THIS IS HOW THE PATH IS BUILT - Odebrecht Informa

THIS IS HOW THE PATH IS BUILT - Odebrecht Informa

THIS IS HOW THE PATH IS BUILT - Odebrecht Informa

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

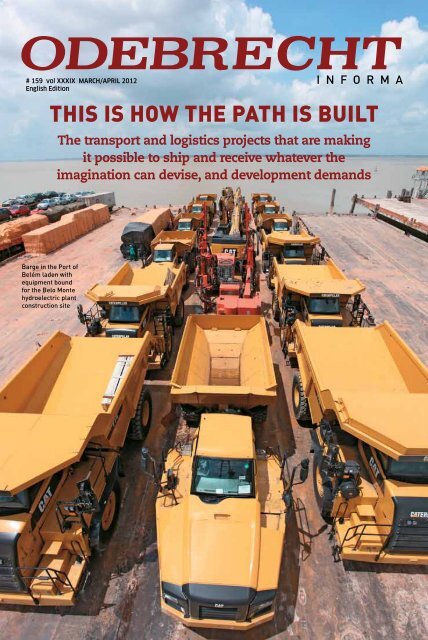

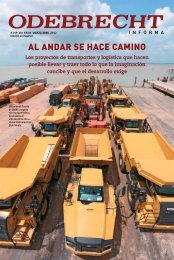

# 159 vol XXXIX MARCH/APRIL 2012<br />

English Edition<br />

<strong>TH<strong>IS</strong></strong> <strong>IS</strong> <strong>HOW</strong> <strong>THE</strong> <strong>PATH</strong> <strong>IS</strong> <strong>BUILT</strong><br />

The transport and logistics projects that are making<br />

it possible to ship and receive whatever the<br />

imagination can devise, and development demands<br />

Barge in the Port of<br />

Belém laden with<br />

equipment bound<br />

for the Belo Monte<br />

hydroelectric plant<br />

construction site<br />

informa<br />

I

II<br />

informa

foto: Lia Lubambo<br />

informa<br />

1

<strong>Odebrecht</strong> <strong>Informa</strong> in digital media<br />

www.odebrechtonline.com.br<br />

You can also read <strong>Odebrecht</strong> <strong>Informa</strong> on your iPad and smartphone<br />

Online edition Online archive iPad & smartphone Video reports Blog<br />

> You can view<br />

this entire issue<br />

in HTML<br />

and PDF<br />

> In the fourth interview for the Savvy project,<br />

Gilberto Neves, <strong>Odebrecht</strong>’s CEO in the United<br />

States, recalls the highlights of his career in<br />

the countries where he has worked<br />

> The Belo Monte hydroelectric plant, under<br />

construction on the Xingú River in Pará, Brazil,<br />

uses the waterway as an alternative means of<br />

transportation for materials and equipment<br />

> The construction of metro lines in Caracas and<br />

Los Teques are the highlights of Venezuela’s<br />

investments in urban mobility<br />

> Access all back issues of <strong>Odebrecht</strong><br />

<strong>Informa</strong> since no. 1, and download full<br />

issues in PDF<br />

> <strong>Odebrecht</strong> Annual Reports since 2002<br />

> Special publications (Special Issue on Social<br />

Programs, 60 years of the <strong>Odebrecht</strong> Group,<br />

40 Years of the <strong>Odebrecht</strong> Foundation and<br />

10 Years of Odeprev)<br />

BELIEVE IN SUCCESS<br />

The Acreditar (Believe) Project graduates<br />

skilled workers and contributes to the<br />

development of communities near the Teles<br />

Pires hydroelectric plant<br />

> Braskem’s “green”<br />

logistics enable it to use<br />

electric forklifts whose<br />

technology is 100%<br />

sustainable and helps<br />

reduce polluting gases<br />

> In the United States, 95%<br />

of Braskem’s production<br />

reaches clients by train,<br />

optimizing costs and<br />

time spent on shipment<br />

operations<br />

> Operational since 1985,<br />

the Carajás Railway is<br />

undergoing works to<br />

widen some sections and<br />

add 114.7 km of track<br />

informainforma<br />

2<br />

> See reports, features,<br />

videos, photos, animations<br />

and infographics in the<br />

magazine’s iPad and<br />

smartphone versions<br />

> Visit the App Store on your<br />

iPad to download issues<br />

of the magazine free of<br />

charge<br />

> You can read <strong>Odebrecht</strong><br />

<strong>Informa</strong> on your<br />

smartphone by<br />

logging onto www.<br />

odebrechtinforma.com.br<br />

> Send your comments and<br />

suggestions to versal@<br />

versal.com.br<br />

Read posts by the<br />

magazine’s reporters and<br />

editors on the <strong>Odebrecht</strong><br />

<strong>Informa</strong> blog.<br />

> Thiago Nehrer, 31,<br />

discusses the challenges<br />

of being part of a major<br />

company<br />

> The Port of Santos, the<br />

largest in Latin America,<br />

marks its 120th anniversary<br />

in 2012<br />

> Read about the Angolan<br />

tailor who is transforming<br />

traditional fabric from his<br />

country into artworks<br />

> When scientific research<br />

is put into practice,<br />

reforestation takes on a<br />

whole new meaning

&<br />

News<br />

Capa<br />

People<br />

Ilustração de Rico Lins<br />

#159<br />

TRANSPORT & LOG<strong>IS</strong>TICS<br />

cover photo: guilherme afonso<br />

6<br />

12<br />

16<br />

18<br />

22<br />

26<br />

30<br />

33<br />

36<br />

40<br />

46<br />

52<br />

54<br />

58<br />

60<br />

64<br />

66<br />

70<br />

72<br />

76<br />

80<br />

84<br />

87<br />

Construction of Lisbon beltway and Porto Metro expansion<br />

symbolize a new era of progress for Portugal’s transport<br />

infrastructure<br />

Ruta del Sol and Electric Train are iconic solutions for improving<br />

mobility in Colombia and Peru<br />

Communication programs are the highlight for <strong>Odebrecht</strong><br />

TransPort’s concessionaire subsidiaries<br />

Transnordestina Railroad: bringing development by linking the<br />

interior of northeastern Brazil with the region’s seaports<br />

Accessibility solutions that will benefit populous regions in<br />

Pernambuco and Rio de Janeiro<br />

Concessions: providing high-quality services for users of trains,<br />

subways and highways in four Brazilian states<br />

Paulo Cesena and the challenges facing <strong>Odebrecht</strong> TransPort, a<br />

company increasingly focused on direct relations with the public<br />

Construction and logistics systems enable the fast-paced execution<br />

of the Jardins Mangueiral housing project in Brasília<br />

Basic petrochemicals reach Braskem’s clients via highways,<br />

railways, waterways and pipelines<br />

In Caracas and Los Teques, an overview of Venezuela’s investments<br />

in better urban mobility<br />

The challenges and stories of Olex, a company that is present in<br />

every move the Organization’s teams make<br />

The Argentine engineer Diego Casarin: family, work and memories<br />

of magic moments provided by basketball<br />

Belo Monte: highlights of the dam’s construction in northern Brazil<br />

include a multi-modal logistics strategy<br />

Imports of equipment and materials for the PTA POY PET Project in<br />

northeastern Brazil involve up to 17 countries and 30 cities<br />

In Angola, highways, expressways and boulevards in major cities<br />

and the interior are opening up avenues for growth<br />

People: find out what makes Juliana Lima, Paulo Brito and<br />

Juliana Calsa always feel motivated to do more and better<br />

Tackling bottlenecks: the contributions of the Embraport Terminal<br />

in the Port of Santos, and the pipeline developed by Logum<br />

OOG is the first Brazilian company to build and operate PLSVs, ships<br />

used to install flexible pipelines in deep waters<br />

Gustavo Prisco writes about the (urgent) need for Brazil to<br />

overcome its infrastructure bottlenecks in transport and logistics<br />

ORGANIZATION<br />

GERMANY<br />

SUSTAINABLE DEVELOPMENT<br />

SAVVY<br />

informa<br />

3<br />

photo: Edu Simões

4<br />

informa

EDITORIAL<br />

It’s right<br />

there in the<br />

dictionary<br />

“While seeking<br />

solutions focused<br />

on better serving<br />

clients, <strong>Odebrecht</strong><br />

Organization<br />

companies are<br />

taking part in the<br />

efforts underway<br />

in Brazil and other<br />

countries to expand<br />

and upgrade<br />

their transport<br />

and logistics<br />

infrastructure”<br />

The Merriam-Webster dictionary defines a “bottleneck” as<br />

“someone or something that retards or halts free movement<br />

and progress.” Therefore, in the life of a nation, bottlenecks<br />

create an obstruction that could present a major obstacle to<br />

growth and development.<br />

The urgent need to improve transport and logistics infrastructure is a<br />

challenge confronting Brazil and other countries with similar potential to<br />

advance and grow their domestic and foreign markets. Just having good<br />

products is not enough. We must get those products to clients on time, with<br />

guaranteed quality. To do so, it is key to have a complex transport and logistics<br />

system in place that functions effectively and efficiently. Getting products<br />

from the hubs of production to the roads and railways and from there to the<br />

ports – that is how we build the pathways that enable nations to meet their<br />

people’s needs and boost their competitiveness in the global marketplace.<br />

While seeking solutions focused on better serving clients, <strong>Odebrecht</strong> Organization<br />

companies are taking part in the efforts underway in Brazil and other<br />

countries to expand and upgrade their transport and logistics infrastructure.<br />

