INSTALLATION WIRING SYSTEMS ENCLOSURES - Pearson Schools

INSTALLATION WIRING SYSTEMS ENCLOSURES - Pearson Schools

INSTALLATION WIRING SYSTEMS ENCLOSURES - Pearson Schools

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 4: Installation of wiring systems and enclosures<br />

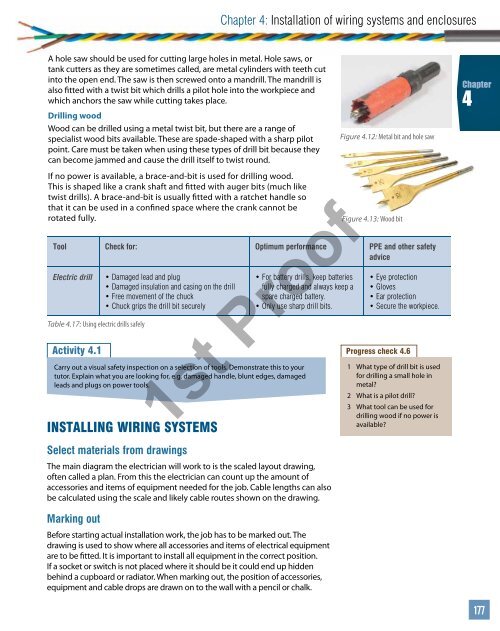

A hole saw should be used for cutting large holes in metal. Hole saws, or<br />

tank cutters as they are sometimes called, are metal cylinders with teeth cut<br />

into the open end. The saw is then screwed onto a mandrill. The mandrill is<br />

also fitted with a twist bit which drills a pilot hole into the workpiece and<br />

which anchors the saw while cutting takes place.<br />

Drilling wood<br />

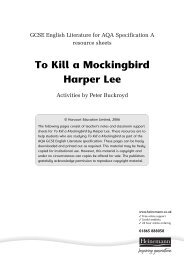

Wood can be drilled using a metal twist bit, but there are a range of<br />

specialist wood bits available. These are spade-shaped with a sharp pilot<br />

point. Care must be taken when using these types of drill bit because they<br />

can become jammed and cause the drill itself to twist round.<br />

If no power is available, a brace-and-bit is used for drilling wood.<br />

This is shaped like a crank shaft and fitted with auger bits (much like<br />

twist drills). A brace-and-bit is usually fitted with a ratchet handle so<br />

that it can be used in a confined space where the crank cannot be<br />

rotated fully.<br />

Activity 4.1<br />

Carry out a visual safety inspection on a selection of tools. Demonstrate this to your<br />

tutor. Explain what you are looking for, e.g. damaged handle, blunt edges, damaged<br />

leads and plugs on power tools.<br />

Figure 4.13: Wood bit<br />

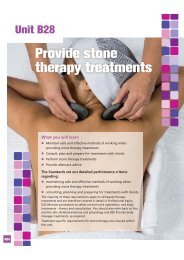

Tool Check for: Optimum performance PPE and other safety<br />

advice<br />

Electric drill<br />

Table 4.17: Using electric drills safely<br />

• Damaged lead and plug<br />

• Damaged insulation and casing on the drill<br />

• Free movement of the chuck<br />

• Chuck grips the drill bit securely<br />

INSTALLING <strong>WIRING</strong> <strong>SYSTEMS</strong><br />

Select materials from drawings<br />

• For battery drills, keep batteries<br />

fully charged a nd always keep a<br />

spare charged battery.<br />

• Only use sharp drill bits.<br />

1st Proof<br />

The main diagram the electrician will work to is the scaled layout drawing,<br />

often called a plan. From this the electrician can count up the amount of<br />

accessories and items of equipment needed for the job. Cable lengths can also<br />

be calculated using the scale and likely cable routes shown on the drawing.<br />

Figure 4.12: Metal bit and hole saw<br />

• Eye protection<br />

• Gloves<br />

• Ear protection<br />

• Secure the workpiece.<br />

Progress check 4.6<br />

1 What type of drill bit is used<br />

for drilling a small hole in<br />

metal?<br />

2 What is a pilot drill?<br />

3 What tool can be used for<br />

drilling wood if no power is<br />

available?<br />

Chapter<br />

4<br />

177<br />

Unit<br />

GH8<br />

Marking out<br />

Before starting actual installation work, the job has to be marked out. The<br />

drawing is used to show where all accessories and items of electrical equipment<br />

are to be fitted. It is important to install all equipment in the correct position.<br />

If a socket or switch is not placed where it should be it could end up hidden<br />

behind a cupboard or radiator. When marking out, the position of accessories,<br />

equipment and cable drops are drawn on to the wall with a pencil or chalk.<br />

177