Fire Protection - Knauf Insulation

Fire Protection - Knauf Insulation

Fire Protection - Knauf Insulation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

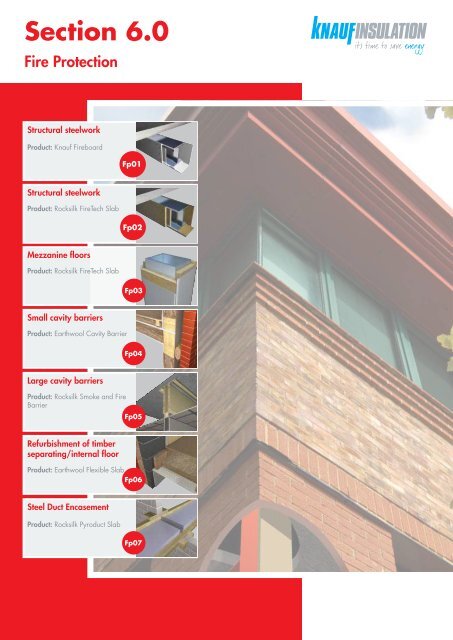

Section 6.0<br />

<strong>Fire</strong> <strong>Protection</strong><br />

Structural steelwork<br />

Product: <strong>Knauf</strong> <strong>Fire</strong>board<br />

Fp01<br />

Structural steelwork<br />

Product: Rocksilk <strong>Fire</strong>Tech Slab<br />

Fp02<br />

Mezzanine floors<br />

Product: Rocksilk <strong>Fire</strong>Tech Slab<br />

Fp03<br />

Small cavity barriers<br />

Product: Earthwool Cavity Barrier<br />

Fp04<br />

Large cavity barriers<br />

Product: Rocksilk Smoke and <strong>Fire</strong><br />

Barrier<br />

Fp05<br />

Refurbishment of timber<br />

separating/internal floor<br />

Product: Earthwool Flexible Slab<br />

Fp06<br />

Steel Duct Encasement<br />

Product: Rocksilk Pyroduct Slab<br />

Fp07

6.1<br />

<strong>Fire</strong> <strong>Protection</strong><br />

<strong>Fire</strong> protection of structural steel<br />

<strong>Fire</strong> protection design<br />

<strong>Knauf</strong> <strong>Insulation</strong> are members of<br />

the Association for Specialist <strong>Fire</strong><br />

<strong>Protection</strong>, and our fire protection<br />

products are listed in the Yellow<br />

Book, which presents economical<br />

methods for the fire protection of<br />

structural steelwork to provide<br />

compliance with Building<br />

Regulations<br />

266<br />

Structural steel requires fire protection because<br />

it loses structural strength at temperatures that<br />

can be rapidly reached in a building fire. This<br />

will consequently have a negative impact on the<br />

structural integrity of the building. Protecting the<br />

structural steel from the heat of a fire will delay<br />

the onset of this loss of strength and the possible<br />

collapse of the building. This is essential<br />

because it allows extra time for both the<br />

occupants of the building to escape and fire<br />

services to tackle the fire. It could also prevent<br />

the actual collapse of the building minimising<br />

insurance losses. Building Regulations covering<br />

fire safety are concerned with the preservation<br />

of life.<br />

With the increasing use of structural steel in<br />

construction, designers need fire protection<br />

solutions that provide a combination of fast<br />

installation and cost-effectiveness whilst<br />

achieving the desired finish.<br />

Whatever the application <strong>Knauf</strong> <strong>Insulation</strong> has<br />

a range of board products and systems to cater<br />

for any project.<br />

When used for the fire protection of structural<br />

steelwork, board systems offer several<br />

compelling advantages over site applied paint<br />

and spray coating systems.<br />

Board systems:<br />

• Are manufactured to factory tolerances – this<br />

enables the specifier to be certain that the<br />

correct thickness of fire protection is being<br />

applied, by simply checking the thickness of<br />

materials supplied<br />

Technical Advice and Support Centre 01744 766666<br />

• Can be installed prior to the building being<br />

sealed and made watertight, in all<br />

temperature and humidity conditions – this<br />

is in contrast to paint and sprays which are<br />

often restricted by normal UK winter<br />

conditions, causing potential delay to<br />

site programs<br />

• Are fast, clean, and dry to install, with<br />

negligible dust levels, allowing other trades<br />

to work in close proximity<br />

• Are quick and easy to check (by visual<br />

inspection) that all relevant areas have<br />

been protected<br />

• Are fully compatible with drylining systems<br />

and allow easy integration with partitioning<br />

schemes<br />

<strong>Fire</strong> protection<br />

Any steel section which is an element of<br />

structure and is deemed by any of the following<br />

regulations to require fire resistance can be<br />

protected with a fire protection system of dense<br />

rock mineral wool slabs or fibre reinforced<br />

gypsum based boards.<br />

1. The Building Regulations (England and<br />

Wales) Approved Document B (<strong>Fire</strong> Safety) –<br />

Volumes 1 and 2 (2006)<br />

2. The Building (Scotland) Regulations,<br />

Technical Booklets, Section 2, 2011<br />

3. The Building Regulations (Northern Ireland)<br />

Technical Booklet E, 2005<br />

4. The Building Regulations (Republic of Ireland)<br />

Technical Guidance Document B (2006)<br />

www.knaufinsulation.co.uk<br />

5. Loss Prevention Council Code of Practice for<br />

Construction of Buildings<br />

Steel sections can include universal beams,<br />

columns and joists (plain and castellated),<br />

structural and rolled tees, angles, channels and<br />

round, square or rectangular hollow sections.<br />

Benefits<br />

Both rock mineral wool slabs and fibre<br />

reinforced gypsum boards offer a number of<br />

advantages for the fire protection of structural<br />

steelwork that make them ideal for fast track<br />

projects.<br />

Rock mineral wool<br />

• Lightweight product – at less than half the<br />

weight of calcium silicate slabs – rock<br />

mineral wool fire protection boards are easy<br />

to handle and fit on site particularly for<br />

overhead work<br />

• Ease of cutting and fixing: Rock mineral wool<br />

slabs are easy to cut with either a saw or a<br />

sharp knife, furthermore there are four fixing<br />

methods, all involve square edge butt joints<br />

between the boards which enables a fast and<br />

simple system to be installed without delaying<br />

other trades and activities<br />

Fibre reinforced gypsum<br />

• Smooth surface – only requires decorative<br />

finishes for completion<br />

• Robust and impact resistant – ideal for<br />

columns and all exposed surfaces<br />

• Easy to cut to size – can be scored and<br />

snapped to speed up cutting and reduce<br />

dust levels

<strong>Fire</strong> <strong>Protection</strong> 6.1<br />

<strong>Fire</strong> protection<br />

Solution optimiser and pathfinder<br />

Key<br />

Pb01<br />

Find online. Visit knaufinsulation.co.uk and key in construction code to find the<br />

most up to date information on your chosen solution.<br />

<strong>Fire</strong> protection<br />

Period of fire resistance (mins)<br />

<strong>Knauf</strong> <strong>Insulation</strong> solution<br />

0 mins 30 mins 60 mins 90 mins 120 mins 150 mins 180 mins 210 mins 240 mins<br />

Structural steelwork<br />

Product: <strong>Knauf</strong> <strong>Fire</strong>board<br />

See page: 268<br />

Fp01<br />

Structural steelwork<br />

Product: Rocksilk <strong>Fire</strong>Tech Slab<br />

See page: 274<br />

Fp02<br />

Mezzanine floors<br />

Product: Rocksilk <strong>Fire</strong>Tech Slab<br />

See page: 280<br />

Fp03<br />

Fp04<br />

Large cavity barriers<br />

Product: Rocksilk Smoke and <strong>Fire</strong> Barrier<br />

6.1<br />

See page: 286<br />

Fp05<br />

Refurbishment of timber separating/<br />

internal floor<br />

Product: Earthwool Flexible Slab<br />

See page: 292<br />

Fp06<br />

Steel Duct Encasement<br />

Product: Rocksilk Pyroduct Slab<br />

See page: 294<br />

Fp07<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk<br />

267

6.1<br />

<strong>Fire</strong> <strong>Protection</strong><br />

<strong>Fire</strong> protection<br />

Structural steelwork<br />

<strong>Knauf</strong> <strong>Fire</strong>board<br />

• Quick and easy to install<br />

Fp01<br />

NEW BUILD<br />

REFURB<br />

• Dry fix system providing up to 2<br />

hours fire protection<br />

• Combined fire protection and<br />

aesthetic finish<br />

<strong>Knauf</strong> Drywall Screws at maximum<br />

100mm centres into backing strips<br />

<strong>Knauf</strong> <strong>Fire</strong>board<br />

<strong>Knauf</strong> <strong>Fire</strong>board<br />

• Non-combustible with a Euroclass<br />

A1 reaction to fire rating<br />

• Zero Ozone Depletion Potential (ODP)<br />

• Zero Global Warming Potential (GWP)<br />

Abutment angles: light gauge<br />

steel angle provides support at<br />

soffit and wall junctions. Fixed to<br />

adjoining soffit or section flange.<br />

Edge fix the boards using<br />

either <strong>Knauf</strong> Drywall Screws<br />

at maximum 150mm centres<br />

or proprietary staples at<br />

120mm centres.<br />

Products<br />

<strong>Knauf</strong> <strong>Fire</strong>board is a gypsum based board<br />

specially developed for high performance lining<br />

and encasement, providing up to two hours of<br />

fire protection.<br />

<strong>Knauf</strong> <strong>Fire</strong>board has a high quality white<br />

smooth surface finish ideally suited as a self<br />

finish. Its surface allows direct decoration with<br />

most paint finishes or it can be plastered*.<br />

<strong>Knauf</strong> Drywall Screws are gold passivated<br />

screws with spoon tips and ‘hi-low’ threads.<br />

<strong>Knauf</strong> <strong>Fire</strong>board can also be installed using<br />

