Peter Joined the <strong>IRSE</strong> as a student in 1964 and has served as chairman of<br />

the Midland & North Western Section and for ten years as a member of the<br />

Examination Committee. He was elected to Council in 1989 and has been a<br />

member of the Institution’s International Technical Committee since its formation<br />

in 1991.<br />

He divides his spare time between playing with the East Woodhay Silver Band<br />

in his home village, of which he has been a member for 24 years, occasional<br />

organ playing (mainly for weddings) and travelling to and from Dartmouth where<br />

he keeps a sailboat.<br />

Peter met his wife Carol in the Students’ Union at Manchester University; they<br />

were married in 1967 and have two children, James, who is an ambulance<br />

technician in Devon, and Helen, who is a musician based in Bristol.

6<br />

The Institution of Railway Signal Engineers<br />

INCORPORATED 1912<br />

SESSION <strong>2002</strong>/<strong>2003</strong><br />

OFFICERS AND COUNCIL<br />

PRESIDENT<br />

P W STANLEY ………………………………………………………………………………………………………………………………………………………………London<br />

VICE-PRESIDENTS<br />

C H PORTER …………………………………………………………………………………………………………………………………………………………………London<br />

J D CORRIE …………………………………………………………………………………………………………………………………………………………………Croydon<br />

COUNCIL<br />

CO-OPTED PAST PRESIDENTS<br />

C KESSELL ……………………………………………………………………………………………………………………………………………………Haywards Heath<br />

C A PORTER …………………………………………………………………………………………………………………………………………………………………London<br />

R E B BARNARD ………………………………………………………………………………………………………………………………………………Borehamwood<br />

FELLOWS<br />

W J COENRAAD ……………………………………………………………………………………………………………………………………………………………Utrecht<br />

A J FISHER …………………………………………………………………………………………………………………………………………………………………Plymouth<br />

P A JENKINS …………………………………………………………………………………………………………………………………………………………………London<br />

J M IRWIN ………………………………………………………………………………………………………………………………………………………………………London<br />

J D FRANCIS ………………………………………………………………………………………………………………………………………………………Chippenham<br />

J PORÉ ………………………………………………………………………………………………………………………………………………………………………………Paris<br />

J F WILSON……………………………………………………………………………………………………………………………………………………………………London<br />

D N WEEDON ………………………………………………………………………………………………………………………………………………………………Croydon<br />

F HOW ……………………………………………………………………………………………………………………………………………………………………………London<br />

F HEIJNEN ……………………………………………………………………………………………………………………………………………………………Chippenham<br />

MEMBERS<br />

D S ANGILL …………………………………………………………………………………………………………………………………………………………Chippenham<br />

R G HALSE ……………………………………………………………………………………………………………………………………………………………Chippenham<br />

P N LANE ………………………………………………………………………………………………………………………………………………………………………London<br />

K L WALTER …………………………………………………………………………………………………………………………………………………………………London<br />

D W CRABTREE ……………………………………………………………………………………………………………………………………………………………London<br />

Mrs C PORTER………………………………………………………………………………………………………………………………………………………………London

OFFICERS AND COUNCIL 7<br />

Photo: Colin Porter<br />

<strong>IRSE</strong> Council & Officers<br />

Front Row (left to right):<br />

Helmut Uebel, Martin Govas, Ken Burrage, Peter Stanley, Colin Porter,<br />

John Corrie, Jacques Poré<br />

Back Row (left to right):<br />

Jim Irwin, Paul Jenkins, Mark Watson-Walker, Robert Halse, John Francis, Alan Fisher, Bill Scheerer,<br />

Peter Lane, Claire Porter, John Haile, Fraser Wilson, Clive Kessell, Derek Edney, Bob Barnard, Karen Gould

8<br />

Addresses of Officers<br />

Chief Executive<br />

K W BURRAGE<br />

3rd Floor, Savoy Hill House, Savoy Hill, London WC2R 0BS<br />

Telephone: +44 (0)20 7240 3290 Facsimile: +44 (0)20 7240 3281 Email: hq@irse.org<br />

Treasurer<br />

M GOVAS<br />

2 The Droveway, Haywards Heath, West Sussex RH16 1LL<br />

<strong>Proceedings</strong> Editor<br />

A PARKER<br />

2NW Rose Court, 2 Southwark Bridge, London SE1 9HS<br />

Telephone: 020 7717 6569 Facsimile: 020 7240 3281 Email: mail_irse@yahoo.co.uk<br />

