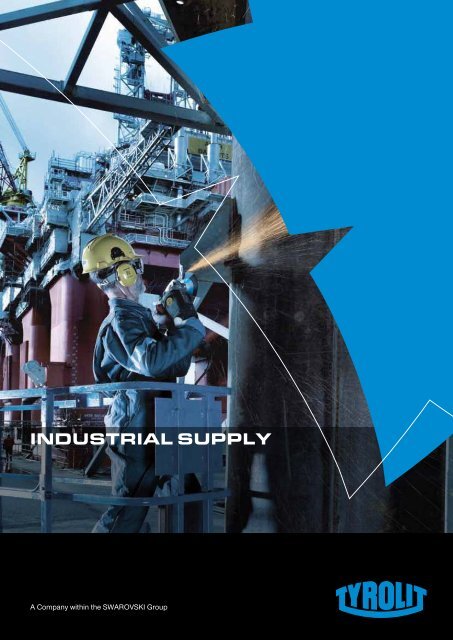

industrial supply

industrial supply

industrial supply

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>industrial</strong> <strong>supply</strong><br />

A Company within the SWAROVSKI Group

tyrOlit<br />

General<br />

Cutting<br />

Restructured 4<br />

TYROLIT in expansion 5<br />

Principles 6<br />

Safety 8<br />

Quality lines 9<br />

The new product design 10<br />

Catalogue overview 11<br />

POS 12<br />

General information 13<br />

Explanation of labels 14<br />

Specific information 18<br />

D 22<br />

Table of recommended<br />

speeds 26<br />

Pictrograms & Safety 27<br />

Dos & don'ts 33<br />

Cutting 35<br />

Application tables 37<br />

Straight grinder Resin 45<br />

Premium 46<br />

Accessories 47<br />

Angle grinder Resin 49<br />

Premium 50<br />

Standard 55<br />

Basic 57<br />

P 59<br />

Premium 60<br />

Standard 62<br />

Basic 64<br />

Stationary 65<br />

Resin<br />

Premium 66<br />

Standard 68<br />

Basic 69<br />

Cutting off & saw sharpening 70<br />

Laboratory cutting-off 72<br />

Cutting off HSS & HM-TC 74<br />

Angle grinder Diamond 75<br />

Premium 76<br />

Standard 80<br />

Basic 81<br />

83<br />

Premium 84<br />

Standard 87<br />

Basic 89<br />

2

grinding<br />

preCisiOn<br />

Grinding 91<br />

Application tables 93<br />

Straight grinders 95<br />

Resin 96<br />

Vitrified-bonded 101<br />

Elastic 108<br />

Cemented carbide cutters 110<br />

Flap points 117<br />

Angle grinder Resin 121<br />

Premium 122<br />

Standard 133<br />

Basic 139<br />

Angle grinder Diamond 143<br />

Premium 144<br />

Standard 145<br />

Precision 147<br />

Table 148<br />

Grinding 149<br />

Floorstand grinding wheels<br />

Conventional 150<br />

Accessories 154<br />

Sharpening and polishing wheels<br />

Elastic 155<br />

External cylindrical grinding<br />

Conventional 157<br />

Resin 161<br />

Reciprocating surface grinding<br />

Conventional 163<br />

Resin 170<br />

Profile surface grinding<br />

Conventional 172<br />

Surface grinding<br />

Conventional 173<br />

Internal cylindrical grinding<br />

Conventional 175<br />

Resin/galvanic 178<br />

Hand held grinding<br />

Vitrified-bonded 182<br />

Elastic-bonded 190<br />

Resin-bonded 191<br />

Galvanic-bonded 192<br />

Sharpening 193<br />

Saw sharpening 194<br />

Universal tool grinding<br />

Ceramic 199<br />

Resin 203<br />

Dressing 213<br />

Pedestal / swing frame grinding<br />

214<br />

Dressing and sharpening 215<br />

3

estruCtured:<br />

prOduCt CatalOgue<br />

Dear business partners,<br />

We have taken the liberty of making the product catalogue clearer.<br />

It is split into the main sections cutting, grinding and precision, where in each section<br />

cutting<br />

petrol cutting saws and stationary cut-off wheels<br />

grinding<br />

and floorstand grinders and<br />

precision<br />

dressing<br />

you are guided to the individual products.<br />

4

tyrOlit is<br />

one of the largest manufacturers of bonded<br />

grinding, cutting, sawing, drilling and dressing<br />

tools in the world.<br />

The company is also a provider of tools and<br />

machines.<br />

A system partner that tailors its complete<br />

cutting and grinding solutions in close<br />

cooperation with its customers, Tyrolit<br />

achieves and provides customer-specific<br />

solutions through the hard work of<br />

highly-skilled application engineers.<br />

A company that is continously investing to ensure that its products are<br />

as environmentally friendly as possible in terms of their manufacture,<br />

use and disposal.<br />

tyrOlit in eXpansiOn<br />

TYROLIT, with its workforce of approximately<br />

4,113 and a wide range of products (over<br />

80,000), has every intention of pushing ahead<br />

with its ambitious expansion plans.<br />

The company has 28 production centres in 13<br />

countries and a global network of sales companies<br />

and distributors that is growing all the time.<br />

5

prinCiples<br />

Customer relations<br />

We view our customers as partners with the aim of achieving a lasting win-win situation.<br />

The success of our customers lies in the quality of our products, our knowledge of<br />

application technology and the provision of customer-specific on-site solutions.<br />

Close cooperation with our customers leads to remarkable strategic developments and<br />

ensures long-term success for both parties.<br />

Our global network of production centres, sales companies and our carefully selected<br />

local service provision means that we see TYROLIT as a global company for our<br />

internationally-active customers all over the world.<br />

6

prinCiples<br />

QualitY<br />

Our strength was, is and remains an unbeatable combination of tradition, innovation<br />

and quality.<br />

Our quality level is characterised by our constant striving to improve quality, an<br />

attribute that is embedded in the strategic orientation of the company. It is this<br />

characteristic that guarantees our customers the usual high quality standards they<br />

expect of TYROLIT.<br />

The TYROLIT quality management system has been certified to ISO 9001:2000 by an<br />

external authorised body for the entire production area. Production is carried out in<br />

accordance with European Standards:<br />

EN12413 for grinding wheels made of bonded abrasives<br />

EN13236 for grinding wheels made of diamond or boron nitride<br />

EN13743 for special abrasives on an underlay such as<br />

Vulcanised fibre grinding wheels<br />

Flap grinding wheels<br />

Flap Discs<br />

Mounted points<br />

innoVation<br />

The development and implementation of our visions and ideas<br />

for the future has always been and remains a key factor in the<br />

success of our company.<br />

The creative potential of our employees is therefore not<br />

just employed constantly looking out for new technology,<br />

developing new materials or continuously optimising<br />

the entire production process, it also helps to gain us<br />

a competitive edge over our rivals.<br />

7

saFety Brand tyrOlit<br />

Our aim was and is to make our products even safer for our users:<br />

Through our work as the founder member of the "Organisation for the<br />

Safety of Abrasives (oSa),"<br />

through close cooperation with the safety authorities,<br />

through practical communication with our users all over the world.<br />

aiM OF Osa<br />

The main aim of oSa is defined in terms of absolute protection<br />

for the users of grinding tools. Members undertake to:<br />

provide a consistently high level of quality,<br />

adopt a rigorous approach towards quality assurance,<br />

strive to develop new, improved standards of safety.<br />

8

Quality lines<br />

The restructuring of the product markings carried out in 2008, the aim of which was to make it easier to select the best<br />

product, has proved to be extremely successful.<br />

preMiuM ★★★<br />

standard ★★<br />

BasiC ★<br />

Quality tools for maximum performance:<br />

TYROLIT PREMIUM products are highest performers in the category,<br />

offering outstanding life and efficiency for optimum performance<br />

Quality tools for daily use:<br />

TYROLIT STANDARD products have been designed where high demands and<br />

frequent use are placed upon the tool in <strong>industrial</strong> and trade applications.<br />

They offer excellent price to performance ratio, reinforced with high efficiency<br />