In this issue of <strong>Odebrecht</strong> <strong>Informa</strong>, the spotlight is on the Organization’s<br />

projects in the Transport & Logistics sector. Here you will find emblematic<br />

stories of the efforts of cities, states and nations to overcome their bottlenecks,<br />

which can involve shipping products to the domestic market as well<br />

as imports and exports, but also has to do with issues like providing good<br />

public services through road concessions, and improving the quality of mass<br />

transport by expanding light-rail and commuter rail systems and building<br />

urban roadways.<br />

From importing the massive equipment required to build the Belo Monte<br />

hydroelectric plant in northern Brazil, to the expansion of the Caracas Metro,<br />

including the shipment of Braskem’s basic petrochemical products and the<br />

construction of expressways in Angola: every day, <strong>Odebrecht</strong> teams are using<br />

their know-how and spirit of service to carry out the task of helping their<br />

local communities find solutions and stop their dreams from being bottlenecked.<br />

Because giving up on goals and hopes of better times ahead is certainly<br />

not in the vocabulary of the <strong>Odebrecht</strong> Organization’s members.<br />

Good reading.

In harmony with<br />

histor<br />

written by Luiz Carlos Ramos<br />

photos by Edu Simões<br />

6<br />

informa<br />

6

y<br />

Metro<br />

and road<br />

construction projects<br />

in Porto and Lisbon<br />

harmonize with the<br />

preservation of the<br />

nation’s cultural and<br />

architectural heritage<br />

City of Porto: Metro<br />

expansion connects<br />

the historic center<br />

with the Douro River<br />

and the nearby town<br />

of Vila Nova de Gaia<br />

informa<br />

7

The tremendous advances Portugal has<br />

made in improving its infrastructure over<br />

the past 25 years, since it joined the European<br />

Union in 1986, mean that the country<br />

is now traversed from north to south by<br />

modern highways and fast trains, in contrast to the limitations<br />

of the 1970s. Bridges, overpasses and tunnels<br />

shorten distances and increase the presence of tourists<br />

from other parts of Europe, attracted by the warm climate<br />

and scenic beaches, mountains, plains and castles,<br />

as well as the exciting cuisine, and wines that are<br />

among the best in the world.<br />

Over the years, during this new era of development,<br />

the nation’s two largest cities, Lisbon and Porto (Oporto),<br />

have gained subway lines and extensive highways while<br />

retaining the narrow streets of their romantic and historic<br />

neighborhoods. <strong>Odebrecht</strong> International is taking part in<br />

the construction of this scenario through Bento Pedroso<br />

Construções (BPC), the contractor responsible for several<br />

projects in Portugal. Three of its most recent projects have<br />

just been completed: two in the Lisbon region and one in<br />

the Porto area.<br />

The complex of highways in the Portuguese capital became<br />

even more extensive and dynamic in 2011 with the<br />

inauguration of a new section of the Lisbon Beltway (CRIL),<br />

marking the completion of that circular route, which connects<br />

the Vasco da Gama and 25 de Abril bridges on the<br />

River Tagus. Leading from Almada, on the outskirts of Lisbon,<br />

on the other bank of the Tagus, the 25 de Abril Bridge<br />

is connected to the Baixo Tejo Highway. BPC has also built<br />

the most recent section of that route, facilitating access to<br />

a region of beaches that are popular with Lisbon residents<br />

and tourists alike.<br />

As for the northern city of Porto, its Metro system is<br />

composed of six lines, and one of the busiest has just been<br />

extended, connecting the city’s historic center to the Douro<br />

River and nearby Vila Nova de Gaia, a major industrial town.<br />

Portugal’s transport and infrastructure projects will<br />

continue in the next few months. Working through BPC,<br />

<strong>Odebrecht</strong> International is among the six companies that<br />

form Elos, Ligações de Alta Velocidade S.A., the joint venture<br />

responsible for the construction of portions of the<br />

future high-speed train line that will make the trip from<br />

Lisbon to Madrid in just three hours. The original design<br />

has undergone changes and is awaiting approval by the<br />

governments of Portugal and Spain, which are interested<br />

in increasing the flow of tourists in the Iberian Peninsula.<br />

Challenges of an urban project<br />

The Lisbon Beltway (CRIL) is 21 km long and runs<br />

through the northern part of the city, providing a quick<br />

route between the International Airport, Oriente Station<br />

and the Vasco da Gama Bridge, as well as connections<br />

to other expressways. This circular route was all but<br />

completed in April 2011 with the delivery of the 3.7-km<br />

stretch between Buraca and Pontinha, passing through<br />

the cities of Lisbon and Amadora Odivelas and nine districts,<br />

including Benfica, where the popular soccer club’s<br />

stadium is located.<br />

Estradas de Portugal S.A. contracted BPC to build<br />

this stage of the complex, and the <strong>Odebrecht</strong> company<br />

carried out its mission in just over three years. The<br />

completion of the road works required the demolition<br />

of houses and the removal of 1,600 families living in the<br />

area, the redevelopment and opening of tunnels, inter-<br />

CRIL: beltway<br />

passes through<br />

northern<br />

Lisbon<br />

8<br />

informa

changes and access routes, and the preservation of two<br />

historic aqueducts: Águas Livres and Francesas. The<br />

Águas Livres Aqueduct and its famous arches are nearly<br />

300 years old. The structure survived the devastating<br />

earthquake of 1755 and is still in use, as well as being a<br />

tourist attraction.<br />

Project Director José Joaquim Ferreira Martins explains:<br />

“It was a very challenging job because of the urban<br />

development situation, which required moving large<br />

amounts of earth. For this stretch, which is nearly 4 km<br />

long, we had to build two tunnels: Benfica, which is 1,446<br />

m long and runs alongside an aqueduct, and Venda Nova,<br />

which is 300 m long.” The project involved 181 workers,<br />

85% Portuguese and 15% from other nationalities.<br />

Antonio Martins, the technical officer Responsible for<br />

Community Relations, recalls: “We had to explain to motorists<br />

why they were facing traffic jams during construction.<br />

It was also necessary to convince the residents who<br />

had to be relocated because of the urban development<br />

works that the freeway is vital to the city.” José Martins<br />

adds: “One day before it was inaugurated, the route was<br />

opened for pedestrians only so people could experience<br />

it on foot.”<br />

There is modern lighting inside the tunnels, and lit<br />

traffic signs and loudspeakers warn drivers about the<br />

risks of accidents and traffic jams. The concrete side<br />

walls are decorated with graffiti art. “Our client, Estradas<br />

de Portugal, held a contest with a prize for the best<br />

graffiti artists. By covering the walls with these drawings,<br />

we avoided the risk of predatory graffiti,” recalls Martins,<br />

who is preparing to join the management team for the<br />

construction of the Portuguese stretch of the Lisbon-<br />

Madrid Railway, in which ultra-fast trains will link the<br />

capital cities of two nations.<br />

informa<br />

9

November 18, 2011, with a modern layout and almost no<br />

curves.”<br />

Gonçalo Matos, the officer Responsible for Engineering,<br />

notes that tourism is not the only sector that has benefited<br />

from this project. Many people live in that region and work<br />

in downtown Lisbon. “It was necessary to demolish houses<br />

and build bridges,” says Gonçalo. “Anyone who complained<br />

