CADKEY PARAMETRICS is Released!

CADKEY PARAMETRICS is Released!

CADKEY PARAMETRICS is Released!

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

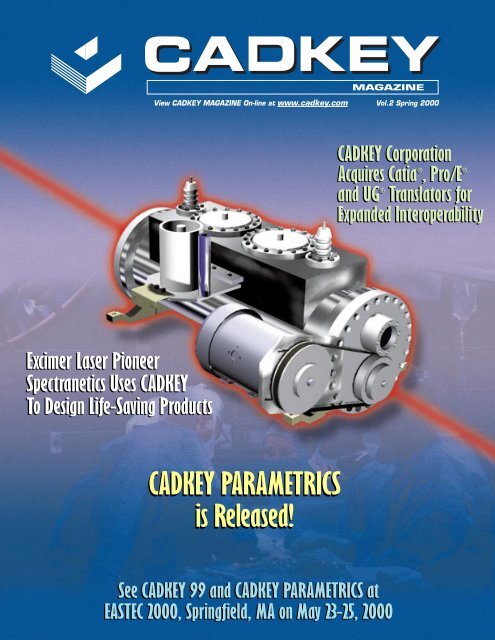

View <strong>CADKEY</strong> MAGAZINE On-line at www.cadkey.com Vol.2 Spring 2000<br />

<strong>CADKEY</strong> Corporation<br />

Acquires Catia ® , Pro/E ®<br />

and UG ®<br />

Translators for<br />

Expanded Interoperability<br />

Excimer Laser Pioneer<br />

Spectranetics Uses <strong>CADKEY</strong><br />

To Design Life-Saving Products<br />

<strong>CADKEY</strong> <strong>PARAMETRICS</strong><br />

<strong>is</strong> <strong>Released</strong>!<br />

See <strong>CADKEY</strong> 99 and <strong>CADKEY</strong> <strong>PARAMETRICS</strong> at<br />

EASTEC 2000, Springfield, MA on May 23-25, 2000

A Letter from the President<br />

Dear Customer,<br />

Contents<br />

3 Web News<br />

4-5 <strong>CADKEY</strong> in the News<br />

6-7 <strong>CADKEY</strong> in Action<br />

8-9 Feature Article –<br />

Spectranetics Corporation<br />

10-11 <strong>CADKEY</strong> <strong>PARAMETRICS</strong><br />

Ships<br />

12 <strong>CADKEY</strong> Classroom<br />

13 Tech Note<br />

14 Educational Corner<br />

15 <strong>CADKEY</strong> Community<br />

Announcements<br />

33 Boston Post Road West<br />

Marlborough, MA 01752 USA<br />

Tel (508) 229-2020<br />

Fax (508) 229-2121<br />

www.cadkey.com<br />

Editors<br />

Belinda Jones<br />

HiTech Marketing LLC<br />

Lizabeth A. Rombek<br />

Marketing Communications Manager<br />

Printed on Recycled Paper<br />

During the National Design Engineering Show in March, we were<br />

overwhelmed with the customer interest in our <strong>CADKEY</strong> <strong>PARAMETRICS</strong><br />

module and the newest version of <strong>CADKEY</strong>. I would like to thank the<br />

hundreds of <strong>CADKEY</strong> users who stopped by our booth and those who<br />

attended our National User Group meeting held during the trade show.<br />

<strong>CADKEY</strong> <strong>PARAMETRICS</strong>, a powerful companion software module for <strong>CADKEY</strong> 99, <strong>is</strong> now<br />

Robert W. Bean<br />

President and CEO<br />

released and will begin shipping shortly. The addition of th<strong>is</strong> technology clearly gives the <strong>CADKEY</strong><br />

product line an unrivaled depth of design functionality in the midrange CAD marketplace. Second<br />

to none in flexibility and interoperability, <strong>CADKEY</strong> <strong>is</strong> the most fully-resourced CAD program for<br />

product development and manufacturing applications. We invite you to sample our streaming<br />

videos illustrating <strong>CADKEY</strong> <strong>PARAMETRICS</strong> at www.cadkey.com/gallery/video.<br />

Continuing our efforts to remain the world’s most interoperable CAD software, in June of 2000<br />

we will expand our product line up by introducing direct translators for use with Pro/Engineer ® ,<br />

Catia ® and Unigraphics ® files. These affordable add-ons can help you exchange data prec<strong>is</strong>ely<br />

and easily with your customers that are using these formats.<br />

Our sights are firmly set on <strong>CADKEY</strong> Version 20— the singlemost major release of <strong>CADKEY</strong> ever<br />

in its fifteen year h<strong>is</strong>tory. Th<strong>is</strong> significant release has been in the works for a three year period. We<br />

will introduce an all new architecture that incorporates all the features and functions users have<br />

asked for…smart assemblies, unlimited levels, new 2D drafting tools, improved layout mode and<br />

dimensioning, high speed graphics and printing/plotting, and more requested user enhancements.<br />

<strong>CADKEY</strong> Version 20 <strong>is</strong> scheduled for release in the Fall of 2000. We know th<strong>is</strong> software will be a<br />

crowd pleaser for all our customers.<br />

The <strong>CADKEY</strong> Web site <strong>is</strong> the most content-rich source of information for the <strong>CADKEY</strong><br />

Community. The site <strong>is</strong> constantly being updated with news, streaming video demonstrations,<br />

new value-added products and services in the Web Store, and much more. We encourage new<br />

users and our veteran <strong>CADKEY</strong> power users to interact via our <strong>CADKEY</strong> User Forum. Take a<br />

few minutes to check out our User Gallery of <strong>CADKEY</strong> images and User Profiles from very diverse<br />

industries. And don’t forget to sign up for <strong>CADKEY</strong> e-News, our online publication delivered<br />

right to your desktop.<br />

In the coming year, I strongly urge you to join our LiveCasts featuring daily demonstrations and<br />

regularly scheduled <strong>CADKEY</strong> CyberClasses via the Internet. Reg<strong>is</strong>tration information for e-Demos<br />

and <strong>CADKEY</strong> CyberClasses can be found at www.cadkey.com.To participate in the real-time<br />

e-Sessions, users must sign up prior to the event.<br />

Enjoy <strong>CADKEY</strong> 99, <strong>CADKEY</strong> <strong>PARAMETRICS</strong>, and most of all, the upcoming Summer season.<br />

Best Regards,<br />

Robert W. Bean, P.E.<br />

President and CEO, <strong>CADKEY</strong> Corporation<br />

The Senior Management Team at <strong>CADKEY</strong><br />

The <strong>CADKEY</strong> MAGAZINE <strong>is</strong> publ<strong>is</strong>hed by <strong>CADKEY</strong> Corporation. Th<strong>is</strong><br />

publication <strong>is</strong> designed to provide accurate and authoritative information<br />

about the <strong>CADKEY</strong> product line and related products and services utilized<br />

for mechanical engineering applications. We welcome suggestions and<br />

comments. Please send your feedback to: editor@cadkey.com<br />

Copyrights & Trademarks<br />

<strong>CADKEY</strong> Magazine © 2000 <strong>CADKEY</strong> Corporation. All rights reserved.<br />

<strong>CADKEY</strong>, <strong>CADKEY</strong> DESIGN SUITE, <strong>CADKEY</strong> <strong>PARAMETRICS</strong>, <strong>CADKEY</strong><br />

WIREFRAME, FastSURF, DRAFT-PAK, <strong>CADKEY</strong> POWER-PAK and<br />

<strong>CADKEY</strong> TRUE TEXT are trademarks or reg<strong>is</strong>tered trademarks of <strong>CADKEY</strong><br />

Corporation. Microsoft, Windows, and MS-DOS are trademarks or reg<strong>is</strong>tered<br />

trademarks of Microsoft, Corp. ACIS <strong>is</strong> a reg<strong>is</strong>tered trademark of Spatial<br />

Technology Inc. Information in th<strong>is</strong> document <strong>is</strong> believed accurate at time of<br />

printing, however we reserve the right to modify our products. All other<br />

brand and product names are trademarks or reg<strong>is</strong>tered trademarks of their<br />

respective owners.<br />

————————————<br />

To be removed from th<strong>is</strong> mailing l<strong>is</strong>t, please FAX a request to Marketing Dept.<br />

at (508) 229-2121. Please include the code # found on your address label.