Quality tools for universal use:<br />

TYROLIT BASIC products offer an excellent price to performance ratio,<br />

whilst still maintaining good performance and service life with assured<br />

total safety<br />

9

tHe neW prOduCt design<br />

The investment in the relaunch of our product image, also in 2008 has exceeded our expectations in just the same way<br />

as the restructuring of the product markings: Making the image of the TYROLIT brand even more visible and ultimately<br />

user-friendly.<br />

Since 2008, TYROLIT has presented:<br />

a new, simplified product marking broken down by quality levels<br />

a new, attractive product image<br />

a new, clearly structured POS<br />

new ways of promoting sales<br />

Aim<br />

To standardise, simplify and make the entire appearance of the<br />

TYROLIT brand more user-friendly.<br />

Benefits<br />

Easier to sell<br />

10

prOMOting sales<br />

tHe CataloGue series BY tYrolit<br />

Construction related trade<br />

This catalogue contains everything<br />

about: Construction related trade<br />

Construction professionals<br />

This catalogue contains everything<br />

about: Construction professionals<br />

Industrial Supply<br />

This catalogue contains everything<br />

about: Industrial Supply<br />

11

prOMOting sales<br />

tHe Pos<br />

It gives the right impression of the brand TYROLIT and ensures a clear organisation of the product in terms of<br />

areas of application<br />

levels of quality<br />

Diameter<br />

the POS also has enough space for additional information materials for customers.<br />

Assembly<br />

If requested, we can take on the planning of<br />

your range to meet customer requirements and<br />

will be happy to advise you regarding the best<br />

selling positions.<br />

The POS is easy to assemble using the<br />

enclosed assembly diagram and is available<br />

in the following versions:<br />

Wall system<br />

Sales element in the room<br />

Counter displays<br />

12

General information<br />

Explanation of labels 14 Table of recommended speeds 26<br />

Specific information 18 Pictrograms & Safety 27<br />

22 Dos & Don'ts 33

Specific information<br />

Resin-bonded<br />

LabeL<br />

Registered<br />

trademark of TYROLIT<br />

,GHQWLILFDWLRQR IWKH<br />

max. permissible speed<br />

Product markings<br />

according to quality<br />

levels:<br />

Pictograms,<br />

application and safety<br />

information<br />

TYROLIT, member<br />

of OSA (Organisation<br />

6DIHW\ $ EUDVLYHV<br />

Expiry date<br />

6KDSHGHVLJ QDWLRQ <br />

specification<br />

Main dimensions<br />

' [ 7[ + LQP P L QFKHV<br />

EAN code<br />

7\ SHQXP EHU<br />

article number<br />

Materials<br />

Specification<br />

abrasive designation Grit size in mesh Designation of hardness type of bond<br />