about the traffic jams while construction was going on can<br />

see how much faster it is to travel on the Baixo Tejo.”<br />

Oriente Station: the CRIL enables faster connections with<br />

the International Airport and Vasco da Gama Bridge<br />

More access to beaches<br />

Portugal’s most popular beaches for foreign tourists,<br />

especially visitors from Northern Europe, are in the Algarve,<br />

in the far south, where the sun shines all year round.<br />

However, the Lisbon region is also blessed with beautiful<br />

bathing spots in the Estoril and Cascais area, as well as<br />

the other side of the River Tagus, in the region called the<br />

Baixo Tejo or Lower Tagus. Inaugurated in 1966 and named<br />

in 1974 in honor of the Carnation Revolution of April 25th,<br />

which democratized the country, the 25 de Abril Bridge is<br />

the most direct route to Almada and the beaches on that<br />

bank, along the river and the sea.<br />

A southern extension of the Lisbon beltway, the Baixo<br />

Tejo Highway includes a total of 70 km of infrastructure<br />

works and provides a direct route to the region’s beaches.<br />

The client, Estradas de Portugal, has awarded the northern<br />

section of that project to BPC and its joint-venture partners<br />

Lena and MSF. Regarding the recent construction of<br />

a 4-km section of divided highway for that complex near<br />

the Caparica resorts, Project Director Bruno Medeiros observes:<br />

“There were huge high-tension power poles along<br />

the route that had to be removed with the authorization of<br />

the power company, which put the project a year behind<br />

schedule. But we overcame that challenge with patience<br />

and confidence, and the road was officially opened on<br />

Growing the Porto Metro<br />

Until 2002, the city of Porto had no Metro system at all.<br />

Its mass transportation system consisted of old trams,<br />

narrow streets and highways under construction. In just 10<br />

years, six lines have been added to the Metro, including one<br />

leading to the airport. There are 81 Metro stations, 14 of<br />

which are underground, but the system runs mostly on the<br />

surface, passing through 7 km of tunnels. Built with French<br />

technology, its yellow trains are silent, sleek and modern,<br />

stopping in seven towns and cities – Porto, Póvoa do<br />

Varzim, Vila do Conde, Maia, Matosinhos, Gondomar and<br />

Vila Nova de Gaia. Thousands of cars are no longer clogging<br />

the streets since their drivers began taking the Metro.<br />

BPC, which has been participating in the expansion of<br />

the Lisbon Metro for years, recently completed a two-year<br />

project in Porto in partnership with Lena – the extension<br />

of Line D, which links the Historic District with São Bento<br />

Porto Metro train: the<br />

system has gained six<br />

lines in just 10 years<br />

10<br />

informa

Baixo Tejo Highway:<br />

benefits tourists and<br />

local residents by<br />

facilitating access to<br />

the coast<br />

Railway Station, Porto Central Hospital and the University<br />

Campus. On October 15, 2011, in Vila Nova de Gaia, BPC<br />

and Lena delivered a brand new station, Santo Ovídio, the<br />

remodeled D. João II Station, and the stretch connecting<br />

these two stations, built along the busy thoroughfare of<br />

Avenida da República.<br />

Luís Temido, who has built up long experience in road<br />

works projects during his 19 years with <strong>Odebrecht</strong>, was the<br />

Project Director for the Porto Metro contract. He recalls:<br />

“The new station is underground, beneath a square where<br />

two streets and the city’s main road intersect. Because of<br />

that, we had to build a road tunnel that runs underneath<br />

and parallel to the subway tunnel.” The road tunnel was<br />

opened to traffic on January 30, 2012. “The biggest challenge<br />

of that project was the need to build it without interrupting<br />

the daily flow of thousands of pedestrians and<br />

vehicles in that area,” says Temido.<br />

Almost all of Luís Temido’s direct team members<br />

were Portuguese nationals. One young Brazilian engineer,<br />

Mariza Maria de Souza Ferreira, was born in Bahia<br />

but has lived in Portugal since her childhood. Mariza,<br />

who joined <strong>Odebrecht</strong> three years ago, explains that the<br />

modern Metro has made the city of Porto more attractive<br />

without detracting from its historic features. “The<br />

recently extended line runs through the old iron bridge<br />

built by Gustave Eiffel, who also built the Eiffel Tower in<br />

Paris. This bridge over the Douro River connects Porto<br />

and Vila Nova de Gaia and is part of the most scenic<br />

landscape in the region.” In Gaia, near the river docks,<br />

there are numerous wine cellars that stock Portugal’s<br />

famous port wine, which is produced and aged in oak<br />

barrels in the Upper Douro region.<br />

There are plans in place to further extend the Metro line<br />

that currently ends at Santo Ovídio, which would benefit<br />

low-income neighborhoods that are home to more than<br />

17,000 people. Luís Temido says he believes there will be<br />

more rail and road works in the Porto region and other<br />

parts of Portugal.<br />

“Sailing is necessary; living is not.” The Portuguese<br />

poet Fernando Pessoa wrote those words nearly 100 years<br />

ago, underscoring the motto of sailors of yore. Pessoa’s<br />

verses still inspire the Portuguese people today: “More and<br />

more, I set the soulful essence of my blood to the impersonal<br />

task of enhancing the homeland and contributing to<br />

the development of humanity. That is the form taken in me<br />

by the mysticism of our race.”<br />

informa<br />

11

12<br />

planeta Terra realiza dois tipos de movimento: a<br />

translação, elíptico em volta do sol, e a rotação, em de lançamento mais avançadas do mundo. Com ela, o<br />

torno de seu próprio eixo. A lição é muito conhecida, Brasil entrará para um seleto grupo de oito países com<br />

ensinada no colégio, nos primeiros anos da educação esse tipo de tecnologia. A <strong>Odebrecht</strong> Infraestrutura<br />

formal brasileira. Pois é justamente o movimento de está realizando as obras civis, participando do Consórcio<br />

Cyclone 4, ao lado da Camargo Corrêa. O cliente da<br />

rotação que faz com que Alcântara, pequena cidade à<br />

beira da Baía de São Marcos, no Maranhão, seja um obra é binacional, a Alcântara Cyclone Space, uma parceria<br />

entre os governos do Brasil e da Ucrânia.<br />

dos principais pontos do mundo para o lançamento de<br />

foguetes e satélites.<br />

O nome Cyclone vem do foguete que será utilizado<br />

Life O município está localizado muito próximo à Linha nos lançamentos, o Cyclone 4. Considerado um dos<br />

do Equador. Isso permite ao veículo lançador utilizar de mais seguros e eficazes do mundo (atinge três tipos<br />

forma mais eficiente o movimento de rotação da Terra<br />

the<br />

de órbita), ele tem o impressionante recorde de apenas<br />

quatro falhas em 226 lançamentos até hoje. Ape-<br />

para executar seu trabalho. Simplificando, pode-se dizer<br />

que ele “aproveita” esse movimento, em razão da nas outras sete nações detêm tecnologia de propulsão<br />

localização provilegiada da base. Isso possibilita uma similar: Estados Unidos, Rússia, Índia, China, França,<br />

economia de até 30% do caríssimo combustível utilizado.<br />

Por esse motivo, os equipamentos são capazes de Para a construção da base, iniciada em 2011, é ne-<br />

Japão e Cazaquistão.<br />

suportar cargas mais pesadas que o normal. “É uma cessária a supressão de uma área de vegetação de cerca<br />

de 100 hectares. Nesse espaço, estarão localizadas<br />

grande vantagem que pode colocar o Brasil em destaque<br />

no aquecido mercado mundial de lançamento de áreas de estoque de combustíveis e de montagem e<br />

satélites”, comenta Clóvis Costa, Gerente de Produção acoplagem de foguetes e satélites. Um trilho de ferro<br />

