Betriebsanleitung Betriebsanleitung - Bio-Circle

Betriebsanleitung Betriebsanleitung - Bio-Circle

Betriebsanleitung Betriebsanleitung - Bio-Circle

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technical Support:<br />

Telefon: +49 (0)5241 9443-0<br />

Telefax: +49 (0)5241 9443-44<br />

E-Mail: service@cb-chemie.de<br />

AL5 3/2009<br />

CB Chemie und <strong>Bio</strong>technologie GmbH<br />

CB Chemie und <strong>Bio</strong>technologie GmbH<br />

Berensweg 200 • D-33334 Gütersloh<br />

Telefon: +49 (0)5241 9443-0<br />

Telefax: +49 (0)5241 9443-44<br />

E-Mail: service@cb-chemie.de<br />

www.cb-chemie.de<br />

bio-chem SEPRO Surface Technology GmbH<br />

Winetzhammerstraße 4 • A-4030 Linz<br />

Telefon: +43 (0)732 376262<br />

Telefax: +43 (0)732 376260<br />

E-Mail: service@bio-chem.at<br />

www.bio-chem.at<br />

WALTER CB-AG<br />

Lettenstrasse 6 • CH-6343 Rotkreuz<br />

Telefon: +41 (0)41 8781166<br />

Telefax: +41 (0)41 8781347<br />

E-Mail: info@walter-cb.ch<br />

www.walter-cb.ch<br />

<strong>Betriebsanleitung</strong><br />

Operating Instructions<br />

Mode d´emploi<br />

Libretto d’istruzioni<br />

G40026-03<br />

G40026-03

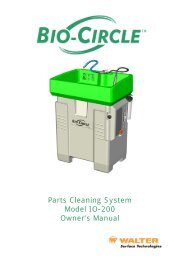

Thank you for purchasing the <strong>Bio</strong>-<strong>Circle</strong>.<br />

This operating instructions have been designed to give you all information on the <strong>Bio</strong>-<strong>Circle</strong>.<br />

To ensure perfect functioning of your <strong>Bio</strong>-<strong>Circle</strong>, carefully read them before using<br />

the machine.<br />

Familiarize yourself with this unit's operation, its particular features, applications and<br />

limitations. You will also find useful tips on safety and maintenance.<br />

CB Chemie und <strong>Bio</strong>technologie GmbH<br />

Should you need more information<br />

please call our<br />

Service Hotline +49 (0)5241 9443-0<br />

ED<br />

D<br />

18 19

Operating instructions <strong>Bio</strong>-<strong>Circle</strong> – English<br />

Table of Contents<br />

1. General Points<br />

1.<br />

2.<br />

3.<br />

General Points<br />

1.1 Key to Safety Instructions<br />

Basic Safety Instructions<br />

Product Description<br />

3.1 Assembly and Mode of Operation<br />

3.2 Intended Use<br />

21<br />

21<br />

21<br />

22<br />

24<br />

<br />

information necessary for its correct handling and usage and covers the initial set up, operation, maintenance,<br />

shut down and waste disposal. The warnings, advice and instructions mentioned in this manual<br />

are to be observed and adhered to. If the product is used in accordance to the regulations corresponding<br />

to these operating instructions, we will be held liable as mentioned in our guarantee conditions.<br />

Keep these operating instructions in a safe place. They are designed to help you with the practical<br />

usage of the Parts Washer and shall be at the user’s disposal near the Parts Washer at all times.<br />

4.<br />

5.<br />

Technical Data<br />

Start Up<br />

25<br />

26<br />

<br />

<br />

authorisation, otherwise the guarantee will then expire and cease to be valid.<br />