Australian Section<br />

Chairman: L BREARLEY Vice-Chairman: K WALKER<br />

Secretary: G WILMOTT Treasurer: G WILMOTT<br />

Benelux Section<br />

Chairman: W COENRAAD<br />

Central European Section<br />

Chairman: H UEBEL Secretary: <strong>IRSE</strong> Office, London<br />

Hong Kong Section<br />

Chairman: P GAFFNEY Vice-Chairmen: F FABBIAN & P K WAI<br />

Secretary: F HUI Treasurer: F HUI<br />

Midland & North Western Section<br />

Chairman: C WILLIAMS Vice-Chairman: I MITCHELL<br />

Secretary: B REDFERN Treasurer: T WALKER<br />

North America Section<br />

Chairman: W SCHEERER Vice-Chairman: W PETIT<br />

Secretary: C C TINKHAM Treasurer: C C TINKHAM<br />

Plymouth Section<br />

Chairman: D HELLIWELL Vice-Chairman: J STILES<br />

Secretary: D CAME Treasurer: D CAME<br />

Scottish Section<br />

Chairman: C HUMPHREYS<br />

Secretary: A KING Treasurer: A McWHIRTER<br />

South African Section<br />

Chairman: B STEIN Vice-Chairman: J C VAN DE POL<br />

Hon Secretary: V BOWLES Treasurer: J C VAN DE POL<br />

Western Section<br />

Chairmen: M GLOVER Vice-Chairman: P DUGGAN<br />

Secretary: D GILLANDERS Treasurer: M BROOKES<br />

York Section<br />

Chairman: D BOWLBY Vice-Chairman: D DYSON<br />

Secretary: J MAW Treasurer: R PRICE<br />

Younger Members’ Section<br />

Chairman: J HAILE<br />

Secretary: K GOODHAND Treasurer: C OYEKANMI

9<br />

Institution Announcements<br />

(The price and subscription rates and other<br />

information given in these announcements are<br />

current at the date of publication – August <strong>2003</strong>)<br />

CHANGE OF ADDRESS<br />

Considerable inconvenience is created by<br />

members failing to notify changes of address. Will<br />

members please inform the Institution office<br />

immediately of any such alteration and so ensure<br />

prompt delivery to themselves of notices, etc.<br />

TRANSFER TO HIGHER CLASS<br />

OF MEMBERSHIP<br />

Members sometimes remain in one class of<br />

membership when their professional standing has<br />

become such as to entitle them to transfer to a<br />

higher one. The Council invites any such person to<br />

make application for transfer, for which purpose a<br />

form can be obtained from the Institution office, and<br />

so take a position in the Institution consonant with<br />

his attainments and responsibilities.<br />

TECHNICAL PAPERS<br />

The Council invites members of all classes to<br />

submit papers for presentation at technical meetings<br />

in London or at local meetings in the United<br />

Kingdom or overseas.<br />

Papers should consist of between four thousand<br />

and six thousand words and while no limit is placed<br />

on the number of illustrations an author uses during<br />

his reading of the paper, the number printed as part<br />

of the advance copy and published in the Journal of<br />

<strong>Proceedings</strong> must not exceed twelve.<br />

The Institution office will be pleased to provide full<br />

particulars upon application.<br />

COPIES OF<br />

TECHNICAL PAPERS<br />

Copies of the technical papers read in London will<br />

be published in <strong>IRSE</strong> News and circulated to all<br />

members. The cost of this service is included in the<br />

Annual Subscription.<br />

SUBSCRIPTIONS AND REMITTANCES<br />

Members are reminded that in accordance with<br />

the Articles of Association subscriptions are payable<br />

on election or by the 1st July each year. The<br />

subscription rates applicable for <strong>2003</strong>/04 have been<br />

determined by Council. Members have been<br />

circulated with details.<br />

Members are reminded that prompt payment of<br />

subscriptions is required. The Institution is grateful<br />

to the vast majority of members who keep administration<br />

costs down by paying at the time requested.<br />

The Treasurer is obliged to send out notices of<br />

arrears to members who have not paid by that date.<br />

Subscriptions should be sent to the Institution<br />

office in London, unless you belong to either the<br />

Southern African or Australian Section. Local<br />

arrangements apply to members of these Sections.<br />

All cheques and money orders, especially those<br />

from overseas, should be crossed.<br />

The attention of members is directed to the<br />

clauses in the Articles of Association under which<br />

neither notices nor copies of <strong>Proceedings</strong> may be<br />

sent to those who are in arrears with their subscriptions<br />

beyond a certain time.<br />

Income Tax – the annual subscription to the<br />

Institution of Railway Signal Engineers is treated as<br />

an allowance expense under Section 16 of the<br />

Finance Act 1958 and should be included in your Tax<br />

Return in the section headed “Expenses in<br />

Employment – Fees or subscriptions to professional<br />

bodies”.<br />

Members of the Institution who have retired and<br />

have paid full subscriptions for at least ten years are<br />

entitled to continue membership of the Institution at<br />

half the full rate applicable to their class of membership.<br />

Similar arrangements are available to others in<br />

special need on application to the Treasurer.<br />

Members of 50 years standing are not required to<br />

pay subscriptions.<br />

LIBRARY<br />

The Institution Library is incorporated with the<br />

Library of the Institution of Electrical Engineers, by<br />

kindness of the Council of the latter body. It is<br />

situated at the Institution of Electrical Engineers’<br />

building at Savoy Place, Victoria Embankment,<br />

WC2. Members of the Institution of Railway Signal<br />

Engineers have been granted the same privileges<br />

with respect to it as those enjoyed by members of<br />

the Institution of Electrical Engineers, and the entire<br />

collection is open to them on equal terms.<br />

The Reference Library, which contains a Reading<br />

Room in which a great number of technical<br />

periodicals are always available, as well as a large<br />

general collection, is open as follows:<br />

Monday to Friday 9.00 am to 5.00 pm<br />

Any member of the Institution of Railway Signal<br />

Engineers entering the Library must sign his name in<br />

the book provided for that purpose.<br />

The use of the Lending Library, which is open<br />

during the same hours as the Reference Library and<br />

which contains the principal works relating to<br />

electrical engineering, its applications and allied<br />

subjects including, of course, railway signalling, is<br />

governed by the following rules, which must be<br />

strictly adhered to:<br />

When applying for a book by post a member of the<br />

Institution of Railway Signal Engineers must state<br />

their class of membership. All communications<br />

should be addressed to the Secretary, Institution of<br />

Electrical Engineers, at the address already given.