A = regular aluminium oxide<br />

ORQJ FKLSSLQJ P DWHULDOV P HWDOV<br />

24 46 80 N Q T % E RQG ERQGLQJ DJ HQW<br />

UHVLQ<br />

& V LOLFRQF DUELGH VKRUW FKLSSLQJ 30 46 O R S<br />

P DWHULDOV VWRQH<br />

ZLWK fibre glass (for safety,<br />

lateral load and max.<br />

RSHUDWLQJ V SHHG<br />

ZA = zirconium aluminium oxide<br />

FDVWP DWHULDOVR UI RUI ODSGLVFV<br />

30 60 120 P S<br />

14

ShapeS<br />

41 &XW RIIZ KHHO<br />

VWUDLJ KWGHVLJ Q<br />

27 ) ODSGLVF FRQLFDOGHVLJ Q<br />

42 &XW RIIZ KHHO<br />

GHSUHVVHG FHQWUHGHVLJ Q<br />

28 ) ODSGLVF IODWGHVLJ Q<br />

27 5 RXJ KJ ULQGLQJ Z KHHOV<br />

29 Rondeller<br />

VHP L IOH[ LEOHJ<br />

ULQGLQJ Z KHHO<br />

28 5 RXJ KJ ULQGLQJ Z KHHOV<br />

coLour coDeS<br />

Label Steel LQ LQ INOX Stone NF metals Cast iron<br />

colour<br />

codes<br />

Blue Blue Red Green Orange Purple<br />

Materials Steel LQ VWHHO<br />

VWDLQOHVVV WHHO <br />

or 3in1 (cast<br />

LURQ VWHHO<br />

VWDLQOHVVV WHHO<br />

Rust and acid<br />

resistant steels<br />

Stone<br />

Aluminium,<br />

copper, zinc,<br />

brass, bronze,<br />

stone<br />

Cast materials<br />

15

Specific information<br />

diamond<br />

LabeL<br />

Registered trademark<br />

of TYROLIT<br />

Product markings<br />

according to quality<br />

levels<br />

Pictograms, application<br />

and safety information<br />

TYROLIT, member<br />

of OSA (Organisation<br />

6DIHW\ $ EUDVLYHV<br />

,GHQWLILFDWLRQR IWKH<br />

max. permissible speed<br />

Main dimensions<br />

' [ 7[ + LQP P L QFKHV<br />

Specification<br />

Materials<br />

Specification<br />

J<br />

$<br />

example: Dcab***-fc / Dcabp-fc<br />

Position 1-2 Program DC Dry cutting<br />

Position 3-4 Application AB Abrasive materials<br />

U 8 QLYHUVDO HQ E XLOGLQJ P DWHULDOV<br />

C Concrete<br />

H Hard stone, granite<br />

A VSKDOW<br />

M Marble, soft stone<br />

T Tiles<br />

Position 5-7 Quality line PREMIUM ***<br />

STANDARD **<br />

BASIC *<br />

Position 8-9 Special quality FC Fast cut<br />

S Silent<br />

LL Long life<br />

16

ShapeS<br />

1a1r<br />

Continuous cutting rim<br />

c3<br />

Close spacing, narrow slots<br />

ZLWKV ORWK ROH<br />

c6<br />

Close spacing, narrow slots<br />

ZLWKV ORWK ROH<br />

c3S<br />

Close spacing, narrow slots<br />

ZLWKK ROHV ORW 3 URWHFWHGZ LWK<br />

a drop wear segment to guard<br />

DJ DLQVWWKHX QGHUFX WLQJ HIIHFW<br />

c6r<br />

Turbo layer, close spacing,<br />

QDUURZV ORWVZ LWKV ORWK ROH<br />

c1<br />

Wide spacing, wide slots<br />

c3r<br />

Turbo layer, close spacing,<br />

QDUURZV ORWVZ LWKV ORWK ROH<br />

c1S<br />

Wide spacing, wide slots.<br />

3URWHFWHGZ LWKDGURSZ HDU<br />

VHJ P HQWWRJ XDUGDJ DLQVWWKH<br />

undercutting effect<br />

coLour coDeS<br />

Label Universal Concrete Hard stone Tiles Marble Abrasive<br />

materials<br />

colour<br />

codes<br />

$ VSKDOW<br />

Yellow Red Blue Green Green Grey Grey<br />

Materials 4 in 1 Concrete Hard stone Tiles Marble<br />

Abrasive<br />

materials<br />

$ VSKDOW<br />

17

Specific information<br />

GRindinG wheel<br />

DeSiGnation<br />

3URGXFWVI URP 7 < 5 2 / ,7DUHODEHOHGV XFKWKDWD OLP SRUWDQWLQIRUP DWLRQF DQE HGLUHFWO\ UHDGR IIULJ KWDZD\ <br />

Information on certification of<br />

TYROLIT<br />

Flange ID<br />

Manufacturer's registered<br />

trademark<br />

Specification<br />

Type no.<br />

Main dimensions<br />

3URGXFWLRQR UGHUZ LWK<br />

item number<br />

Type no.<br />

Manufacturer's registered<br />

trademark<br />

Test certification<br />

Observe maximum permissible operating<br />

speed, max. RPM as well as colour code<br />

RQJ ULQGLQJ Z KHHODQGDFFRP SDQ\ LQJ <br />

documentation.<br />

6KDSH<br />

Specification<br />

Maximum permissible<br />

operating speed<br />

3URGXFWLRQR UGHUZ LWK<br />

item number<br />

18

abraSive<br />

Classification, abbreviation and area of<br />

DSSOLFDWLRQR IWKHI RXUP DLQW\ SHVR IDEUDVLYH<br />

grains used. Classification as conventional<br />

abrasive and superabrasive is generally<br />

standard.<br />

conventional abrasive grain<br />

Aluminium<br />

oxide<br />

CBN<br />

IRUORQJ FKLSSLQJ GXFWLOHP DWHULDOV <br />

e.g. steels, super alloys<br />

Superabrasives<br />

SiC<br />

Diamond<br />

IRU VKRUW FKLSSLQJ EULWOH P DWHULDOV stone,<br />

glass, tungsten carbide, grey cast iron,<br />

brass. Exception: Titanium, titanium alloy<br />

Hardness comparison of abrasives and<br />

P DWHULDOV 7 KHI RORZLQJ J HQHUDO\ DSSOLHV <br />

7KHJ UHDWHUWKHK DUGQHVVGLIIHUHQFH<br />

EHWZHHQWKHDEUDVLYHJ UDLQDQGWKHJ URXQG<br />

ZRUNSLHFH WKHK LJ KHUWKHJ ULQGLQJ S RZHU<br />

6WHHO KDUGHQHG<br />

Quartz<br />

Garnet<br />

Carbides<br />

in HSS<br />

WC<br />

PCD<br />

GROUND MATERIALS<br />

Emery<br />

Aluminium oxide<br />

Silicon carbide<br />

Boron carbide<br />

Cub. boron nitride<br />

Natural abrasives<br />

Conventional abrasives<br />

Superabrasives<br />

&RQYHUVLRQ RI KDUGQHVV YDOXHV<br />

2<br />

* SD N1 P≈ P100 NS P P 2<br />

Diamond<br />

. QRRS KDUGQHVV LQ * 3D<br />

* UDLQV L] HVLQ P HVK LQDFFRUGDQFHZ LWK<br />

) ( 3$ V WDQGDUG 7 KHQXP EHUR IV LHYH<br />

RSHQLQJ V P HVK S HU LQFKLVX VHGDVWKH<br />

J ULWV L] H 7 KHUHGXFWLRQR IWKHR SHQLQJ V<br />

DVDUHVXOWR IWKHZ LUHWKLFNQHVVLVDOVR<br />

FRQVLGHUHGE \ WKHV WDQGDUG<br />

P HVK<br />

P HVK<br />

LQFK<br />

Grain<br />

P HVK QXP EHU RI VFUHHQ RSHQLQJ V SHU LQFK<br />

7KH FRDUVHU WKH J UDLQ <br />

WKH VP DOHU WKH QXP HULF YDOXH<br />

,QIOXHQFH RI ZLUH WKLFNQHVV<br />

0 HVK Dx<br />

P P <br />

a<br />

P P <br />

10 2,54 2,0<br />

30 0,85 0,6<br />

a<br />

Dx<br />

19

onD<br />

Important bond types for grinding tools.<br />

7KHF KRLFHR IE RQGLQJ W\ SHGHSHQGVR QWKH<br />

J ULQGLQJ WDVN WKHV HOHFWHGJ UDLQW\ SHDQGWKH<br />

P DFKLQHF RQGLWLRQV<br />

Sintered<br />

bonds<br />

Metal Ceramic Organic<br />

Galvanic<br />

bonds<br />

Sintered<br />

bonds<br />

(porcelain<br />

W\ SH<br />

Main groups<br />

Melted<br />

bonds<br />

J ODVVW\ SH<br />

Magnesite,<br />

SKRVSKDWH <br />

silicate<br />

bonds (cold<br />

KDUGHQHUV<br />

3KHQRO<br />

resins<br />

+ LJ K<br />

temperature<br />

resins,<br />

polyimides<br />

Natural<br />

substances,<br />

VKHODF<br />

glue<br />

Epoxides<br />

Polyamides,<br />

Rubber<br />

polyester,<br />

acrylic<br />

resins<br />

Poly-<br />

XUHWKDQH<br />

3URSHUWLHVR IJ ULQGLQJ Z KHHOE RQGV <br />

7KHH[ WUHP HVR IWKHE RQGVDUHUHSUHVHQWHGE \ <br />

WKHP HWDOE RQGVR QR QHV LGHR IWKHWDEOHDQG<br />

WKHR UJ DQLFE RQGVR QWKHR WKHU <br />

Metal<br />

Ceramic<br />

3KHQRO<br />

resins<br />

+ LJ K<br />

temperature<br />

resins,<br />

polyimides<br />

Organic<br />

Epoxides,<br />

polyamides,<br />

polyester<br />

Rubber<br />

3RO\ XUHWKDQH<br />

+<br />

+<br />

+ +<br />

+<br />

+<br />

LJ K Hardness Low<br />

LJ K Stiffness/dimensional stability Low<br />

LJ K Low Toughness LJ K<br />

Low Damping LJ K<br />

LJ K Resistance to temperature, coolant,<br />

environment<br />

Low<br />

Poor Good Profilability Good<br />

6KDSLQJ FXW<br />

+ LJ KHU 6XUIDFH URXJ KQHVV ZRUNSLHFH<br />

contourfollowing<br />

Low <br />

3ROLVKLQJ<br />

&RP SDULVRQR IWKHS URSHUWLHVR IYDULRXV<br />

ERQGLQJ V \ VWHP VDQGWKHLUUHDFWLRQWRWKH<br />

impact effect of grinding forces during<br />

FKLSI RUP DWLRQ , QWKHF DVHR IULJ LGE RQGV <br />

WKH grains remain in place and oscillate;<br />

ZLWKHODVWLFE RQGV WKH\ E DUHO\ R VFLODWHDQG<br />

are displaced.<br />

Extreme case 1<br />

Hard<br />

bond<br />

Rigid<br />

Brittle<br />

6OLJ KW GDP SLQJ<br />

+ LJ K WHP SHUDWXUH UHVLVWDQFH<br />

Bond<br />

Effect of surge-type grinding<br />

forces<br />

Extreme case 2<br />

bond<br />

Soft<br />

Elastic<br />

7RXJ K<br />

+ LJ K GDP SLQJ<br />

Low temperature resistance<br />

cracks<br />

Fatigue cracks in<br />

bond web<br />

Low<br />

Damping<br />

Loosening of<br />

WKH SDUWLFOH<br />

+ LJ K<br />

Displacement<br />

+<br />

+ J J J<br />

1 RQH P LQ Particle displacement<br />

Relatively big<br />

Less<br />

6XUIDFH ILQLVK<br />

LJ KHU<br />

LJ K 6KDSH LYLQJ ULQGLQJ<br />

6KDSH DFFXUDF\ Low: VKDSH IRORZLQJ ULQGLQJ<br />

Examples:<br />

Ceramic Metal 3KHQRO UHVLQ<br />

Special resins<br />

Rubber<br />

HSR[ \ SRO\ HVWHU<br />

"Elastic"<br />

PU<br />

20

DeScription of wheeL ShapeS<br />

Examples of different grinding tool groups:<br />

&RQYHQWLRQDOJ ULQGLQJ Z KHHOV J ULQGLQJ <br />

ZKHHOVZ LWKV XSHUDEUDVLYHV<br />

&RQYHQWLRQDO J ULQGLQJ ZKHHO UHFHVVHG RQ RQH VLGH<br />

Shape 5<br />

Order details: D x T x H - P x F<br />

7RRO J ULQGLQJ ZKHHO ZLWK VXSHUDEUDVLYH<br />

&XS ZKHHO e.g. TYROLIT Amigo or Diago<br />

Shape 11V9<br />

Order details: D x T x H<br />

D - W - X<br />

$ QH[ DP SOHR IWKHGHVLJ QDWLRQR IJ ULQGLQJ <br />

ZKHHOVZ LWKV XSHUDEUDVLYHV<br />

7RROJ ULQGLQJ Z KHHO 9<br />

Basic shape 11 Abrasive layer V Arrangement of abrasive layer 9<br />

Shape Description Fig. Fig. Shape Fig. Reference Arrangement Fig.<br />

11 tapered pot with cylindrical<br />

collar<br />

sloping inwards 8 fully penetrated<br />

S<br />

11<br />

tapered pot without<br />

collar<br />

U<br />

sloping outwards<br />

9 special part of "corner" perimeter<br />

12<br />

14<br />

Plate<br />

straight wheel, recessed<br />

on both sides<br />

V<br />

VV<br />

of the perimeter<br />

10 inner ring<br />

Designation of dimensions of grinding<br />

WRROVI RUS UHFLVLRQDQGURXJ KJ ULQGLQJ <br />

Diam. External diameter<br />

E Floor thickness<br />

H Bore diameter<br />

J Diameter of hub<br />

K Diameter of face<br />

L Total length<br />

L1 Length of shaft<br />

L2 Abrasive coating length<br />

E<br />

S<br />

T<br />

T1<br />

U<br />

U1<br />

Radius<br />

outer body angle/diameter of<br />

mandrel<br />

Total width<br />

reduced width<br />

Abrasive coating width<br />

(if smaller than T or T1)<br />

reduced abrasive coating width<br />

V<br />

W<br />

X<br />

Y<br />

Abrasive coating angle<br />

Grinding wheel width<br />

Abrasive coating thickness<br />

Diameter of mandrel<br />

21

DreSSinG – the baSicS<br />

dRessinG with stationaRy dResseRs<br />

$ VDUHVXOWR IF KDQJ HVLQWKHE RQG WKHDEUDVLYHJ UDLQDQGWKHV KDSHR IWKHJ ULQGLQJ Z KHHOV WHP P LQJ I URP WKHZ HDU<br />

RIWKH J ULQGLQJ Z KHHO J ULQGLQJ LVDQHYHUF KDQJ LQJ S URFHVV 7 KHF KDQJ HVDIIHFWJ ULQGLQJ I RUFHV Z RUNSLHFHV XUIDFHV<br />