proprietary staples.<br />

*Consult plaster manufacturer prior to application of plaster<br />

finish.<br />

Typical construction<br />

<strong>Knauf</strong> <strong>Fire</strong>board is used in frameless<br />

encasements. The product has been specially<br />

developed to accept direct edge fixings.<br />

Casings consist of <strong>Knauf</strong> <strong>Fire</strong>board screwed or<br />

stapled to itself at abutting corners.<br />

For steelwork encased on all four sides, <strong>Knauf</strong><br />

<strong>Fire</strong>board is fixed at each corner directly<br />

through the material, independent of the column<br />

or beam. For partial encasement, involving wall<br />

or ceiling abutments, <strong>Knauf</strong> <strong>Fire</strong>board is fixed to<br />

light gauge steel angles.<br />

<strong>Knauf</strong> <strong>Insulation</strong> recommend the use of <strong>Knauf</strong><br />

Drywall Screws, essential for fast construction,<br />

solid fixing and tightly closed edge joints.<br />

268<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk

<strong>Fire</strong> <strong>Protection</strong> 6.1<br />

Typical specification<br />

<strong>Knauf</strong> <strong>Fire</strong>board, ...…mm thick, to be used to<br />

provide fire protection to structural steelwork.<br />

Stagger joints by 300mm minimum<br />

<strong>Knauf</strong> <strong>Fire</strong>board casing<br />

It is to be installed on beam*/column* as a<br />

complete 4 sided*/3 sided*/2 sided*<br />

encasement (*specifier’s choice) to provide<br />

......minutes fire protection as detailed in the<br />

Installation section.<br />

Alternatively, consult the National<br />

Building Specifications, Standard<br />

version clause/clauses…<br />

K10/265……………<br />

<strong>Knauf</strong> <strong>Insulation</strong> specification clauses can be<br />

downloaded from knaufinsulation.co.uk/nbs<br />

Direct edge-fixing with <strong>Knauf</strong> Drywall<br />

Screws at 200mm centres or<br />

proprietary staples at 120mm centres<br />

Performance<br />

<strong>Fire</strong> performance<br />

The system can provide up to 2 hours fire<br />

protection. For precise calculation of fire<br />

protection periods, please contact <strong>Knauf</strong><br />

<strong>Insulation</strong> Technical Advice and Support Centre.<br />

Operating temperatures<br />

Continuous long term exposure to temperatures<br />

over 50ºC can induce a change of state which<br />

would reduce the physical performance and<br />

serviceability of the boards.<br />

<strong>Knauf</strong> <strong>Fire</strong>board is non-combustible<br />

to BS 476: Part 4: 1970 (1984) and Class 1<br />

surface spread of flame to BS 476: Part 7:<br />

1997. <strong>Knauf</strong> <strong>Fire</strong>board complies with the Class<br />

‘0’ requirements of the Building Regulations<br />

when tested to BS 476: Part 6: 1989 and Part<br />

7: 1997 and with the limited combustibility<br />

described in the Building Regulations.<br />

Health and safety<br />

<strong>Knauf</strong> <strong>Fire</strong>board must be installed with care.<br />

Ensure adequate ventilation during installation,<br />

particularly when cutting boards. Avoid harsh<br />

body contact with sharp cut edges of metal<br />

components. Refer to <strong>Knauf</strong> <strong>Insulation</strong> Material<br />

Safety Data Sheets and to the Health and Safety<br />

Executive publications.<br />

6.1<br />

Humidity<br />

Constant humidity over 95% or subjection to<br />

continuous water will reduce the serviceability<br />

of the boards.<br />

For Hp/A tables please visit<br />

knaufinsulation.co.uk<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk<br />