6.<br />

Operation<br />

27<br />

1.1 Key to Safety Instructions<br />

7.<br />

8.<br />

Maintenance<br />

Notes for Waste Disposal<br />

28<br />

28<br />

Danger symbol<br />

<br />

material damage). Take note of this instruction and behave cautiously!<br />

9.<br />

Optional Accessories<br />

9.1 Filter Set<br />

9.2 Drain valve<br />

9.3 Lid<br />

29<br />

30<br />

31<br />

Prohibition symbol<br />

<br />

result in direct personal injury and material damage.<br />

It is imperative that prohibition symbols are complied with!<br />

10.<br />

11.<br />

12.<br />

13.<br />

Trouble Shooting Guide<br />

Diagram Showing Electrical Connections<br />

Regulations<br />

Terms of Guarantee<br />

32<br />

33<br />

33<br />

34<br />

2. Basic Safety Instructions<br />

Every person who works with the product must be familiar with the content of the operating instructions<br />

booklet. These operating instructions are part of the apparatus and must be placed at the<br />

disposal of the operating staff at all times.<br />

The operating staff are to be shown the operating instructions; the danger symbols and prohibition<br />

symbols in particular must be pointed out to them.<br />

The apparatus is to be protected with a protective circuit (ELCB - Earth Leakage Circuit Breaker - F1<br />

switch) provided by the customer. Please have this checked and tested by a specialist in electrics!<br />

The apparatus must only be operated by people authorised to do so.<br />

E<br />

D<br />

20 21

Operating instructions <strong>Bio</strong>-<strong>Circle</strong> – English<br />

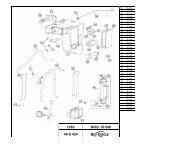

3. Product Description<br />

3.1 Assembly and Mode of Operation<br />

3<br />

19<br />

10<br />

2<br />

13<br />

6<br />

19<br />

23<br />

17<br />

20/21<br />

26<br />

9<br />

12<br />

11<br />

15<br />

5<br />

24/25<br />

18<br />

8<br />

7<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

8.<br />

9.<br />

10.<br />

11.<br />

12.<br />

13.<br />

14.<br />

15.<br />

16.<br />

17.<br />

18.<br />

19.<br />

20./21.<br />

22.<br />

23.<br />

24./25.<br />

26.<br />

Base with tank<br />

Sink<br />

3-Way ball valve<br />

Control panel<br />

Heater<br />

Fluid pump<br />

Level switch<br />

Temperature sensor PT 100<br />

Flow-through brush<br />

<br />

Plastic Filter sieve 600 µm<br />

<br />

<br />

Filter housing (optional)<br />

Mounting plate for heater/level switch/ temperature sensor<br />

Temperature monitor<br />

Lid (optional)<br />

Air pump<br />

<br />

Screw-in connector (outer thread)<br />

Feed cable 230 V<br />

Screw-in connector (inner thread)<br />

Air sprinkler incl. tube (800 mm)<br />

<br />

Order No.<br />

G24826<br />

G27226<br />

G23826<br />

G20126<br />

G24126<br />

G24226<br />

G20726<br />

G23626<br />

G23126<br />

G20926<br />

G23526<br />

G25026<br />

G23726<br />

G28026<br />

G24726<br />

G23926<br />

G23326<br />

G23226<br />

G24326<br />

G25926<br />

G24026<br />

G23026<br />

20/21<br />

14<br />

4<br />

16<br />

1<br />

22<br />

E<br />

D<br />

22 23

Operating instructions <strong>Bio</strong>-<strong>Circle</strong> – English<br />

The pump is electrically operated and pumps the cleaning liquid through the connecting tube to the<br />

3-way ball valve. Depending on its position the cleaner can either be propelled to the sink via the tube<br />

with the brush or via the versatile jointed hose. The work piece is located in the interior of the table<br />

<br />

the container. Microorganisms then break down the oil and fat impurities.<br />

Comparison between conventional Parts Cleaner with Cold Cleaner and <strong>Bio</strong>-<strong>Circle</strong> Parts Cleaner<br />