DQGJ HRP HWULFDFFXUDF\ 7 RHQVXUHWKHJ ULQGLQJ Z KHHOLVDOZD\ VDEOHWRS URYLGHR SWLP XP J ULQGLQJ UHVXOWV DS HULRGLF<br />

FRQGLWLRQLQJ F \ FOHP XVWE HP DLQWDLQHG 7 KLVF \ FOHHQDEOHVWKHJ ULQGLQJ F DSDELOLW\ R IWKHJ ULQGLQJ E RG\ WRE HUHSURGXFHG<br />

%\ FRQGLWLRQLQJ DJ ULQGLQJ Z KHHOF RUUHFWO\ WKHV XEVHTXHQWJ ULQGLQJ S URFHVVF DQE HR SWLP LVHGLQWHUP VR IS HUIRUP DQFH<br />

HIILFLHQF\ DQGV XUIDFHI LQLVK<br />

choosing the right dresser<br />

photo<br />

DreSSinG tooL GrinDinG wheeL profiLe GrinDinG proceSS /<br />

DetaiLeD DeScription<br />

proDuction type<br />

Single-grain dresser<br />

/ LQHDU F\ OLQGULFDO F RQLFDO<br />

Single-profile<br />

FRQYH[ F RQFDYHUDGLL<br />

External cylindrical, surface,<br />

internal cylindrical and centreless<br />

grinding<br />

Single and small-lot production<br />

single-edge<br />

Profile diamond<br />

Multi-profile<br />

External cylindrical, surface and<br />

FRP SOH[ S URILOHVZ LWKQDUURZI ODQNV centreless grinding<br />

DQGUDGLL<br />

Single and small-lot production<br />

multi-edge<br />

Multi-grain dresser / LQHDU F\ OLQGULFDO F RQLFDO Surface and external cylindrical<br />

grinding<br />

Single and small-lot production<br />

22

choosing the right dresser<br />

photo<br />

DreSSinG tooL GrinDinG wheeL profiLe GrinDinG proceSS /<br />

DetaiLeD DeScription<br />

proDuction type<br />

Multi-set diamond dresser / LQHDU F\ OLQGULFDO F RQLFDO Surface and external cylindrical<br />

grinding<br />

Single and small-lot production<br />

Diamond grain dressing plate<br />

/ LQHDU F\ OLQGULFDO F RQLFDO External cylindrical, surface and<br />

6LQJ OH SURILOH FRQYH[ FRQFDYH UDGL centreless grinding<br />

Single to large-scale production<br />

multi-edge<br />

Needle dressing plates<br />

/ LQHDU F\ OLQGULFDO F RQLFDO External cylindrical, surface and<br />

6LQJ OH SURILOH FRQYH[ FRQFDYH UDGL centreless grinding<br />

Single to large-scale production<br />

' UHVVLQJ S ODWHVZ LWK0 . ' URGV<br />

/ LQHDU F\ OLQGULFDO F RQLFDO External cylindrical, internal<br />

6LQJ OH SURILOH FRQYH[ FRQFDYH UDGL cylindrical, surface and centreless<br />

grinding<br />

Single to large-scale production<br />

23

coMMon errorS when DreSSinG:<br />

,IWKHGUHVVLQJ WRROLVGULYHQ RYHUWKH e D<br />

J ULQGLQJ Z KHHOZ LWKRXWLQIHHG WKHZ KHHOE HFRP HVE OXQW DQGF ORJ VX S <br />

7KHUHVXOWVLQDJ UHDWHUULVNR IR YHUKHDWLQJ Z KHQ J ULQGLQJ <br />

7KHI UHHF ODP SLQJ OHQJ WKR IWKHGUHVVHULVWRRODUJ H 9 LEUDWLRQVDULVHDQGWKHJ ULQGLQJ Z KHHOV XUIDFHE HFRP HVLUUHJ XOD<br />

7KLVI DFHLVUHSURGXFHGR QWKHZ RUNSLHFHLQWKHV XEVHTXHQWJ ULQGLQJ S URFHVV<br />

: KHQWKHGUHVVLQJ LQIHHGV HOHFWHG e! D P P LVWRRK LJ K WKLVF DXVHVDI UDFWXUHLQWKHE RQGE ULGJ HVLQWKHJ ULQGL<br />

ZKHHODQGWKHJ UDLQVWRF RP HR XWWRRV RRQ 7 KLV UHVXOWVLQDS RRUHUZ RUNSLHFHV XUIDFHGXHWRI RUP DWLRQVR IF RP P D<br />

VKDSHGV FUDWFKHV<br />

7KHF RROLQJ V \ VWHP LVQRWV ZLWFKHGR QLQWLP H $ VDUHVXOWR IWKHUP DOR YHUORDG WKHGLDP RQGLVGHVWUR\ HGE HFDXVHR I<br />

WKHT XHQFKLQJ R UE HFDXVHWHP SHUDWXUHVDUHWRR KLJ K 5 HP HG\ 7 KHF RROLQJ V \ VWHP V KRXOGE HV ZLWFKHGR QE HIRUHWKH<br />

J ULQGLQJ Z KHHOI LUVWF RP HVLQWRF RQWDFWZ LWKWKHGUHVVHU<br />

7KHF RROLQJ V \ VWHP LVV ZLWFKHGR QWRRV RRQDIWHUGUHVVLQJ 7 KHJ UDLQDQGE RQGUHVLGXHWKDWK DVF RP HR XWWKURXJ K<br />

GUHVVLQJ F DQQRWE HV XIILFLHQWO\ UHP RYHG ULQVHGR XW 7 KLVF DQOHDG DP RQJ VWR WKHUWKLQJ V WRWKHI RUP DWLRQR IF RP P<br />

VKDSHGV FUDWFKHVR QWKHZ RUNSLHFHV XUIDFH<br />

7KH VLQJ OH J UDLQ GLDP RQG LV J URXQG GRZQ WRR P XFK P HDQLQJ WKDW LP SOHP HQWDWLRQ RI WKH GLDP RQG LV QR ORQJ HU SRVVLEOH<br />

<br />

DiaMonD Size (ct) in relation to grinding wheel dimensions<br />

<br />

<br />

<br />

ct<br />

ct<br />

RXWVLGH GLDP HWHU RI J ULQGLQJ ZKHHO P P <br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

ct<br />

ct<br />

ct<br />

ct<br />

ct<br />

ct<br />

<br />

<br />

* ULQGLQJ ZKHHO ZLGWK P P <br />

24

interreLationShip; Surface rouGhneSS / Grit Size<br />

7KHWDEOHE HORZZ LOK HOS\ RXV HOHFWWKHULJ KWJ ULWV L] HWRDFKLHYHWKHV XUIDFHURXJ KQHVVUHVXOWUHTXLUHG 9 DULDEOHS URFHVV<br />

SDUDP HWHUV H J WKH GUHVVLQJ P HWKRG KDYH D VLJ QLILFDQW HIIHFW DV WR ZKLFK VXUIDFH URXJ KQHVV FDQ EH DFKLHYHG ZLWK D J ULW<br />

7KHUHIRUH WKHWDEOHE HORZDOVROLVWVWKHV XUIDFHDUHDV J UDLQV L] H<br />

< RXV KRXOGWDNHLQWR DFFRXQWWKDWODUJ HJ UDLQV L] HVUHP RYHV OLYHUV P DWHULDO P RUHV LP SO\ , WLVQRWQHFHVVDU\ WRV HOHFWW<br />

ILQHVWI RUHDFKLQLWLDOV HOHFWLRQR IWKHJ ULWV L] H<br />

$<br />

interreLationShip; Surface rouGhneSS / Grit Size<br />

Surface<br />

Grit size<br />

P LFURLQFK& / µm Ra 36 46 60 80 100 120 150 180 220<br />

42 1,1 *<br />

32 0,8 * *<br />

26 0,7 *<br />

21 0,5 * *<br />

16 0,4 *<br />

14 0,35 * *<br />

11 0,25 *<br />

8 0,2 * *<br />

7 0,17 *<br />

6 0,14 * *<br />

5 0,12 * *<br />

4 0,1 * *<br />

3 0,08 * *<br />

2 0,05 *<br />

interreLationShip; profiLe raDiuS / Grit Size<br />

7KH WDEOH EHORZ SURYLGHV DQ RYHUYLHZ RI ZKLFK J ULW VL] H FDQ DFKLHYH D P LQLP XP SURILOH UDGLXV $ V D VWDQGDUG YDOXH LW FDQ<br />

DVVXP HG WKDW WKUHH DEUDVLYH J UDLQV DUH UHTXLUHG WR P DLQWDLQ D P LQLP XP SURILOH UDGLXV 7R DFKLHYH D SURILOH UDGLXV RI<br />