WEB NEWS<br />

<strong>CADKEY</strong> Website Features Streaming<br />

Demos on <strong>CADKEY</strong> 99 Using RealPlayer ®<br />

Video demonstrations of <strong>CADKEY</strong> 99’s newest features<br />

have never been easier to view. Using Realplayer software,<br />

<strong>CADKEY</strong> users can observe the newest innovations in<br />

<strong>CADKEY</strong> 99 including the Body Healer, Advanced Blending<br />

features, new solid modeling Local Operators, and the product’s<br />

superior overall interoperability. If you have a 28K Internet<br />

connection or higher, you do not have to download the demo to<br />

view it. The streaming demonstrations are a perfect complement<br />

to <strong>CADKEY</strong> LiveCast Demos. Check out a variety of topics at<br />

www.cadkey.com/gallery/video.<br />

New – <strong>CADKEY</strong> <strong>PARAMETRICS</strong><br />

Part 2 of 3 Overview Now Available<br />

Th<strong>is</strong> streaming video covers the following Sketching topics:<br />

Planes, Sketches, and Constraints. Special sketching tools in<br />

<strong>CADKEY</strong> <strong>PARAMETRICS</strong> offer significant enhancements to the<br />

basic task of two-dimensional<br />

drawing and can be<br />

applied to more than just<br />

solid modeling. Sketch<br />

entities and dimensions<br />

utilize animated “click and<br />

drag” placement and editing<br />

capabilities for improved<br />

v<strong>is</strong>ualization and a reduced<br />

number of menu selections.<br />

Dimensions and geometric<br />

constraints (such as coincident, parallel, tangent and equal size)<br />

hold or drive the desired form of a sketch profile during editing.<br />

Sketching also provides a quick means of creating simple 2D<br />

drawings. V<strong>is</strong>it the GALLERY section of www.cadkey.com to<br />

view our wide array of streaming videos!<br />

Algor Holds Live Webcasts Every Tuesday<br />

Featuring InCAD Plus for <strong>CADKEY</strong><br />

Algor <strong>is</strong> now hosting live one-hour Webcasts for<br />

cyberv<strong>is</strong>itors who want to learn more about Algor’s InCAD Plus<br />

FEA software for mechanical engineers. These free, public<br />

Webcasts give <strong>CADKEY</strong> users the opportunity to see Algor<br />

software in action with <strong>CADKEY</strong> 99. After the live broadcast,<br />

Webcasts are also made available for replay for a personal<br />

screening at any time.<br />

The one-hour Webcast covers general news about InCAD Plus<br />

for <strong>CADKEY</strong> and the host answers frequently asked technical<br />

questions received by telephone or e-mail before and during the<br />

broadcast. The main presentation shows how to access InCAD Plus<br />

from <strong>CADKEY</strong> and covers a variety of FEA capabilities including<br />

full analys<strong>is</strong> tools within <strong>CADKEY</strong>, feature suppression tools,<br />

surface and solid meshing options, and the report Wizard and<br />

VRML. Additional topics are working with assemblies, surface<br />

loading, applying boundary conditions, performing analys<strong>is</strong><br />

and reviewing the results. The Webcast also includes a panel<br />

d<strong>is</strong>cussion on the main topic. To access Algor Webcasts, go<br />

to www.algor.com/webcast.<br />

<strong>CADKEY</strong> WEB CONNECTION Adds<br />

PlotFast for Windows<br />

<strong>CADKEY</strong> Annual Update Contract (AUC) Customers can<br />

take advantage of PlotFast for Windows, another free value-added<br />

technology available through the <strong>CADKEY</strong> WEB CONNECTION at<br />

www.cadkey.com. PlotFast for Windows <strong>is</strong> an offline utility that<br />

works specifically with the <strong>CADKEY</strong> Uniplot format (.PLT). Th<strong>is</strong> utility<br />

<strong>is</strong> beneficial for <strong>CADKEY</strong> users who have older vector plotters and/or<br />

plotters not supported in Windows. PlotFast<br />

<strong>is</strong> also useful for companies who need vector<br />

HPGL output for desktop publ<strong>is</strong>hing. AUC<br />

customers with the DOS PlotFast version can<br />

now upgrade to the Windows version at no<br />

charge. PlotFast for Windows features advanced batch plotting of .PLT<br />

files and allows users to easily assign different plot configurations.<br />

3<br />

The <strong>CADKEY</strong> WEB CONNECTION gives AUC customers access<br />

to free valuable resources such as downloadable programs,<br />

software utilities, and other special items to increase productivity<br />

when using <strong>CADKEY</strong>. Active <strong>CADKEY</strong> AUC clients can take<br />

advantage of these programs after reg<strong>is</strong>tering with their<br />

contract number.<br />

Free Downloadable Viewer For <strong>CADKEY</strong> 99<br />

The <strong>CADKEY</strong> 99 Viewer <strong>is</strong> an easy and convenient way to view<br />

<strong>CADKEY</strong> 99 partfiles. Great for <strong>CADKEY</strong> users and non-CAD users in<br />

your enterpr<strong>is</strong>e, the <strong>CADKEY</strong> 99 Viewer <strong>is</strong> free of charge, less than<br />

4 MB in size, and can be downloaded from the <strong>CADKEY</strong> website. The<br />

Viewer’s popular Windows interface makes it simple to use by departments<br />

outside of engineering, such as marketing, sales, support and<br />

service personnel. These departments do not have to learn or install a<br />

full <strong>CADKEY</strong> system in order to view a partfile.<br />

The <strong>CADKEY</strong> Viewer has many features to let you closely examine<br />

a design, but won’t let you change the file in any way. Users can print<br />

or plot to all Windows-supported devices from the Viewer. When<br />

viewing a 3D model, you can measure any size/d<strong>is</strong>tance and verify<br />

entity attributes and positions. You can also use standard <strong>CADKEY</strong> pan,<br />

zoom and rotate tools to view a <strong>CADKEY</strong> model. Toggle between 3D<br />

model mode and any drawing layouts. The Viewer has full support for<br />

all <strong>CADKEY</strong> entity types and text.<br />

You can also open multiple files at the same time with MDI<br />

(Multiple Document Interface), as well as export images to a Windows<br />

Metafile or raster/vector clipboard. Minimum system requirements are<br />

Windows 95, 98 or NT 4.0; 16 MB RAM; 6 MB hard drive space for<br />

installation; and 640 x 480 resolution.<br />

<strong>CADKEY</strong> eNews - Delivered to Your Desktop<br />

<strong>CADKEY</strong> eNews <strong>is</strong> a free monthly online compilation of <strong>CADKEY</strong><br />

top stories, upcoming events, product announcements, <strong>CADKEY</strong><br />

community and industry news. <strong>CADKEY</strong> users and those interested in<br />

receiving th<strong>is</strong> free cybernews source can sign up by v<strong>is</strong>iting the<br />

<strong>CADKEY</strong> website at www.cadkey.com. It <strong>is</strong> easy to subscribe—<br />

simply enter your email address in the <strong>CADKEY</strong> eNews section at the<br />

bottom of the <strong>CADKEY</strong> home page at www.cadkey.com.

In the News<br />

<strong>CADKEY</strong> <strong>PARAMETRICS</strong> <strong>is</strong> <strong>Released</strong>!<br />

Limited-time Promotions -<br />

Upgrade Now and Save $$$<br />

Parametric modeling inside <strong>CADKEY</strong> <strong>is</strong> now a reality, and a<br />

phenomenal new option! <strong>CADKEY</strong> <strong>PARAMETRICS</strong> fully integrates<br />

complete parametric definition and editing of dimension-driven<br />

solid models into the award-winning <strong>CADKEY</strong> software. Providing<br />

an unrivaled depth of design functionality, <strong>CADKEY</strong> 99 and its<br />

companion <strong>CADKEY</strong> <strong>PARAMETRICS</strong> offer unique hybrid combinations<br />

of feature-based solid modeling and impressive freeform<br />

hybrid solid modeling to give you the ultimate toolset for product<br />

design and manufacturing applications. <strong>CADKEY</strong> <strong>PARAMETRICS</strong><br />

will sell for $ 1,195 USD for <strong>CADKEY</strong> 99 customers and <strong>is</strong> free of<br />

charge to all <strong>CADKEY</strong> DESIGN SUITE customers.<br />

SPECIAL INTRODUCTORY PROMOTIONS<br />

• Save $ 200! <strong>CADKEY</strong> 99 users can purchase <strong>CADKEY</strong><br />

<strong>PARAMETRICS</strong> for just $ 995 USD.<br />

• Save $ 400! Customers with previous <strong>CADKEY</strong><br />

versions can Upgrade to <strong>CADKEY</strong> 99 and get a one year<br />

<strong>CADKEY</strong> AUC* plus <strong>CADKEY</strong> <strong>PARAMETRICS</strong> for only<br />

$ 1,995 USD.<br />

• Save over $ 250 ! <strong>CADKEY</strong> 99 customers can Upgrade<br />

to <strong>CADKEY</strong> DESIGN SUITE (FastSURF, DRAFT-PAK,<br />

<strong>CADKEY</strong> <strong>PARAMETRICS</strong>, and all-inclusive AUC*)<br />

for only $ 1,995 USD.<br />

These Special Introductory Offers End September 1, 2000! Call<br />

your <strong>CADKEY</strong> VAR for Additional Promotions and Details!<br />

Note: Prices may vary outside the US and Canada<br />

* AUC = Annual Update Contract<br />

<strong>CADKEY</strong> Financial Update<br />

by Robert C. Macomber - Chief Financial Officer<br />

Since founded in 1989, <strong>CADKEY</strong> Corporation<br />

(formerly known as Baystate Technologies, Inc.)<br />

has seen increasing revenues every year. The<br />

third quarter of our current f<strong>is</strong>cal year ended on<br />

March 31, 2000, and I am happy to report that<br />

our sales are good and earnings are up from<br />

the prior quarter. Our balance sheet remains healthy and our<br />

cash position <strong>is</strong> strong. The heavy investments we have been<br />

making in product development over the past year and a half<br />

are beginning to drive our sales figures. <strong>CADKEY</strong> 99 has already<br />

proven to be a robust, stable release; <strong>CADKEY</strong> <strong>PARAMETRICS</strong> <strong>is</strong><br />

ready; <strong>CADKEY</strong> 20 <strong>is</strong> in alpha, and many new offerings are<br />

about to appear on our <strong>CADKEY</strong> Webstore. All signs point to a<br />

very good upcoming quarter!<br />

4<br />

<strong>CADKEY</strong>'s Superior Interoperability<br />

Expands with Three New Data<br />

Translators<br />

<strong>CADKEY</strong> Corporation announced that th<strong>is</strong> summer it will<br />

be releasing three new Windows-based translators which will<br />

allow <strong>CADKEY</strong> users to directly translate Catia ® , Pro/E ® and<br />