What is the effect of increased<br />

contamination?<br />

What contaminations<br />

can be removed ?<br />

Organic, apolar (grease, oil)<br />

Inorganique, polar (salts)<br />

Inorganique, apolar (iron fillings, dust)<br />

What materials can be cleaned with?<br />

Stainless steel<br />

Steel<br />

Aluminium<br />

Non-ferrous heavy metals<br />

Safety and health provisions for workers<br />

Cold<br />

Cleaner<br />

saturation of the cleaning liquid<br />

– cleaning effect falls off<br />

Very good results<br />

Poor results<br />

Poor results<br />

Very good results<br />

Very good results<br />

Very good results<br />

Very good results<br />

<strong>Bio</strong>-<strong>Circle</strong><br />

<strong>Bio</strong>-<strong>Circle</strong> L<br />

good stable<br />

results the<br />

whole time<br />

Very good results<br />

Very good results<br />

Good results<br />

Very good results<br />

Very good results<br />

Very good results<br />

Very good results<br />

4. Technical Data<br />

Dimensions<br />

Weight when empty<br />

Power input<br />

Electrical connection<br />

Fuse protection<br />

Working Height<br />

Load capacity<br />

Tank<br />

<br />

<br />

Usable workspace<br />

Heating<br />

Level switch<br />

Temperature sensor<br />

Pump<br />

1010 x 785 x 1140 mm<br />

55 kg<br />

1,1 kW<br />

1/N/PE 230 V~<br />

10 A<br />

950 mm<br />

250 kg<br />

Material PE LD<br />

100 l<br />

60 l<br />

930 mm x 545 mm<br />

Stainless steel heater output 1 kW<br />

55 l<br />

Factory set to 41 °C<br />

approx. 380 l/h<br />

Health damage<br />

(Source: Reinigen und Entfetten, BG Maschinenbau- und Metall-BG 1997)<br />

Cold<br />

Cleaner<br />

<strong>Bio</strong>-<strong>Circle</strong><br />

<strong>Bio</strong>-<strong>Circle</strong> L<br />

Damage to the nervous system<br />

Damage to the skin<br />

Toluene, Xylenes, Trichlorethylene, no<br />

Benzenes (Hexane isomers, Pentane,<br />

Heptane, Octane)<br />

Yes<br />

no<br />

Damage to the liver<br />

Dichlormethane, Trichlorethylene,<br />

Toluene, Xylenes, Methanol, Ethanol<br />

no<br />

Damage to the kidneys<br />

Damage to the blood cells<br />

Trichlorethylene, Kerosene, Petrol/gasoline,<br />

Hexane, Heptane,<br />

Toluene, Xylene, Alcohols<br />

Toluene, Benzine<br />

no<br />

no<br />

Mutagens and teratogenes<br />

Organic solvents<br />

no<br />

Cancerogen<br />

Benzene<br />

no<br />

3.2 Intended Use<br />

* The used micro-organisms are non-pathogen bacteria of group 1 acc. to Directive 2000/54/EC.<br />

(Group 1 means that they are unlikely to cause human disease.)<br />

The <strong>Bio</strong>-<strong>Circle</strong> parts washer is an environmentally<br />

<br />

clean machine parts, motors, casings or other parts<br />

covered in oil and grease with the aid of <strong>Bio</strong>-<strong>Circle</strong><br />

Liquid, a biological cleaning liquid.<br />

<strong>Bio</strong>-<strong>Circle</strong> Liquid<br />

A02026 <strong>Bio</strong>-<strong>Circle</strong>L 20 L jerrycan<br />

A20026 <strong>Bio</strong>-<strong>Circle</strong>L 200 L drum<br />

E<br />

D<br />

24 25

Operating instructions <strong>Bio</strong>-<strong>Circle</strong> – English<br />

5. Start Up<br />

After removing the packaging, check the casing and control for any possible transport damage.<br />

Should any transport damage be detected, do not connect the apparatus to the mains. Instead, report<br />

the damage to the carrier and to CB Chemie und <strong>Bio</strong>technologie GmbH. The original packaging<br />

must be retained. Place the unit in a dry and stable place of your choice.<br />

The ground must be level. If it is necessary level the ground out with suitable material.<br />

<br />

<br />

Connect the unit to the electricity supply.<br />

<br />

not be used!<br />

Please ensure that the current entry provided by the customer is furnished with an ELCB<br />

(Earth Leakage Circuit Breaker - FI switch).<br />

Control Panel<br />

1. Connect the machine to power supply.<br />

Heating system starts warming up the solution to its proper working temperature of 41°C (105.8°F).<br />

2. <br />

switch again. The pump will stop automatically after one hour.<br />

3. If needed, press the ON/OFF switch for 3 seconds to set unit into standby mode.<br />

Attention: The circuit board is still energized.<br />

4. When solution level falls below minimum (60 liters), the display indicates „LO”.<br />

<br />

Never turn off the <strong>Bio</strong>-<strong>Circle</strong> unit unless for servicing or longer periods of non-use (more<br />