0.3 mm, an approximate grit size diameter of 0.1 mm is required.<br />

Min. profile<br />

radius<br />

interreLationShip; profiLe raDiuS / Grit Size<br />

Grit size 36 46 60 80 100 120 150 180 220<br />

mm 1 0,8 0,6 0,45 0,3 0,2 0,15 0,12 0,1<br />

LQFKHV 0,04 0,03 0,03 0,02 0,1 0,01 0,01 0,01 0,00<br />

25

SpeeD recommenDationS<br />

5 RWDWLRQDOV SHHGVDQGS HULSKHUDOV SHHGVGHSHQGLQJ R QWKHH[ WHUQDOGLDP HWHUš ' R IWKHJ ULQGLQJ Z KHHOV<br />

D in<br />

mm<br />

Rotations n per minute min -1 GHSHQGVR QH[ WHUQDOGLDP HWHU' R IJ ULQGLQJ Z KHHODQGWKH<br />

P D[ LP XP R SHUDWLQJ V SHHG9 S<br />

Maximum operating speed V S<br />

in m/s<br />

26

pictoGramS | machineS<br />

Hand guided dressing<br />

Floorstand grinder<br />

' UHVVLQJ Z LWKGLDP RQG<br />

Pedestal and Swing frame grinding<br />

External cylindrical grinding<br />

6WDWLRQDU\ F X WLQJ RIIP DFKLQH<br />

Surface grinding<br />

Cut-off grinder<br />

6WUDLJ KWJ ULQGHUV Tool grinding<br />

Hand guided tool<br />

Angle grinder<br />

Internal cylindrical grinding $ QJ OHJ ULQGHUZ LWKE UXVK<br />

6DZV KDUSHQLQJ $ QJ OHJ ULQGHUZ LWKF XSZ KHHO<br />

r* ULQGLQJ E UXVKLQJ GULOLQJ<br />

r5 RXJ KLQJ<br />

r& X WLQJ RII<br />

27

pictoGramS | materialS<br />

Steel<br />

Rails<br />

Stainless steel<br />

Plastics, lacquers, paints<br />

6WHHO VWDLQOHVVV WHHO<br />

$ VSKDOW<br />

Stone, universal building materials<br />

Concrete<br />

Cast iron<br />

Abrasive materials<br />

Nonferrous metals<br />

Hard stone, granite<br />

HSS: tool steel<br />

Ceramics, tiles<br />

HM-TC: tungsten carbide<br />

Soft stone<br />

Stone and nonferrous metals<br />

Cast iron, steel, INOX<br />

Safety information<br />

3D\ D WHQWLRQWRWKHV DIHW\ UHFRP P HQGDWLRQV Personal safety<br />

Use dust mask<br />

Not permitted for side grinding<br />

Use eye protection<br />

Dry grinding<br />

Use ear protection<br />

Wet grinding<br />

Use gloves<br />

1 RI UHHKDQGZ RUN<br />

' RQRWX VHGDP DJ HGZ KHHOV<br />

28

examples of identifying wheel orientation<br />

7KHI RORZLQJ S OD\ DQHTXDOS DUWZ KHQLWF RP HVWRV DIHW\ Z KHQJ<br />

0 DFKLQHP DQXIDFWXUHU<br />

* ULQGLQJ Z KHHOS URGXFHUDQG<br />

User<br />

ULQGLQJ<br />

* ULQGLQJ Z KHHOVDUHV XEMHFWWRDK LJ KORDGGXULQJ WKHJ ULQGLQJ S URFHVV 7 KLVLVZ K\ <br />

* ULQGLQJ P DFKLQHV<br />

Grinding bodies<br />

Handling and application<br />

P XVWE HR SWLP DO\ K DUP RQLVHGWRHQVXUHV DIHJ ULQGLQJ ) RUWKHJ ULQGLQJ P DFKLQHV LWLVJ HQHUDO\ LP SRUWDQWWRR EVHUYH<br />

WKHP DFKLQHF RQGLWLRQVDQGWKHV WLSXODWLRQR IWKHS URWHFWLRQF RYHU<br />

: KHUHDVWKHP DQXIDFWXUHULP SOHP HQWVWKHV DIHW\ P HDVXUHVLQOLQHZ LWKUHJ XODWLRQVLQUHODWLRQWRWKHJ ULQGLQJ P DFKLQH<br />

DQGJ ULQGLQJ Z KHHOV WKHX VHULVUHVSRQVLEOHI RUV DIHW\ Z KHQJ ULQGLQJ WKURXJ KX VHR IWKHJ ULQGLQJ P DFKLQHI RUWKH<br />

LQWHQGHGS XUSRVH DVZ HODVWKURXJ KF RUUHFWK DQGOLQJ DQGDSSOLFDWLRQR IWKHJ ULQGLQJ Z KHHOV <br />

7KHI RORZLQJ P XVWE HR EVHUYHG<br />

&KHFNLQJ R IJ ULQGLQJ E RGLHVR QGHOLYHU\<br />

Handling and storage of grinding bodies<br />

/ DEHOLQJ V \ QFKURQLVDWLRQZ LWKP DFKLQHGDWD<br />

&KHFNLQJ R IJ ULQGLQJ Z KHHOVS ULRUWRF ODP SLQJ<br />

&ODP SLQJ P HWKRGVI RUJ ULQGLQJ Z KHHOV<br />

Test run of grinding bodies prior to start-up<br />

( \ HS URWHFWLRQDQG SURWHFWLYHF ORWKLQJ VHHDOVR) ( 3$ 6 DIHW\ & RGH<br />

checking of grinding wheels on delivery<br />

&KHFNS DFNDJ LQJ R QGHOLYHU\ , IGDP DJ HLVYLVLEOHR QWKHS DFNDJ LQJ WKHJ<br />

WKRURXJ KO\ I RUDQ\ S RVVLEOHWUDQVSRUWGDP DJ H<br />

ULQGLQJ Z KHHOV KRXOGE HF KHFNHGS DUWLFXODUO\ <br />

Storage of the grinding wheels<br />

* ULQGLQJ Z KHHOVDUHWRE HV WRUHGLQV XLWDEOHUDFNVR UF RQWDLQHUVV RWKDWWKH\ DUHQRWGDP DJ HGDQGV RWKDWLWLVHDVLO\ <br />

SRVVLEOHWRUHP RYHZ KHHOVZ LWKRXWGLVWXUELQJ WKHV WRUDJ HV HWXS 2 OGHUV WRFNV KRXOGE HX VHGI LUVW <br />

' XULQJ V WRUDJ H WKHI RORZLQJ P XVWE HQRWHG <br />

6WRUH WKHJ ULQGLQJ Z KHHOVLQDGU\ UXVW IUHHF RQGLWLRQ<br />

' RQRWH[ SRVHJ ULQGLQJ Z KHHOVWRODUJ HWHP SHUDWXUHI OXFWXDWLRQV<br />

\ \<br />

Storage for different types of grinding body:<br />

6WRUHF XW RIIZ KHHOVR QDOHYHOX QGHUOD\ Z LWKRXWLQWHUP HGLDWH<br />

OD\ HUV DQGZ HLJ KWKHP GRZQZ LWKDV WHHOR UF DVW LURQS ODWH<br />

6WRUHODUJ HV WUDLJ KWJ ULQGLQJ Z KHHOVLQDQX SULJ KW SRVLWLRQDQG<br />

P DNHV XUHWKH\ F DQQRWURODZD\<br />

6WDFNF OLQGHUZ KHHOV F OLQGULFDOJ ULQGLQJ GLVFVDQGJ ULQGLQJ <br />

plates using soft intermediate layers<br />

6WDFNJ ULQGLQJ GLVFV V KDSH LQHDFKF DVHI DFHVR UE DVHV<br />

WRJ HWKHU<br />

6WRUHV P DOJ ULQGLQJ Z KHHOVLQV XLWDEOHF RQWDLQHUV<br />

29

identification of the grinding wheels<br />

7KHS XUSRVHR IWKHLGHQWLILFDWLRQLVWRJ LYHS HUVRQV LQS DUWLFXODUWKRVHZ KRF DUU\ R XWWKHF ODP SLQJ R IWKHJ ULQGLQJ <br />

ZKHHOV LQIRUP DWLRQI RUV DIHX VHDQGS URSHUDSSOLFDWLRQ<br />

* ULQGLQJ Z KHHOVP D\ R QO\ E HX VHGLIWKH\ DUHLGHQWLILHGZ LWKWKHI RORZLQJ P LQLP XP LQIRUP DWLRQ <br />

Manufacturer<br />

' LP HQVLRQVR IJ ULQGLQJ Z KHHO<br />

0 DWHULDO DWOHDVWWKHW\ SHR IE RQG<br />

0 D[ LP XP S HUP LVVLEOH5 30 R IQHZJ ULQGLQJ Z KHHO<br />

0 D[ LP XP R SHUDWLQJ V SHHGLQP V<br />

7KHX VHULVR EOLJ HGWRP DWFKWKHP DFKLQHV SHHGWRWKHP D[ LP XP S HUP LVVLEOHV SHHGJ<br />

LYHQLQWKHLGHQWLILFDWLRQ<br />

Additional identification markings are as follows:<br />

E OXH P V<br />

\ HORZ P V<br />

UHG P V<br />

J UHHQ P V<br />

E OXHZ LWK\ HORZ<br />

P V<br />

checking of Grinding Wheels prior to clamping<br />

( DFK WLP H EHIRUH FODP SLQJ WKH J ULQGLQJ ZKHHOV P XVW EH FOHDQHG DQG FKHFNHG IRU GDP DJ H E\ P HDQV RI D YLVXDO LQVSHFWLRQ<br />