Unigraphics ® files. The new Catia translator will offer two-way<br />

translation of geometry and topology data for Catia (*.model /<br />

*.exp) files. The Catia translator supports bi-directional conversions<br />

of solid and surface entities. The Pro/E and Unigraphics<br />

translators will allow those native files to be directly imported<br />

into <strong>CADKEY</strong>, supporting a uni-directional conversion of solid<br />

and surface entities. Details on pricing and availability will be<br />

announced on our website shortly at www.cadkey.com.<br />

Robert W. Bean Joins Industrial Review<br />

Board for Innovative Advanced Technology<br />

Project Launched by STEP Tools, Inc.<br />

Robert W. Bean, President and CEO of <strong>CADKEY</strong> Corporation,<br />

and John Ryan, VP of <strong>CADKEY</strong> Product Development, will<br />

participate as members of STEP Tools, Inc.’s newly formed<br />

Industrial Review Board (IRB) cons<strong>is</strong>ting of leading manufacturers,<br />

software vendors and machine tool controls companies.<br />

STEP Tools launched their $2M Advanced Technology Project<br />

(ATP) with a kick-off meeting in December 1999. The ATP<br />

Award was <strong>is</strong>sued to STEP Tools, Inc. by the National Institute of<br />

Standards and Technology, an agency of the U.S. Commerce<br />

Department’s Technology Admin<strong>is</strong>tration. The ATP award will<br />

fund STEP Tool’s “Model Driven Intelligent Control of Manufacturing”<br />

project, dubbed the Super Model project, to develop an<br />

integrated design-to-manufacturing system that allows numerically<br />

controlled (CNC) machine tools to be controlled by product<br />

design data.<br />

As a member of the Industrial Review Board, Mr. Bean will<br />

participate in an adv<strong>is</strong>ory capacity for over a three year period,<br />

as STEP Tools leads the development of a prototype integrated<br />

data-sharing system for design-to-manufacturing. The STEP<br />

Tools Industrial Review Board includes a cross-section of<br />

members from all sectors of the industrial marketplace: NIST<br />

Intelligent Systems Div<strong>is</strong>ion, IBM Corporation, The Boeing<br />

Company, Lawrence Livermore National Laboratory, NASA/<br />

GSFC, General Motors Powertrain, Lockhead Martin Tactical<br />

Aircraft Systems, General Electric CR&D, GE Fanuc Automation,<br />

FIPER project, General Dynamics Land Systems, National Center<br />

for Manufacturing Sciences, NIIIP Development Office, Hurco<br />

Machine Tool Products, Monarch Machine Tool Company and<br />

CIMPlus, Inc. CAM software vendors include Gibbs and<br />

Associates and CNC Software, Inc.<br />

Prices reflect US domestic, manufacturer’s suggested retail; prices outside the United States will vary significantly<br />

due to currencies, exchange rates, import tariffs and taxes, value added taxes and shipping and<br />

handling costs. Please contact your local d<strong>is</strong>tributor. Resellers are free to establ<strong>is</strong>h their own selling prices.

<strong>CADKEY</strong> Aids in STEP Tools Demonstration<br />

of STEP-NC Progression<br />

STEP Tools will be hosting their second meeting of the<br />

“Super Model” Industrial Review Board on Thursday, May 25<br />

and Friday, May 26, 2000 in Troy, NY. The main focus of th<strong>is</strong><br />

meeting <strong>is</strong> to show project progression, and d<strong>is</strong>cuss plans for<br />

upcoming deliverables. STEP Tools will show a STEP-NC database<br />

containing all the information required to manufacture the<br />

Super Model test part. In December 1999, STEP Tools previewed<br />

a spreadsheet being used to add ISO 14649 manufacturing<br />

features to STEP geometry. At th<strong>is</strong> second meeting, STEP will<br />

complete the database by adding manufacturing strategy, path<br />

planning and tool selection information. As part of the demonstration,<br />

STEP Tools will also show <strong>CADKEY</strong> and FBMach Process<br />

Planning system both creating data similar to that required by<br />

ISO 14649 manufacturing standards.<br />

HighRES SuperLite Reverse<br />

Engineering Software Offered<br />

on <strong>CADKEY</strong> Webstore<br />

<strong>CADKEY</strong> Corporation continues to expand its Web<br />

commerce by offering the HighRES SuperLite version ($ 995.00<br />

USD) of reverse engineering software on the <strong>CADKEY</strong> Webstore<br />

at www.cadkey.com/webstore. Online Shoppers will find<br />

HighRES SuperLite both affordable and seamless with<br />

<strong>CADKEY</strong> 99.<br />

HighRES <strong>is</strong> now also shipping a new release of advanced<br />

3D reverse engineering software products for <strong>CADKEY</strong> 99<br />

including HighRES SuperLite,<br />

HighRES SmartPlanes,<br />

HighRES Studio, and two<br />

power modules— HighRES<br />

SuperSpline and HighRES<br />

SmartChain. With a new<br />

CDE (<strong>CADKEY</strong> Dynamic<br />

Extension) interface,<br />

HighRES products run at<br />

executable speeds while<br />

sharing the <strong>CADKEY</strong><br />

database for geometry<br />

definitions and storage.<br />

HighRES has redesigned its<br />

HighRES and <strong>CADKEY</strong> were used to<br />

3D digitize th<strong>is</strong> hand-sculpted candy icon-driven menu structure<br />

mold that was then sent for mold to reflect its tiered reverse<br />

making to mass produce candies. engineering solutions.<br />

<strong>CADKEY</strong> users can choose from entry level, mid-level or<br />

advanced HighRES products with two additional modules<br />

specific to digitizer enhancements or unique boundary treatments.<br />

<strong>CADKEY</strong> users can also create and customize reverse<br />

engineering icons specific to the features they use most often in<br />

a worksession.<br />

5<br />

ARTICLES OF INTEREST<br />

Read About <strong>CADKEY</strong> and <strong>CADKEY</strong> Users in Industry Publications.<br />

For additional articles, v<strong>is</strong>it www.cadkey.com<br />

MARCH 2000<br />

■ Redesigned Fixture Reduces Turning Time for Tool Manufacturers,<br />

JOB SHOP TECHNOLOGY, March 2000<br />

■ CAD software, QUALITY, March 2000<br />

■ Surfacing Features Make Modeler a Reverse-Engineering Tool,<br />

MACHINE DESIGN, March 23, 2000<br />

■ The Best Program for Learning CAD,<br />

THE TECHNOLOGY TEACHER, March 15, 2000<br />

■ Shipping No<strong>is</strong>e Out To Sea,<br />

PRODUCT DESIGN & DEVELOPMENT, January 2000<br />

FEBRUARY 2000<br />

■ Designing An Uncommon Stick,<br />

MECHANICAL ENGINEERING, February 2000<br />

■ <strong>CADKEY</strong> Crafts Key Feature for Advanced Solid Modeling,<br />

MANUFACTURING AUTOMATION, February 2000<br />

■ Parametric Capability Enhances CAD Software,<br />

INJECTION MOLDING, February 2000<br />

■ Editor’s Observations: Engineering, START, February 2000<br />

JANUARY 2000<br />

■ Buying into the Technology Factor,<br />

MOLDMAKING TECHNOLOGY, January 2000<br />

■ <strong>CADKEY</strong> 99 Provides CAD Interoperability, CADALYST, January 2000<br />