269

6.1<br />

<strong>Fire</strong> <strong>Protection</strong><br />

<strong>Fire</strong> protection<br />

Installation of column system<br />

Installation sequence<br />

Cut two boards to<br />

1 the width of the 2<br />

column flange.<br />

Hold in place the<br />

first 2 boards<br />

with clamps.<br />

3<br />

After measuring the<br />

size of the remaining<br />

2 sides, cut another<br />

two to the depth of<br />

the column plus<br />

twice the thickness<br />

of the board.<br />

4<br />

Apply the remaining<br />

boards, adjusting<br />

the length of<br />

adjoining boards to<br />

ensure that board<br />

joints are staggered<br />

by at least 300mm.<br />

5<br />

Edge-fix the boards<br />

using either self<br />

drilling <strong>Knauf</strong><br />

<strong>Fire</strong>board Gripper<br />

Screws at 200mm<br />

centres or proprietary<br />

staples at 120mm<br />

centres. <strong>Knauf</strong><br />

<strong>Fire</strong>board Gripper<br />

Screws should<br />

penetrate into the<br />

casing by at least<br />

30mm<br />

Installation<br />

Steelwork encasements must be installed in full<br />

accordance with <strong>Knauf</strong> <strong>Insulation</strong>’s<br />

recommendations and in compliance with<br />

BS 8212: 1995 and BS 8000: Part 8: 1994.<br />

The installation procedures outlined here relate<br />

to normal single layer applications.<br />

<strong>Knauf</strong> Drywall Screws<br />

<strong>Knauf</strong> Drywall Screws should penetrate into the<br />

casing by at least 30mm.<br />

Four-sided column encasement<br />

• Cut two boards to the width of the column<br />

flange. Cut another two to the depth of the<br />

column plus twice the thickness of the board<br />

• Adjust the length of adjoining boards to<br />

ensure that board joints are staggered by at<br />

least 300mm<br />

• Edge-fix the boards using either <strong>Knauf</strong><br />

Drywall Screws at 200mm centres or<br />

proprietary staples at 120mm centres<br />

Partial column encasement<br />

Assuming a typical three-sided encasement<br />

where one of the column flanges straddles a<br />

wall, follow the same procedure as outlined<br />

for four-sided encasement with the following<br />

differences:<br />

• Fix 25 x 25mm light gauge steel angles,<br />

in continuous lengths, to either the abutting<br />

wall face or the inner flange of the column.<br />

Use appropriate proprietary fixings at<br />

600mm centres<br />

Double layer application<br />

Install the first layer as described for either full<br />

or partial encasement. Secure the second layer<br />

to the first with fixings spaced as for the first<br />

layer but avoid coincident fixing positions.<br />

It is good practice that board joints are<br />

staggered – as with the first layer – between<br />

adjoining boards and also between the two<br />

layers. In the case of structural steelwork,<br />

double layer encasement will obviate the need<br />

for joint backing strips.<br />

270<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk

<strong>Fire</strong> <strong>Protection</strong> 6.1<br />

<strong>Fire</strong> protection<br />

Installation of beam system<br />

Installation sequence<br />

1<br />

Install continuous lengths of<br />

25 x 25mm angle using<br />

appropriate proprietary<br />

2<br />

Cut two boards to the depth<br />

of the section plus twice the<br />

board thickness plus l0mm.<br />

3<br />

Cut a soffit board to the<br />

width of the steel flange.<br />

The length of this board must<br />

4<br />

Cut board off-cuts 100mm<br />

wide as joint backing strips.<br />

Fit these, half lapped, behind<br />

fixings at 600mm centres, fix<br />

further lengths of 25 x 25mm<br />

angle at any end abutment.<br />

Screw-fix these to the angles<br />

at 150mm centres with<br />

35mm <strong>Knauf</strong> Drywall<br />

Screws.<br />

differ from the side boards to<br />

ensure adjacent board joints<br />

are staggered by at least<br />

300mm.<br />

all butt joints at the sides<br />

and soffit of the beam.<br />

Fix with <strong>Knauf</strong> <strong>Fire</strong>board<br />

Gripper Screws at maximum<br />

Edge-fix horizontal board to<br />

100mm centres.<br />

the two vertical boards using<br />

either <strong>Knauf</strong> <strong>Fire</strong>board<br />

Gripper Screws at 150mm<br />

centres or proprietary staples<br />

at 120mm centres.<br />

Beam encasement<br />

Assuming a typical three-sided encasement,<br />

where a beam is exposed directly below a level<br />

soffit, fix light gauge steel angles to either the<br />

adjoining soffit or the top flange of the beam.<br />

Install continuous lengths of 25 x 25mm angle<br />

using appropriate proprietary fixings at 600mm<br />

centres.<br />

• Cut board off-cuts 100mm wide as joint<br />

backing strips. Fit these, half-lapped, behind<br />

all butt joints at the sides and soffit of the<br />

beam fixed with <strong>Knauf</strong> Drywall Screws at<br />

maximum 100mm centres<br />

Double layer application<br />

Install the first layer as described for either full<br />

nominal 150mm centres, screw lengths should<br />

be equal to the thickness of the second layer,<br />

plus 30mm. Where two different thicknesses of<br />

<strong>Fire</strong>board are applied, the thicker layer is<br />

installed first.<br />

6.1<br />

• Fix further lengths of 25 x 25mm angle at any<br />

or partial encasement. Secure the second layer<br />

end abutment<br />

to the first with fixings spaced as for the first<br />

• Cut two boards to the depth of the section<br />

layer but avoid coinciding fixing positions.<br />

plus twice the thickness of the board plus<br />

It is good practice that board joints are<br />

l0mm. Screw-fix these to the angles at<br />

staggered – as with the first layer – between<br />

150mm centres with 35mm <strong>Knauf</strong> Drywall<br />

adjoining boards and also between the two<br />

Screws<br />

layers. In the case of structural steelwork,<br />

• Cut a soffit board to the width of the steel<br />

flange. The length of this board must differ<br />

from the side boards to ensure adjacent<br />

board joints are staggered by at least<br />

300mm. Edge-fix this horizontal board to the<br />

two vertical boards using either self-drilling<br />

<strong>Knauf</strong> Drywall Screws at 150mm centres or<br />

double layer encasement will obviate the need<br />

for joint backing strips.<br />

The second layer of boards across the webs are<br />

fixed to the angle attached to the upper flange<br />

using 55mm long <strong>Knauf</strong> Drywall Screws at<br />

150mm centres and the second layer across the<br />

bottom flange using <strong>Knauf</strong> Drywall Screws at<br />

staples at 120mm centres<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk<br />

271

6.1<br />

<strong>Fire</strong> <strong>Protection</strong><br />

<strong>Fire</strong> protection<br />

Application details for beams<br />

Beam with partition abutment<br />

25 x 25mm angle secured to top flange<br />

of beam, or alternatively to soffit<br />

<strong>Knauf</strong> Drywall Screws at maximum<br />

100mm centres<br />

<strong>Fire</strong>board casing<br />

Backing strip<br />

10mm gap<br />

Direct edge fixing with <strong>Knauf</strong> Drywall<br />

Screws at maximum 150mm centres or<br />

staples at 120mm centres<br />

C-Stud partition with standard<br />

U-Channel head track<br />

Beam with wall abutment<br />

25 x 25mm angle secured to top flange of<br />

beam, or alternatively to soffit<br />

<strong>Knauf</strong> Drywall Screws at maximum<br />

100mm centres<br />

<strong>Fire</strong>board casing<br />

Direct edge fixing with <strong>Knauf</strong><br />

<strong>Fire</strong>board Gripper Screws at<br />

maximum 150mm centres or<br />

staples at 120mm centres<br />

Continuous 25 x 25mm <strong>Knauf</strong><br />

<strong>Fire</strong>board Angle secured to substrate<br />

using appropriate fixings<br />

Masonry wall<br />

272<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk

<strong>Fire</strong> <strong>Protection</strong> 6.1<br />

Column with partition abutment<br />

Direct edge fixing with <strong>Knauf</strong> Drywall<br />

Screws at maximum 200mm centres or<br />

staples at 120mm centres<br />

<strong>Knauf</strong> C-Stud toggle-fixed to <strong>Knauf</strong><br />

<strong>Fire</strong>board casing<br />

<strong>Knauf</strong> Wallboard not fixed to this C-Stud<br />

Column with wall lining abutment<br />

Continuous 25 x 25mm <strong>Knauf</strong><br />

<strong>Fire</strong>board angle at each corner<br />

<strong>Knauf</strong> Wallboard not fixed to this C-Stud<br />

6.1<br />

Direct edge fixing with <strong>Knauf</strong> Drywall<br />

Screws at maximum 200mm centres or<br />

staples at 120mm centres<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk<br />

273

6.1<br />

<strong>Fire</strong> <strong>Protection</strong><br />

<strong>Fire</strong> protection<br />

Structural steelwork<br />

Rocksilk <strong>Fire</strong>Tech Slab<br />

• Flexible system with four installation<br />

methods<br />

• Maintenance free, passive system<br />

• Clean installation process with<br />

negligible dust generation<br />

Fp02<br />

Rocksilk <strong>Fire</strong>Tech Slab<br />

REFURB<br />

Rocksilk <strong>Fire</strong>Tech Slab<br />

• Non-combustible with a Euroclass A1<br />

reaction to fire rating<br />

• Zero Ozone Depletion Potential (ODP)<br />

• Zero Global Warming Potential (GWP)<br />

Pig tail screws<br />

Noggin of Rocksilk <strong>Fire</strong>Tech Slab<br />

or Rocksilk <strong>Fire</strong>Tech Dry Fix Noggin<br />

Slab<br />

Product<br />

Rocksilk <strong>Fire</strong>Tech Slab is a dense rock mineral<br />

wool slab. It is available unfaced or faced with<br />

a bright Class ‘0’ reinforced aluminium foil, for<br />

applications above clean rooms, within air<br />

plenums, or for aesthetic purposes.<br />

Plaster manufacturers advice and guidance<br />

should be followed regarding pre-treatment of<br />

Rocksilk <strong>Fire</strong>Tech Slabs before application of<br />

plaster finishes<br />

Rocksilk <strong>Fire</strong>Tech Dry Fix Noggin Slab is an ultra<br />

high density rock mineral wool slab used for the<br />

noggin in the Rocksilk <strong>Fire</strong>Tech Dry Fix Noggin<br />

System.<br />

Typical construction<br />

The exposed surfaces of any steel section are<br />

fully enclosed in Rocksilk <strong>Fire</strong>Tech Slab, using<br />

any of the fixing systems shown on the following<br />

pages.<br />

Rocksilk <strong>Fire</strong>Tech Slab can be used to provide<br />

up to 4 hours fire protection to structural steel<br />

and cast iron columns, beams and trusses. Steel<br />

sections may include universal beams, columns<br />

and joists (plain and castellated), structural and<br />

rolled tees, angles, channels and round, square<br />

or rectangular hollow sections.<br />

Installation<br />

Rocksilk <strong>Fire</strong>Tech Slab can be used with four<br />

types of fixing methods for the fire protection of<br />

structural steelwork and each system has its own<br />

performance characteristics.<br />

Fixing methods:<br />

• Dry Fix Noggin System<br />

• Adhesive Noggin Fixing System<br />

• Combination Fixing System<br />

• Welded Pin Fixing System<br />

274<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk

<strong>Fire</strong> <strong>Protection</strong> 6.1<br />

Technical specification<br />

Rocksilk <strong>Fire</strong>Tech Slab, ...…mm thick, to be<br />

used to provide fire protection to structural<br />

steelwork.<br />

Noggin of Rocksilk <strong>Fire</strong>Tech Slab or<br />

Rocksilk <strong>Fire</strong>Tech Dry Fix Noggin<br />

Slab<br />

Pig Tail Screws<br />

It is to be installed using the dry fix noggin<br />

system*/adhesive noggin fixing system*/<br />

combination fixing system*/welded pin<br />

fixing system* (*specifier’s choice) as<br />

detailed in the Installation section.<br />

Alternatively, consult the National<br />

Building Specifications, Standard<br />

version clause/clauses…<br />

K11/885……………<br />

<strong>Knauf</strong> <strong>Insulation</strong> specification clauses can be<br />

downloaded from knaufinsulation.co.uk/nbs<br />

Rocksilk <strong>Fire</strong>Tech Slab<br />

Performance<br />

<strong>Fire</strong> performance<br />

Rocksilk <strong>Fire</strong>Tech Slab is classified as<br />

non-combustible to BS 476: Part 4:<br />

1970(1984), Class 1 surface spread of flame<br />

to BS 476: Part 7: 1997, and Class ‘0’ to the<br />

Building Regulations. Rocksilk <strong>Fire</strong>Tech Slab is<br />

designed to provide up to 4 hours fire<br />

protection to structural steelwork, thereby<br />

satisfying the Building Regulations and<br />

insurance demands for periods of fire<br />

resistance.<br />

Durability<br />

Rocksilk <strong>Fire</strong>Tech Slab is rot proof, does not<br />

sustain vermin and will not encourage the<br />

growth of fungi, mould or bacteria.<br />

Rocksilk <strong>Fire</strong>Tech Slab is odourless and<br />

non-hygroscopic.<br />

Rocksilk <strong>Fire</strong>Tech Slab is non-wicking when<br />

tested to BS 2972: 1989: Section 12.<br />

When exposed to 90% relative humidity and<br />

20ºC, Rocksilk <strong>Fire</strong>Tech Slab absorbs less than<br />

0.004% of moisture.<br />

6.1<br />

For Hp/A tables please visit<br />

knaufinsulation.co.uk<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk<br />

