PARC Flexible Electronics Services

PARC Flexible Electronics Services

PARC Flexible Electronics Services

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>PARC</strong> <strong>Flexible</strong> <strong>Electronics</strong> <strong>Services</strong><br />

Application Development: Case Study & Example Technologies<br />

For companies interested in creating high-value, low-cost electronics applications, <strong>PARC</strong> can<br />

customize, build, and integrate devices into the desired form factor.<br />

Set up for low cost and disposability, <strong>PARC</strong>’s printed and flexible electronic expertise and<br />

devices can be adapted for consumer health electronics, manufactured packaging, and electromechanical<br />

sensing in a broad range of biomedical applications.<br />

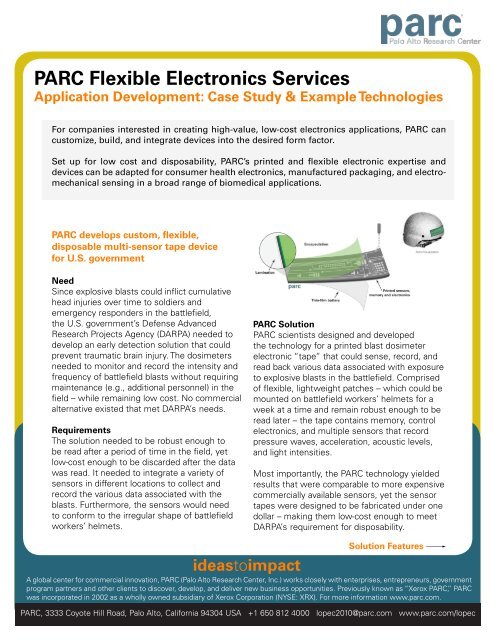

<strong>PARC</strong> develops custom, flexible,<br />

disposable multi-sensor tape device<br />

for U.S. government<br />

Need<br />

Since explosive blasts could inflict cumulative<br />

head injuries over time to soldiers and<br />

emergency responders in the battlefield,<br />

the U.S. government’s Defense Advanced<br />

Research Projects Agency (DARPA) needed to<br />

develop an early detection solution that could<br />

prevent traumatic brain injury. The dosimeters<br />

needed to monitor and record the intensity and<br />

frequency of battlefield blasts without requiring<br />

maintenance (e.g., additional personnel) in the<br />

field – while remaining low cost. No commercial<br />

alternative existed that met DARPA’s needs.<br />

Requirements<br />

The solution needed to be robust enough to<br />

be read after a period of time in the field, yet<br />

low-cost enough to be discarded after the data<br />

was read. It needed to integrate a variety of<br />

sensors in different locations to collect and<br />

record the various data associated with the<br />

blasts. Furthermore, the sensors would need<br />

to conform to the irregular shape of battlefield<br />

workers’ helmets.<br />

<strong>PARC</strong> Solution<br />

<strong>PARC</strong> scientists designed and developed<br />

the technology for a printed blast dosimeter<br />

electronic “tape” that could sense, record, and<br />

read back various data associated with exposure<br />

to explosive blasts in the battlefield. Comprised<br />

of flexible, lightweight patches – which could be<br />

mounted on battlefield workers’ helmets for a<br />

week at a time and remain robust enough to be<br />

read later – the tape contains memory, control<br />

electronics, and multiple sensors that record<br />

pressure waves, acceleration, acoustic levels,<br />

and light intensities.<br />

Most importantly, the <strong>PARC</strong> technology yielded<br />

results that were comparable to more expensive<br />

commercially available sensors, yet the sensor<br />

tapes were designed to be fabricated under one<br />

dollar – making them low-cost enough to meet<br />

DARPA’s requirement for disposability.<br />

Solution Features<br />

ideastoimpact<br />

A global center for commercial innovation, <strong>PARC</strong> (Palo Alto Research Center, Inc.) works closely with enterprises, entrepreneurs, government<br />

program partners and other clients to discover, develop, and deliver new business opportunities. Previously known as “Xerox <strong>PARC</strong>,” <strong>PARC</strong><br />

was incorporated in 2002 as a wholly owned subsidiary of Xerox Corporation (NYSE: XRX). For more information www.parc.com.<br />

<strong>PARC</strong>, 3333 Coyote Hill Road, Palo Alto, California 94304 USA +1 650 812 4000 lopec2010@parc.com www.parc.com/lopec

For DARPA’s unique requirements, <strong>PARC</strong> developed a solution with the following specifications:<br />

OVERALL SOLUTION FEATURES<br />

• Modular, customizable sensor architecture<br />

• Printed customizable organic electronic circuits<br />

• Mechanically flexible and conformal<br />

• Reduced sensitivity to stress or deformation<br />

• Lightweight<br />

• Compatible with low-cost roll-to-roll processing<br />

– fabrication techniques such as inkjet printing,<br />

laser machining, lamination, die cutting<br />

• Non-contact variable digital data printing with<br />

inkjet technology<br />

• Low-voltage complementary organic circuitry<br />

ELECTRONICS<br />

• Complementary organic transistor electronics<br />

• Low-voltage organic transistors<br />

• Printed organic inverters, clock circuit, and shift<br />

registers<br />

MEMORY<br />

• Non-volatile, low device count analog memory<br />

• All-additive inkjet-printed design<br />

BATTERY<br />

SENSORS<br />

• Fabrication compatible with roll-to-roll<br />

processing<br />

• Piezopolymer-based pressure, acoustic, and<br />

acceleration sensors<br />

• Piezopolymer sensing for low power, low drift,<br />

and compatibility with solution processing<br />

• All-printed organic light sensor<br />

Pressure<br />

• 5-100psi pressure pulse range<br />

• Reduced thermal cross sensitivity<br />

Acoustic<br />

• 100-175dB acoustic range (measured<br />

up to ~500Hz)<br />

• Reduced thermal cross sensitivity<br />

Acceleration<br />

• 5-1000g range<br />

• High-resonance frequency design<br />

Optical<br />

• Linear response from 100-400klux<br />

• Maximum sensitivity between 350-500nm<br />

• Thin-film flexible battery<br />

To have <strong>PARC</strong> develop an application to<br />

meet your needs, contact:<br />

Jennifer Ernst<br />

Director of Business Development<br />

lopec2010@parc.com<br />

+1 650 812 4916<br />

<strong>PARC</strong>, 3333 Coyote Hill Road, Palo Alto, California 94304 USA +1 650 812 4000 lopec2010@parc.com www.parc.com/lopec