da <strong>Odebrecht</strong>.<br />

de aproximadamente 800 m que levará o foguete para<br />

informainforma<br />

12<br />

Em Alcântara, está sendo construída uma das bases

Passengers on the<br />

Electric Train in Lima:<br />

a decisive contribution<br />

to improving the<br />

Peruvian capital’s<br />

public transport<br />

system<br />

a área de lançamento propriamente dita.<br />

Babaçu e sustentabilidade<br />

A vegetação predominante na área é o babaçu, uma<br />

espécie de palmeira, da qual são retirados o óleo e a<br />

palha. Será realizado um replantio ostensivo da mata<br />

em outra região. Mas o que fazer com a madeira retirada<br />

(que não é de alto valor comercial) e que normalmente<br />

seria descartada?<br />

A partir de uma ideia criativa do Gerente de Produção<br />

Clóvis Costa e sua equipe, o Cyclone 4 conseguiu<br />

criar um ciclo sustentável para o babaçu, que foi reintegrado<br />

à paisagem natural, tornando possível a preservação<br />

da identidade visual maranhense em um município<br />

de importância histórica como Alcântara, ocupado<br />

pela primeira vez no século XVII, pelos franceses.<br />

Uma das mais belas praias da região é a dos Guarás.<br />

Por causa do avanço da maré, a única passagem<br />

para esse santuário ecológico começou a ruir, praticamente<br />

fechando qualquer travessia terrestre. A estrada<br />

ficava cada vez mais estreita. O Consórcio Cyclone<br />

4 construiu um talude (plano inclinado que limita um<br />

written by Zaccaria Junior<br />

aterro) utilizando o babaçu e alargou a estrada. Além<br />

photos by Bruna Romaro<br />

da palmeira, foi usada também uma manta porosa geotêxtil.<br />

A tecnologia faz com que a água do mar bata e<br />

volte sem danificar a encosta.<br />

A obra foi essencial para a sustentabilidade da comunidade<br />

local. O pescador Luiz Santana Cantanhêde,<br />

51 anos, corria o risco de ter sua atividade encerrada<br />

devido ao fim iminente da passagem. “Agora posso<br />

continuar minha pesca, além de outras atividades,<br />

como levar turistas para o outro lado margem, onde<br />

The Ruta del Sol<br />

and Electric Train<br />

are iconic projects<br />

that symbolize<br />

Colombia’s and<br />

Peru’s investments<br />

há uma praia muito bonita”, diz. “O mais interessante é<br />

que respeitamos a identidade in mobility<br />

visual da região. O talude<br />

de babaçu é confortável para os olhos, pois não destoa<br />

da paisagem”, acrescenta Coriolano Bahia, Gerente<br />

Administrativo da <strong>Odebrecht</strong>.<br />

Da forma como foi colocado o talude, até mesmo veículos<br />

maiores, como microônibus, podem passar por<br />

ali. Quem também se beneficiou com a solução foi Lincoln<br />

Salles, 33 anos, dono da Pousada dos Guarás, uma<br />

pequena pérola próxima ao mar e ao mangue, onde o<br />

hóspede desfruta do melhor suco de bacuri da região.<br />

A pousada simplesmente ficaria isolada do mundo. A<br />

passagem estreita já não possibilitava sequer o trânsito<br />

dos fornecedores de alimentos. Mas a situação mudou.<br />

“Foi uma solução ambiental, que respeita a vegetação<br />

daqui. Um exemplo que poderia ser seguido pelas autoridades”,<br />

destaca Lincoln.<br />

José Eduardo:<br />

aprendizados<br />

Ponte de babaçu<br />

precisam se<br />

Comunidade e turistas de Alcântara converter não foram em os<br />

únicos a saírem ganhando com as soluções sustentáveis<br />

do babaçu. Clóvis Costa usou a mesma técnica<br />

dentro da própria obra. Ele criou uma ponte (uma passagem<br />

rente ao chão) em cima de um Igarapé com a<br />

palmeira local. A ponte liga os lados leste e oeste da<br />

obra. Antes da ponte, os caminhões e veículos eram<br />

obrigados a percorrer uma distância de 12 km para<br />

chegar de um lado a outro do projeto.<br />

A passagem de babaçu é uma solução inédita e ecológica.<br />

Ela não atrapalha o fluxo da água, que atravessa<br />

a madeira e mantém as características daquele ecossistema.<br />

E mais: com a diminuição do percurso, reduz<br />

moveinforma<br />

informa<br />

13

Aroute that connects Bogota with Colombia’s<br />

Atlantic ports (on the Caribbean<br />

Coast). A light rail system in Lima,<br />

Peru, that reduces traveling time from<br />

two and a half hours by car to 30 minutes<br />

by metro. These projects may be very different in<br />

terms of format, but they are totally synergistic when it<br />

comes to one of the main concerns of modern life: mobility.<br />

In his book On the Move: Mobility in the Modern<br />

Western World, published by Routledge in 2006, an internationally<br />

recognized expert on that subject, geographer<br />

Tim Cresswell, alerted us to the fact that the phenomenon<br />

of mobility involves a varied range of factors<br />

and processes that are simultaneously present in the<br />

basic structure of the production system and people’s<br />

daily lives, up to and including the transportation system<br />

and the public management of those spaces.<br />

The Ruta del Sol (“Route of the Sun”) is the most important<br />

highway in Colombia. It covers 1,071 km and runs<br />

through an area that concentrates 70% of the country’s<br />

Gross Domestic Product (GDP) while connecting its two<br />

most important cities, Bogota and Medellin, with the Caribbean<br />

Coast. The target of a USD 2.5 billion investment,<br />

the concession for this route is divided into three sectors.<br />

Sector Two, the longest (528 km) and most important of<br />

the three, is the responsibility of the Rota do Sol S.A.S.<br />

concessionaire, led by <strong>Odebrecht</strong> (62.1%), whose partners<br />

are two Colombian companies, Corficolombiana<br />

(33%) and Solarte (4.99%). The venture represents an<br />

investment of approximately USD 1.5 billion. In addition<br />

to investing in the project, which includes the operation<br />

and maintenance of the highway for 25 years, <strong>Odebrecht</strong><br />

is also present as the contractor refurbishing the route.<br />

Begun in May 2011, the road works will be completed in<br />

five years under the responsibility of Ruta del Sol (Consol),<br />

a joint-venture contractor formed by <strong>Odebrecht</strong> and<br />

two Colombian companies, Corficolombiana and CSS<br />

Constructores S.A.<br />

According to Eder Ferracuti, President of the Rota<br />

do Sol S.A.S. concessionaire, the improvements to the<br />

highway will enable the route to realize its full potential.<br />

“It is mainly used for cargo transportation. The average<br />

amount of traffic in Sector Two is 20,000 vehicles<br />

per day, of which 70% are heavy vehicles. It is essential<br />

to improve this infrastructure to increase Colombia’s<br />

competitiveness,” he observes. “The improvements being<br />

made in road infrastructure have a direct impact on<br />

reducing the Vehicle Operating Cost, which is directly<br />

reflected in lower costs for foreign trade,” he adds.<br />

The Colombian Government estimates that the improvements<br />

being made on the Ruta del Sol will contribute<br />

to a 5% reduction in the Vehicle Operating Cost, which<br />

represents 4% savings on the cost of cargo transport on<br />

this corridor. This would represent additional gains for<br />

the country of up to USD 1.5 billion per year.<br />

“<strong>Odebrecht</strong> is also positioning itself in this country<br />

as a company that invests in infrastructure. Colombia is<br />

an extremely interesting country, where there are many<br />

Cities to coast<br />

possibilities and there’s plenty to do,” says the CEO of<br />

<strong>Odebrecht</strong> Colombia, Luiz Antonio Bueno Junior. “Travel<br />

time between Bogota and the Caribbean Coast will<br />

be reduced from 16 hours to 10,” he observes.<br />

The Colombian Transport Minister, Germán Cardona<br />

Gutiérrez, points out that the Ruta del Sol is a<br />

strategic project for his government. “We are entering<br />

a new era for concessions in Colombia, and this is<br />

the first example of the new phase of concessions. We<br />

need to set the priorities for the organization, execution<br />

and efficiency of these road infrastructure projects<br />

so the Colombian people will have a clear picture<br />

of the impact they will have on Colombia’s economy<br />

and development,” emphasizes Germán Cardona.<br />

On track for mobility<br />

With a population of over 8 million people, Lima still<br />

needs to develop its mass transit infrastructure. The<br />

informality of the bus and taxi systems in the Peruvian<br />

capital compromises the quality of transit and induces<br />

informa<br />

14

Ruta del Sol and Germán<br />

Cardona: “We are entering<br />

a new era for concessions<br />

in Colombia”<br />

people to travel in their own vehicles, a domino effect<br />

that eventually leads to massive traffic jams at any time<br />

of day. Long-standing plans to build a light-rail system –<br />

known as the Electric Train in Peru – got off the drawing<br />

board during President Alan Garcia’s first term in office<br />

in the second half of the 1980s, but the project ground to<br />