275

6.1<br />

<strong>Fire</strong> <strong>Protection</strong><br />

<strong>Fire</strong> protection<br />

Installation of Rocksilk <strong>Fire</strong>Tech Slab<br />

Dry Fix Noggin System<br />

Up to 2 hours fire protection<br />

Adhesive Noggin Fixing System<br />

Up to 2 hours fire protection<br />

100mm wide noggins of<br />

Rocksilk <strong>Fire</strong>Tech Dry Fix<br />

Noggin Slab friction fitted<br />

between the flanges.<br />

Attach web pieces to<br />

noggins with pig tail<br />

screws at 100mm centres.<br />

Attach flange pieces to web<br />

pieces using pig tail screws<br />

positioned 25mm in from<br />

each end and at 150mm<br />

centres.<br />

Attach web pieces to noggins<br />

with pig tail screws at<br />

100mm centres.<br />

100mm wide noggin of<br />

Rocksilk <strong>Fire</strong>Tech Slab<br />

glued into place using<br />

suitable adhesive<br />

Attach flange pieces to<br />

web pieces using pig tail<br />

screws positioned 25mm<br />

in from each end and at<br />

150mm centres.<br />

Combination Fixing System<br />

Up to 3 hours fire protection<br />

Welded Pin Fixing System<br />

Up to 4 hours fire protection<br />

Attach the Rocksilk <strong>Fire</strong>Tech<br />

Slab web pieces by impaling<br />

over the welded pins and<br />

securing in place with 38mm<br />

spring steel washers.<br />

Attach flange pieces to web<br />

pieces using pig tail screws<br />

at 150mm centres.<br />

Adhesive should be used at<br />

the joint between subsequent<br />

web pieces.<br />

Attach the Rocksilk <strong>Fire</strong>Tech<br />

Slab web and flange pieces<br />

by impaling over the 3mm<br />

diameter welded mild steel<br />

pins and securing in place<br />

with 38mm spring steel<br />

washers.<br />

Adhesive should be used at<br />

the joint between subsequent<br />

web pieces.<br />

Alternative installation methods<br />

The Dry Fix Noggin System<br />

Is a fast and efficient friction fit noggin system<br />

that does not require adhesive. It can give up to<br />

2 hours fire protection to BS 476: Part 21.<br />

When installing 20, 25 and 30mm Rocksilk<br />

<strong>Fire</strong>Tech Slab, noggins should be cut from a<br />

30mm Rocksilk <strong>Fire</strong>Tech Dry Fix Noggin Slab.<br />

When greater thicknesses of Rocksilk <strong>Fire</strong>Tech<br />

Slab are used, the noggins are cut from a<br />

corresponding thickness of Rocksilk <strong>Fire</strong>Tech Dry<br />

Fix Noggin Slab.<br />

The Adhesive Noggin Fixing System<br />

Can be used to provide up to 2 hours fire<br />

protection to all sizes of structural steelwork.<br />

The Combination Fixing System<br />

Can be used to provide up to 2 hours fire<br />

protection to all sizes of structural steelwork,<br />

and up to 3 hours fire protection to steelwork<br />

with section factors (Hp/A) of up to 133m -1 for<br />

columns and 143m -1 for beams.<br />

The Welded Pin Fixing System<br />

Can be used to provide up to 3 hours fire<br />

protection to all sizes of structural steelwork,<br />

and up to 4 hours fire protection to steelwork<br />

with section factors (Hp/A) of up to 172m -1 for<br />

columns and 184m -1 for beams.<br />

If section factors are above 260m -1 contact our<br />

Technical Advice and Support Centre.<br />

The use of a dense rock mineral wool slab<br />

requires no special vee cuts, drilling or<br />

sub-frames, making it fast and easy to install.<br />

Rock mineral wool slabs can be easily cut using<br />

hand or power tools.<br />

Note: Rocksilk <strong>Fire</strong>Tech Dry Fix Noggin Slab has a density<br />

of 200 kg/m 3 .<br />

276<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk

<strong>Fire</strong> <strong>Protection</strong> 6.1<br />

Greater<br />

than<br />

500mm<br />

Full<br />

depth<br />

Greater<br />

than<br />

500mm<br />

Y<br />

100mm<br />

100mm<br />

X<br />

Solid noggin formed from one or more pieces<br />

of Rocksilk <strong>Fire</strong>Tech Slab<br />

T-shaped noggin formed from two pieces of<br />

Rocksilk <strong>Fire</strong>Tech Slab joined at right angles<br />

using pig tail screws<br />

Insert noggins as described at 600mm<br />

centres and if practicable leave for 4 hours<br />

for adhesive to cure.<br />

Cut Rocksilk <strong>Fire</strong>Tech Slab to size as follows:<br />

Beams: flange pieces to dimension X, web<br />

pieces to dimension Y + t (t = thickness of<br />

board)<br />

Columns: flange pieces to dimension X,<br />

web pieces to dimension Y + 2t<br />

Attach web pieces to noggins using pig tail<br />

screws at 100mm centres<br />

Attach flange pieces to web pieces using pig<br />

tail screws positioned 25mm in from each<br />

end at 150mm centres.<br />

Note: For flanges greater than 400mm use welded pin<br />

and spring steel washers to provide extra retention of<br />

the flange piece of insulation. The welded pins should<br />

be located along the centre line of the flange at 300mm<br />

centres.<br />

Adhesive noggin fixing system<br />

Noggins are cut 100mm wide from 20mm thick<br />

Rocksilk <strong>Fire</strong>Tech Slab. They should be cut to a<br />

suitable length relative to the web size to give<br />

a tight compression fit.<br />

Noggins are glued top and bottom using a<br />

typical adhesive thickness of 0.5mm and friction<br />

fitted between the flanges at 600mm centres.<br />

The noggins should be installed in such a way<br />

that they are slightly 'proud' of the flange (by<br />

about 2mm) and such that they coincide with<br />

joints between the boards.<br />

It is preferable to leave the noggins in position<br />

for 4 hours to allow the adhesive to cure.<br />

However, where this is impractical Rocksilk<br />

<strong>Fire</strong>Tech Slab can still be fitted before the<br />

adhesive cures since the noggins are essentially<br />

friction fitted.<br />

For web depths greater than 500mm, T-shaped<br />

or solid noggins should be used, formed from<br />

Rocksilk <strong>Fire</strong>Tech Slab, and screwed together<br />

using pig tail screws.<br />

6.1<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk<br />

277

6.1<br />

<strong>Fire</strong> <strong>Protection</strong><br />

<strong>Fire</strong> protection<br />

Application details for beams<br />

Partition abutment using a noggin fixing system<br />

Pig tail screws at maximum<br />

100mm centres<br />

Rocksilk <strong>Fire</strong>Tech noggin<br />

Rocksilk <strong>Fire</strong>Tech Slab<br />

Direct edge fixing with pig tail screws at<br />

maximum 150mm centres<br />

Attach flange piece to web piece by<br />

impaling over welded pins and securing<br />

the board to board joint with pig tail<br />

screws at 150mm centres. Spring steel<br />

washers are used over the welded pins to<br />

retain the insulation, any excess pin<br />

length being trimmed off<br />

C-Stud partition with standard U-Channel<br />

head track<br />

Wall abutment using a noggin fixing system<br />

Pigtail screws at maximum 100mm centres<br />

Masonry wall<br />

Rocksilk <strong>Fire</strong>Tech Slab<br />

Direct edge fixing with pig tail screws at<br />

maximum 150mm centres<br />

Attach flange piece to web piece by impaling<br />

over welded pins and securing the board to<br />

board joint with pig tail screws at 150mm<br />

centres. Spring steel washers are used over<br />

the welded pins to retain the insulation, any<br />

excess pin length being trimmed off<br />

278<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk

<strong>Fire</strong> <strong>Protection</strong> 6.1<br />

Adhesive detail<br />

The adhesive used for gluing Rocksilk <strong>Fire</strong>Tech<br />

Slabs should be a thixotropic paste type based<br />

on soluble solids of silicate and potassium<br />

mixed with clay or refractory mineral filler to an<br />

approximate ratio of 70:30 by weight.<br />

Steelwork should ideally be dry but the<br />

presence of condensation will merely prolong<br />

the cure time, not weaken the bond strength.<br />

Since only the top and bottom surface of each<br />

noggin is glued with a typical adhesive<br />

thickness of 0.5mm, excellent rates of usage are<br />

achievable.<br />

Note: Steelwork should be clean and free from grease prior<br />

to the application of adhesive.<br />

*For further details contact our Technical Advice and<br />

Support Centre.<br />

Pig tail screws<br />

The spirally wound or pig tail screws are<br />

made from 16 gauge galvanised wire and<br />

are available from stockists. A specification<br />

is available on request from our Technical<br />

Advice and Support Centre.<br />

The screws should be installed flush at 150mm<br />

centres on board to board joints and 100mm<br />

centres over noggins, using either power or<br />

hand tools. There is no need to countersink the<br />

screw heads.<br />

Column with partition abutment<br />

Rocksilk <strong>Fire</strong>Tech Slab<br />

<strong>Knauf</strong> Wallboard not fixed to this C-Stud<br />

Direct edge fixing with pig tail screws at<br />

maximum 150mm centres<br />

Column with wall lining abutment<br />

6.1<br />

Masonry wall<br />

<strong>Knauf</strong> Wallboard not fixed to this C-Stud<br />

Rocksilk <strong>Fire</strong>Tech Slab<br />

Direct edge fixing with pig tail screws at<br />

maximum 150mm centres<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk<br />

279

6.1<br />

<strong>Fire</strong> <strong>Protection</strong><br />

<strong>Fire</strong> protection<br />

Mezzanine floors<br />

Rocksilk <strong>Fire</strong>Tech Slab<br />

• Simple, clean and quick to install<br />

• Provides up to 3 hours fire resistance<br />

• System covers section factors up to<br />

310 Hp/A - (A/V)<br />

Fp03<br />

REFURB<br />

Rocksilk <strong>Fire</strong>Tech Slab<br />

• Non-combustible with a Euroclass A1<br />

reaction to fire rating<br />

• Zero Ozone Depletion Potential (ODP)<br />

• Zero Global Warming Potential (GWP)<br />

Rocksilk <strong>Fire</strong>Tech Slab<br />

Product<br />

Rocksilk <strong>Fire</strong>Tech Slab is a dense rock mineral<br />

wool slab specifically designed for the fire<br />

protection of structural steelwork.<br />

Typical construction<br />

The exposed surface of a steel section is fully<br />

enclosed in Rocksilk <strong>Fire</strong>Tech Slab, using a<br />

metal clip, snap-lock system.<br />

Installation<br />

The column case is pre-fabricated to suit the<br />

specific beam or column. It is lined with Rocksilk<br />

<strong>Fire</strong>tech Slab which is pre-bonded to the steel<br />

skin. Note that no adhesive is applied to the<br />

joints between individual slabs. The column<br />

case is made of galvanized or PVC coated steel<br />

minimum 0.7mm thick. For columns, the casing<br />

is normally supplied in two pieces with the<br />

closing face fixed with snap-lock joints.<br />

Three-sided encasements are secured at 300mm<br />

centres to continuous galvanized steel angles,<br />

or the flange of the steel section, or to the wall<br />

or floor at 500mm nominal centres.<br />

Alternatively the casing may be secured using<br />

an integral lip on the casing.<br />

Performance<br />

<strong>Fire</strong> performance<br />

Rocksilk <strong>Fire</strong>Tech Slab is classified as<br />

non-combustible to BS 476: Part 4: 1970<br />

(1984). Class 1 Surface Spread of Flame to BS<br />

476: Part 7:1977, and Class ‘O’ to the<br />

Building Regulations. Rocksilk <strong>Fire</strong>Tech Slab is<br />

designed to provide up to 3 hours fire<br />

protection to the mezzanine floor column<br />

support system, thereby satisfying the current<br />

Building Regulations and insurance industry fire<br />

resistance performance standards.<br />

Performance<br />

Rocksilk <strong>Fire</strong>Tech Slab is rot proof, does not<br />

sustain vermin, will not encourage the growth of<br />

fungi, mould or bacteria and is odourless and<br />

non-hygroscopic.<br />

280<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk

<strong>Fire</strong> <strong>Protection</strong> 6.1<br />

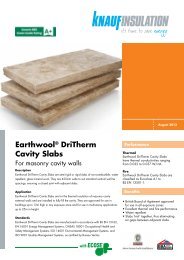

Table 1 - Mezzanine floors<br />

Time - mins Board Thickness (mm) Hp/A<br />

60 20 224<br />

25 260<br />

30 310<br />

35 310<br />

40 310<br />

45 310<br />

90 20 91<br />

25 115<br />

Technical specification<br />

Rocksilk <strong>Fire</strong>Tech Slab….mm thick, to be<br />

used to provide fire protection to structural<br />

steelwork in a mezzanine floor system.<br />

Alternatively, consult the National<br />

Building Specifications, Standard<br />

version clause/clauses…<br />

K11/885…………<br />

<strong>Knauf</strong> <strong>Insulation</strong> specification clauses can be<br />