■ CAD Software 1, ENGINEERING AUTOMATION REPORT,<br />

January 2000<br />

■ Editor’s Observations: Engineering, START, Bob Rakow, January 2000<br />

■ Redesigned Fixture Reduces Turning Time for Tool Manufacturer,<br />

JOB SHOP TECHNOLOGY, January 2000<br />

■ Engineering the Off-Road Race Truck,<br />

MACHINE DESIGN, January 27, 2000.<br />

■ Creating Constellations with CAD, CAD SYSTEMS, January 2000<br />

■ Handling the Curves: Hybrid Modeling for Complex Surfaces,<br />

DESKTOP ENGINEERING, January 2000<br />

NOVEMBER 1999<br />

■ CAD/CAM Tools Aim at Moldmakers,<br />

MOLDING SYSTEMS, November 1999<br />

■ Wire-frame, 2D CAD, and Solid Modeling in One Design Package,<br />

MACHINE DESIGN, November 1999<br />

■ MMS Shop Talk, MODERN MACHINE SHOP, November 1999<br />

■ Transitioning to 3D <strong>is</strong> Easier Than You Might Think,<br />

DESIGN NEWS, November 1, 1999<br />

■ High Technology Corporate Notes,<br />

BOSTON BUSINESS JOURNAL, November 18, 1999<br />

OCTOBER 1999<br />

■ Entry level MCAD, COMPUTER GRAPHICS WORLD, October 1999<br />

■ Machine Different Views with NC Programming System,<br />

MODERN MACHINE SHOP<br />

■ Selling the Key to e-CAD, CANADIAN COMPUTER RESELLER,<br />

October 6, 1999<br />

■ <strong>CADKEY</strong> and Pure Geometry: The Key to Interoperability,<br />

GLOBAL DESIGN NEWS, October 15, 1999

<strong>CADKEY</strong> Corporation Prepares For the<br />

EASTEC 2000 Trade Show in May<br />

<strong>CADKEY</strong> Corporation will exhibit at the EASTEC Trade Show held<br />

at the Big E Exposition Center in Springfield, MA from May 23-25,<br />

2000. EASTEC <strong>is</strong> the largest regional industrial trade show in New<br />

England. You are cordially invited to stop by and get a hands-on<br />

demonstration of the entire <strong>CADKEY</strong> product line in Booth #6051<br />

in Building 6. EASTEC show hours are 9am to 6pm on Tuesday<br />

and Wednesday, 9am to 5pm on Thursday.<br />

European Road Show Rescheduled<br />

for May 15 – 20, 2000<br />

Mark C. Graveline, VP of Sales, will be the featured guest<br />

speaker at <strong>CADKEY</strong> User Meetings to be held in in the U.K., France<br />

and Italy. He will be joined by Luca Cariglia, <strong>CADKEY</strong> Corporation’s<br />

European Sales Representative. Mr. Graveline will speak about the<br />

<strong>CADKEY</strong> <strong>PARAMETRICS</strong> product and the “all new” <strong>CADKEY</strong> 20,<br />

which <strong>is</strong> scheduled for release later th<strong>is</strong> year. <strong>CADKEY</strong> customer sites<br />

will also be v<strong>is</strong>ited to view first-hand how <strong>CADKEY</strong> <strong>is</strong> used in applications<br />

such as moldmaking, intricate jewelry design, machine design<br />

and manufacturing.<br />

The first User Meeting will be hosted by <strong>CADKEY</strong> D<strong>is</strong>tributor<br />

Radix Solutions Ltd (www.radix-solutions.com), in Dorset, UK on<br />

May 15. The next stop will be on May 16-17 in Cedex, France at the<br />

headquarters of ATLP (www.cadkey-fr.com) the #1 <strong>CADKEY</strong> D<strong>is</strong>tributor<br />

for Europe last year. The two will conclude their trip in Italy with a<br />

v<strong>is</strong>it to UNOCAD (www.unocad.it), long-time <strong>CADKEY</strong> D<strong>is</strong>tributor, on<br />

May 18-19. UNOCAD will conduct customer v<strong>is</strong>its as well as a User<br />

Group meeting on May 19th. For more information, v<strong>is</strong>it<br />

www.cadkey.com/events.<br />

“Dr. Walt” / Pro Cad, Inc. Hosts<br />

<strong>CADKEY</strong> USER EVENT May 4th<br />

On May 4th “Dr. Walt” hosted a <strong>CADKEY</strong> DAY of <strong>CADKEY</strong> 99<br />

Productivity Demonstrations, Power Technical Sessions, Super Macros<br />

Session, and a Doctor Walt’s <strong>CADKEY</strong> Clinic! <strong>CADKEY</strong> Corp representatives<br />

Mark Graveline (VP Sales), Dale Arseneault (VAR Manager) and<br />

Andy Beaupre (Application Engineer) were there to answer questions<br />

and help demonstrate the new <strong>CADKEY</strong> <strong>PARAMETRICS</strong>, as well as<br />

show a sneak preview of the soon-to-be-released <strong>CADKEY</strong> 20.<br />

Every attendee received a free Doctor Walt’s Book! Pro CAD, Inc.<br />

<strong>is</strong> an Authorized <strong>CADKEY</strong> Reseller.<br />

6<br />

RECENTLY HELD EVENTS…<br />

Parametrics Module and <strong>CADKEY</strong>’s Unrivaled Depth<br />

of Design Functionality Highlighted at NDES 2000<br />

<strong>CADKEY</strong> Corporation presented the all-new <strong>CADKEY</strong><br />

<strong>PARAMETRICS</strong> for <strong>CADKEY</strong> 99 and <strong>CADKEY</strong> DESIGN SUITE at<br />

the National Design Engineering Show (NDES), McCormick Place<br />

(Chicago, IL) from March 13 to 16, 2000. Attendees got a birdseye<br />

view of the much<br />

anticipated <strong>CADKEY</strong><br />

<strong>PARAMETRICS</strong> product<br />

that rounds out<br />

<strong>CADKEY</strong>’s extensive<br />

range of freeform 3D<br />

automation tools. Also<br />

highlighted during the<br />

trade show was<br />

<strong>CADKEY</strong>’s superior<br />

interoperability and its<br />

essential “collection” of<br />

features needed for the<br />

highest level of data<br />

handling and compatibility:<br />

1) an open hybrid<br />

modeling environment,<br />

2) world class data<br />

translators, 3) core<br />

technology based on<br />

pure geometry, and<br />

4) the most extensive set<br />

of design, edit, and<br />

validation tools in the<br />

PC-CAD industry.<br />

Free hands-on<br />

training sessions for<br />

<strong>CADKEY</strong> Users were also<br />

hosted by <strong>CADKEY</strong><br />

Corporation during the<br />

entire NDES Show.<br />

Training topics included<br />

parametric functionality,<br />

The <strong>CADKEY</strong> Team at NDES 2000 (L to R):<br />

John Ryan, Dale Arseneault, Va<strong>is</strong>hali<br />

Mehta, Lizabeth Rombek, and Mark<br />

Graveline.<br />

and power design and<br />

productivity tips and<br />

tricks that take advantage<br />

of <strong>CADKEY</strong>’s<br />

unique hybrid modeling.<br />

<strong>CADKEY</strong> was demonstrated on powerful HEWLETT-PACKARD<br />

machines at NDES 2000. Special thanks to the HP team for<br />

their support and sponsorship in providing PC’s for the<br />

<strong>CADKEY</strong> booth, training and User Group!

National <strong>CADKEY</strong> User Group Meeting<br />

Held at NDES 2000<br />

<strong>CADKEY</strong> Corporation hosted the National <strong>CADKEY</strong> User<br />

Group Meeting at the National Design Engineering Show, on<br />

March 14 and 15, 2000, at McCormick Place North, Chicago.<br />

Mark Graveline, Vice President of Sales, d<strong>is</strong>cussed the company’s<br />

exciting, innovative plans for the Year 2000 and beyond. Attendees<br />

enjoyed demonstrations of the newest <strong>CADKEY</strong> products, as<br />

well as news about the upcoming <strong>CADKEY</strong> 20 release.<br />

Europeans Get Sneak Peek of <strong>CADKEY</strong><br />

<strong>PARAMETRICS</strong> at CeBit 2000 –<br />

the Largest European Trade Show<br />

<strong>CADKEY</strong> European D<strong>is</strong>tributors presented the full <strong>CADKEY</strong><br />

product line and previewed <strong>CADKEY</strong> <strong>PARAMETRICS</strong> at CeBit<br />

2000, held in Hannover, Germany on Feb 24 – March 1 st , 2000.<br />

CeBit, one of the largest computer trade shows in the world, <strong>is</strong><br />

held in 25 halls with more than half a million v<strong>is</strong>itors each year.<br />

<strong>CADKEY</strong> hosted the booth with six<br />

of their major European D<strong>is</strong>tributors:<br />

AGS GmbH (Germany, Switzerland<br />

and Austria), ATLP (France), Radix<br />

Solutions Ltd (UK & Eire), UNOCAD<br />

(Italy), VLECAD (Benelux), and 3E<br />

Praha Engineering (Czech Republic,<br />

Slovakia, Poland, Bulgaria). <strong>CADKEY</strong><br />

Corporation’s Mark Graveline, VP of Sales, and Luca Cariglia,<br />

European Sales, were on hand to support the show activities.<br />

The <strong>CADKEY</strong> product line <strong>is</strong> represented throughout Eastern and<br />

Western Europe by over 20 D<strong>is</strong>tributors and a network of sub-<br />

Dealers. The product has been translated into many international<br />

language versions including German, French, Italian, Span<strong>is</strong>h,<br />

Portuguese, Czechoslovakian, Hungarian, Hebrew and more.<br />

Special thanks to longtime <strong>CADKEY</strong> D<strong>is</strong>tributor AGS GmbH for<br />

coordinating the show and making it a success!<br />

ATLP Features <strong>CADKEY</strong> Products at<br />

MICAD 2000 in Par<strong>is</strong>, France<br />

ATLP, <strong>CADKEY</strong>’s major d<strong>is</strong>tributor for France, attended the<br />