a halt before it was completed. It resumed by the end of<br />

Alan Garcia’s second administration in 2009, when nine<br />

stations were added to seven existing ones, and 13 km<br />

were added to the 9 km of lines already built. However,<br />

structural changes and updates were required. To get an<br />

idea of the results obtained from the implementation of<br />

the Electric Train project, it takes just 30 minutes to get<br />

from the first to last station of the Lima Metro. The same<br />

trip by car takes at least two and a half hours.<br />

According to Carlos Nostre, <strong>Odebrecht</strong>’s Electric<br />

Train Project Director: “There is no doubt about the<br />

need for this transport system, the way things are now.<br />

We took on a very difficult project, with<br />

the challenging deadline of 18 months<br />

to develop the plans, build the metro and<br />

get the trains up and running,” he says.<br />

One of challenges Nostre underscores is<br />

the fact that the Lima Metro runs overhead<br />

and not underground, which meant<br />

that its construction had a bigger impact<br />

on the public’s daily life.<br />

Directly involved in the resumption<br />

of the Electric Train project, Enrique<br />

Cornejo, a former Peruvian Minister of<br />

Transport and Communications, argues<br />

that light-rail systems are a necessity<br />

for any city in the world with over 4 million<br />

inhabitants. “It was important for our citizens to<br />

see that it was possible to finish this project and confirm<br />

that the metro is actually an important solution to<br />

the urban transport problem in Lima,” says Enrique<br />

Cornejo.<br />

The new metro is very popular. Oswaldo Plasencia,<br />

Executive Director of the Autonomous Electric Train<br />

Authority, observes that preliminary studies indicating<br />

that Lima’s light-rail system would transport 300,000<br />

passengers per day have been updated, doubling that<br />

figure to 600,000. “We have succeeded in building this<br />

project in record time, with excellent quality and virtually<br />

no inconvenience to the public. In just over two weeks<br />

of operations, the Electric Train has carried about 2<br />

million users,” says Plasencia. He adds that it is just<br />

a matter of time before the public takes a liking to the<br />

new system and there is a demand for the network to<br />

be expanded by adding more stations and lines.<br />

Oswaldo Plasencia:<br />

number of Electric<br />

Train users surpassed<br />

expectations<br />

informa<br />

15

Communication<br />

open dialogue<br />

operates the Dom Pedro I Corridor in<br />

Campinas, São Paulo.<br />

Six months ago, the company<br />

launched a bulletin titled De Olho<br />

na Rota (An Eye on the Route),<br />

which provides information on<br />

traffic conditions throughout the<br />

highway system, including closed<br />

lanes and road works. It sends<br />

seven daily updates of the bulletin<br />

to radio stations and news websites,<br />

especially at peak times.<br />

Rota das Bandeiras is also preparing<br />

to launch its new website,<br />

which will publish real-time imwritten<br />

by Renata Meyer photo by Artur Ikishima<br />

Comprehensive programs de s-<br />

ig ned to communicate with the<br />

community and the media have<br />

been an important ally of <strong>Odebrecht</strong><br />

TransPort’s concessionaire subsidiaries<br />

when fulfilling one of the company’s<br />

basic principles: ensuring the continuing<br />

improvement of the services it provides.<br />

“As providers of public services, we are<br />

committed to communicating with our<br />

users effectively, foreseeing events<br />

and avoiding surprises,” says Marco<br />

Be natti, the officer Responsible for<br />

Communication at Rota das Bandeiras,<br />

the concession company that<br />

<strong>Odebrecht</strong><br />

TransPort’s<br />

concessionaire<br />

subsidiaries use<br />

communication<br />

tools to maintain<br />

close relations<br />

with the<br />

community and<br />

the press<br />

informa<br />

16

Bahia Norte’s<br />

publications: full<br />

accountability<br />

ages from the cameras installed<br />

along the highways.<br />

Rota das Bandeiras has adopted<br />

a transparent and proactive<br />

stance in its press relations.<br />

“Nothing goes unanswered,” says<br />

Benatti. He says that speed and<br />

accuracy when working with the<br />

press have made all the difference<br />

in earning media professionals’<br />

trust.<br />

At SuperVia, the concessionaire<br />

that runs the commuter rail system<br />

in the Rio de Janeiro metropolitan<br />

region, the challenge of providing<br />

information to users quickly<br />

has the support of technology. The<br />

company has invested BRL 2.9 million<br />

in an integrated communication<br />

system with its clients – the<br />

passengers aboard its trains –<br />

which is managed at the Operational<br />

Control Center (OCC). This<br />

new system enhances operational<br />

security and safety while streamlining<br />

the OCC’s communications<br />

with train drivers.<br />

The concession company is<br />

also investing in the deployment<br />

of television screens on<br />

trains and in stations to broadcast<br />

institutional programs that<br />

provide background information<br />

about its operations and help<br />

answer passengers’ most frequently<br />

asked questions, among<br />

other content.<br />

The Bahia Norte concessionaire,<br />

which is responsible for<br />

administering the BA-093 state<br />

highway system in the Salvador<br />

metropolitan region in northeastern<br />

Brazil, has also put an extensive<br />

communication program<br />

in place. Between December<br />

2010 and June 2011, the company<br />

conducted a survey of users,<br />

residents and business leaders in<br />

the region to help identify the best<br />

communication strategies.<br />

“We want to show the public<br />

that our work is not limited to<br />

collecting tolls. We are here to<br />

provide high-quality service and<br />

make essential improvements to<br />

the local transport infrastructure,”<br />

says Cledson Castro, the<br />

officer Responsible for Communication<br />

at the Bahia Norte concession<br />

company.<br />

From this perspective, Bahia<br />

Nor te’s communication efforts<br />

focus on accountability to the<br />

community. It periodically invests<br />

in informative campaigns on<br />

matters like the delivery schedule<br />

for road works and changes<br />

in traffic flow and intensity.<br />

Bahia Norte also maintains<br />

an active presence on social<br />

networks. To inform the public<br />

about traffic conditions, it<br />

has created a Twitter page and<br />

updates it several times a day.<br />

Users can also obtain this information<br />

by logging on to the concessionaire’s<br />

website.<br />

In Cabo de Santo Agostinho,<br />

Pernambuco, where Rota dos<br />

Coqueiros manages 6.5 kilometers<br />

of highway, face-to-face<br />

communication has made a big<br />

difference in the community’s<br />

life. The concessionaire invests<br />

in traffic education, road safety<br />

and environmental awareness<br />

campaigns through seminars,<br />

training sessions and recreational<br />

activities for local residents.<br />

It has also started publishing<br />

a bimonthly newsletter<br />

to communicate with the highway’s<br />

users. With a circulation<br />

of 10,000 copies, the newsletter<br />

is distributed at the toll plaza,<br />

which is the company’s main<br />

point of communication with the<br />

public. “Through the newsletter<br />

we show our users what we are<br />

doing for the community. As a<br />

result, they can take part in our<br />

projects and see that our work<br />

goes beyond maintaining and<br />

operating the highway,” says<br />

Elias Lages, President and CEO<br />

of Rota dos Coqueiros.<br />

informa<br />

17

Anyone who visits the 25 work fronts<br />

for the New Transnordestina Railroad<br />

in the Brazilian states of<br />

Pernambuco, Piauí and Ceará,<br />

and sees the accelerated work of<br />

around 9,000 people and thousands of machines,<br />

would never imagine the time it took for the project<br />

to leave the drawing board. Residents of the<br />

Northeast had nurtured that dream since Emperor<br />

Pedro II visited that part of the country in the<br />

nineteenth century and promised to build a railroad<br />

to link the interior of the region to the coastal<br />

cities. Over 100 years later, the new route of<br />

the railway, which will connect existing portions<br />

of the old network, is one of the main projects in<br />

the Federal Growth Acceleration Program (CAP),<br />

with an investment of BRL 7.5 billion. The 1,728-<br />

km New Transnordestina will connect the city of<br />

Eliseu Martins in southern Piauí with the ports of<br />

Pecém in Ceará and Suape in Pernambuco.<br />

<strong>Odebrecht</strong> Infraestrutura is responsible for<br />

building the Eliseu Martins-Suape stretch and<br />