<br />

skim off or absorb any accumulation of oil.<br />

6. Operation<br />

<br />

any brushes prior to cleaning; this will prevent grease and dirt from sticking to the surfaces.<br />

The maximum load of 250 kg must not be exceeded!<br />

Depending on the positioning of the 3-way ball valve, cleaning can occur via:<br />

Washing by means of a versatile jointed hose with nozzle<br />

<br />

Note: In centre position both outlets are open.<br />

Note: Any parts susceptible to oxidation should not be left in the sink after cleaning.<br />

As with all parts cleaners, excess grease and oil should be disposed of prior to washing. Do<br />

not use this unit as a waste dump. Do not introduce<br />

coolant, chlorinated, acidic or alkaline solutions into this system. Do not add water.<br />

Activate the pump with the help of the on/off switch with the cleaning symbol.<br />

After the cleaning process has ended ON/OFF switch off the pump again.<br />

Display<br />

ON/OFF<br />

Switch<br />

Note:<br />

To re-start press the ON/OFF switch.<br />

Depending on the initial temperature of the liquid, the heating process can take approx. 2,5 hours.<br />

The temperature is set by the factory to maintain the solution at 41°C.<br />

Once the correct temperature has been reached, the unit is ready for use.<br />

The optimal temperature for the activity of micro-organisms and therefore for the breakdown of oil<br />

is approximately 41°C. Therefore leave the apparatus switched on all the time.<br />

For optimal activity of microorganisms and thus of the breakdown of oil, it is essential that the<br />

micro-organisms have a constant supply of oxygen. This is why an air sprinkler is permanently<br />

switched on, which guarantees the required oxygen supply for the microorganisms. If the unit is<br />

switched off, or fails because of a defect, the result is that the microorganisms become inactive.<br />

E<br />

D<br />

26 27

Operating instructions <strong>Bio</strong>-<strong>Circle</strong> – English<br />

7. Maintenance<br />

<br />

the plug from the mains! Check that the apparatus has no current!<br />

For maintenance purposes the table can be opened sideways. For that purpose, raise on the right<br />

half of the table and support the table by means of the in-lying metal pole.<br />

Fill Level<br />

<br />

<br />

and heating switch off automatically for safety reasons. The “LO” shows this visually. The display will<br />

show the actual liquid temperature until 41°C is reached again.<br />

Filters<br />

<br />

<br />

<br />

9. Optional Accessories<br />

9.1 Filter Set<br />

<br />

<br />

-<br />

<br />

care that the o-ring sits correctly.<br />

Assembly instructions<br />

1. Assembling filter holding plate with the 4 lens head screw on the filter body.<br />

2. Filter has to be fixed with 2 lens head screws in the intended, deepened sites on the basic part.<br />

3. Attend to central adjustment of the gland (see picture below).<br />

4. Connecting tube has to be disconnected at the exit- and entry points of the filter.<br />

5. Push the tube on the tube mandrel and the tube with hose clamps.<br />

Periodic maintenance<br />

It is recommended that your <strong>Bio</strong>-<strong>Circle</strong> is inspected and cleaned at least once a year to perform at<br />

<br />

the bottom of the tank over time, which can negatively affect the bioremediation activity.<br />

To facilitate the removal of the sludge turn off the unit and unplug it. Open the sink and empty the unit<br />

from all the cleaning solution using a hand pump until the sludge becomes visible. If cleaning solution<br />

is still cleaning well, save it for re-use. Remove the sludge and clean the tank walls and pumps.<br />

If a drain valve (optional accessories) is installed, connect a hose to drain valve and fully open the<br />

valve, wait a few seconds and then close the valve. Repeat these steps 3 times to remove most<br />

<br />

temperature of 41°C before cleaning parts. Visually inspect pumps, tubing and connections. Replace<br />

parts that show excessive wear.<br />

1 screw-in sleeve R3/8"<br />

2 filter<br />

3 screw-in connector R 3/8"<br />

4 pipe plug mandrel AD 3/8"-ID 3/8"<br />

5 filter holding plate<br />

6 slotted pan head screw 4,8x16 A2<br />

to 3-Way ball valve<br />

from pump<br />

8. Notes for Waste Disposal<br />

For this product, no waste disposal key, according to the European Waste Catalogue (EWC) can be<br />