MICAD 2000 trade show held in Par<strong>is</strong>, France on March 28–30,<br />

2000. The company previewed the <strong>CADKEY</strong> PARAMETRIC<br />

module for the French audience, and demonstrated <strong>CADKEY</strong>’s<br />

hybrid environment offering wireframe, surface and solid<br />

modeling. ATLP<br />

(www.cadkey-fr.com) has<br />

been recognized as <strong>CADKEY</strong><br />

Corporation’s #1 International<br />

D<strong>is</strong>tributor for both<br />

1998 and 1999.<br />

7<br />

2000 L<strong>is</strong>ting of Value Added Resellers<br />

North America <strong>CADKEY</strong> Resellers and Office Locations<br />

3D Tech<br />

OK, KS, MO<br />

3DATUM<br />

GA, TN, AL, TX, FL<br />

A.C.C. System, Inc<br />

NY<br />

Acuity, Inc.<br />

OR<br />

Advanced Business Systems, Inc. IL<br />

Albright Design Solutions CA<br />

All Set Manufacturing Solutions CA<br />

Anderson CAD/CAM Inc. MN<br />

Cad Wire<br />

Canada<br />

CAE Systems Inc.<br />

MI<br />

CIM Solutions & Networking MI, OH<br />

Cincinnati CAD Systems<br />

OH<br />

Computer-Source of LA, Inc. LA<br />

Cornerstone Technology<br />

MI, Canada<br />

D<strong>is</strong>tance Engineering<br />

MI<br />

High-Res, Inc.<br />

CA<br />

Marchetti Design & Engineering MA, NY<br />

Maven Micro Systems<br />

CA, CO<br />

Mid-West Tech<br />

IA<br />

New Tech!<br />

WI<br />

Olmsted Engineering<br />

MI<br />

OptiPro Systems<br />

NY<br />

Prec<strong>is</strong>ion CAD/CAM Systems MD, NY, PA, VA<br />

ProCAD Inc.<br />

NJ<br />

Quality Inspection<br />

CA<br />

Quannon CAD Systems<br />

MN<br />

Software Ventures<br />

MI<br />

Tech Ed Concepts, Inc.<br />

MA, NH<br />

Tech-Net<br />

WA<br />

Tri-Tech Solutions, Inc.<br />

NC<br />

Unitec, Inc<br />

CT<br />

International <strong>CADKEY</strong> Resellers and Territories<br />

3E Praha Engineering<br />

Czech Republic, Poland, Slovakia<br />

AGS<br />

Germany, Switzerland, Austria<br />

Altec Research International Taiwan, Hong Kong, China<br />

AME<br />

Sweden<br />

Arqui Punto Systems<br />

Spain<br />

ATLP<br />

France<br />

CAD Design<br />

Denmark<br />

CAG CAD/CAM<br />

Turkey<br />

Caliber Engineering<br />

Israel<br />

Champion Tool<br />

Thailand<br />

Computek<br />

Taiwan, Hong Kong, China<br />

Daesung Industrial<br />

Korea<br />

DIO Enterpr<strong>is</strong>es<br />

Norway<br />

EuroCAD Ltd<br />

Hungary<br />

Hi-Smart International<br />

Taiwan, Hong Kong, China<br />

IME Trading Co.<br />

Indonesia, Malaysia, Singapore<br />

Kubotek Corporation<br />

Japan<br />

Mecad Systems<br />

South Africa<br />

NewCAM<br />

Portugal<br />

Optim Systems<br />

Greece<br />

PB Systems/MET Cad<br />

Turkey<br />

PCS / GB Tool / ECS<br />

New Zealand<br />

Powerway de Mexico<br />

Mexico<br />

Radix<br />

United Kingdom<br />

Sia Colla<br />

Latvia, Lithuania, Estonia, Russia<br />

Sigemaz<br />

Portugal<br />

Specialized Technical Services Australia, New Zealand, Vietnam<br />

TechCadd Technologies<br />

Brazil<br />

Unocad<br />

Italy<br />

VLECAD<br />

Belgium, Netherlands, Holland<br />

Zenex<br />

Finland<br />

For more details v<strong>is</strong>it www.cadkey.com

<strong>CADKEY</strong><br />

Feature Story<br />

<strong>CADKEY</strong> Helps Excimer Laser<br />

Pioneer Spectranetics Corp. to<br />

Design Life-Saving Products<br />

Heart pacemakers save many lives, and doctors annually<br />

implant them, along with their defibrillator lead wires, in some<br />

500,000 patients worldwide. However, removing a defective<br />

pacemaker or defibrillator leads could cost lives as well.<br />

An installed heart pacer has from one to three lead wires<br />

running from the pacemaker to the patient’s heart. After a<br />

period of time, the pacer or the wire leads<br />

may fail and need to be replaced.<br />

“Doctors used to leave the wires in<br />

place because, over time, scar t<strong>is</strong>sue<br />

grows over them and they can become<br />

difficult and hazardous to remove,” said<br />

Paul Hollendorfer, laser systems engineer<br />

for The Spectranetics Corporation<br />

(NASDAQ:SPNC), Colorado Springs, CO,<br />

one of the first and most successful<br />

companies to develop photo-ablative<br />

excimer lasers for cardiovascular use.<br />

“Doctors were reluctant to extract them<br />

because the old kind of retractors required<br />

a lot of force, which could tear arteries<br />

and cause other dangerous complications.<br />

So they tended to leave them, and place<br />

new ones in the patient as well.”<br />

Then, a pacemaker manufacturer recalled the leads from<br />

some of their pacemakers because the tips of the leads could<br />

split – leaving sharp wire ends that possibly could puncture the<br />

heart sac. Several patients died, but even with such a frightening<br />

problem, doctors did not want to remove the leads because they<br />

believed removing them would be as dangerous as leaving them<br />

in place.<br />

Spectranetics,<br />

manufacturers of the<br />

CVX 300 excimer<br />

laser and laser procedure<br />

catheters, knew<br />

they could core out the<br />

leads safely. So their<br />

engineers designed the<br />

Spectranetics Laser<br />

Sheath (SLS) catheter to<br />

solve the hazardous<br />

problem.<br />

Hollendorfer describes the SLS as a hollow tube containing a<br />

ring of optic fibers and a radio-opaque tip at the end to allow<br />

the doctor to v<strong>is</strong>ualize the position of the device in the body by<br />

means of fluoroscopy. “The physician threads the catheter over<br />

the wire he wants to remove until the SLS hits res<strong>is</strong>tant scar or<br />

other unwanted t<strong>is</strong>sue. At that point, the doctor fires the laser<br />

and ablates – or d<strong>is</strong>solves – the scar<br />

t<strong>is</strong>sue and the SLS continues down the<br />

wire. It may encounter one or many<br />

binding sites, and it advances and<br />

ablates until the wire comes free.”<br />

The old lead removal procedure had<br />

a limited success rate – between 60%<br />

and 65% – underscoring physicians’<br />

fears of undertaking lead removal. In<br />

sharp contrast, since its introduction<br />

with full FDA approval in September<br />

1998, the SLS has proved 94% successful.<br />

“Our biggest hope,” said<br />

Hollendorfer, “now that we’ve provided<br />

a more effective way to remove old<br />

pacer leads, <strong>is</strong> that doctors will have<br />

them removed routinely – eliminating<br />

the unnecessary r<strong>is</strong>ks of infection and<br />

obstructive scar t<strong>is</strong>sue that result from leaving them in place.”<br />

In June 1999, the FDA l<strong>is</strong>ted the SLS as one of 21 “significant<br />

medical device breakthroughs” cleared by the agency in its<br />

1998 f<strong>is</strong>cal year.<br />

Spectranetics uses <strong>CADKEY</strong> for product design. They use<br />

the CAD program for designing and refining their core product,<br />

the CVX 300 excimer laser, and to document and manufacture<br />

catheter products, including the SLS. Hollendorfer explained,<br />

“Catheter design <strong>is</strong> esoteric. The components seem straightforward<br />