10<br />

INSTITUTION ANNOUNCEMENTS<br />

Anyone desirous of making a presentation to the<br />

collection should forward it to the same address,<br />

when its receipt will be suitably acknowledged.<br />

Similar facilities also exist at the Scottish<br />

Engineering Centre, The Teacher Building, 14 St<br />

Enoch Square, Glasgow G1 4DB.<br />

SCOTTISH LIBRARY FACILITIES<br />

The Scottish Engineering Centre Library in<br />

Glasgow provides extensive library and information<br />

services, including on-line databases and the<br />

Internet. <strong>IRSE</strong> material is now available, including<br />

the new <strong>IRSE</strong> Professional Examination Reading<br />

List.<br />

The <strong>IRSE</strong> library is situated in the information<br />

centre in The Teacher Building, 14-16 St Enoch<br />

Square, Glasgow G1 4DB, Tel: 0141 566 1871.<br />

Access is restricted so please check opening times<br />

and arrangements by telephoning before hand.<br />

SIGNAL AND TELEGRAPH<br />

TECHNICAL SOCIETIES<br />

The following S&T Technical Societies are<br />

affiliated to the Institution:<br />

The Signal & Electrical Engineers’ Society –<br />

General Secretary: M B Simmonds<br />

3 Gybbon Rise, Staplehurst, Kent TN12 0LT<br />

Email: mathew.simmonds@tubelines.com<br />

Tel: 020 7308 2517<br />

<strong>IRSE</strong> PROFESSIONAL EXAMINATION<br />

REQUIREMENTS FOR CORPORATE<br />

MEMBERSHIP<br />

The aim of the examination is to establish the<br />

professional competence of educationally qualified<br />

electrical, electronic and communications engineers<br />

in railway signalling and communication engineering.<br />

It is intended to test the main concepts of the<br />

subject material without bias to any one railway<br />

practice and is designed to demonstrate that the<br />

student has reached the necessary professional<br />

educational standard required by a signalling or<br />

telecommunications engineer for Corporate<br />

Membership of the Institution.<br />

This standard is typified by the exercising of<br />

judgement in the preparation, assessment,<br />

amendment or application of specifications and<br />

procedures, and is applicable to personnel engaged<br />

in the following activities:<br />

• Signalling/telecommunications principles, practices,<br />

rules and regulations for the safe<br />

operation of railway traffic.<br />

• Design and development of signalling/telecommunications<br />

equipment and systems.<br />

• Preparation and understanding of equipment<br />

drawings and specifications and/or design.<br />

• Planning, site installation and testing of<br />

signalling/telecommunications equipment and<br />

systems.<br />

• Practices related to assembly, wiring and testing<br />

of signalling/telecommunications equipment<br />

and systems.<br />

• Maintenance and servicing of signalling/<br />

telecommunications equipment and systems.<br />

In order to meet the examination requirements for<br />

corporate membership, candidates must, within a<br />

period of five years, obtain a pass in Module 1, plus<br />

three of the remaining six optional modules.<br />

It is possible to obtain exemptions from individual<br />

modules where you can demonstrate that you have<br />

passed an examination by a recognised body, which<br />

has substantially covered the syllabus of a particular<br />

<strong>IRSE</strong> examination module. Due to the specialised<br />

nature of the <strong>IRSE</strong> Examination, the scope for<br />

exemption is fairly limited.<br />

Claims for exemption must be made within five<br />

years of obtaining the particular qualification for<br />

which recognition is being claimed. The reason for<br />

this condition is that the exemption is based on<br />

information that may not be available where a<br />

qualification has been discontinued or changed.<br />

MODULE 1<br />

Safety of Railway Signalling and Communications<br />

– No exemptions will be given.<br />

MODULE 2<br />

Signalling the Layout – Please apply, no exemptions<br />

currently agreed.<br />

MODULE 3<br />

Signalling Principles – Please apply, no exemptions<br />

currently agreed.<br />

MODULE 4<br />

Communications Principles – This is the most<br />

commonly sought after exemption. Many of the<br />

applicants for exemption claim that telecommunications<br />

has been part of their Degree course and<br />

that, on this basis, exemption should be granted.<br />

Unfortunately it has been clear that the content of<br />

the telecommunications element within a typical<br />

university Engineering Degree is, at best, a basic<br />

overview. Occasionally, students study a telecommunications<br />

topic for their final year project, but<br />

these tend to be about a research topic<br />

narrowly specialising in a particular field and the<br />

Council is not convinced that such study justifies<br />

module exemption. As a basic guideline, therefore,<br />

please do not ask for exemption to this module<br />

unless: your university study has predominantly<br />

been in telecommunications; or your university study<br />

has included telecommunications and your present<br />

career is railway telecommunications engineering.<br />

Module 5<br />

Signalling & Control Equipment, Applications<br />

Engineering – Please apply, no exemptions currently<br />

agreed.<br />

Module 6<br />

Communications Equipment, Applications<br />

Engineering – Please apply, no exemptions currently<br />

agreed.<br />

Module 7<br />

Systems, Management & Engineering – Please<br />

apply, no exemptions currently agreed.<br />

The examination is generally held in October of<br />

each year and the regulations are available from the

INSTITUTION ANNOUNCEMENTS 11<br />

Head Office. The following support materials are<br />

also available to students:<br />

• Information for Students<br />

• Examination Syllabus<br />

• Reading List<br />

• Past Papers<br />

• Model Answers<br />

• Examiners Reports<br />

A new service will be introduced for the year 2000<br />

examination candidates, who are registering for the<br />

examination. For a small annual registration fee,<br />

candidates can be sure that they will automatically<br />

receive all updates of examination material, as it<br />

becomes available.<br />

THE THORROWGOOD<br />

SCHOLARSHIP AWARD<br />

The Thorrowgood Scholarship is awarded<br />

annually to a student member excelling in the<br />

Institution’s Professional Examination. The award<br />

consists of the Institution’s Thorrowgood Scholarship<br />

Medallion, and a cheque in the region of<br />

£1,000, that is presented at the Annual General<br />

Meeting of the Institution in the April following the<br />

examination.<br />

The terms of the Thorrowgood bequest require<br />

that it should be utilised to assist the development of<br />

young engineers employed in the railway signalling<br />

and telecommunications field. A requirement of the<br />

award is that it is used to finance a study tour of<br />

railway and/or signalling installations or manufacturing<br />

facilities, usually in a foreign administration, and<br />

that the award holder presents a report about the<br />

study tour to the Younger Members’ Section.<br />

To be eligible for the award students are usually<br />

expected to have sat the required four modules in<br />

the same year, and achieved outstanding results.<br />

Institution Sales<br />

All items are available from the Institution office and<br />

postage and packing is not included.<br />

INSTITUTION TIE<br />

An Institution tie bearing a single motif of the<br />

Institution crest in light blue on a navy background is<br />

available, price £10.00.

12<br />

INSTITUTION SALES<br />

Non-<br />

Members Members<br />

TEXT BOOKS<br />

Introduction to Signalling (+ p&p £8 UK and £15 overseas) £25.00 £60.00<br />

Railway Signalling £35.00 £60.00<br />

Railway Control Systems £35.00 £60.00<br />

European Railway Signalling £50.00 £65.00<br />

Fifty Years of Railway Signalling – O S Nock (reprint) £10.00 £11.95<br />

British Railway Signalling Practice – Mechanical (Green Books 1, 2, 3, 10) £9.00 £9.95<br />

British Railway Signalling Practice – Signalling Instruments (Green Books 4, 12, 13) £7.00 £7.95<br />

British Railway Signalling Practice – Electrical (Green Books 7, 9, 11) £8.00 £8.95<br />

TECHNICAL REPORTS<br />

No. 1 Safety System Validation – Cross Acceptance of Signalling Systems £12.00 £30.00<br />

No. 2 The Operational Availability of Railway Control Systems £12.00 £30.00<br />

No. 3 The Influence of Human Factors on the Performance of Railway Systems £12.00 £30.00<br />

No. 4 The Implications of Applying Transmission Based Signalling £12.00 £30.00<br />

No. 5 The Contribution of Signalling to the Future of Road Traffic Management £12.00 £30.00<br />

No. 6 Proposed Cross Acceptance Processes for Railway Signalling Systems<br />

& Equipment (includes CD-ROM) £20.00 £50.00<br />

Testing and Commissioning £12.00 £30.00<br />

Signalling Philosophy Review (April 2001) £12.00 £50.00<br />

CONFERENCE PAPERS<br />

Mathematically Formal Techniques in Signalling (April 1996 London) £10.00 £20.00<br />

Traction/Signalling Compatibility (April 1997 London) £10.00 £20.00<br />

New Techniques to Demonstrate Electromagnetic Compatibility between<br />

Rolling Stock and the Signalling Infrastructure (February 1998 London) £10.00 £20.00<br />

Improvements in the Delivery of Signalling Projects and Products (March 1998 Glasgow) £10.00 £20.00<br />

The Lifecycle of a Major Railway Project (Younger Members June 1998 London) £10.00 £20.00<br />

The Skill of the Tester (November 1998 London) £10.00 £20.00<br />

Life Long Learning (February 1999 London) £10.00 £20.00<br />

Keep It Safe, Keep It Legal (December 1999 London) £10.00 £20.00<br />

The Pitfalls of Commercial Contracting in the S&T Business (January 2000 Birmingham) £10.00 £20.00<br />

Competence Assurance in the S&T Business (May 2000 London) £10.00 £20.00<br />

The Railway as a System (Younger Members July 2000 Birmingham) £10.00 £20.00<br />

ERTMS and its Application (November 2000 London) £10.00 £20.00<br />

Future Trends in Signalling and Train Control (January 2001 London) £10.00 £20.00<br />

Train Detection (October 2001 Paris) CD-ROM format only £12.00 £24.00<br />

New Technology for Interlocking & Train Control (November 2001 London) CD-ROM format only £12.00 £24.00<br />

Bringing Innovation to the UK Railway (February <strong>2002</strong> London) CD-ROM format only £12.00 £24.00<br />

Proposed Cross-Acceptance Processes for Railway Signalling Systems &<br />

Equipment (Seminar 21st November <strong>2002</strong> London) CD-ROM format only £12.00 £24.00<br />