See figure, bottom left.<br />

7KHV RXQGWHVWV KRXOGE HUHSHDWHG ' DP DJ HGJ ULQGLQJ Z KHHOVP XVWQRWE HP RXQWHG<br />

) RUWKHV RXQGWHVW OLJ KWZHLJ KWJ ULQGLQJ Z KHHOVDUH SXVKHGR QWRDP DQGUHOR UV KDIW K HDY\ J ULQGLQJ Z KHHOVDUHS ODFHGR<br />

a firm floor.<br />

7KHJ<br />

ULQGLQJ Z KHHOLVWDSSHGZ LWKDQRQ P HWDOR EMHFWDWV HYHUDOS RLQWV<br />

$ QX QGDP DJ HGJ ULQGLQJ Z KHHOJ LYHVDF OHDUULQJ Z KLOHDGDP DJ HGR QHJ LYHVDGX OR UF ODQNLQJ V RXQG<br />

$ OF RQWDFWV XUIDFHVR QJ ULQGLQJ Z KHHOV LQWHUP HGLDWHOD\ HUVDQGZ KHHOI ODQJ HVP XVWE HOHYHO IODW DQGE HI UHHI URP <br />

IRUHLJ QE RGLHV ) RUHLJ QS DUWLFOHVE HWZHHQJ ULQGLQJ ZKHHOVDQGZ KHHOI ODQJ HVF UHDWHS UHVVXUHS RLQWVDQGV WUHVVHV Z KLFK<br />

FDQOHDGWRE UHDNDJ HR IWKHJ ULQGLQJ Z KHHO<br />

Contact - spindle - bore<br />

( [ DP SOHVR IWDSSLQJ S RLQWVGXULQJ WKHV RXQGWHVW<br />

( [ DP SOHVR ILGHQWLI\ LQJ Z KHHOR ULHQWDWLRQ<br />

30

clamping methods for Grinding Wheels<br />

\ 7KHF ODP SLQJ R IWKHJ ULQGLQJ Z KHHOVP XVWE HF DUULHGR XWDQGV XSHUYLVHGE DT XDOLILHGS HUVRQ<br />

' HSHQGLQJ R QWKHW\ SHR IP DFKLQHDQGJ ULQGLQJ P HWKRG DVZ HODVWKHJ ULQGLQJ Z KHHOV KDSH DGLVWLQFWLRQF DQE HP DG<br />

EHWZHHQWKHI RORZLQJ F ODP SLQJ P HWKRGV<br />

0 RXQWLQJ LQWKHF HQWUDOE RUHX VLQJ Z KHHOI ODQJ HV<br />

Mounting using embedded fixing elements<br />

Mounting using support plates<br />

0 RXQWLQJ X VLQJ F ODP SLQJ K HDG<br />

5 HFHVVHGZ KHHOI ODQJ H Stepped flange Locating flange 7DSHUHGZ KHHOI ODQJ H 6WUDLJ KWZ KHHOI ODQJ H<br />

5.1. MOUNTING IN THE CENTRAL BORE USING WHEEL FLANGES<br />

$ GLVWLQFWLRQV KRXOGE HP DGHE HWZHHQWKHI RORZLQJ Z KHHOI ODQJ HW\ SHVI RUF HQWUDOE RUHV<br />

5 HFHVVHGZ KHHOI ODQJ H<br />

6WUDLJ KWZ KHHOI ODQJ HVI RUS RUWDEOHJ ULQGLQJ P DFKLQHV<br />

Special flanges<br />

Stepped flanges<br />

Locating flanges<br />

7DSHUHGZ KHHO IODQJ HV<br />

7KHS XUSRVHR IWKHZ KHHOI ODQJ HVLVWRWUDQVIHUGULYHI RUFHV 7 KH\ P XVWWKHUHIRUHE HLQV XFKDF RQGLWLRQWKDWWKHUHLVQR<br />

GHIRUP DWLRQR IWKHZ KHHOI ODQJ HGXULQJ F ODP SLQJ <br />

7KHF RQWDFWV XUIDFHVP XVWE HOHYHO IODW DQGP XVWQRWV KRZDQ\ E XUULQJ DQGWKHUXQ RXWR IWKHJ ULQGLQJ Z KHHOP XVWE<br />

safeguarded.<br />

2 QO\ Z KHHOI ODQJ HVWKDWK DYHWKHV DP HH[ WHUQDOGLDP HWHUDQGWKHV DP HV KDSHR QWKHF RQWDFWV LGHP D\ E HX VHG 7 KH\ <br />

P XVWE HUHFHVVHGV R WKDWR QO\ DULQJ VKDSHGDUHDR IWKHZ KHHOI ODQJ HLVR QWKHV XUIDFH <br />

( [ DP SOHR IWKHF RUUHFWZ D\ WRX VHUHGXFLQJ ULQJ V<br />

5.2. CLAMPING USING EMBEDDED FIXING ELEMENTS<br />

7KHJ ULQGLQJ Z KHHOVDUHI L[ HGX VLQJ HP EHGGHGI L[ LQJ HOHP HQWVR QWKHJ ULQGLQJ P DFKLQH <br />

D<br />

D<br />

d f<br />

) LJ XUH OHIW & ODP SLQJ R IWDSHUF XSZ KHHOVZ LWKDWKUHDGLQVHUW<br />

) LJ XUH F HQWUH & ODP SLQJ R IDJ ULQGLQJ F RQH V KDSH Z LWKDWKUHDGLQVHUW<br />

) LJ XUH ULJ KW & ODP SLQJ R IJ ULQGLQJ V HJ P HQWVLQF ODP SLQJ K HDGV/ I &<br />

d f ≥ 0.33 D<br />

d f<br />

d f ≥ 0.5 D<br />

( [ DP SOHVR IWKLVDUHWKHF ODP SLQJ R IF \ OLQGULFDODQGWDSHUF XSZ KHHOV R UWKHI L[ LQJ R IP RXQWHGS RLQWVZ LWKHP EHGGHG<br />

VWHHOV KDIWVLQF ROHWV RQS RUWDEOHJ ULQGLQJ P DFKLQHV<br />

31

5.3. CLAMPING OF GRINDING WHEELS ON SUPPORT PLATES<br />

7KHJ<br />

ULQGLQJ Z KHHOVDUHHLWKHUF HP HQWHGR UI L[ HGZ LWKLQVHUWHGQXWV<br />

Collet<br />

Plate<br />

10 min.<br />

Figure 1 Figure 2 Figure 3<br />

Figure 4<br />

) LJ * ULQGLQJ Z KHHO F HP HQWHG<br />

) LJ * ULQGLQJ Z KHHOZ LWKLQVHUWHGQXWV<br />

) LJ & RUUHFWE ROWF RQQHFWLRQ E ROWHQGP XVWQRWWRXFKWKHE DVHR IWKHJ ULQGLQJ Z KHHO<br />

Fig. 4: Clamping of mounted points<br />

5.4. CLAMPING OF GRINDING SEGMENTS IN CLAMPING HEADS<br />

* ULQGLQJ V HJ P HQWVDUHF ODP SHGWRR QHJ ULQGLQJ X QLW VHJ P HQWK HDG LQF ODP SLQJ K HDGV<br />

2 QWKHF RQWDFWV XUIDFHVE HWZHHQWKHJ ULQGLQJ V HJ P HQWVDQGWKHF ODP SLQJ S LHFHV DGKHVLYHV WULSVF DQE HS ODFHGR QWKH<br />