downloaded from knaufinsulation.co.uk/nbs<br />

30 139<br />

35 165<br />

40 190<br />

45 217<br />

50 244<br />

55 260<br />

60 270<br />

65 310<br />

120 20 57<br />

25 72<br />

30 87<br />

35 102<br />

40 117<br />

45 133<br />

50 149<br />

55 165<br />

60 181<br />

65 198<br />

180 30 49<br />

6.1<br />

35 58<br />

40 66<br />

45 75<br />

50 84<br />

55 92<br />

60 101<br />

65 110<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk<br />

281

6.1<br />

<strong>Fire</strong> <strong>Protection</strong><br />

Cavity barriers<br />

Cavity barrier design<br />

Design considerations<br />

Every building must be designed and<br />

constructed in such a way that in the event of<br />

an outbreak of fire within the building, the<br />

unseen spread of fire and smoke within<br />

concealed cavities in its structure and fabric is<br />

inhibited. The Building Regulations require<br />

cavity barriers to sub-divide voids if they extend<br />

beyond certain dimensions.<br />

In addition cavity barriers are also required to<br />

be placed above fire resisting partitions. Both<br />

glass and rock mineral wool products are ideal<br />

to act as cavity barriers due to their inherent<br />

non-combustibility.<br />

In the case of fire stopping minor imperfections<br />

of fit between construction elements or<br />

components, it is acceptable to seal small gaps<br />

with unfaced glass or rock mineral wool<br />

products. However, for specific periods of fire<br />

resistance in small and large voids (as required<br />

by the Building Regulations) it is necessary to<br />

use specific products that have been tested and<br />

assessed to offer the required performance<br />

when installed in a specific way, if necessary,<br />

using specific fixing components.<br />

Concealed cavities<br />

<strong>Fire</strong> and smoke spread in concealed spaces is<br />

particularly hazardous because fire can spread<br />

quickly throughout a building and remain<br />

undetected by the occupants of the building.<br />

Cavity barriers are used to sub divide<br />

cavities and so prevent smoke and flame from<br />

by-passing fire-resisting walls and partitions.<br />

The maximum distance between barriers must<br />

be appropriate to the location of each cavity.<br />

Also, due consideration must be given to the<br />

class of surface exposed within the cavity.<br />

Cavity barriers should achieve at least 30<br />

minutes fire resistance, providing a minimum of<br />

30 minutes integrity and 15 minutes insulation.<br />

Detailed requirements are complex. For full<br />

details about the position and spacing of cavity<br />

fire barriers refer to the relevant sections of the<br />

appropriate Building Regulations.<br />

Small cavity barriers<br />

Small voids include the cavities in external walls<br />

and voids beneath raised access floors. Larger<br />

voids include the spaces between suspended<br />

ceilings and soffits or roofs.<br />

In cavities in external walls the resilient<br />

properties of glass mineral wool mean that it<br />

can be compression fitted, between the outer<br />

leaf and the inner leaf or frame. The noncombustible<br />

nature of glass mineral wool allows<br />

it to resist the effects of fire, enabling it to<br />

remain in place during the fire and effectively<br />

block the transfer of fire through the cavity.<br />

Large cavity barriers<br />

In England, Wales and Northern Ireland, all<br />

cavity barriers should be constructed to provide<br />

at least 30 minutes fire resistance and 15<br />

minutes insulation. In Scotland large cavity<br />

barriers, which are defined as being greater<br />

than 1m x 1m in size, must provide the same.<br />

Fixing systems<br />

Any product used for fire protection can only be<br />

considered to be offering a specific period of<br />

fire protection when it is installed in the manner<br />

specified in the appropriate fire test report. This<br />

includes the specification of all associated<br />

fixings and supporting frame work.<br />

282<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk

<strong>Fire</strong> <strong>Protection</strong> 6.1<br />

Photograph courtesy of Henley Building Systems<br />

30 minutes fire resistance 1 hour fire resistance<br />

Definitions<br />

The following definitions are taken from<br />

Approved Document B (<strong>Fire</strong> safety) - Volume<br />

2: Buildings other than dwellinghouses<br />

(2006)<br />

50mm Rocksilk<br />

Smoke and <strong>Fire</strong><br />

Barrier<br />

Suspended ceiling<br />

of 12.5mm plasterboard<br />

50mm cavity<br />

50mm Rocksilk<br />

Smoke and<br />

<strong>Fire</strong> Barrier<br />

Cavity barrier<br />

A construction, other than smoke curtain,<br />

provided to close a concealed space against<br />

penetration of smoke or flame, or provided to<br />

restrict the movement of smoke or flame<br />

within such a space.<br />

<strong>Fire</strong> stop<br />

Seal provided to close an imperfection of<br />

fit or design tolerance between elements or<br />

components, to restrict the passage of fire<br />

or smoke. Any unfaced glass or rock mineral<br />

product can be used as a fire stop.<br />

Period of fire resistance (mins)<br />

6.1<br />

<strong>Knauf</strong> <strong>Insulation</strong> solution 0 mins 30 mins 60 mins 90 mins 120 mins 150 mins 180 mins 210 mins 240 mins<br />

Small cavity barriers - to be deleted<br />

Fp04<br />

Large cavity barriers<br />

Product: Rocksilk Smoke and <strong>Fire</strong> Barrier<br />

See page: 286<br />

Fp05<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk<br />

283

6.1<br />

<strong>Fire</strong> <strong>Protection</strong><br />

<strong>Fire</strong> protection<br />

Small cavity barriers<br />

Earthwool Cavity Barrier<br />

• Meets Building Regulation<br />

requirements for fire, acoustics and<br />

party wall bypass applications<br />

• Simple, clean and quick to install<br />

• Colour coded for easy identification<br />

Fp04<br />

NEW BUILD<br />

Earthwool Cavity Barrier<br />

• Non-combustible with a Euroclass A1<br />

reaction to fire rating<br />

• A+ Generic BRE Green Guide rating<br />

• Zero Ozone Depletion Potential (ODP)<br />

• Zero Global Warming Potential (GWP)<br />

Earthwool Cavity Barrier stapled through top flange to<br />

sheathing to fully fill the cavity<br />

Brick outer leaf<br />

Product<br />

Earthwool Cavity Barrier is manufactured from<br />

a continuous length of non-combustible glass<br />

mineral wool which is compressed within a<br />

resilient polythene sleeve incorporating two<br />

flanges designed for ease of fixing.<br />

The polythene sleeve is colour coded to suit a<br />

variety of cavity widths from 50mm to 100mm<br />

and eliminates the need for weather protection<br />

during installation.<br />

The barriers are 1200mm long and can be<br />

used in both vertical and horizontal<br />

applications, and are available in two standard<br />

widths (100mm and 300mm). 100mm barriers<br />

are used for normal fire stopping and noise<br />

reduction applications. 300mm barriers are<br />

used where higher performance levels are<br />

specified and at party wall/external wall cavity<br />

junctions.<br />

Typical construction<br />

Earthwool Cavity Barriers are engineered to<br />

prevent the spread of smoke and fire through<br />

walls, floors and cavities in timber frame, metal<br />

frame and masonry buildings.<br />

They are also suitable for reducing flanking<br />

noise transmission in these concealed cavities.<br />

The use of the correct size of Earthwool Cavity<br />

Barrier is essential. Earthwool Cavity Barriers<br />

are designed to compress to a tight fit in<br />

cavities and in the event of fire breaking into<br />

the cavity, Earthwool Cavity Barriers do not rely<br />

on the polythene flanges to hold them in place,<br />

but on their compression between the inner and<br />

outer leaf.<br />

It is, therefore, essential to specify the Earthwool<br />

Cavity Barrier by reference to the actual<br />

constructed cavity width.<br />

Installation<br />

In vertical applications, both flanges of the<br />

Earthwool Cavity Barrier should be fixed to the<br />

inner leaf.<br />

In horizontal applications, the top flange of<br />

the polythene sleeve should be fixed to the<br />

inner leaf.<br />

All joints and intersections of Earthwool Cavity<br />

Barriers should be closely butted.<br />

284<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk

<strong>Fire</strong> <strong>Protection</strong> 6.1<br />

Typical junction with party wall<br />

300mm wide Earthwool<br />

Cavity Barrier - stapled to<br />

sheathing board either<br />

side of party wall<br />

Earthwool Timber Frame<br />

Party Wall Slab<br />

Earthwool FrameTherm<br />

Technical specification<br />

Timber frame construction<br />

Earthwool Cavity Barrier 100mm*/300mm*<br />

wide, coloured yellow*/ blue*/white* to be<br />

friction fitted in the positions shown on the<br />

drawings. Earthwool Cavity Barrier to fully fill<br />

the depth of the cavity.<br />

Polythene flanges to be stapled to the<br />

timber*/sheathing board* to hold the cavity<br />

barrier in place.<br />

All joints and intersections of Earthwool<br />

Cavity Barriers should be closely butted<br />

together.<br />

Alternatively, consult the National<br />

Building Specifications, Standard<br />

version clause/clauses…<br />

P10/420……………<br />

<strong>Knauf</strong> <strong>Insulation</strong> specification clauses can be<br />

downloaded from knaufinsulation.co.uk/nbs<br />

Masonry construction<br />

Earthwool Cavity Barrier 100mm*/ 300mm*<br />

wide, coloured yellow*/ blue*/white* to be<br />

friction fitted in the positions shown on<br />

the drawings.<br />

Performance<br />

<strong>Fire</strong> performance<br />

Earthwool Cavity Barriers are manufactured<br />

from glass mineral wool which has a Euroclass<br />

A1 rating when classified in accordance with<br />

BS EN 13501-1.<br />

Earthwool Cavity Barriers have been tested for<br />

fire resistance in accordance with BS 476: Part<br />

8: 1972 and will provide 60 minutes stability,<br />

integrity and insulation.<br />

Acoustic performance<br />

Table 2 - Colour coding<br />

Cavity width (mm)<br />

Colour<br />

50-65 yellow<br />

66-80 blue<br />

81-100 white<br />

Earthwool Cavity Barrier to fully fill the depth<br />

of the cavity.<br />

All joints and intersections of Earthwool<br />

Cavity Barriers should be closely butted<br />

together.<br />

Alternatively, consult the National<br />

Building Specifications, Standard<br />

version clause/clauses…<br />

P10/420……………<br />

<strong>Knauf</strong> <strong>Insulation</strong> specification clauses can be<br />