Technical Visit to the ETCS Level 2 Pilot Line – Olten, Lucerne (22nd-23rd November<br />

<strong>2002</strong> Switzerland) CD-ROM format only £12.00 £24.00<br />

GREEN BOOKLETS (Note that these are photocopy reprints of old publications unless otherwise stated)<br />

No. 5 Power Points £5.00 £10.00<br />

No. 6 Signalling Relays £5.00 £10.00<br />

No. 7 Signal Control Circuits (original version only – limited availability while stocks last) £5.00 £10.00<br />

No. 8 Typical Selection Circuits £5.00 £10.00<br />

No. 10 Mechanical Signalling (original version only – limited availability while stocks last) £5.00 £10.00<br />

No. 14 Multiple Aspect Signalling £5.00 £10.00<br />

No. 15 Circuits £5.00 £10.00<br />

No. 16 Route Holding £5.00 £10.00<br />

No. 17 Signalling for AC Electrified Areas £5.00 £10.00<br />

No. 18 Principles of Relay Interlocking & Control Panels £5.00 £10.00<br />

No. 19 LTE Route Control Systems £5.00 £10.00<br />

No. 20 Route Relay Interlocking – Westinghouse System £5.00 £10.00<br />

No. 21 Route Relay Interlocking – AEI AEI-GRS System £5.00 £10.00<br />

No. 22 Route Relay Interlocking – SGE System £5.00 £10.00<br />

No. 24 AWS/ATC (1964) £5.00 £10.00<br />

No. 25 Level Crossings £5.00 £10.00<br />

No. 26 Remote Control £5.00 £10.00<br />

No. 27 Signalling the Layout (British Practice) £5.00 £10.00<br />

No. 28 Route Control Systems (LT Practice) £5.00 £10.00<br />

No. 29 Solid State Interlocking £5.00 £10.00<br />

ANNUAL PROCEEDINGS – BACK NUMBERS<br />

1990/91 to day (inclusive) (please state years required) each £20.00 £50.00<br />

Send your orders, with cheque made payable to the <strong>IRSE</strong> to:<br />