part of the Salgueiro-Pecém section. The work is<br />

divided into two phases. The first is infrastructure,<br />

which includes grading and construction of bridges<br />

and viaducts – that is, preparing the ground for<br />

tracks. “This stage is the most challenging part of<br />

the project because it involves obtaining environmental<br />

permits, land expropriation, relations with<br />

maroon and indigenous communities and managing<br />

our own impact on urban areas,” says Tufi Daher<br />

Filho, CEO of Transnordestina Logistica S.A.,<br />

the CSN Group company that has been responsible<br />

for operating the freight railway system in<br />

the Northeast since 1998.<br />

The second phase involves the superstructure,<br />

Tracks across the<br />

backl<br />

Section of the Transnordestina<br />

Railroad in Salgueiro,<br />

Pernambuco: the city marks<br />

the beginning of the railway<br />

line. Opposite page, Brazilian<br />

President Dilma Rousseff<br />

during her visit to the jobsite:<br />

harnessing the region’s<br />

potential<br />

that is, installing the sleepers, rails and gravel –<br />

the railway itself. This phase began in the second<br />

18<br />

half of 2011. About 200 km of the railway have been<br />

built so far. Trains are already riding the rails, but<br />

for now there are just enough to carry materials for<br />

the works themselves: rails, sleepers and gravel.<br />

“We can lay up to 2.5 km of track per day. We’ll<br />

have built 600 km of the railway by the end of 2012,<br />

and the Eliseu Martins-Suape section will be up<br />

and running by 2013,” says Tufi.<br />

informa<br />

18

ands<br />

A 200-km stretch<br />

of the ongoing<br />

Transnordestina<br />

Railroad project is<br />

already built and<br />

changing lives in a<br />

vast region of Brazil<br />

The Transnordestina Railroad is equipped with<br />

the latest features. One is the gauges (distance between<br />

rails) used – broad gauge (1.6 m) tracks for<br />

modern trains, and mixed gauges in some places,<br />

which allow older narrow-gauge (one-meter)<br />

trains to operate. It also uses concrete sleepers<br />

instead of wood. The rails purchased from China,<br />

Italy and Poland measure 24 m per unit. Each unit<br />

is attached to nine more to form a 240-m Long<br />

Welded Rail (LWR). The slope of the line is a maximum<br />

of 1.5% and the radius of curvature is 400 m<br />

per kilometer. Thanks to these features, a 104-car<br />

train can safely travel at up to 80 km/hour.<br />

A corridor of opportunities<br />

When the 1,728-km railway system is completed<br />

in 2014, the business opportunities will<br />

be huge. The railway will carry 30 million metric<br />

tons of cargo per year. Transnordestina Logística’s<br />

cars already carry products like cement, raw<br />

materials for steel mills, and fuel (ethanol, diesel<br />

and gasoline), and the company wants to expand<br />

its business and transport grain and minerals as<br />

well. Two clear targets are in sight: the Mapito<br />

region (covering Maranhão, Piauí and Tocantins),<br />

a major grain producer, and the Araripina Plaster<br />

Hub in Pernambuco, which contains one of<br />

the largest gypsum deposits in Brazil. Iron ore<br />

and copper mining ventures in Pernambuco and<br />

written by Edilson Lima<br />

photos by Marcelo Pizzato<br />

informa<br />

19

Alagoas are already underway. Other possibilities<br />

include transporting fruit from Petrolina, Pernambuco,<br />

and northern Bahia, and the return of<br />

essential products such as fertilizers.<br />

In 2012, Transnordestina Logística will also restore<br />

a 500-km section of the original rail network<br />

between Cabo de Santo Agostinho, Pernambuco,<br />

and Porto Real do Colégio, Alagoas, which was<br />

damaged by heavy rains and floods two years ago.<br />

As a result, the system will once again connect<br />

the northeastern railway with the Central Atlantic<br />

Railroad, which crosses part of the Midwest and<br />

Southeast of Brazil.<br />

“The New Transnordestina will expand the<br />

range of options available to businesses. They<br />

will be able to choose the best way to distribute<br />

their products within Brazil or to other countries.<br />

Our goal is to increase the market share for rail<br />

transport from the current 15% to 40% of freight<br />

in the region,” says Tufi Daher Filho.<br />

Strategic position<br />

Strategically located, about 600 km from several<br />

major cities in the Northeast, Salgueiro is<br />

the hub for the New Transnordestina Railroad<br />

works. Workers from the Northeast and other<br />

parts of Brazil have been arriving in that city<br />

since construction began in late 2009. Since<br />

then, it has grown by 25%, and now has 60,000<br />

inhabitants.<br />

“The booming economy has affected everything<br />

from increased consumption of food and<br />

fuel to high occupancy in hotels,” says Mayor<br />

Marcones Libório de Sá. Banks, household appliance<br />

stores and footwear outlets have arrived<br />

there as well. With more tax revenue, the city<br />

can invest in paving streets, installing sewer<br />

systems, building a sanitary landfill and expanding<br />

Salgueirão Stadium, in addition to improving<br />

education and health care. In 2011, Marcones<br />

received the Idepe Award from the State of Per-<br />

20<br />

informa

Workers installing rails<br />

and sleepers and, in the<br />

smaller photo, Mayor<br />

Marcones Libório de Sá:<br />

recognized efforts<br />

nambuco for his efforts to promote basic<br />

education. “It was a recognition of our efforts<br />

to improve education in this city,” he<br />

says.<br />

The mayor is also celebrating the work<br />

opportunities generated by the project<br />

itself. Previously, the city had an unemployment<br />

rate of 30%. Today, that figure<br />

is down to 6%. “It isn’t any lower because<br />

the economy requires more skilled<br />

workers,” he says. The city has achieved<br />

this by partnering up with <strong>Odebrecht</strong> Infraestrutura.<br />

“Finding qualified people<br />

was a major challenge on this project. We<br />

had to train about 4,000 workers through<br />

the Ongoing Professional Education Program<br />

– Acreditar,” says <strong>Odebrecht</strong> Project<br />

Director Pedro Leão. “Everywhere we<br />

go, the local authorities and people in<br />

the community are talking about how this<br />

project is benefiting their towns.”<br />

Ieunice Elenira Primo, 23, and Lucian<br />

Alves da Silva, 22, were born and<br />

raised in Salgueiro. When they heard<br />

about the courses available at Acreditar<br />

(“Believe” in Portuguese), they signed up<br />

right away. By the middle of 2010, both<br />

of them had jobs on the railway works.<br />

“When I got the call, I was thrilled to<br />

bits! I started out as a production assistant<br />

and now I’m in training to become<br />

a machine operator at the sleeper plant.<br />

As long as the opportunities are there,<br />

I’ll keep growing,” she says. Just as enthusiastic<br />

as Ieunice, Lucian, who works<br />

as a steelfixer, says: “This project makes<br />

us all proud. I know I’m playing a part in<br />

the history of the Northeast and Brazil.<br />

I want to keep studying, and maybe I’ll<br />

even become a construction supervisor<br />

one day.”<br />

In February, Brazilian President Dilma<br />

Rousseff visited the construction site in<br />

Salgueiro, and said: “Connecting the interior<br />

of Brazil to its ports will increase<br />

our capacity to get products to market<br />

and develop the region’s potential.”<br />

informa<br />

21

coming<br />

22<br />

A road complex in<br />

Pernambuco and an<br />

expressway in<br />

Rio de Janeiro put<br />

technological<br />

and entrepreneurial<br />

innovation at the<br />

service of accessibility<br />

Despite the almost 2,400-km distance<br />

that lies between them, Rio de Janeiro<br />

and Pernambuco are very similar when<br />

it comes to the execution of major projects.<br />

In recent years, both states have<br />

seen economic growth higher than the national average<br />

in Brazil, and both are investing in infrastructure<br />

projects, some of the most significant being in<br />

the mobility sector. In the Southeast and Northeast<br />

of the country, the <strong>Odebrecht</strong> Organization’s companies<br />

are partners in this development process as<br />

22<br />

informa

through<br />

written by Heloísa Eterna and Rodrigo Vilar<br />

photos by André Valentim<br />

Works on the TransOeste<br />

project in Barra da Tijuca:<br />

making Rio de Janeiro’s<br />

West Zone more accessible<br />

investors and builders of projects that are expanding<br />

the logistical capacity of these states.<br />

Located in the Recife metropolitan area, the Port<br />

and Industrial Complex of Suape, controlled and<br />

administered by the State of Pernambuco, is consolidating<br />

its position as one of the most important<br />

investment hubs in Brazil. The complex receives<br />