downloaded from knaufinsulation.co.uk/nbs<br />

6.1<br />

Building Regulations require the use of a cavity<br />

closer to reduce flanking noise transmission<br />

along party wall cavities and external wall<br />

cavities in masonry and timber frame<br />

constructions.<br />

Earthwool Cavity Barriers meet the generic<br />

description for cavity closers and will therefore<br />

ensure compliance with Part E and Robust<br />

Details in timber frame and masonry wall<br />

constructions.<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk<br />

285

6.1<br />

<strong>Fire</strong> <strong>Protection</strong><br />

<strong>Fire</strong> protection<br />

Large cavity barrier<br />

Rocksilk Smoke and <strong>Fire</strong> Barrier<br />

• Simple, clean and quick to install<br />

• Provides both fire and acoustic<br />

performance<br />

• Versatile, flexible and adaptable<br />

system<br />

Fp05<br />

Metal angle fixed to soffit<br />

REFURB<br />

Rocksilk Smoke and <strong>Fire</strong> Barrier<br />

• Non-combustible with a Euroclass<br />

A1 reaction to fire rating<br />

• Zero Ozone Depletion Potential (ODP)<br />

• Zero Global Warming Potential (GWP)<br />

Rocksilk Smoke and <strong>Fire</strong> Barrier<br />

50mm airgap<br />

Rocksilk Smoke and<br />

<strong>Fire</strong> Barrier fixed to 50mm<br />

timber spacer<br />

Product<br />

Rocksilk Smoke and <strong>Fire</strong> Barrier is made from<br />

rock mineral wool and formed into a flexible<br />

mattress faced on one side with galvanised<br />

wire mesh stitched in position.<br />

Rocksilk Smoke and <strong>Fire</strong> Barrier is also<br />

available foil faced on one or both sides.<br />

Rocksilk Smoke and <strong>Fire</strong> Barrier must be<br />

installed in accordance with the specifications<br />

detailed below and on the following pages. If<br />

these specifications are not strictly followed the<br />

installation cannot be deemed to offer any<br />

specific period of fire protection.<br />

Fixing components:<br />

Angle: Mild steel - 50mm x 50mm x 2mm or<br />

60mm x 40mm x 2mm<br />

Strip: Mild steel - 40mm x 2mm<br />

See Table 3 for suitable method of fixing angles<br />

and strips to substrate.<br />

Typical construction<br />

For half an hour fire resistance<br />

A single layer of 50mm Rocksilk Smoke and<br />

<strong>Fire</strong> Barrier, applied as a hanging curtain,<br />

supported continuously from above and both<br />

sides, using the fixings listed in the Table 3.<br />

At the base Rocksilk Smoke and <strong>Fire</strong> Barrier is<br />

either lapped freely on to the back of a<br />

suspended ceiling or fixed to a partition head.<br />

Suitable for drops up to 7 metres.<br />

For one hour fire resistance<br />

Two layers of 50mm Rocksilk Smoke and <strong>Fire</strong><br />

Barrier, separated by a 50mm air space,<br />

applied as a hanging curtain with wire mesh<br />

to the outside, supported continuously from<br />

above and both sides, using the fixings listed in<br />

Table 3. At the base it is either lapped freely on<br />

to the back of a suspended ceiling, or fixed to a<br />

partition head.<br />

Use foil faced Rocksilk Smoke and <strong>Fire</strong> Barrier<br />

when the ceiling void is used as an air plenum.<br />

Installation<br />

See page 288 - 291 for installation details.<br />

See Table 3 for specification of fixings and<br />

supporting metalwork.<br />

286<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk

<strong>Fire</strong> <strong>Protection</strong> 6.1<br />

Metal angles<br />

fixed to soffit<br />

Rocksilk Smoke<br />

and <strong>Fire</strong> Barrier<br />

Rocksilk Smoke and <strong>Fire</strong> Barrier<br />

fixed to timber spacer<br />

Technical specification<br />

Half hour cavity barrier<br />

A single layer of 50mm Rocksilk Smoke and<br />

<strong>Fire</strong> Barrier (*foil faced) to be installed in the<br />

positions marked on the drawings, and fixed<br />

in accordance with the manufacturer’s<br />

recommendations. All joints either tightly<br />

butted, overlapped, or with edges returned,<br />

and stitched in a continuous spiral loop with<br />

1mm diameter galvanised lacing wire.<br />

(* delete as appropriate)<br />

One hour cavity barrier<br />

Two layers of 50mm Rocksilk Smoke and<br />

<strong>Fire</strong> Barrier (*foil faced), separated by a<br />

50mm air space to be installed in the<br />

positions marked on the drawings, and<br />

fixed in accordance with the manufacturer’s<br />

recommendations. All joints either tightly<br />

butted, overlapped, or with edges returned,<br />

and stitched in a continuous spiral loop with<br />

1mm diameter galvanised lacing wire.<br />

(* delete as appropriate)<br />

Alternatively, consult the National<br />

Building Specifications, Standard<br />

version clause/clauses…<br />

K10/545……………<br />

<strong>Knauf</strong> <strong>Insulation</strong> specification clauses can be<br />