<strong>IRSE</strong> Administration<br />

3rd Floor, Savoy Hill House, Savoy Hill, London WC2R 0BS

13<br />

Institution Awards<br />

PRESIDENT’S AWARD<br />

The President’s Award is made only rarely as it<br />

recognises truly exceptional, meritorious service to<br />

the membership and work of the Institution or a<br />

major contribution to a significant achievement in<br />

the field of railway control and communications.<br />

The President’s Award has been conferred on Dr<br />

Peter Winter, of Swiss Federal Railways. The award<br />

is made in recognition of his significant personal<br />

commitment, leadership and efforts for more than<br />

ten years in encouraging and supporting the work of<br />

signal engineers of European railways and the<br />

supply industry in the development of the concept,<br />

specification, testing and implementation of the<br />

European Train Control System.<br />

During this time Dr Winter directed work on<br />

specification and simulation by the Union International<br />

de Chemin de Fer (UIC) and the European<br />

Rail Research Institute (ERRI), and supported the<br />

European Commission projects on development,<br />

test and pilot installation projects for both ETCS and<br />

Dr Peter Winter (left) receives the President’s Award from<br />

Peter Stanley at this year’s Annual General Meeting<br />

Photo: C H Porter<br />

GSM-R, its supporting communications infrastructure.<br />

As Infrastructure Director of Swiss Federal<br />

Railways he participated in the planning of a tenyear<br />

national implementation programme that<br />

produced the first resulting new line in passenger<br />

operation between Olten and Luzern in April <strong>2002</strong>.<br />

DELL AWARD<br />

Matt Shelley (right) receives the Dell Award, which includes<br />

an engraved plaque, from Peter Stanley at the Annual<br />

Dinner held at the Savoy Hotel in London Photo: K W Burrage<br />

The winner of the Dell Award this year is Matt<br />

Shelley of Metronet Rail BCV Ltd. Matt graduated<br />

from Exeter University with a MEng in Electronic<br />

Engineering in 1998. He joined London Underground<br />

in the same year as a Graduate Trainee. On completion<br />

of his training, he specialised in automatic<br />

train operation (ATO).<br />

Matt became an enthusiastic member of the team<br />

involved with the introduction of ATO on the Central<br />

Line and made a significant contribution to the<br />

successful commissioning of the system. In <strong>2002</strong> he<br />

was appointed to the role of Senior ATO Engineer<br />

taking over the leadership of the Automatic Train<br />

Control Team within his Infraco. Since then he and<br />

his team have played a major role in the successful<br />

completion of ATO so that it now operates reliably<br />

over the entire Central Line. Matt has contributed to<br />

past conferences of the <strong>IRSE</strong> Younger Members’<br />

Section.<br />

WING AWARD FOR SAFETY<br />

Mr Aidan Nelson, Director Policy & Standards at<br />

Railway Safety, was selected as the winner this year<br />

for the Wing Award. The selection was made in<br />

recognition of his substantial influence upon, and<br />

contribution to, improvements achieved in trackside<br />

safety behaviour in recent years and especially in the<br />

context of the present disaggregated nature of the<br />

mainline railway structure. The award was presented<br />

by the President at the Annual Track Safety Quiz and<br />

Awards held in Birmingham in April.<br />

The Wing Award for Safety was introduced in 1994<br />

to commemorate the life and work of the late Peter<br />

Wing, a Fellow of this Institution and an employee of<br />

British Rail, who, during his career, made a major<br />

contribution to the cause of lineside safety. Peter<br />

Wing, whose career in BR spanned 31 years, spent<br />

much of his working life dedicated to the safety of<br />

President Peter Stanley (left) with Aiden Nelson (centre) and<br />

John Armitt, following presentation of the Wing Award<br />

Photo: courtesy Network Rail<br />

his colleagues.<br />

It was his care and concern that became the<br />

driving force behind the national campaign in 1992/3

14<br />

INSTITUTION AWARDS<br />

that was entitled “Dead Serious About Safety” and<br />

which had such a major impact in reducing the<br />

numbers of lineside fatalities in subsequent years.<br />

The <strong>IRSE</strong> administers the award scheme on behalf<br />

of members of the Railway Group, the Railway<br />

Supply Industry and the Health & Safety Executive<br />

who, amongst others, supported the formation of<br />

the Wing Award for Safety.<br />

Previous winners of the Wing Award have been:<br />

1995 R Dickinson, BR<br />

1996 W Hill, Amec<br />

1997 I Keys, LUL<br />

1998 R Hickman, Centrac<br />

1999 A Ross, LUL<br />

2000 A Franklin, GTRM<br />

2001 P Graham, Railtrack<br />

<strong>2002</strong> A Swann, Safety Consultant<br />

The award takes the form of a certificate and an<br />

amount of £700 to be devoted to personal<br />

development and is presented to an individual<br />

who has made an outstanding personal contribution<br />

to railway track safety by, for example, coming<br />

forward with novel ideas for improvement, is a<br />

long-term champion of, or has made a significant<br />

contribution to the awareness of track safety in his<br />

business.<br />

THORROWGOOD SCHOLARSHIP<br />

Matthew Lupton accepts the Thorrowgood Scholarship<br />

prize from Peter Stanley during the Annual Dinner at the<br />

Savoy Hotel in London<br />

Photo: K W Burrage<br />

The Institution’s Thorrowgood Scholarship for the<br />

year <strong>2002</strong> has been awarded to Matthew Lupton, of<br />

Network Rail, in recognition of his outstanding<br />

achievement in the <strong>2002</strong> Signalling Examination in<br />

which he achieved a pass, credit and two distinctions<br />

across the four modules undertaken.<br />

The terms of the Thorrowgood Bequest require<br />

that it should be utilised to assist the development of<br />

young engineers employed in the railway signalling<br />

and telecommunications field and it is the wish of<br />

the Council that the amount granted should be used<br />

to finance a tour of railway and/or signalling installations<br />

or manufacturing facilities of the winner’s<br />

choice. This may be in the UK or elsewhere. The<br />

value of the Award is £700 and is accompanied<br />

by the Institution’s Thorrowgood Scholarship<br />

Medallion.<br />

Obituaries<br />

ARMAND CARDANI<br />

1921 – <strong>2002</strong><br />

Armand Cardani was born on 20th June 1921. He<br />

joined the S&T Department of the London & North<br />

Eastern Railway in 1938 and, following an apprenticeship,<br />

was appointed as an engineering graduate.<br />

During that time he gained Honours grade in the<br />

London University BSc (Special) Degree. His main<br />

area of work activity was in connection with the<br />

Great Eastern electrification and this continued until<br />

1947 when he joined the Great Western Railway.<br />

The GWR – God’s Wonderful Railway – was, I<br />

think, Armand’s true home. He was immensely<br />

proud of their achievements, both historic and<br />

current. His career blossomed there; he became<br />

Assistant Signal Engineer of the Western in 1957 and<br />

in 1959, at the age of 38, became the youngest Chief<br />

S&T Engineer of that Region. In 1953 or 54 he gave<br />

a lecture to the Gloucestershire Railway Society,<br />

followed a short while afterwards by a site visit to<br />

Ealing where he explained to a 14 year old schoolboy<br />

sufficient about signalling to set him on a<br />

lifelong career. That schoolboy was Tony Howker<br />

who went on to become President of the <strong>IRSE</strong>! Brian<br />

Heard (another Past President), in a message from<br />

the Philippines, also comments on the tremendous<br />

benefit he received from early training with Armand.<br />

This interest in bringing on the youngsters in the<br />

profession was a hallmark of Armand’s career.<br />

By 1968, when he transferred to the London<br />

Midland Region as Chief S&T Engineer, he had

OBITUARIES 15<br />

overseen the conversion of over 1,700 single-track<br />

km of the WR to multi-aspect signalling and the<br />

creation of one of the first co-axial trunk telecomms<br />

systems on the railway. On the LMR he had similar<br />

success with the major schemes at Trent, Derby and<br />

Saltley followed by the West Coast work controlled<br />

from Warrington, Preston and Carlisle.<br />

In 1975 he was appointed as the BR Director of<br />

S&T Engineering, a post in which he successfully<br />

steered the industry through many difficult technical<br />

and contractual changes until his retirement in 1981<br />

after 42 loyal years of service to the railway.<br />

Armand joined the <strong>IRSE</strong> as a Student in 1942,<br />

progressing to the Council by 1960 and giving many<br />

years of service to the Miniaturisation and<br />

Examination Committees. He became President in<br />

1970 and led us on the first Convention to Spain –<br />

and what a joy that was!<br />

In his Presidential address, as we all do, he made<br />

predictions. Most of them came to pass, but he<br />

doubted that computers would become involved in<br />

the safety side of signalling. When he joined the<br />