J ULQGLQJ V HJ P HQWVWRDYRLGV WUHVVHVLQWKHJ ULQGLQJ V HJ P HQWV<br />

test run prior to Start-Up<br />

( YHU\ VWDQGDUGJ ULQGLQJ Z KHHO ' J UHDWHUWKDQ P P P XVWX QGHUJ RDWHVWUXQDWP D[ LP XP R SHUDWLQJ V SHHGE HIRUH<br />

EHLQJ XVHGI RUWKHI LUVWWLP HDQGDIWHUHYHU\ UH P RXQWLQJ <br />

7KHGXUDWLRQR IDWHVWUXQI RUJ ULQGLQJ Z KHHOVLV<br />

RQS RUWDEOHJ ULQGLQJ P DFKLQHV P LQXWH<br />

RQD OR WKHUJ ULQGLQJ P DFKLQHV P LQXWH<br />

RQFHWKHWHVWUXQK DVE HHQS DVVHGZ LWKRXWF RP SODLQW <br />

eye protection and protective clothing<br />

$ OJ ULQGLQJ WDVNVZ KHUHS HUVRQVDUHDWULVNI URP I O\ LQJ S DUWLFOHVR IIJ ULQGLQJ Z KHHOVR UZ RUNSLHFHVP XVWR QO\ E HF DUULHG<br />

RXWX VLQJ H\ HS URWHFWLRQ SURWHFWLYHJ RJ J OHV DQGZ KHQQHFHVVDU\ R WKHUS URWHFWLYHF ORWKLQJ H J OHDWKHUDSURQDQG<br />

OHDWKHUJ ORYHV <br />

Summary<br />

7KHP RVWLP SRUWDQWS RLQWVI RUV DIHX VHR IJ<br />

ULQGLQJ Z KHHOVDUHV XP P DULVHGDJ DLQE HORZ<br />

$ GMXVWP HQWR IWKHP DFKLQHGDWDWRWKHLGHQWLILFDWLRQGDWD<br />

&KHFNLQJ R IJ ULQGLQJ Z KHHOVS ULRUWRP RXQWLQJ <br />

Mounting carried out by skilled persons<br />

&KHFNLQJ R IWKHI XQFWLRQDOLW\ R IWKHP DFKLQHJ XDUG<br />

7HVWUXQR IJ ULQGLQJ Z KHHOVS ULRUWRJ ULQGLQJ Z RUN<br />

Personal safety<br />

( [ DP SOHR IWKHX VHR IS URWHFWLYHWDSHR QF HUDP LFZ KHHOV<br />

32

DoS & Don'tS<br />

<br />

+ DQGOHDQGV WRUHJ ULQGLQJ WRROVF DUHIX O\ X VHWKHR OGHVW<br />

tools first.<br />

3ULRUWRP RXQWLQJ R UX VH J ULQGLQJ Z KHHOVP XVWE H<br />

FOHDQHGDQGX QGHUJ RDYLVXDOF KHFNI RUF UDFNVR U<br />

possible damage.<br />

Ceramic bonded grinding tools must undergo a sound<br />

FKHFNE HIRUHP RXQWLQJ <br />

0 DNHV XUHWKDWWKHV SHHGR IWKHP DFKLQH 5 30 GRHV<br />

QRWH[ FHHGWKHP D[ LP XP R SHUDWLQJ V SHHGV SHFLILHGR Q<br />

WKHS DFNDJ LQJ R UR QWKHDEUDVLYH<br />

$ VLQWHQGHGR UV XSSOLHG X VHWKHLQWHUP HGLDWHOD\ HUV<br />

EHWZHHQWKHJ ULQGLQJ Z KHHODQGZ KHHOI ODQJ HV<br />

2 QO\ X VHP DFKLQHVZ LWKS URWHFWLRQ J XDUGVDQGHQVXUH<br />

WKHLUS URSHUF RQGLWLRQDQGI L[ WXUHE HIRUHWKHP DFKLQHLV<br />

VZLWFKHGR Q<br />

$ IWHUHDFKP RXQWLQJ F DUU\ R XWDWHVWUXQI RUDWOHDVW<br />

RQHP LQXWHDWWKHR SHUDWLQJ V SHHGDQGHQVXUHP DFKLQH<br />

J XDUGLVP RXQWHGF RUUHFWO\ , QGRLQJ V R HQVXUHWKDWDQ\ <br />

IUDJ P HQWVZ RXOGQRWE HDEOHWRK LW\ RXR UV RP HRQHHOVH<br />

LQWKHHYHQWR IDS RVVLEOHE UHDNDJ H<br />

Eye protection is always recommended for all grinding<br />

SURFHVVHV ) RUR II KDQGJ ULQGLQJ S URWHFWLYHJ RJ J OHVR U<br />

a safety mask is recommended.<br />

<br />

' RQRWX VHDEUDVLYHVWKDWDUHH[ SRVHGWRS DUWLFXODUO\ <br />

KXP LG ZHWF RQGLWLRQVR UK LJ KWHP SHUDWXUHVS ULRUWR<br />

mounting.<br />

1 HYHUX VHDEUDVLYHVWKDWK DYHE HHQGURSSHG GDP DJ HG<br />

RUWKDWORRNOLNHWKH\ Z RXOGQRWE HI LWI RUS XUSRVH<br />

1 HYHUH[ FHHGWKHP D[ LP XP S HUP LVVLEOHR SHUDWLQJ V SHHG<br />

specified.<br />

' RQRWX VHZ KHHOI ODQJ HVZ LWKV XUIDFHVWKDWDUHQRWI UHH<br />

RII RUHLJ QE RGLHV H J J ULQGLQJ V ZDUI I ODWR UE XUU IUHH<br />

' RQRWWLJ KWHQWKHF ODP SLQJ GHYLFHR UZ KHHOI ODQJ H<br />

too P XFK<br />

' RQRWX VHUHFHVVHGZ KHHOI ODQJ HVR UI ODQJ HVZ LWK<br />

WKDWWKHZ KHHOI ODQJ HVDUHF OHDQ I ODW WKHV DP HV L] HDQG<br />

recesses for grinding discs or cones.<br />

VXLWDEOHI RUWKHJ ULQGLQJ WRROWRE HF ODP SHG<br />

1 HYHUX VHI RUFHZ KHQF ODP SLQJ DQGGRQRWP DNHDQ\ <br />

FKDQJ HVWRWKHJ ULQGLQJ WRRO<br />

2 QO\ X VHR QH ZD\ DGDSWHUV KXEV R QFH<br />

2 QO\ V ZLWFKR QWKHP DFKLQHZ KHQWKHS URWHFWLRQF RYHULV<br />

FRUUHFWO\ DQGV HFXUHO\ I L[ HG P DFKLQHJ XDUGVR UF RYHUV<br />

VKRXOGE HV HWLQV XFKDZ D\ WKDWWKH\ GLYHUWV SDUNVDQG<br />

J ULQGLQJ S DUWLFOHVDZD\ I URP WKHE RG\ <br />

2 QO\ V WDUWWKHP DFKLQHLIWKHUHLVQRF RQWDFWE HWZHHQWKH<br />

ZRUNSLHFHDQGWKHJ ULQGLQJ WRRO<br />

1 HYHUZ RUNZ LWKJ ULQGLQJ WRROVZ LWKRXWV XIILFLHQWDLU<br />

VXSSO\ QHYHUZ LWKRXWE UHDWKLQJ DSSDUDWXVDQGHDU<br />

SURWHFWLRQ S DUWLFXODUO\ LQHQFORVHGV SDFHV DQGZ LWKRXW<br />

SHUVRQDOV DIHW\ HTXLSP HQW VHHS LFWRJ UDP <br />

: KHQZ RUNLQJ Z LWKF XW RIIR UURXJ KLQJ Z KHHOV HQVXUH<br />

WKDWWKHDLUV XSSO\ DQGS URWHFWLYHP HDVXUHVV XIILFLHQWO\ create excessive grinding particles and dust.<br />

