Munsell & Collaborative Testing Services - X-Rite

Munsell & Collaborative Testing Services - X-Rite

Munsell & Collaborative Testing Services - X-Rite

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Munsell</strong> Marketing<br />

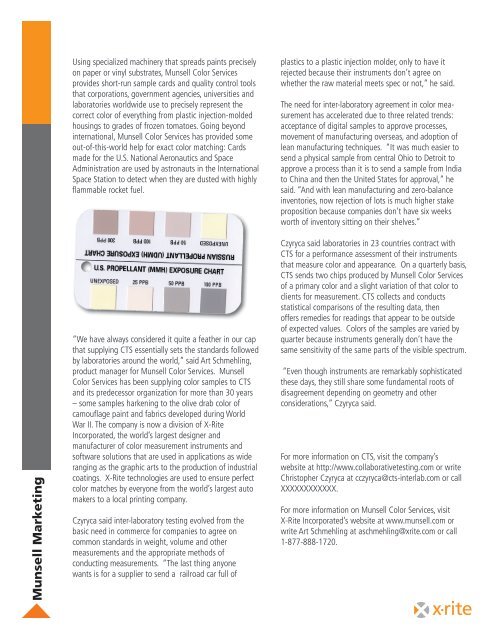

Using specialized machinery that spreads paints precisely<br />

on paper or vinyl substrates, <strong>Munsell</strong> Color <strong>Services</strong><br />

provides short-run sample cards and quality control tools<br />

that corporations, government agencies, universities and<br />

laboratories worldwide use to precisely represent the<br />

correct color of everything from plastic injection-molded<br />

housings to grades of frozen tomatoes. Going beyond<br />

international, <strong>Munsell</strong> Color <strong>Services</strong> has provided some<br />

out-of-this-world help for exact color matching: Cards<br />

made for the U.S. National Aeronautics and Space<br />

Administration are used by astronauts in the International<br />

Space Station to detect when they are dusted with highly<br />

flammable rocket fuel.<br />

“We have always considered it quite a feather in our cap<br />

that supplying CTS essentially sets the standards followed<br />

by laboratories around the world,” said Art Schmehling,<br />

product manager for <strong>Munsell</strong> Color <strong>Services</strong>. <strong>Munsell</strong><br />

Color <strong>Services</strong> has been supplying color samples to CTS<br />

and its predecessor organization for more than 30 years<br />

– some samples harkening to the olive drab color of<br />

camouflage paint and fabrics developed during World<br />

War II. The company is now a division of X-<strong>Rite</strong><br />

Incorporated, the world’s largest designer and<br />

manufacturer of color measurement instruments and<br />

software solutions that are used in applications as wide<br />

ranging as the graphic arts to the production of industrial<br />

coatings. X-<strong>Rite</strong> technologies are used to ensure perfect<br />

color matches by everyone from the world’s largest auto<br />

makers to a local printing company.<br />

Czyryca said inter-laboratory testing evolved from the<br />

basic need in commerce for companies to agree on<br />

common standards in weight, volume and other<br />

measurements and the appropriate methods of<br />

conducting measurements. “The last thing anyone<br />

wants is for a supplier to send a railroad car full of<br />

plastics to a plastic injection molder, only to have it<br />

rejected because their instruments don’t agree on<br />

whether the raw material meets spec or not,” he said.<br />

The need for inter-laboratory agreement in color measurement<br />

has accelerated due to three related trends:<br />

acceptance of digital samples to approve processes,<br />

movement of manufacturing overseas, and adoption of<br />

lean manufacturing techniques. “It was much easier to<br />

send a physical sample from central Ohio to Detroit to<br />

approve a process than it is to send a sample from India<br />

to China and then the United States for approval,” he<br />

said. “And with lean manufacturing and zero-balance<br />

inventories, now rejection of lots is much higher stake<br />

proposition because companies don’t have six weeks<br />

worth of inventory sitting on their shelves.”<br />

Czyryca said laboratories in 23 countries contract with<br />

CTS for a performance assessment of their instruments<br />

that measure color and appearance. On a quarterly basis,<br />

CTS sends two chips produced by <strong>Munsell</strong> Color <strong>Services</strong><br />

of a primary color and a slight variation of that color to<br />

clients for measurement. CTS collects and conducts<br />

statistical comparisons of the resulting data, then<br />

offers remedies for readings that appear to be outside<br />

of expected values. Colors of the samples are varied by<br />

quarter because instruments generally don’t have the<br />

same sensitivity of the same parts of the visible spectrum.<br />

“Even though instruments are remarkably sophisticated<br />

these days, they still share some fundamental roots of<br />

disagreement depending on geometry and other<br />

considerations,” Czyryca said.<br />

For more information on CTS, visit the company’s<br />

website at http://www.collaborativetesting.com or write<br />

Christopher Czyryca at cczyryca@cts-interlab.com or call<br />

XXXXXXXXXXXX.<br />

For more information on <strong>Munsell</strong> Color <strong>Services</strong>, visit<br />

X-<strong>Rite</strong> Incorporated’s website at www.munsell.com or<br />

write Art Schmehling at aschmehling@xrite.com or call<br />

1-877-888-1720.