British Railways Board, and heard of the preliminary<br />

work in BR Research by Alan Cribbens’ team, he<br />

quickly, gracefully and with great good humour,<br />

accepted that things had changed. He then stuck his<br />

neck out to support the SSI development and played<br />

a major part in securing approval for the work to proceed.<br />

To do that, in the climate then existing showed<br />

true greatness.<br />

In 1982 he was elected an Honorary Fellow and<br />

continued to give regular support to the Institution at<br />

meetings and social events. It was a particular<br />

pleasure to see him at the Members Lunch in 2001,<br />

which coincided with his 80th birthday, and again in<br />

<strong>2002</strong> when he completed 60 years of membership.<br />

Throughout his working and Institution life he had<br />

wonderful support from his wife Joyce. Her death in<br />

1995 was a blow which left him devastated.<br />

Now, after a lifetime of service to our Industry,<br />

which will live on in the newly created Armand<br />

Cardani Memorial Fund, it is his turn to be mourned.<br />

We are grateful for all that he has done and we will<br />

miss his leadership, guidance, friendship and unfailing<br />

good humour.<br />

Whatever the grief we as colleagues feel at<br />

Armand’s passing it is as nothing compared to that<br />

of his family. Our prayers and condolences go out to<br />

all of them.<br />

J Waller<br />

Past President 1978 and 1991<br />

Guidance for Equivalents to the <strong>IRSE</strong> Examination<br />

as part of the new Bye Laws.<br />

Ron had served the industry since the 1960s and<br />

received a broad training in railway telecommunications<br />

that served him well in later years. His career<br />

started in 1967 as a Technical Assistant in the<br />

Nottingham Divisional Engineer's office. He rapidly<br />

acquired the skills to survive at the sharp end, which<br />

was fortunate because the two projects of Derby<br />

and Trent power boxes of 1969 had their last minute<br />

crises, with much of the telecom external wiring<br />

having to be redone in the four weeks prior to the<br />

first commissioning. Teams of office technical staff<br />

and local technicians carried this out and Ron was<br />

part of this mammoth effort where we all worked<br />

long hours for nigh on three months continually. A<br />

toolkit and van were the only essential requirements.<br />

On the due day, everything worked perfectly with the<br />

S&T management being unaware of what had gone<br />

before.<br />

The cut and thrust of local management had an<br />

attraction for Ron and, with his now considerable<br />

experience, he took on the role of District Telecom<br />

Engineer initially at Bedford and latterly at Euston.<br />

Those were the days when the Divisional set up was<br />

king and if the District Engineer said it can or can't<br />

be done, then that was it. Ron invariably said 'yes'<br />

and the spirit of motivation that he instilled in the<br />

local staff was a credit to everyone. At that time,<br />

Euston staff looked after the main offices of the LMR<br />

and also the BRB. Weekends were always fraught<br />

with the innumerable telecom moves and changes<br />

that had to be done to accommodate the constant<br />

alterations to the organisational structure. Many of<br />

these would be advised at the last minute and very<br />

often were devised on the hoof on the day.<br />

Complaints were few, but Ron and the team can be<br />

forgiven if the records were somewhat lacking.<br />

The promotion trail led Ron to a post with<br />

Transmark and he was despatched to various<br />

locations around the world where his experience of<br />

ground level improvisation was always welcome<br />

advice. After a short spell in Mozambique, he drew<br />

the supposedly short straw and was posted to<br />

Northern Ireland. This was during the 1980s when<br />

life in the Province was somewhat precarious. He set<br />

about upgrading the NIR telecom network and made<br />

a good many friends in the process.<br />

The ground level work continued to have the<br />

RON HALL<br />

1944 – <strong>2003</strong><br />

Ron Hall, a Fellow of the <strong>IRSE</strong>, died suddenly on<br />

24th March <strong>2003</strong> at the age of 58.<br />

Ron was one of a small band of Telecom members<br />

who strove to get a greater telecom following and<br />

membership within the Institution. He had been a<br />

member of Membership Committee for some years<br />

where he could always be relied upon to call us to<br />

order if, on occasions, we were tempted to stray outside<br />

the rules. His advice was always valued and he<br />

had been active recently in the team that drafted the

16<br />

OBITUARIES<br />

biggest pull and Ron became Telecom Field<br />

Engineer on the Western Region in 1987. This gave<br />

him responsibility for all the Region's technician staff<br />

and the old challenges of getting things done by<br />

whatever means was what Ron was best at.<br />

Although a 'Midland man', Ron was quickly<br />

accepted by the Western fraternity who respected<br />

both his knowledge and his people skills.<br />

A spell of enhanced technology in the Data Group<br />

at Paddington followed where his transmission<br />

knowledge was put to good use, and then came the<br />

migration to BRT and privatisation. This was an<br />

unsettling time for all of us, but Ron saw it as an<br />

opportunity for the railway to show to the outside<br />

world that its capability was as good as anything<br />

that existed in the private sector. Under Racal, he<br />

became General Manager, Projects and Works, back<br />

in the old Midland territory of Birmingham and<br />

succeeded in developing the business to be the<br />

natural choice for all types of telecom new works in<br />

the chaos of the newly fragmented railway. Various<br />

reorganisations and the subsequent sale of Racal to<br />

Thales were kind to Ron in that he could remain<br />

based at Birmingham and where his final post was to<br />

head up the Telecom Design resource for the whole<br />

company.<br />

Ron retired in July 2001 but it was inevitable that<br />

his considerable skills would be sought out, and<br />

latterly, he was developing the new telecom maintenance<br />

concepts for Network Rail.<br />

Ron and his wife, Gerry, were regular participants<br />

at <strong>IRSE</strong> Conventions and like so many of us, were<br />

able to see and experience different cultures from all<br />

over the globe, courtesy of the Institution. I had the<br />

privilege of knowing him for all his railway career and<br />

can vouch for his immense knowledge and caring<br />

personality. Ron would always get the best out of<br />

people and was never one to criticise others behind<br />

their back. He could be tough when needed but<br />

even then, it was done in a spirit of fairness. He had<br />

a great love of motorcars and built his own on two<br />

occasions. The first one, a Ginetta from around<br />

1970, was a real pride and joy; experiencing a ride in<br />

this was something you never forgot! Latterly he had<br />

just completed a JBA Falcon Tourer and a superb<br />

machine this is. It will now be for someone else to<br />

enjoy the thrill of a replica sports car on the open<br />

road.<br />

All his colleagues within industry and the<br />

Institution were much saddened by his untimely<br />

death and many will miss him. Clive Kessell<br />

Region Technical Society becoming responsible for<br />

preparing the drawings for the slides and proceedings,<br />

cutting the Roneo skins with a stylus in his<br />

artistic hand, for which he became known throughout<br />

his career. He was once asked to design a dial<br />

label for the Region’s telephones, the printers,<br />

however, just copied his handwritten original sketch,<br />

which was full size, but the letters around the<br />

circumference started large and then became<br />

narrower towards the end to get them all in. It did not<br />

seem to matter. The labels were in use for many<br />

years, so his handiwork was seen everywhere<br />

throughout the Region.<br />

He was a perfectionist; only the correct way was<br />

good enough. We trainee draughtsmen were put<br />

through our paces with practice sessions every day<br />

until we could be trusted to produce an acceptable<br />

result. To this day I print using the methods that Reg<br />

Hawkins instilled in me.<br />

In his early days with the railway Reg was a very<br />

keen cyclist and liked to go to see the professionals<br />

race at the Herne Hill Track. He was a very good<br />

swimmer and became involved with the SR<br />

Swimming Club for many years.<br />

I first met Reg in 1961 when he persuaded me to<br />

apply to be a draughtsman in the drawing office at<br />

Wimbledon. I worked for and with him for many<br />

years until I left the Region in 1976. When I first used<br />

to go on site with Reg everyone seemed to know<br />

him, we could not go anywhere without almost every<br />

person we met saying hello. I know now that this<br />

was a measure of the regard that everyone had for<br />

him.<br />

Following his retirement he continued to serve his<br />

fellows by organising the Retired Friends of the<br />

Former S&T Engineering Department of British<br />

Railways, Southern Region. This is an informal<br />