– plastic tubes, bundles of fiber optics and some form of<br />

radio-opaque tip. But they vary widely in design, depending<br />

upon use. So we design physical prototypes by hand on the<br />

R&D floor and then do assembly drawings with <strong>CADKEY</strong>, as well<br />

as using the CAD program to document the design.”<br />

The company gets many of its product ideas from the<br />

customer. “A doctor may say that he wants to do some specific<br />

thing, but has no way to do it. Our designers then try to<br />

v<strong>is</strong>ualize how that function can be performed better by the laser<br />

than by current technology,” he said. “With the SLS, we knew<br />

8

that the leads were<br />

embedded in scar t<strong>is</strong>sue, so<br />

we had to work out how to<br />

use the laser to remove the<br />

scar t<strong>is</strong>sue safely. We<br />

needed a cutting action –<br />

which dictated how to<br />

arrange the optical fibers.”<br />

In addition, when<br />

encasing the fiber in a<br />

plastic tube, “you can<br />

Th<strong>is</strong> image depicts a catheter ablating an unwanted blockage inside<br />

an artery which has been previously treated by an arterial stent.<br />

U.S. News & World<br />

Report’s 1999 ranking of<br />

America’s Best Hospitals<br />

have the Spectranetics<br />

CVX 300 laser installed:<br />

Cleveland Clinic, Mayo<br />

Clinic, Brigham and<br />

Women’s Hospital, Duke<br />

University Medical Center,<br />

Johns Hopkins Hospital,<br />

Texas Heart Institute,<br />

produce different degrees of stiffness and flexibility,”<br />

Hollendorfer said. “Prototyping engineers experiment with a<br />

number of different plastics and other materials to reach the<br />

flexibility the physician needs. For example, angioplasty catheters<br />

are very flexible, while the SLS needed to be stiffer.”<br />

Once the Spectranetics engineers design some physical<br />

models, doctors test the prototypes for usability, and the one<br />

found most acceptable undergoes testing at Spectranetics on<br />

heart and fluids models. “We document the design and run<br />

clinical trials after R&D testing,” Hollendorfer said. “After<br />

collecting and analyzing data gathered from the clinical trials,<br />

along with the physicians’ opinions, we’re sure the product <strong>is</strong><br />

safe and effective, and we apply to the FDA for approval.”<br />

The next step in the design cycle centers on making sure the<br />

design can be manufactured. “Sometimes these designs turn<br />

out too complex to reproduce. All these catheters are d<strong>is</strong>posable,<br />

and we have to ensure complete reproducibility to very,<br />

very tight tolerances. We may change the design to make it<br />

manufacturable. As we go along, we use <strong>CADKEY</strong> to document<br />

what we’ve done and to generate assembly drawings in a living<br />

document that reflects all changes in the design,” he said.<br />

From the design team, the <strong>CADKEY</strong> drawings go to the<br />

production department, where parts are procured for volume<br />

production. Once in full production mode, the drawings show<br />

the assemblers what and how to make and serve to verify that<br />

quality products go out the door. “The documentation we<br />

produce with <strong>CADKEY</strong> <strong>is</strong> needed both for FDA approval and for<br />

our own production lines,” Hollendorfer added.<br />

The engineers use <strong>CADKEY</strong> in its solids mode when<br />

designing new components for the CVX 300. “The laser <strong>is</strong> a very<br />

stable product,” said Hollendorfer, “but it’s continually being<br />

Emory University Hospital, Stanford University Hospital and<br />

Barnes Jew<strong>is</strong>h Hospital.<br />

The laser cons<strong>is</strong>ts of several complex mechanical assemblies:<br />

the laser vessel, optical train and the systems frame and<br />

cabinetry. “It has between 100 and 200 subassemblies,<br />

totaling at least several hundred parts in a machine that<br />

measures three feet tall by four feet long and two feet wide.<br />

Our design process goes from designing components to<br />

subassemblies, to the whole product.”<br />

To make their job easier and faster, the Spectranetics<br />

design engineers decided to build a library of all laser parts as<br />

<strong>CADKEY</strong> solid models. “So far, we’ve done about of all the<br />

parts. Th<strong>is</strong> library lets us respond very quickly to technology<br />

changes. For example, when we made an improvement in the<br />

laser’s cooling system, <strong>CADKEY</strong> made it possible for us to<br />

model all the new fans to see where they fit in the ex<strong>is</strong>ting<br />

framework – with no production guesswork.”<br />

Spectranetics began to use <strong>CADKEY</strong> in 1994, just after the<br />

release of Generation Four of the CVX 300. “Back then, we<br />

wanted to be able to give our assemblers 3D <strong>is</strong>ometric<br />

drawings for assemblies, because the new assemblies were<br />

smaller and more complex. <strong>CADKEY</strong> had the easiest to use 3D<br />

capability of all the programs we looked at, as well as being<br />

the best-priced program. Nowadays <strong>CADKEY</strong>’s flexibility <strong>is</strong><br />

most important to us. We use solid models as much as<br />

possible, and use the program to edit legacy data such as<br />

those 3D <strong>is</strong>ometric drawings – and also for its photo-real<strong>is</strong>tic<br />

modeling abilities. We can import <strong>CADKEY</strong> imagery into<br />

medical, investor and marketing presentations very easily – and<br />

that makes <strong>CADKEY</strong> very popular with the whole company,”<br />

Hollendorfer said.<br />

upgraded and updated.” Nine of the top 10 hospitals l<strong>is</strong>ted in<br />

9

<strong>PARAMETRICS</strong> - The Perfect Companion<br />

<strong>CADKEY</strong> <strong>PARAMETRICS</strong> was designed specifically for users<br />

looking to leverage <strong>CADKEY</strong>’s breadth of hybrid design functionality<br />

and enhance their productivity with feature-based solid<br />

modeling and/or constraint-based sketching tools. Our independent<br />

user survey told us that <strong>CADKEY</strong> users did not want to be<br />

forced into a parametric, solid-only system, nor give up the<br />

freeform design tools they love. So we choose to develop<br />

<strong>CADKEY</strong> <strong>PARAMETRICS</strong> as an integrated enhancement product<br />

for those who can truly leverage the technology.<br />

<strong>CADKEY</strong> <strong>PARAMETRICS</strong> significantly expands the hybrid<br />

modeling approach with a powerful level of interaction between<br />

traditional 2D drawing, wireframe, freeform solid, surface and<br />

feature-based modeling. Th<strong>is</strong> advancement <strong>is</strong> unprecedented in<br />

the mid-range CAD market. In typical <strong>CADKEY</strong> fashion,<br />

functions of th<strong>is</strong> new product can be accessed in a myriad of<br />

ways including hotkeys, icons, toolbars, classic mode, and an<br />

optional new folder tree and popup-menu system. The major<br />

time saving advantages to adding <strong>CADKEY</strong> <strong>PARAMETRICS</strong> to<br />

your current toolkit can be separated into three benefit categories;<br />

Feature-based Modeling, Hybrid Parametric and Sketching/<br />

Constraining.<br />

Feature-based Modeling<br />

<strong>CADKEY</strong> <strong>PARAMETRICS</strong> makes editing solids easy with full<br />

access to values used in each model’s creation and interactions<br />

between sets of features and parts.<br />

Changing the radius of a complex multi-edge fillet feature <strong>is</strong><br />

Fig.2 Four part assembly driven with one dimension.<br />

The creation of a set of prints for a family of parts can be<br />

automated by modeling and detailing a single parametric<br />

model. Adjusting the design parameters transforms the model<br />

and causes the layout to update automatically. Th<strong>is</strong> approach<br />

also prevents errors, saves the time in redrawing the other<br />

members of the family and allows changes to be propagated<br />

through the whole family, saving even more editing time.<br />

Another advantage of feature-based modeling <strong>is</strong> Suppression,<br />

which significantly accelerates the d<strong>is</strong>play of large parametric<br />

models by temporarily turning off individual or categories<br />

of detail-level features, such as fillets or small holes that are<br />

unimportant to the v<strong>is</strong>ual clarity of the model.<br />

Hybrid Parametric<br />

Typical mid-range parametric solid modeling software<br />

forces users to completely rebuild legacy data in their own<br />

proprietary feature-based format before any changes can occur.<br />

Because of <strong>CADKEY</strong> <strong>PARAMETRICS</strong> unique hybrid abilities, there<br />

<strong>is</strong> no need to rebuild ex<strong>is</strong>ting or imported solids. Parametric<br />

features can be added to and created from non-parametric<br />

solids. Even more impressive <strong>is</strong> th<strong>is</strong> integration still allows the<br />

non-parametric portions of a model to be edited with <strong>CADKEY</strong>’s<br />

extensive face modification functions.<br />

Features, such as the mold cavity (shown in Fig.3) formed<br />

Fig.1 Editing a fillet feature.<br />

as simple as selecting a blend face and typing in a new radius<br />

in the dialog as shown in Fig.1. In th<strong>is</strong> case, the parametric<br />

fillet feature had been previously added to the imported<br />

non-parametric solid shown.<br />

Changes to a group of parts with mating relationships such<br />

as the shaft, bushings and block (Fig.2) can easily be driven with<br />

a single variable. Updating mating parts th<strong>is</strong> way saves time and<br />

more importantly prevents errors that can result by editing each<br />

separately.<br />

10<br />

Fig.3 Parametric mold cavity created with<br />

an imported solid.

to <strong>CADKEY</strong><br />

Sketching/Constraining<br />

Special sketching tools in <strong>CADKEY</strong> <strong>PARAMETRICS</strong> offer<br />

major enhancement to the basic task of two-dimensional<br />

drawing and can be applied to more than just solid modeling.<br />

Sketch entities and dimensions utilize animated “click and<br />

drag” placement and editing capabilities resulting in improved<br />

v<strong>is</strong>ualization and a reduced number of menu selections.<br />

Fig.4 Creating features from a standard parts library.<br />

by subtracting the volume of an imported non-parametric solid,<br />

will update automatically if the imported solid <strong>is</strong> replaced or<br />

modified. The position of features such as water lines dependant<br />

on the cavity will also update appropriately or provide<br />

feedback if conflicts ar<strong>is</strong>e. Th<strong>is</strong> capability allows contract<br />

manufacturers to quickly re-apply value-added changes to a<br />

customer’s design if/when a new version <strong>is</strong> received.<br />

Hybrid parametric modeling allows standard design<br />

features, such as a bolt pattern for a model motor (shown in<br />

Fig.4), to be stored as a library of solids in industry-standard file<br />

formats like SAT, XT, STEP and IGES. Th<strong>is</strong> approach allows the<br />