<br />

code number has to be determined in accordance with the local waste disposer.<br />

Take unused <strong>Bio</strong>-<strong>Circle</strong> Liquid to a sewage plant in accordance with federal, state and local<br />

environmental regulations. Consider pH-value.<br />

E<br />

D<br />

28 29

Operating instructions <strong>Bio</strong>-<strong>Circle</strong> – English<br />

9.2 Drain valve<br />

9.3 Lid<br />

Install drain valve in accordance with the assembly instructions.<br />

1.<br />

For mounting the lid, please use the contemplated screw threads M8 on the table. The lid set contains<br />

two allen screws for that purpose. Attention: Tighten screws softly to allow smooth moving of<br />

the lid.<br />

Assembly instruction<br />

1. Screw off hexagonal nut (1)<br />

in the tank bottom (inside)<br />

2. Pull banjo bolt (2) out of the tank<br />

3. Dismantle screw-cap (3) off the banjo bolt<br />

4. Connect drain valve (4) with banjo bolt<br />

5. Install it bottom-up in the tank<br />

6. Fasten it with the hexagonal nut<br />

in the tank bottom (inside)<br />

7. Check leak tightness<br />

1 hexagonal nut<br />

tank bottom inside<br />

tank bottom outside<br />

2 banjo bolt<br />

3 screw-cap<br />

4 drain valve<br />

E<br />

D<br />

30 31

Operating instructions <strong>Bio</strong>-<strong>Circle</strong> – English<br />

10. Trouble Shooting Guide<br />

11. Diagram Showing Electrical Connections<br />

<br />

Pull the plug from the mains! Check that the apparatus has no current!<br />

Work on fixtrures are only allowed to be done by trained persons.<br />

<strong>Bio</strong>-<strong>Circle</strong> control board<br />

Errors will be indicated on the display by codes F1 to F7.<br />

F1: Heater is out of order.<br />

Possible cause: cable break, defective fuse (fuse 10 A T 6,3 x 32 mm)<br />

or temperature control release.<br />

The temperature monitor can be found in space between the two<br />

tank walls, glued in the lower third of the wall. For the reset it is<br />

inevitable to disconnect the machine from the current, remove<br />

the front panel and push the red button.<br />

F2: Fluid pump is out of order.<br />

Possible cause: cable break or defective fuse (fuse 1 A T 5 x 20 mm).<br />

F3: Air pump is out of order.<br />

Possible cause: cable break or defective fuse (fuse 100 mA T 5 x 20 mm).<br />

electrical network<br />

heater<br />

pump<br />

membrane pump<br />

level<br />

foot switch<br />

F4: Float switch is not connected.<br />

F5: <br />

thermo switch<br />

F6: Heat sensor PT100 is not connected<br />

F7: Short circuit at the heat sensor PT100.<br />

Overheating:<br />

To prevent damage by impact of overheating <strong>Bio</strong>-<strong>Circle</strong> is equipped with a temperature control.<br />

Heater will stop when the temperature has risen above 41 °C .<br />

12. Regulations<br />

The units are subject to strict safety regulations. Therefore, faulty parts must be replaced by original<br />

spare parts only. A spare parts list is available on request.<br />

<strong>Bio</strong>-<strong>Circle</strong> comply with the CE criteria. The declaration of conformity is available on request.<br />

E<br />

D<br />

32 33

Operating instructions <strong>Bio</strong>-<strong>Circle</strong> – English<br />

13. Terms of Guarantee<br />

All CB Chemie und <strong>Bio</strong>technologie GmbH articles are inspected and tested before shipment and are<br />

warranted to be free from any defect in material and faulty workmanship. CB Chemie und <strong>Bio</strong>technologie<br />

GmbH gives guarantee of 12 months on the machines, except wear parts. This warranty<br />

does not apply when normal maintenance is required, repairs or replacements have been made by<br />

anyone other than CB Chemie und <strong>Bio</strong>technologie GmbH authorized personnel, and does not cover<br />

<br />

If an examination shows that the malfunction was caused by defective material or faulty workmanship,<br />

CB Chemie und <strong>Bio</strong>technologie GmbH will repair (or at our option, replace).<br />

Garantie starts with the date of delivery at the costumer or date of invoice.<br />

E<br />

D<br />

34 35