arrangement whereby old colleagues meet once a<br />

month in a pub for lunch, the pubs being located<br />

around the former Region to facilitate travel by the<br />

participants. The highlight of the year was the<br />

Christmas lunch, always meticulously organised<br />

with invitations, lists and place cards, all prepared by<br />

hand in that unmistakable script. We will all miss<br />

Reg.<br />

Reg is survived by his second wife, Doris and his<br />

three children Pam, Christopher and Sylvia.<br />

M Tyrrell<br />

REG HAWKINS<br />

1920 – <strong>2002</strong><br />

Reg Hawkins joined the Southern Railway when<br />

he was demobbed from the Army in 1947 having<br />

served in India and Burma. He told me once of the<br />

network of telephone lines the Army had which<br />

stretched across the width of the Indian continent.<br />

Reg joined the embryo Southern Region S&T<br />

Telecommunications Drawing office at Wimbledon,<br />

to help form the nucleus of the office he was<br />

eventually to lead until his retirement in 1985.<br />

He soon became very active in the S&T Southern

17<br />

Annual Dinner and Dance<br />

The Institution’s Annual Dinner Dance for <strong>2002</strong><br />

returned this year to a London location after an<br />

absence of four years and to a venue that the<br />

Institution had used many times in the past. The<br />

Copthorne Tara Hotel, Kensington, London, was the<br />

venue for the dinner dance this year, which was held<br />

on Friday 18th October. The venue is spacious and<br />

attractive and the hotel events management helpful<br />

and efficient which enabled the event to take place<br />

in a happy and relaxed atmosphere.<br />

The Institution is grateful for the financial support<br />

it receives from sponsors, which permitted the<br />

dinner dance to be arranged and accommodated in<br />

such an attractive setting and provided the<br />

surroundings conducive to the happy and friendly<br />

occasion in which members and their guests could<br />

relax.<br />

The reception this year was provided by the<br />

Institution. The sponsors were, Siemens<br />

Transportation Systems who sponsored the music<br />

for dancing and Westinghouse Rail Systems who<br />

contributed towards the table decorations.<br />

Members and their guests were greeted by the<br />

President, Mr Peter Stanley and his wife Carol at the<br />

opening reception.<br />

The principal guest on this occasion was Dr Peter<br />

Watson OBE, Chairman AEA Technology plc and<br />

formerly BRB board member for Engineering, who<br />

was accompanied by his wife. An excellent threecourse<br />

dinner was served followed by coffee and<br />

mints. After dinner, the President introduced his<br />

principal guest to the gathering and Dr Watson, who<br />

had been the principal guest at the dinner dance ten<br />

years earlier in 1992, referred back to the remarks he<br />

made in 1992 and spoke about the current state of<br />

the railway Industry and the contribution that can be<br />

made by S&T engineering. His comments were<br />

made in an encouraging and amusing manner that<br />

was thoroughly enjoyed by all present.<br />

Music for dancing following the dinner was<br />

provided by the East Woodhay Silver Band who<br />

played a selection of music in a variety to suit all<br />

musical tastes and dancing styles.<br />

Regrettably numbers were significantly down on<br />

previous years and a number of the major signalling<br />

suppliers were absent. However, the 114 members<br />

and their guests that did attend all enjoyed a<br />

pleasant and happy evening.<br />

Fourth Members’ Luncheon<br />

The fourth Members’ Luncheon was held on 19th<br />

June <strong>2002</strong> when 75 members of the Institution,<br />

including 12 Past Presidents and nine members<br />

with over 50 years membership, took luncheon at<br />

the Victory Services Club in Seymour Street,<br />

London.<br />

The 78th person to serve as President since the<br />

Institution’s formation in 1912, Mr Peter Stanley,<br />

addressed the members present with a brief speech<br />

and mentioned the forthcoming programme for his<br />

presidential year of office.<br />

The Chief Executive reported that the current<br />

membership of the Institution was 2,979 and<br />

continues to grow steadily. There are now 30<br />

members with over 50 years’ membership, nine of<br />

whom were able to accept the President’s invitation<br />

to be present at the luncheon as guests of the<br />

Institution.<br />

Another 12 members have over 60 years membership<br />

and two of these were also present – Peter<br />

Guyatt and, also the longest serving Past President,<br />

Armand Cardani, who was President 31 years ago in<br />

1970.<br />

There are also three members who have over 70<br />

years membership. The longest serving member is<br />

believed to be Mr S E W Stokes, who resides in<br />

Brazil, with 78 years membership of the Institution<br />

but it has not been possible to obtain a response<br />

from his last known address. However, letters of<br />

good wishes had been received from Douglas Kidd,<br />

a member for 72 years residing in Shaftesbury and<br />

aged 97, and also from Wilfred Hardman, a member<br />

for 73 years and living in New Zealand. Many other<br />

members who were unable to attend in person had<br />

sent letters of apology and good wishes.<br />

Regrettably, 17 members had died since the lunch<br />

last year including David Wittamore, who served the<br />

Institution as a member of Council and on the<br />

Recruitment Committee for many years; Frank<br />

Smith, a former Chief S&T Engineer of the LMR;<br />

more recently Roger Pope, another long-standing<br />

servant of the Institution, particularly on the<br />

Examination Committee; and also Reg Hawkins,<br />

who did so much in the last 20 years to arrange the<br />

regular reunions of ex-SR S&T staff. The members<br />

present expressed their grateful thanks for the<br />

service that all of these friends and colleagues<br />

performed for the Institution during their time with<br />

us.<br />

The activity of the Institution continues to increase<br />

and the Institution is asked to contribute more and<br />

more frequently its expertise to the development of<br />

the industry and the profession. The Strategic Rail<br />

Authority recently granted the Institution another<br />

£250,000 on top of the £100,000 grant last year to<br />

continue the work being done, with the co-operation<br />

of the signalling industry, to recreate the recruitment,<br />

training and career development frame work for<br />

signalling engineers to overcome the current skills<br />

shortage in the discipline that has occurred since<br />

privatisation.<br />

During the year a major task had been the introduction<br />

of a new membership database computer

18<br />

FOURTH MEMBERS’ LUNCHEON<br />

system in the office. This will help in keeping track of<br />

members and in managing Institution events. The<br />

opportunity has also been taken to update the<br />

membership list and to purge it of old and out of<br />

date information.<br />

Another major task in the last year had been the<br />

revision of the Articles to update the qualifications<br />

for membership, to include the grade of Associate<br />

Member within the class of Corporate Member and<br />

also, now that the activity of the Institution has<br />

expanded significantly, the introduction of Byelaws<br />

to assist Council in its management of Institution<br />

affairs.<br />

As a nominated body of the Engineering Council<br />

(UK) the Institution registers Incorporated Engineers<br />

and Engineering Technicians with the Engineering<br />

Council and 12 of our members were registered last<br />

year.<br />

The Chief Executive said that none of this<br />

substantial effort would be possible without the<br />

wholehearted support and hard work of the<br />

Institution team comprising Mark Watson-Walker,<br />

Linda Collins, Karen Gould and Linda Mogford and<br />

concluded by expressing his thanks on behalf of the<br />

membership to the staff of the Institution for their<br />

hard work and wholehearted support during the last<br />

year.<br />

The luncheon concluded in a most pleasant and<br />

happy atmosphere of friendship and camaraderie<br />

and was judged a great success, having been<br />

thoroughly enjoyed by all present.<br />

The fifth Members’ luncheon has been provisionally<br />

arranged to take place on Wednesday 18th<br />

June <strong>2003</strong> at the same venue.<br />

K W Burrage

19<br />

The Institution of Railway Signal Engineers<br />

(COPYRIGHT RESERVED)<br />

Presidential Address<br />

of<br />

P W STANLEY BSc CEng FIEE F<strong>IRSE</strong><br />

Making the Possible Happen<br />

I have no doubt that at the start of their<br />

presidential year, every one of my predecessors has<br />

looked with some amazement at the demands and<br />

current problems of the Industry and the number of<br />

things that need to be done, with just a slight<br />

concern as to how the President can make a<br />

meaningful contribution in the space of one short<br />

year. It is certainly the way that I feel at this moment.<br />

Like most incoming presidents I face an immediate<br />

difficulty. What can I say that has not been said<br />

before? What ideas can come to mind that have not<br />

been thought, debated and acted on many times<br />