downloaded from knaufinsulation.co.uk/nbs<br />

Performance<br />

<strong>Fire</strong> performance<br />

Rocksilk Smoke and <strong>Fire</strong> Barrier is made from<br />

rock mineral wool and is classified as noncombustible<br />

to BS 476: Part 4: 1970. Rocksilk<br />

Smoke and <strong>Fire</strong> Barrier has a Class 1 Surface<br />

Spread of Flame to BS 476: Part 7: 1997 and<br />

is Class ‘0’ to the Building Regulations.<br />

When subjected to full scale fire resistance tests<br />

to BS 476: Part 22: 1987, a system comprising<br />

one layer of 50mm Rocksilk Smoke and <strong>Fire</strong><br />

Barrier, fixed by using the components and<br />

methods detailed on the following pages<br />

achieved 19 minutes insulation, and retained its<br />

integrity for 35 minutes, after which time the test<br />

was discontinued. 50mm Rocksilk Smoke and<br />

<strong>Fire</strong> Barrier thereby satisfies the criteria laid<br />

down in the Building Regulations for cavity<br />

barriers, by exceeding the minimum<br />

requirement of 15 minutes insulation and 30<br />

minutes integrity .<br />

When subjected to full scale fire resistance tests<br />

to BS 476: Part 22: 1987, a system comprising<br />

a double layer of 50mm Rocksilk Smoke and<br />

<strong>Fire</strong> Barrier, fixed by using the components and<br />

methods detailed on the following pages,<br />

achieved 61 minutes insulation, and retained its<br />

integrity for 66 minutes, after which time the test<br />

was discontinued.<br />

A double layer of 50mm Rocksilk Smoke and<br />

<strong>Fire</strong> Barrier thereby satisfies the criteria laid<br />

down in the Building Regulations for one hour<br />

cavity barriers.<br />

These tests incorporated vertical and horizontal<br />

joints between barriers. <strong>Fire</strong> resistance is<br />

effective from either side of the barrier. When<br />

tested, the wire side was exposed to the furnace<br />

as this is the side most vulnerable to fire.<br />

6.1<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk<br />

287

6.1<br />

<strong>Fire</strong> <strong>Protection</strong><br />

<strong>Fire</strong> protection<br />

Installation of half hour cavity barrier<br />

80mm<br />

minimum<br />

1. Metal angle fixed to purlin 2. Fixed to purlin 3. Fixed to rib of coffered slab<br />

4. Fixed across coffered ceiling 5. Perimeter fixing with steel strip 6. Junction with ceiling<br />

Installation<br />

The following information and illustrations<br />

outline typical details for the installation of large<br />

cavity barriers. In case of uncertainty, refer to<br />

<strong>Knauf</strong> <strong>Insulation</strong>.<br />

Metal deck with overdeck insulation<br />

If Rocksilk Smoke and <strong>Fire</strong> Barrier runs with the<br />

slope of the roof, a supporting steel angle<br />

should be fixed between purlins and the smoke<br />

and fire barrier clamped to this with steel strip<br />

(Figure 1). The insulation should project 80mm<br />

beyond the strip to ensure a good seal.<br />

If fitted across the sheeting profile, Rocksilk<br />

Smoke and <strong>Fire</strong> Barrier should be bolted to the<br />

purlins (Figure 2). It is returned at the top, to a<br />

length equivalent to 3 times the profile depth, to<br />

allow for cutting at troughs and pushing<br />

securely into profiles. Alternatively, proprietary<br />

profile fillers may be used.<br />

Concrete decks<br />

Rocksilk Smoke and <strong>Fire</strong> Barrier is clamped<br />

between the deck and steel angle secured by<br />

expanding bolts. If the deck is coffered it should<br />

usually be possible to locate the cavity barrier<br />

along one of the ribs (Figure 3). If fitted across<br />

the coffering it should be clamped by steel strip,<br />

to the steel angle which is secured to the ribs.<br />

If the depth of coffering is less than 100mm,<br />

Rocksilk Smoke and <strong>Fire</strong> Barrier should be<br />

returned at the top by 300mm, to allow for<br />

cutting at the ribs and pushed securely into the<br />

coffering (Figure 4). If the depth of coffering is<br />

greater than 100mm, Rocksilk Smoke and <strong>Fire</strong><br />

Barrier should be fixed around the coffering<br />

using steel angle, as described above.<br />

Alternatively, proprietary profile fillers may be<br />

used.<br />

The perimeter of the barrier should be secured<br />

with steel strip (Figure 5).<br />

At the ceiling junction, Rocksilk Smoke and <strong>Fire</strong><br />

Barrier is cut and draped on and between the<br />

joists, and secured by fixing to steel angle,<br />

which is itself fixed to the joists (Figure 6). For<br />

suspended ceilings, see Figure 11.<br />

At partitions or wall heads, if a secure fixing is<br />

available, as at soffits, Rocksilk Smoke and <strong>Fire</strong><br />

Barrier should be clamped with a steel strip<br />

Two layers of 50mm Rocksilk Smoke and <strong>Fire</strong><br />

Barrier with a 50mm air space between them<br />

are needed for one hour fire resistance. In<br />

general two separate layers should be installed<br />

back to back, each in a manner identical to that<br />

shown for half hour fire resistance. The joints in<br />

the two layers should be staggered and Rocksilk<br />

Smoke and <strong>Fire</strong> Barrier returned outward at the<br />

top and bottom. The wire reinforced sides<br />

should be placed outward, see Figure 7.<br />

288<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk

<strong>Fire</strong> <strong>Protection</strong> 6.1<br />

<strong>Fire</strong> protection<br />

Installation of one hour cavity barrier<br />

7. Fixed to concrete slab 8. Fixing to wall head<br />

9. Fixing to timber spacer<br />

10. Fixing at perimeter<br />

Partitions and wall heads<br />

If possible, Rocksilk Smoke and <strong>Fire</strong> Barrier<br />

should be secured with steel strip to the partition<br />

or wall head so as to maintain the 50mm air<br />

space (Figure 8). If this is not possible, it should<br />

be draped with a return of at least 150mm, or<br />

fixed to a timber spacer which is fixed to the<br />

partition or wall head (Figures 6 and 9).<br />

Perimeter fixing<br />

Rocksilk Smoke and <strong>Fire</strong> Barrier should be<br />

secured with steel strip to the sides of the<br />

perimeter wall, so as to maintain the 50mm air<br />

space (Figure 10).<br />

Fixing system specifications<br />

Table 3 - Specification of angles and strips<br />

Angle: Mild steel - 50mm x 50mm x 2mm or 60mm x 40mm x 2mm<br />

Strip: Mild steel - 40mm x 2mm<br />

Angle fixings to concrete decks and steel sections: angles 50 x 50 x 2mm<br />

<strong>Fire</strong> resistance<br />

Maximum spacing of fixings (m) for the following drop heights (m)<br />

period (mins) 3 3.5 4 4.5 5 5.5 6 6.5 7<br />

30 2 2 2 2 2 2 2 2 2<br />

60 2 2 1.75 1.5 1.5 1 1 0.75 0.75<br />

Key:<br />

M8 M6<br />

bolts bolts<br />

Angle fixings to timber beams and trusses: angles 50 x 50 x 2mm<br />