Fig.5 Dimemsion-driven and constrained 2D drawing.<br />

library to be shared with other users and CAD systems.<br />

Designers experienced in parametric modeling will appreciate<br />

that many complex models with hundreds of features<br />

become very difficult to work with due to congestion in the<br />

feature tree. In many cases, significant numbers of design<br />

features don’t require parametric editing or definition. <strong>CADKEY</strong><br />

<strong>PARAMETRICS</strong> provides a solution to these <strong>is</strong>sues by allowing<br />

sets of features to be defined as a single non-parametric solid<br />

feature.<br />

Fig.6 Animation of Range of Motion of linkage and motor.<br />

Dimensions and geometric constraints (like coincident, parallel,<br />

tangent and equal size) hold or drive the desired form of a<br />

sketch profile during editing. Ordinarily a sketch would be<br />

extruded or swept to generate a solid, but not every part design<br />

or engineering task requires a 3D model. Sketching also<br />

provides a quick means of creating simple 2D drawings (see<br />

Fig.5). Intelligent associativity between 2D orthographic views<br />

can be constructed using constraints, so that changing the value<br />

of a dimension will update all views that are effected.<br />

A constrained 2D sketch can be used in the study of multilink<br />

kinematic mechan<strong>is</strong>ms. In the sketch (Fig.6), grabbing the<br />

link on the motor and dragging it in a circular path will animate<br />

the range of motion of the whole linkage.<br />

Ex<strong>is</strong>ting or imported wireframe data can be quickly<br />

converted into sketches and automatically constrained. Years of<br />

legacy CAD data can be re-used in th<strong>is</strong> manner to speed up the<br />

redesign process by aiding<br />

in the creation of<br />

adjustable<br />

parametric<br />

solid models.<br />

11

<strong>CADKEY</strong> Classroom<br />

Zero to Sixty in Less Than a Week!<br />

By Jacques P. Marchetti, President<br />

Marchetti Engineering<br />

Authorized <strong>CADKEY</strong> VAR and Training Center<br />

Performance cars are rated in terms of how fast a model<br />

can accelerate from 0 to 60 mph. The most favorable indices<br />

accompany models having well-balanced weight to drag<br />

coefficients. Although an important factor, engine power will<br />

play a small role in th<strong>is</strong> performance benchmark. CAD systems<br />

also have similar performance specs. Some CAD software<br />

packages are extremely robust, yet are notoriously complicated<br />

to learn, thus adding “drag” to the overall system. As an<br />

instructional facility, we find that <strong>CADKEY</strong> <strong>is</strong> exceptionally well<br />

balanced. With the right training, users can quickly meet and<br />

exceed their productivity goals often within time frames as little<br />

as one week.<br />

To be productive and to fully enjoy its benefits, particularly<br />

the workings of any CAD package, the user must be trained.<br />

Organizations especially sat<strong>is</strong>fied with their CAD solution are<br />

those which invest in their staff’s training on a continuing bas<strong>is</strong>.<br />

Coincidentally, these same organizations exhibit the best growth<br />

rates. Even the most experienced professionals,<br />

in diverse fields of expert<strong>is</strong>e, need training both<br />

when using new software or simply to maintain<br />

proficiency between interim upgrades. In some<br />

cases, users have been using only a small portion<br />

of the CAD tool’s power. They may only be using<br />

the 2D toolset and are not harnessing the 3D solid<br />

modeling power “under the hood.”<br />

There are no two ways around it. Locking<br />

yourself in a room for a month until you figure<br />

things out on your own <strong>is</strong>n’t effective. In case you<br />

haven’t noticed, manuals and on-line help are not<br />

getting any more detailed. I recall once reading the<br />

on-line help from one manufacturer’s CAD package,<br />

explaining the use of the HELIX command. It read as<br />

follows: “The HELIX function will create a HELIX. To<br />

use the Helix command, click the HELIX icon or, from<br />

the pull-down menu, click on HELIX. Then, select the elements<br />

that will be used to form the HELIX.” Th<strong>is</strong> <strong>is</strong> helpful? Given th<strong>is</strong><br />

type of content, it’s pretty safe to say that the days of selflearning<br />

are over.<br />

Or do you think technical support will solve all your<br />

problems? In many cases, customers will invest in a technical<br />

support agreement all for the wrong reasons. Contracts<br />

typically cost about $500 and are usually limited to <strong>is</strong>sues<br />

related to performance and suspected bugs. It <strong>is</strong> interesting to<br />

note that the majority of TS calls logged are not related to any<br />

of these <strong>is</strong>sues. In almost each case, the call <strong>is</strong> a “how to”<br />

question. Extended technical support <strong>is</strong> certainly a valuable<br />

option to have in place. As products become progressively more<br />

complex, the need to have a direct pipeline to a knowledgeable<br />

technician that can provide fast solutions <strong>is</strong> crucial to the<br />

software investment. But, th<strong>is</strong> support <strong>is</strong> never a substitute for<br />

training. How will you know what support to ask for if you<br />

don’t know what your software <strong>is</strong> designed to do? Our<br />

stat<strong>is</strong>tics show that companies or individuals that invest in<br />

training and maintain proficiency with their software maximize<br />

their in-house productivity. Training directly impacts the<br />

company’s bottom line. It’s a relational benefit.<br />

Now that we agree on the benefits of training, what kind<br />

of training will enable you to make the best use of your tools?<br />

Many VARS, including Marchetti Engineering, offer on-site<br />

training at your place of business. While th<strong>is</strong> might seem like<br />

the most convenient solution, th<strong>is</strong> type of training forum<br />

generally has a higher price tag associated with it because of its<br />

consultative nature. Your trainees may be d<strong>is</strong>tracted from the<br />

training by the ongoing workday demands and interruptions.<br />

Also, the trainer may be using machines that aren’t optimally<br />

configured for training purposes. Oftentimes, the scope of the<br />

desired training <strong>is</strong> not properly defined. Th<strong>is</strong> inability to communicate<br />

can leave you frustrated and d<strong>is</strong>heartened on taking<br />

future training sessions.<br />

Much more effective and economical <strong>is</strong><br />

formal classroom training. A good training facility<br />

<strong>is</strong> one which provides a state-of-the-art learning<br />

environment, and which presents the materials<br />

and curriculum in very logical manner. The best<br />

facilities offer a range of tiered curriculums<br />

starting with the very basics, and leading to<br />

more advanced, application–specific d<strong>is</strong>cussions.<br />

These facilities and their staffs are trained to<br />

respond to students various learning levels.<br />

An outgrowth of our years of classroom<br />

training <strong>is</strong> our soon to be released reference<br />

manual entitled Solids Modeling – Methods<br />

and Applications. Th<strong>is</strong> easy to use reference<br />

manual <strong>is</strong> a corollary to our teaching methods.<br />

The manual <strong>is</strong> designed to be beneficial<br />

to users at multiple levels. Your local<br />

<strong>CADKEY</strong> VAR may have access to th<strong>is</strong> textbook and<br />

others to help you become an expert CAD user. New users as<br />

well as those having many years in the field can appreciate its<br />

benefit.<br />

Drive your CAD software like a pro; make the investment in<br />

proper, professional training and maximize the benefits <strong>CADKEY</strong><br />

brings to its class of CAD productivity tools.<br />

- Enjoy the springtime!<br />

Jacques Marchetti <strong>is</strong> President and Founder of Marchetti Design<br />

and Engineering, Leominster, MA (www.marcehttieng.com),<br />

serving the New England area. The company was founded in<br />

1995 and <strong>is</strong> dedicated to providing comprehensive solutions for<br />

the CAD/CAM and CAE market, offering sales, training and<br />

technical support for <strong>CADKEY</strong> products.<br />

12

TECH Note<br />

Locking Control Bars Into Position<br />

<strong>CADKEY</strong> provides users with unmatched usability in a<br />

multitude of ways, one of which <strong>is</strong> the option to customize the<br />

<strong>CADKEY</strong> interface to meet user-specific preferences. When<br />

running <strong>CADKEY</strong> after the interface has been customized, the<br />

Control Bars don't always dock to the location where they were<br />

placed by the user. Th<strong>is</strong> tends to happen more frequently when<br />

multiple <strong>CADKEY</strong> menus are placed on the left side of the<br />

<strong>CADKEY</strong> application window (see Figure 1). The positioning<br />

<strong>is</strong> done by Windows to comply with the non-maximized<br />

window rules.<br />

Some users have reported that certain screen configurations<br />

cause the arranged <strong>CADKEY</strong> Control Bars to shift when<br />

going from one <strong>CADKEY</strong> session to the next. If one of the<br />

<strong>CADKEY</strong> Control Bars <strong>is</strong> positioned at the bottom of the<br />

application window when Windows positions them on program<br />

startup, it may shift (see Figure 2).<br />

Procedure<br />

The above situation can be remedied by performing the<br />

following easy steps:<br />

1. If the <strong>CADKEY</strong> application <strong>is</strong> already maximized, click on the<br />

Windows “Restore” button (the middle button at the very<br />

top right of the <strong>CADKEY</strong> application window – see Figure 3).<br />