before? What actions can be proposed that have not<br />

been tried before? I shall start by saying thank you<br />

to all my many colleagues who, during the 14 years<br />

that I have served on Council, have been a source of<br />

help and encouragement. Without such support, I<br />

could not be here today.<br />

This time last year Bob Barnard ended his address<br />

with a look forward to things that the Institution<br />

should do in future; I intend to start where he left off,<br />

and with time being short, the best place for me to<br />

start is with my conclusions.<br />

CONCLUSIONS<br />

Modern train control systems are dependent on<br />

communications as an integral part of the system to<br />

the extent that old divisions between ‘S’ and ‘T’ no<br />

longer apply. I believe that my comments apply to all<br />

railway S&T engineers, whatever their specialisation<br />

may be.<br />

Today we have the possibility of applying new<br />

technology to railways, capable of delivering<br />

systems that are safer, more reliable, more available,<br />

more adaptable and with greater functionality. If we<br />

do not also have the skilled people, workable<br />

procedures for gaining safety approvals and<br />

sufficient economic benefit to justify investment,<br />

then the possibility will remain just that; we must<br />

make the possible happen.<br />

I believe that our Institution can and should<br />

develop its services to members and its role within<br />

the industry by offering guidance, giving leadership<br />

and developing services in five important areas:<br />

• Meeting the demand for S&T engineers;<br />

• Introducing new technology;<br />

• Harmonising safety acceptance procedures;<br />

• Delivering additional functionality and economic<br />

benefit;<br />

• Making the benefits of membership of our<br />

Institution more widely available in developing<br />

countries.<br />

THE DEMAND FOR S&T ENGINEERS<br />

RECOGNISING PROBLEMS – AVAILABILITY OF<br />

EXPERTISE<br />

If I want to say anything even slightly revolutionary,<br />

I had better start with the wheel of progress, which<br />

as it turns, sooner or later brings up old railway<br />

problems in new guises.<br />

Even if recurring problems are recognised as such,<br />

essential details could be elusive, existing only in the<br />

memories of the original experts who might not be<br />

around to be consulted.<br />

Many organisations are now structured to deal<br />

with current tasks and have neither a company<br />

collective memory that could recognise old<br />

problems when they recreate-occur, nor easy<br />

access to records of solutions that were considered<br />

previously, nor knowledge of why one solution was<br />

selected and others rejected, nor the expertise to

20<br />

PRESIDENTIAL ADDRESS<br />

recognise the root cause nor the manpower to<br />

develop a timely solution.<br />

In some cases, problems are faced by managers<br />

with a limited railway background who may think<br />

that every problem is new, and that every existing<br />

practice is deficient and ripe for change.<br />

It is here that our Institution can play an important<br />

role. Records of papers, discussions, conferences<br />

and visits form a vital resource, allowing us to<br />

revisit our history and experience and use the<br />

collected wisdom of the past<br />

The key, unavoidable need is for people of<br />

appropriate training and experience able to search<br />

and interpret such information.<br />

STRUCTURAL CHANGES IN THE INDUSTRY<br />

The recent changes in our industry, especially in<br />

the UK, are leading to the fragmentation of long<br />

established organisations, the privatisation of many<br />

areas of technical and operational specialisation and<br />

the creation of new and unfamiliar contractual<br />

boundaries more attuned to financial flows than<br />

service delivery<br />

The new organisations have tended to direct their<br />

resources towards the management of their contracts,<br />

eliminating in-company expertise and relying<br />

on the availability of expert service companies to<br />

which the solving of problems can be outsourced as<br />

and when they arise.<br />

Since technical problems often fall across the new<br />

contract boundaries and have commercial and legal<br />

significance, each party to the contract may need<br />

independent expert advice and support, placing<br />

additional demands on the limited supplies of<br />

technical specialists.<br />

Another effect has been the great reduction across<br />

the industry in the numbers of technical specialists<br />

in R&D, not currently required for the day to day<br />

operation of the railway, but needed almost<br />

immediately to investigate the causes of mishaps<br />

and to support accident inquiries, at which time they<br />

suddenly become a very scarce resource.<br />

In the UK, efforts are being made to recreateestablish<br />

co-operative funding of R&D programmes<br />

across the industry, but with a tendency to ignore<br />

the existing pool of knowledge.<br />

Again, the Institution can provide guidance on the<br />

existence of relevant studies and reports and<br />

on the location of appropriate knowledge and<br />

experience.<br />

SUPPLIER DIVERSITY<br />

Quite apart from the inevitable opening up of<br />

home markets as a result of EC competition legislation,<br />

in the UK mainline network there has been a<br />

policy of introduction of systems based on new<br />

technology from suppliers outside the traditional<br />

supplier base with little or no previous UK application<br />

experience.<br />

New suppliers have brought additional pressure<br />

on resources in the areas of safety approval,<br />

application and interface engineering, testing<br />

and commissioning and training of maintenance<br />

staff.<br />

SAFETY ASSURANCE<br />

In parallel with the organisational changes, we<br />

have seen the development of safety law, with new<br />

procedures for equipment safety approval and<br />

risk assessment, mitigation and management.<br />

Formalisation of process in the UK has led to a<br />

protracted and expensive system of assessment<br />

and approval based on committees, technical<br />

advisors and independent safety assessors, each<br />

requiring people who possess appropriate<br />

competence.<br />

MEETING THE DEMAND<br />

These factors lead to a heavy demand for scarce<br />

resources and a number of important questions<br />

come to mind:<br />

• How can the demand for railway signal and<br />

telecommunications specialists be met?<br />

• How will those now starting their careers in the<br />

industry gain the necessary range of knowledge<br />

and experience?<br />

• Given the specialisation of the employing<br />

companies and the increase in support services<br />

companies with interests beyond railways, is it<br />

more likely that career paths will lead outside<br />

the industry?<br />

SO WHAT MAKES AN S&T ENGINEER?<br />

THE RANGE OF EXPERTISE<br />

The life cycle of every new generation of technology<br />

and every different implementation of that<br />

technology must be supported by a wide range of<br />

expertise, leading it from development to application<br />

design, to implementation, maintenance, modification<br />

and eventually to recovery.<br />

Given the asset life demanded of railway assets,<br />

several generations of equipment will have to<br />

co-exist within any network, and not only in the<br />

maintenance and recovery phases; for it is the very<br />

nature of railways that changing traffic patterns<br />

and service demands will require infrastructure<br />

alterations. As a result, there will be a need for the<br />

creation of new interfaces to existing systems, so<br />

perpetuating the need for relevant expertise over<br />

several generations of engineers.<br />

If we look at the range of technologies that still<br />

exist, at various stages of their life cycle we might be<br />

somewhat surprised at the range of expertise that<br />

must be available somewhere.<br />

Clearly, at one end of the spectrum we have<br />

people with expertise in a particular technology but<br />

with no knowledge of its application; at the other<br />

end we have people who are expert in their understanding<br />

of the needs of operators, signallers and<br />

drivers, but have only a limited knowledge of the<br />

technology. The role of the S&T Engineer and of this<br />

Institution is to provide the essential bridge between<br />

these two extremes.<br />

RECRUITING S&T ENGINEERS<br />

Perhaps we should also ask why anyone would<br />

choose a career in railway control and command<br />

systems engineering. Probably not as a result of<br />

such an uninspiring role description, so I shall think

PRESIDENTIAL ADDRESS 21<br />

in terms of S&T Engineering!<br />

Perhaps as a start I could relate my own experiences.<br />

Like most youngsters I had ideas about what<br />

I wanted to be when I left school, first a policeman,<br />

then a train driver then a boat builder then a<br />

musician, but at some stage reality intervened. After<br />

graduating in electrical engineering, I looked at a<br />

number of opportunities that seemed to involve<br />

being tucked away in the corner of a design office<br />

dealing with some small area of product design.<br />