60,000 workers daily and covers an area of 13,500<br />

hectares – geographically larger than the city of<br />

Olinda and equivalent to the entire urban area of<br />

Recife. More than 100 companies are operating<br />

there, and another 35 are in the implementation<br />

phase, representing a total investment of USD 17<br />

billion. In 2011, Suape’s port operations registered<br />

25% growth in tonnage transported and 33% growth<br />

in container handling.<br />

This success story has encouraged the administrators<br />

of Suape and the State of Pernambuco to<br />

implement plans to expand and upgrade the complex’s<br />

access roads. “We are carrying out a plan to<br />

keep pace with this growth in the medium and long<br />

term. One initiative is the road concession won by<br />

informa<br />

23

photo: Elvio Luiz<br />

<strong>Odebrecht</strong> TransPort and Invepar at the end of 2011,”<br />

says Frederico Amâncio, Vice President of Suape.<br />

Through a 35-year contract and investments of<br />

BRL 450 million, the Rota do Atlântico S.A. concession<br />

company (CRA) – 50% owned by <strong>Odebrecht</strong><br />

TransPort and 50% by Invepar – manages a 43-km<br />

section of the Expressway road and Logistics Complex.<br />

The road concession starts on BR-101 South<br />

at D. Helder Câmara Hospital, and runs through<br />

the district of Nossa Senhora do Ó, in Ipojuca, leading<br />

to Porto de Galinhas Beach, on the south coast<br />

of the state.<br />

In addition to building and upgrading access<br />

roads, the business plan also provides for the modernization<br />

and implementation of a signaling system,<br />

the installation of street lighting, and the deployment<br />

of metal safety fences and barriers in high-risk areas.<br />

The project also includes construction of an Operational<br />

Control Center, a Base of Operations with<br />

a User Service Center, mobile weigh stations, two<br />

logistics yards, five toll plazas and a new Highway<br />

Military Police station.<br />

Transversality<br />

Two Organization companies are working together<br />

in the CRA concessionaire: <strong>Odebrecht</strong> TransPort is<br />

the investor and operator, and <strong>Odebrecht</strong> Infraestrutura<br />

is responsible for civil works. “We aim to de-<br />

Workers<br />

building<br />

TransOeste:<br />

Rio de Janeiro<br />

is improving<br />

its transport<br />

infrastructure<br />

24<br />

informa

Building the structure<br />

for the Expressway in<br />

Pernambuco: a strategic<br />

project for the Suape<br />

Industrial and Port<br />

Complex. Below, Júlio<br />

Perdigão and Ana Carolina<br />

Farias: two <strong>Odebrecht</strong><br />

companies are directly<br />

involved in planning and<br />

execution<br />

velop a quality project that meets the needs of the<br />

[35-year] concession’s users, while keeping in mind<br />

the overall value and the deadlines agreed with the<br />

grantor,” says <strong>Odebrecht</strong> Infraestrutura Project Director<br />

Ana Carolina Farias. According to Júlio Perdigão,<br />

Investment Director of <strong>Odebrecht</strong> TransPort<br />

and President and CEO of CRA, both companies are<br />

actively involved in planning and execution to ensure<br />

maximum efficiency. “Structured projects like this<br />

one encourage the full application of the <strong>Odebrecht</strong><br />

Entrepreneurial Technology (TEO), influencing and<br />

being influenced at all times in pursuit of what is<br />

right. It is a relationship of discipline, respect and<br />

trust between colleagues and partners.”<br />

photo: Elvio Luiz<br />

stretch in the Recreio dos Bandeirantes neighborhood,<br />

where all lanes are fully operational,” says<br />

Project Director Pedro Moreira.<br />

One of the highlights of the TransOeste project is<br />

the construction of the Grota Funda tunnel, linking<br />

Barra de Guaratiba and Recreio dos Bandeirantes.<br />

Once completed, the tunnel will reduce travel time by<br />

50%, eliminate traffic jams in the Serra da Grota Funda<br />

mountains and benefit over 200,000 people daily.<br />

There will be 25 BRT stations along the 23.8 km<br />

route of the TransOeste Expressway. Their platforms<br />

will be level with the bus doors. Equipped with occupancy<br />

sensors that will open doors automatically,<br />

they will also be accessible to people with special<br />

Building a dream<br />

In Rio de Janeiro, the works being built in the runup<br />

to the 2014 FIFA World Cup and the 2016 Olympics<br />

will leave a legacy that will benefit the economy, local<br />

residents and tourists who visit the state capital. One<br />

of the projects underway is the TransOeste Expressway,<br />

which aims to improve accessibility between the<br />

Barra da Tijuca and Santa Cruz districts in the West<br />

Zone of the city, including an express corridor for a<br />

BRT (Bus Rapid Transit) system.<br />

<strong>Odebrecht</strong> Infraestrutura is responsible for building<br />

two of four sections of TransOeste, and has already<br />

completed 90% of the works. “This project is<br />

a long-held dream, especially for urban residents.<br />

Before it is completed, they can already enjoy the<br />

needs, and the stations’ architectural design provides<br />

a light and airy ambience. “The public’s needs, the<br />

City Government’s dream and <strong>Odebrecht</strong> Infraestrutura’s<br />

ability to get things done are making this project<br />

happen,” says Moreira, who adds that it will be<br />

completed and officially opened in April of this year.<br />

The sections of the Expressway under <strong>Odebrecht</strong><br />

Infraestrutura’s responsibility are located between<br />

Ayrton Senna and Benvindo de Novaes avenues (9.9<br />

km), and Benvindo de Novaes Avenue and Estrada da<br />

Matriz highway (13.9 km). The project involves cordoning<br />

off BRT lanes, building side lanes, refurbishing<br />

the existing roadway, building a second roadway<br />

alongside the original one, and building tunnels, two<br />

bridges and six overpasses.<br />

informa<br />

25

Activity on Line 4 of the São<br />

Paulo Metro and (smaller<br />

photo), bank worker Leandro<br />

Rocha: better quality of life<br />

s<br />

The constant pursuit of<br />

technological, operational<br />

and managerial<br />

26<br />

improvement is the<br />

hallmark of <strong>Odebrecht</strong><br />

TransPort’s concessions<br />

in four Brazilian states<br />

informa<br />

26

ervice<br />

At its users’<br />

written by Renata Meyer photos by Dario de Freitas<br />

São Paulo, Tuesday, late afternoon. Leandro<br />

Rocha is returning home after a<br />

hard day’s work at the bank. The commute<br />

from the city center to his home<br />

in the Santo Amaro district, which used<br />

to last two hours by bus, now takes less than 60 minutes<br />

on Line 4 of the Metro. He describes the benefits<br />

in a nutshell: “Now I have a better quality of life.”<br />

In Cabo de Santo Agostinho, Pernambuco, real<br />

estate broker Thiago Lein travels on the 6.2-km Coqueiros<br />

Route, which leads to the south coast of the<br />

state and the industries in the Suape Complex. “I take<br />

this route several times a week. You can save time<br />

and drive more safely,” he says.<br />

Leandro and Thiago are among the thousands of<br />

Brazilians who are benefitting from the <strong>Odebrecht</strong><br />

TransPort’s operations in the areas of road transportation<br />

and urban mobility, currently located in<br />

four Brazilian states: São Paulo, Rio de Janeiro,<br />

Pernambuco and Bahia. In the area of urban mobility<br />

alone, which includes the operation of trains<br />

and light rail systems, the company transports 1.3<br />

million passengers daily in the two largest cities in<br />

the country and expects to invest BRL 6.5 billion<br />

through its assets.<br />

Its main challenges include improving and modernizing<br />

the rail industry through a BRL 2.4-billion<br />

investment program carried out in partnership with<br />

the State Government, which includes renewing the<br />

fleet, refurbishing stations and revitalizing the system’s<br />

infrastructure.<br />

In São Paulo, <strong>Odebrecht</strong> TransPort is one of shareholders<br />

of Via Quatro, the concessionaire that runs<br />

Line 4 of the megacity’s Metro system. The first stage<br />

of this venture was completed in 2011. When completed,<br />

it will be 12.8 km long, with 11 stations linking<br />

the West Zone of São Paulo and the city center.<br />

“Anyone who travels on this line every day can see<br />

the major leap in quality that it represents for our<br />

transportation system. As a user I hope that more<br />

train and subway lines will also get this kind of infrastructure<br />

in the future,” says Leandro Rocha.<br />

Urban trains<br />

In the Rio de Janeiro Metropolitan Region, <strong>Odebrecht</strong><br />

TransPort has been running SuperVia since<br />

November 2010, serving over 500,000 passengers<br />