2. Manually drag the edges of the <strong>CADKEY</strong> application window<br />

as far as they will go until it covers the entire screen<br />

(see Figure 4).<br />

3. Manually Arrange the Control Bars to your liking.<br />

4. Select the Windows “Maximize” button (see Figure 5) to<br />

maximize the <strong>CADKEY</strong> application window (you will see<br />

a very slight repositioning).<br />

The Control Bars in <strong>CADKEY</strong> will no longer shift from one session<br />

to the next. For more information, please review Technote #1146,<br />

publ<strong>is</strong>hed by <strong>CADKEY</strong> Corporation in the SUPPORT section of our<br />

website at www.cadkey.com.<br />

Fig.1 – th<strong>is</strong> shows a<br />

<strong>CADKEY</strong> Control Bar<br />

placed at the bottom<br />

of the application<br />

window.<br />

Fig.3 – Windows<br />

“Restore” button<br />

Restore<br />

Control Bar<br />

Fig.2 – the application menu<br />

previously at bottom has<br />

shifted up near the top<br />

and the viewport has<br />

been decreased.<br />

Control Bar<br />

Fig.4 – Drag the<br />

edges of the <strong>CADKEY</strong><br />

viewport as far as<br />

they will go.<br />

Fig.5 - Windows<br />

“Maximize” button<br />

Maximize<br />

13

Educational Corner<br />

<strong>CADKEY</strong> Computer-Aided Design<br />

Curriculums Unfold in American and<br />

Canadian School Systems<br />

Greater Essex County School Board in Windsor, Canada<br />

Purchases 500 Educational Seats of <strong>CADKEY</strong><br />

Cornerstone Technology, a <strong>CADKEY</strong> Authorized Reseller in<br />

Windsor, Ontario, Canada, received a purchase order from the<br />

Greater Essex County School Board for 500 educational seats of<br />

<strong>CADKEY</strong> 99. The <strong>CADKEY</strong> mechanical CAD (Computer-aided<br />

Design) software will be used at 15 secondary schools located<br />

throughout the city and county.<br />

Paul Coleman of Cornerstone Technology stated, “When<br />

the Greater Essex County School Board polled local employers<br />

with the question, ‘Which software do you feel <strong>is</strong> the most<br />

appropriate to give our Ontario Youth Apprenticeship Program<br />

students a good grounding in preparation for work?’ The<br />

response was <strong>CADKEY</strong>. The School Board surveyed local<br />

businesses and found that over 60% of manufacturing and<br />

engineering firms in the area were using <strong>CADKEY</strong> as their<br />

design software. The Greater Essex County School Board took<br />

an aggressive step to change their engineering curriculums, and<br />

we met their challenge.”<br />

“<strong>CADKEY</strong>’s intuitive interface and comprehensive hybrid<br />

modeling toolset make it the perfect ease-into-3D design<br />

software for educators and students alike. Students can really<br />

learn the basics with <strong>CADKEY</strong>…from wireframe to solids to<br />

surface modeling,” states Mark Graveline, Vice President of<br />

Sales at <strong>CADKEY</strong> Corporation.<br />

Tech Ed Concepts Trains New<br />

Instructors in the United States<br />

Dick Amarosa of TEC and Brian Bailey IT Manager, recently<br />

trained teachers new to CAD in Bridgeport, Connecticut on<br />

<strong>CADKEY</strong> 99 and CAD LAB 2000 ® . The city of Bridgeport<br />

recently purchased a fifty-station license from Education Valueadded<br />

Reseller, Frank Gregorio of Electronic Marketing.<br />

Tech Ed Trainer, Dr. Jack Miller, traveled to Dillard University<br />

in New Orleans, LA for a few days of supplemental training.<br />

The School of Engineering recently upgraded to <strong>CADKEY</strong> 99.<br />

Dr. Miller reported the Engineering Professors were especially<br />

impressed with the product’s v<strong>is</strong>ualization features and surface<br />

modeling capabilities.<br />

TEC Launches CAD LAB 2000 ®<br />

Powered by <strong>CADKEY</strong><br />

Tech Ed Concepts, Inc., the National Academic D<strong>is</strong>tributor<br />

of the <strong>CADKEY</strong> product line, has designed a unique curriculum<br />

and software package for the Introduction to Mechanical<br />

Drafting. Because many teachers in the United States need<br />

curriculum to meet their state standards and objectives for<br />

Technology Education, CAD Lab 2000 was developed by Richard<br />

Amarosa, President of Tech Ed Concepts, Inc. and well -known<br />

author/former educator Dr. Len Nasman. CAD LAB 2000<br />

provides teachers and students the tools to experience creativity,<br />

problem solving, technology research and most importantly the<br />

opportunity to communicate and heighten the thought process.<br />

CAD LAB 2000 <strong>is</strong> guaranteed to go beyond the normal technology<br />

module experience using <strong>CADKEY</strong>.<br />

CAD Lab 2000 has built-in flexibility to adapt to a school’s<br />

specific curriculum needs. The program can be used as the<br />

bas<strong>is</strong> for a two day Awareness Program to a fifteen-day Exploratory<br />

Module. The Master Module contains <strong>CADKEY</strong> software<br />

for the instructor and licenses for five student stations, a Tutor<br />

CD, one for the instructor and one for each student license, an<br />

instructors guide for Mechanical CAD basics module, a student<br />

workbook, a real-world application instructor pack and a<br />

laminated poster of CAD LAB’s toolbar series. To learn more<br />

about CAD LAB 2000 and receive the new CAD LAB brochure<br />

be sure to v<strong>is</strong>it www.Tecedu.com or call TEC at 800-338-2238.<br />

Sixth Annual <strong>CADKEY</strong> TEC Summer<br />

Camp for North American Technical<br />

Educators Set for July 2000<br />

Tech Ed Concepts, Inc. (Pembroke, NH) will hold its sixth<br />

annual TEC Summer Camp for all levels of technical educators at<br />

the Wayfarer Inn in Bedford, New Hampshire in July 2000.<br />

Course dates have been scheduled for the weeks of July 10 th ,<br />

and July 17 th . Attendees will receive quality, personalized training<br />

from certified professional secondary and post-secondary<br />

classroom instructors. College or teacher credits can be earned<br />

through th<strong>is</strong> training program.<br />

The highly affordable TEC Summer Camp 2000 <strong>is</strong> designed<br />

to expand the educator’s knowledge of <strong>CADKEY</strong> and prepare<br />

them to teach the latest advances in the upcoming fall semester.<br />

Technical instructors will explore all facets of 3D mechanical<br />

design utilizing <strong>CADKEY</strong> ‘s hybrid modeling technology during a<br />

a full week of hands-on training. The comprehensive courses<br />

includes 40+ instructional<br />

hours, free CAD software,<br />

classroom materials, open<br />

evening labs with an<br />

ass<strong>is</strong>tant, and TEC’s famous<br />

New England Cookout. Also<br />

on the agenda are special<br />

academic/commercial<br />

guests, modular and<br />

innovative curriculum, and a seminar featuring science/math/<br />

technology integration. The entire week of camp <strong>is</strong> priced at<br />

just $ 595 USD including lunch. Hotel accommodations are<br />

available at corporate rates. Courses are offered to educators<br />

only on a first-come first-served bas<strong>is</strong>. For more information,<br />

contact TEC at 1-800-338-2238, v<strong>is</strong>it the TEC Website at<br />

www.tecedu.com or Email: summercamp@tecedu.com.<br />

14

Community News<br />

Prec<strong>is</strong>ion Pneumatics’ Dual Slide<br />

Named in Product Design &<br />

Development Magazine’s<br />

Top 40 Designs of 1999<br />

Prec<strong>is</strong>ion Pneumatics, Ronkonkoma, NY, founded by Ron<br />

and Adriana Nollet in 1999, designed and manufacturers the<br />

first-ever pick-and-place actuators offering two axes of movement<br />

in a single unit. The “Dual Slide” automatically loads<br />

parts for processing and/or assembly in specialty assembly and<br />

machine tools. Until the Dual Slide entered the market,<br />

machine makers had to purchase two separate slides and bolt<br />

them together at a 90° angle to each other to obtain the range<br />

of motion available in th<strong>is</strong> one unit. Less than 10 months after<br />

its initial introduction, the Dual Slide became one of Product<br />

Design & Development’s Top 40 Designs of 1999.<br />

The slides lift objects<br />

vertically – objects varying in<br />

size from screws on their way<br />

to having their slots machined,<br />

all the way up to electric<br />

motors –transports them<br />

horizontally and drops them<br />

vertically. Ron Nollet, President<br />

of Prec<strong>is</strong>ion Pneumatics,<br />

said, “Having a single unit<br />

capable of moving both vertically and horizontally saves<br />

machine builders time in their design, assembly and testing<br />

processes. People try it once, and they’re sold.”<br />

The Dual Slide comes in three different bore cylinder sizes –<br />