<strong>Fire</strong> resistance Maximum spacing of fixings (m) for the following drop heights (m)<br />

period (mins) 3 3.5 4 4.5 5 5.5 6 6.5 7<br />

30 2 2 2 2 2 2 2 2 2<br />

60 2 2 1.75 1.5 1.5 1 1 0.75 0.75<br />

Key:<br />

Buildex HT screws, minimum 25mm thread penetration into timber<br />

Buildex HT screws, minimum 40mm thread penetration into timber<br />

Steel strip fixings: To masonry and concrete Buildex Tapcon 4H masonry anchors<br />

To timber<br />

Buildex HT range of fixings<br />

To steel angle<br />

Steel bolts<br />

6.1<br />

Minimum return of Rocksilk Smoke and <strong>Fire</strong> Barrier - When clamped to flat surface (vertical or horizontal)<br />

80mm. When loose laid over horizontal surface - 150mm.<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk<br />

289

6.1<br />

<strong>Fire</strong> <strong>Protection</strong><br />

<strong>Fire</strong> protection<br />

Jointing Rocksilk Smoke and <strong>Fire</strong> barrier<br />

11. Junction with suspended ceiling<br />

12. Vertical butt joint 13. Vertical returned joint 14. Vertical lap joint<br />

500mm<br />

minimum<br />

overlap<br />

15. Perpendicular joint 16. Horizontal joint at a drop<br />

Suspended ceilings<br />

With suspended ceilings where positive fixing<br />

to wall heads or partition heads is not possible,<br />

the weight of Rocksilk Smoke and <strong>Fire</strong> Barrier<br />

and the stiffness of wire facing are such that it<br />

will form an effective seal if it laps the<br />

horizontal surface by a minimum of 150mm.<br />

Lapped joints are only permissible where the<br />

suspended ceiling has the same fire resistance<br />

as the cavity barrier. Rocksilk Smoke and <strong>Fire</strong><br />

Barrier must be slit and fitted around any<br />

crossing tees to eliminate gaps and ensure that<br />

excessive loads are not transferred to the ceiling<br />

(Figure 11).<br />

Jointing<br />

This section describes the approved methods for<br />

joining adjacent pieces of Rocksilk Smoke and<br />

<strong>Fire</strong> Barrier. The methods are applicable to both<br />

half and one hour large cavity barriers.<br />

Vertical and horizontal joints<br />

Three methods of securing the joints between<br />

adjacent pieces of Rocksilk Smoke and <strong>Fire</strong><br />

Barrier are approved.<br />

Joints are tightly butted together and stitched in<br />

a continuous spiral loop with 1mm diameter<br />

galvanised lacing wire. The stitching should<br />

pass through the reinforcement mesh and the<br />

wool on each side of the butt joint at centres not<br />

exceeding 100mm (Figure 12).<br />

Alternatively the Rocksilk Smoke and <strong>Fire</strong><br />

Barrier edges are returned at least 80mm and<br />

wired together (Figure 13), or they may be<br />

lapped at least 100mm and wired together<br />

(Figure 14).<br />

Perpendicular joints<br />

The junction between two barriers should be<br />

securely wired together (Figure 15) with a<br />

return of at least 80mm.<br />

Drops<br />

All barriers can be used for drop heights up to<br />

5m without additional support. For drops<br />

between 5m and 7m it is necessary to introduce<br />

additional supporting members in order to<br />

support the weight of the fire barriers (Figure<br />

16).<br />

Services<br />

Services which are permitted by Building<br />

Regulations to penetrate barriers, should<br />

be provided with collars of Rocksilk Smoke and<br />

<strong>Fire</strong> Barrier at least 300mm long, sewn to the<br />

main barrier and then strapped or wired so as<br />

to avoid any possibility of gaps (Figure 17).<br />

A half hour barrier requires a collar on<br />

one side of the barrier. A one hour barrier<br />

requires one collar on both sides of the barrier<br />

system.<br />

290<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk

<strong>Fire</strong> <strong>Protection</strong> 6.1<br />

<strong>Fire</strong> protection<br />

Penetrating pipes and ducts<br />

300mm<br />

minimum<br />

17. Penetrating pipe<br />

18. Penetrating steelwork<br />

19. Temporary framework to ease handling<br />

Penetrating steelwork<br />

Handling<br />

Following trades<br />

This should be provided with a collar of Rocksilk<br />

Smoke and <strong>Fire</strong> Barrier at least 300mm long<br />

Depending on the size of the barrier and the<br />

working space available, it is sometimes difficult<br />

The integrity of barriers must be restored if<br />

disturbed by following trades, either during<br />

6.1<br />

(Figure 18). The collar is fixed to the concrete or<br />

to hold the material in place while top fixings<br />

the building process or after completion.<br />

metal deck by clamping against these surfaces<br />

are being secured. It will be found helpful to<br />

This instruction should be incorporated into<br />

behind steel angle. The voids in the steelwork<br />

make a temporary prop from, e.g. slotted<br />

the building handbook.<br />

are filled with Rocksilk Smoke and <strong>Fire</strong> Barrier<br />

angle. This may comprise a crosspiece of length<br />

(figure 18). A half hour barrier requires a collar<br />

appropriate to the width of the Rocksilk Smoke<br />

on one side of the barrier. A one hour barrier<br />

and <strong>Fire</strong> Barrier, with studs on the top which will<br />

requires one collar on both of the layers of the<br />

hook into the wire mesh of the Rocksilk Smoke<br />

barrier system.<br />

and <strong>Fire</strong> Barrier. This may be swivelled on the<br />

Access<br />

Where permanent access is needed through the<br />

barrier, a fire door and frame, rated to the<br />

appropriate fire resistance, must be used.<br />

Rocksilk Smoke and <strong>Fire</strong> Barrier should be fixed<br />

securely to the frame.<br />

top of a handle, and secured horizontally or to<br />

the angle of the roof by an adjustable brace. It<br />

is used to hold the Rocksilk Smoke and <strong>Fire</strong><br />

Barrier up, 100mm or so behind the fixing<br />

location, while fixing is being carried out.<br />

When fixing to a sloping deck, the top of the<br />

Rocksilk Smoke and <strong>Fire</strong> Barrier should be<br />

trimmed to the correct angle to ensure that joints<br />

are truly vertical (Figure 19).<br />

Technical Advice and Support Centre 01744 766666<br />

www.knaufinsulation.co.uk<br />

291

6.1<br />

<strong>Fire</strong> <strong>Protection</strong><br />

Internal floor<br />

Refurbishment of timber separating/internal floor<br />

Earthwool Flexible Slab<br />

• Existing ceiling can be<br />

retained, avoiding disruption<br />

to rooms below<br />

• Provides thermal and acoustic<br />

insulation as well as fire<br />

resistance<br />

•<br />

Meets the requirements of<br />

Approved Document E for sound<br />

resistance of internal floors<br />

Fp06<br />

REFURB<br />

Earthwool Flexible Slab<br />

• Non-combustible with a Euroclass A1<br />

reaction to fire rating<br />

• A+ Generic BRE Green Guide rating<br />