per day. The concession company is responsible for<br />

the administration of one of the region’s main transport<br />

systems until 2048, comprising 270 km of railways,<br />

with 98 stations in 12 counties.<br />

informa<br />

27

must concentrate on fulfilling the public’s expectations.<br />

This entails major challenges, such as promptly<br />

meeting our users’ needs with quality services, safety<br />

and punctuality,” says Paulo Cesena, President and<br />

CEO of <strong>Odebrecht</strong> TransPort.<br />

Thiago Lein uses<br />

Rota dos Coqueiros<br />

in Pernambuco:<br />

more safety and less<br />

commuting time<br />

Line 4, which links the other Metro lines with the<br />

metropolitan train system, stands out for its modernity.<br />

It is the first light-rail branch in Latin America<br />

with glass partitions separating the platform from<br />

the tracks, a feature that increases passenger safety.<br />

It also uses driverless technology.<br />

“Due to the enormous challenges involved, in<br />

terms of technology, operations and management,<br />

our experiences in Rio de Janeiro and São Paulo<br />

have qualified us to work on urban mobility projects<br />

in other major Brazilian cities,” says Irineu Meireles,<br />

Regional Director of <strong>Odebrecht</strong> TransPort.<br />

The focus on quality service is a point that all of<br />

<strong>Odebrecht</strong> TransPort’s operations share in common.<br />

“When we operate public utility services, we<br />

photos: Lia Lubambo<br />

Road transportation<br />

Working with the same focus, <strong>Odebrecht</strong> Trans-<br />

Port’s road concession companies are upgrading<br />

some of the most important highway systems in the<br />

country. This is the case with the Dom Pedro I Corridor,<br />

which the company has managed since 2009<br />

through Rota das Bandeiras in São Paulo State. This<br />

297-km system connects 17 cities in the metropolitan<br />

region of Campinas and the Paraíba Valley, an<br />

area with about 2.5 million inhabitants. The 30-year<br />

concession includes a BRL 3.5-billion investment in<br />

the maintenance, refurbishment and modernization<br />

of the road network.<br />

In the northeastern state of Bahia, <strong>Odebrecht</strong><br />

TransPort and its partner Invepar control the Bahia<br />

Norte concession company, which is responsible for<br />

the administration of a 121-km section of the BA-<br />

093 state highway system, covering nine counties in<br />

the Salvador metropolitan region and serving more<br />

than 3 million residents. Composed of six routes, this<br />

system is an important artery for industrial production,<br />

serving the Aratu and Camacari manufacturing<br />

hubs, which contain a total of 298 companies and are<br />

responsible for roughly 60% of Bahia’s GDP.<br />

28<br />

informa

<strong>Odebrecht</strong> TransPort is also Invepar’s partner in<br />

the Litoral Norte concession company (CLN), which<br />

manages 217 km of Estrada do Coco (Coconut Highway)<br />

and the Linha Verde (Green Line), part of state<br />

highway BA-099. This route links the city of Lauro de<br />

Freitas, in the Salvador metropolitan region, with the<br />

border between the states of Bahia and Sergipe, and<br />

plays an important role in regional tourism.<br />

According to Renato Mello, <strong>Odebrecht</strong> TransPort’s<br />

Regional Director, the company’s priority in the road<br />

transportation sector is working on urban projects<br />

that are of major strategic importance for regional<br />

economic, industrial and tourism development. “Our<br />

goal is to help build new hubs of development in Brazil,<br />

as well as alternative means of public transport<br />

to minimize traffic bottlenecks in our cities,” he says.<br />

Through the Rota do Atlântico concessionaire, the<br />

company is investing in the Expressway Road and<br />

Logistics Complex (see article on page 22), which is<br />

located in a major hub of economic expansion in the<br />

northeastern state of Pernambuco. The 43-km highway<br />

is not only an alternative route to Recife’s south<br />

coast beaches but will reduce traffic on the roads<br />

leading to the Suape Industrial Complex, which is<br />

now home to over 100 companies.<br />

In Pernambuco, <strong>Odebrecht</strong> TransPort also manages<br />

the road system comprised of Via Parque (Park<br />

Highway) and the Arquiteto Wilson Campos Bridge,<br />

in Reserva do Paiva. Managed by Rota dos Coqueiros,<br />

this 30-year concession was the first public-private<br />

road partnership in Brazil. In addition to making it<br />

easier to get to the state’s southern beaches, the<br />

road reduces the distance to Recife by 30 km.<br />

Last year, more than 61 million vehicles traveled<br />

the 686 km of highways <strong>Odebrecht</strong> TransPort operates.<br />

The company plans to invest a total of BRL 7.6 billion in<br />

this sector through its concessionaires.<br />

Foto: Carlos Junior<br />

SuperVia, in Rio de<br />

Janeiro: 500,000<br />

passengers daily<br />

informa<br />

29

INTERVIEW<br />

Paulo Cesena: one<br />

of <strong>Odebrecht</strong> TransPort’s<br />

main focuses is<br />

grooming teams<br />

30<br />

30<br />

informa

service<br />

The Spirit of<br />

written by Álvaro Oppermann and Renata Meyer<br />

photo by Paulo Fridman<br />

Created in 2010, <strong>Odebrecht</strong> TransPort is<br />

growing and consolidating its standing<br />

as one of the leading transportation and<br />

logistics companies in Brazil. With net<br />

earnings of BRL 1.618 billion in 2011, its<br />

assets include SuperVia (a commuter rail<br />

system in the Rio de Janeiro metropolitan region), Rota<br />

das Bandeiras and Rota dos Coqueiros (highway systems),<br />

and Embraport, the country’s largest multipurpose private<br />

port terminal, in Santos, São Paulo. In this interview,<br />

<strong>Odebrecht</strong> TransPorts’s Executive Director Paulo Cesena,<br />

who has spent 14 of his 39 years with the Organization,<br />

underscores how, by investing in and operating infrastructure<br />

assets, the company is embarking on a new phase of<br />

entrepreneurship for the Organization, which is now a coparticipant<br />

in public services with a major social impact.<br />

Speaking to the <strong>Odebrecht</strong> <strong>Informa</strong> team in his office in São<br />

Paulo, Cesena revealed the strategies and opportunities of<br />

a company facing many challenges on the road ahead. He<br />

also believes there is a need for entrepreneurship focused<br />

on ongoing user satisfaction. “We must see ourselves as<br />

public service providers who are prepared to fulfill the expectations<br />

of our clients and users with promptness and<br />

excellence in our operations of trains, subways, highways,<br />

ports, and eventually, airports.”<br />

<strong>Odebrecht</strong> <strong>Informa</strong> – <strong>Odebrecht</strong><br />

TransPort is a new company. It<br />

emerged within <strong>Odebrecht</strong> Infraestrutura<br />

(Infrastructure), and<br />

is still part of that company. How<br />

does the relationship between<br />

the two companies work?<br />

Paulo Cesena – There is a synergistic partnership<br />

between the two companies under the leadership of<br />

our Entrepreneurial Leader (CEO) Benedicto Junior.<br />

<strong>Odebrecht</strong> Infraestrutura contributes its competitiveness<br />

in Engineering & Construction, and <strong>Odebrecht</strong><br />

TransPort focuses on investment, financing<br />

and operations. This partnership means we are always<br />

working together in a unique relationship with<br />

our clients during the planning and construction<br />

phase.<br />

OI – What is the main advantage of this synergy?<br />

Cesena – It is nationwide capillarity and proactivity.<br />

This relationship makes us better able to understand<br />

our clients throughout Brazil and to look ahead, coming<br />

up with relevant projects. This only happens when<br />

entrepreneur-partners are on the same page, with the<br />

common goal of serving clients and creating value.<br />

OI – Are acquisitions part of <strong>Odebrecht</strong> TransPort’s<br />

growth strategy?<br />

Cesena – Not exactly. Our difference lies in the development<br />

of new ventures, called greenfield projects.<br />

But we may occasionally make acquisitions that allow<br />

us to enter new lines of business. For example,<br />

we have purchased Embraport, which now allows us<br />

to see ourselves as a participant in the entire Brazilian<br />

container market. Also, we recently acquired a<br />

company that operates bulk liquid storage terminals<br />

because we want to be qualified to service clients<br />

such as Braskem, ETH Bioenergy, <strong>Odebrecht</strong> Oil &<br />

Gas (OOG) and others, as an experienced partner in<br />

these operations.<br />

informa<br />

31

OI – At the beginning of our conversation [when Paulo<br />

Cesena welcomed the news team to his office], you<br />

said your team is facing a new challenge in terms of<br />

entrepreneurship. How so?<br />