FRUUHVSRQGZ LWKWKHP DWHULDOWRE HS URFHVVHG 6 XLWDEOH<br />

$ YRLGP HFKDQLFDOGDP DJ HWRWKHJ ULQGLQJ Z KHHODV<br />

H[ WUDFWLRQV \ VWHP VV KRXOGE HI LWHGI RUD OGU\ J ULQGLQJ <br />

a UHVXOWR II RUFHHIIHFWV MROWLQJ R UK HDWLQJ <br />

processes.<br />

1 HYHUX VHJ ULQGLQJ P DFKLQHVLQDQLP SURSHUF RQGLWLRQR U<br />

2 QO\ X VHP DFKLQHVWKDWDUHDOVRV XLWDEOHI RUJ ULQGLQJ <br />

WKDWF RQWDLQI DXOW\ F RP SRQHQWV<br />

WRROVZ LWKK XE<br />

' RQRWX VHF XW RIIZ KHHOVI RUJ ULQGLQJ Z RUN GR QRWH[ HUW<br />

%H IRUHV WRSSLQJ WKHP DFKLQH F XWR IIWKHV XSSO\ R I<br />

DODWHUDOORDGR QDQ\ F XW RIIZ KHHOVR IV KDSH R U <br />

FRROLQJ OXEULFDQWDQGUHP RYHWKHH[ FHVVF RROLQJ <br />

OXEULFDQWI URP WKHJ ULQGLQJ Z KHHO<br />

1 HYHUP RXQWP RUHWKDQR QHJ ULQGLQJ WRROR QR QHV KDIW<br />

33

Cutting<br />

STRAIGHT GRINDER RESIN<br />

ANGLE GRINDER RESIN<br />

PETROL CUTTING GRINDER RESIN<br />

STATIONARY RESIN<br />

ANGLE GRINDER DIAmOND<br />

PETROL CUTTING GRINDER DIAmOND<br />

35

STRAIGHT GRINDER<br />

PRODUCTS QUALITY LINES AREAS OF APPLICATION TARGET GROUPS<br />

Resin-bonded<br />

cut-off wheels<br />

Premium INOX, steel Steel construction, terotechnology,<br />

shipbuilding, building construction, vehicle<br />

repair workshops, heating, plumbing and<br />

air-conditioning technology<br />

ANGLE GRINDER<br />

PRODUCTS QUALITY LINES AREAS OF APPLICATION TARGET GROUPS<br />

Diamond<br />

dry-cutting saws<br />

Premium <br />

Standard <br />

Concrete, hard stone, tiles/<br />

marble, asphalt and abrasive<br />

materials, for universal use<br />

Building construction, road and garden<br />

construction, interior finishing, tilers,<br />

stonemasons<br />

Basic <br />

Resin-bonded<br />

cut-off wheels<br />

Premium <br />

Standard <br />

Basic <br />

Steel, rust and acid resistant<br />

steels, aluminium, brass,<br />

bronze, copper, zinc, cast<br />

materials, plastics<br />

Steel construction, terotechnology,<br />

shipbuilding, building construction, vehicle<br />

repair workshops, heating, plumbing and<br />

air-conditioning technology<br />

PETROL CUTTING GRINDER<br />

PRODUCTS QUALITY LINES AREAS OF APPLICATION TARGET GROUPS<br />

Diamond<br />

dry-cutting saws<br />

Premium <br />

Standard <br />

Concrete, hard stone, tiles/<br />

marble, asphalt and abrasive<br />

materials, for universal use<br />

Building construction, road and garden<br />

construction, interior finishing, tilers,<br />

stonemasons<br />

Basic <br />

Resin-bonded<br />

cut-off wheels<br />

Premium <br />

Standard <br />

Basic <br />

Steel, rust and acid resistant<br />

steels, aluminium, brass,<br />

bronze, copper, zinc, cast<br />

materials, plastics<br />

Steel construction, terotechnology,<br />

shipbuilding, building construction, vehicle<br />

repair workshops, heating, plumbing and<br />

air-conditioning technology<br />

STATIONARY CUT-OFF WHEELS<br />

PRODUCTS QUALITY LINES AREAS OF APPLICATION TARGET GROUPS<br />

Resin-bonded<br />

cut-off wheels<br />

Premium <br />

Standard <br />

Basic <br />

Steel, rust-resistant and<br />

acid-resistant steels,<br />

aluminium, brass, bronze,<br />

copper, zinc, cast materials,<br />

plastics<br />

Steel construction, terotechnology,<br />

shipbuilding, building construction, vehicle<br />

repair workshops, heating, plumbing and<br />

air-conditioning technology<br />

36

AppliCAtion tAbles<br />

CUT-OFF WHEELS<br />

premium ★★★<br />

Specification<br />

TA60P-BFXA<br />

Material<br />

Steel materials Stainless steels Aluminium Brass/bronze Cast materials Plastics Stone<br />

A60R-BFXA<br />

A46R-BFXA<br />

A30R-BFXA<br />

A60S-BFXA<br />

A46S-BFXA<br />

A30S-BFXA<br />

A60Q-BFXA<br />

A46Q-BFXA<br />

A30Q-BFXA<br />

A46P4BF59A2<br />

A30P4BF59A2<br />

ZA30R-BFXA<br />

ZA30P-BFXA<br />

C46S-BFXA<br />

stAndArd ★★<br />

Specification<br />

A60-BF INOX<br />

Material<br />

Steel materials Stainless steels Aluminium Brass/bronze Cast materials Plastics Stone<br />

A46-BF INOX<br />

A30-BF INOX<br />

A30-BF<br />

C30-BF<br />

bAsiC ★<br />

Specification<br />

A60-BF INOX<br />

Material<br />

Steel materials Stainless steels Aluminium Brass/bronze Cast materials Plastics Stone<br />

A46-BF<br />

A30-BF<br />

C30-BF<br />

Long service life combined with maximum cutting ability.<br />

Long service life and good cutting ability<br />

37

CUTTING | ANGLE GRINDER<br />

AppliCAtion tAbles<br />

UP TO š 0 0<br />

premium ★★★<br />

material FAST CUT SILENT FAST CUT<br />

Asphalt<br />

Abrasive concrete<br />

Concrete<br />

Concrete roofing tiles<br />

Hard concrete<br />

Lightly reinforced concrete<br />

Concrete blocks<br />

Pumice stone<br />

Floor pavement/plaster<br />

Soft fire-resistant bricks<br />

Gas concrete<br />

Fibreglass reinforced plastic<br />

Gneiss<br />

Granite<br />

Hard sand-lime brick<br />

Soft sand-lime brick<br />

Clinkers<br />

Marble<br />

Poroton<br />

Porphyry<br />

Sandstone<br />

Slate<br />

Slag concrete<br />

Clay bricks + slabs<br />

Washed-out concrete<br />

Ceramic tiles<br />

Porcelain stoneware<br />

Long service life combined with maximum cutting ability.<br />

Long service life and good cutting ability.<br />

38

CUTTING | ANGLE GRINDER<br />

AppliCAtion tAbles<br />

UP TO š 0 0<br />

stAndArd ★★<br />

material FAST CUT FAST CUT<br />

Asphalt<br />

Abrasive concrete<br />

Concrete<br />

Concrete roofing tiles<br />

Hard concrete<br />

Lightly reinforced concrete<br />

Concrete blocks<br />

Pumice stone<br />

Floor pavement/plaster<br />

Soft fire-resistant bricks<br />

Gas concrete<br />

Fibreglass reinforced plastic<br />

Gneiss<br />

Granite<br />

Hard sand-lime brick<br />

Soft sand-lime brick<br />

Clinkers<br />

Marble<br />

Poroton<br />

Porphyry<br />

Sandstone<br />

Slate<br />

Slag concrete<br />

Clay bricks + slabs<br />

Washed-out concrete<br />

Ceramic tiles<br />

Porcelain stoneware<br />

Long service life combined with maximum cutting ability.<br />

Long service life and good cutting ability.<br />

39

CUTTING | ANGLE GRINDER<br />

AppliCAtion tAbles<br />

UP TO š 0 0<br />

bAsiC ★<br />

material<br />

Asphalt<br />

FAST CUT<br />

Abrasive concrete<br />

Concrete<br />

Concrete roofing tiles<br />

Hard concrete<br />

Lightly reinforced concrete<br />

Concrete blocks<br />

Pumice stone<br />

Floor pavement/plaster<br />

Soft fire-resistant bricks<br />

Gas concrete<br />

Fibreglass reinforced plastic<br />

Gneiss<br />

Granite<br />

Hard sand-lime brick<br />

Soft sand-lime brick<br />

Clinkers<br />

Marble<br />

Poroton<br />

Porphyry<br />

Sandstone<br />

Slate<br />

Slag concrete<br />

Clay bricks + slabs<br />

Washed-out concrete<br />

Ceramic tiles<br />

Porcelain stoneware<br />

Long service life combined with maximum cutting ability.<br />

Long service life and good cutting ability.

CUTTING | PETROL CUTTING GRINDER<br />

AppliCAtion tAbles<br />

UP TO š 0 0<br />

premium ★★★<br />

material FAST CUT FAST CUT 2 in 1<br />

Asphalt<br />

Abrasive concrete<br />

Concrete<br />

Concrete roofing tiles<br />

Hard concrete<br />

Lightly reinforced concrete<br />

Concrete blocks<br />

Pumice stone<br />

Floor pavement/plaster<br />

Soft fire-resistant bricks<br />

Gas concrete<br />

Fibreglass reinforced plastic<br />

Gneiss<br />

Granite<br />

Hard sand-lime brick<br />

Soft sand-lime brick<br />

Clinkers<br />

Marble<br />

Poroton<br />

Porphyry<br />

Sandstone<br />

Slate<br />

Slag concrete<br />

Clay bricks + slabs<br />

Washed-out concrete<br />

Ceramic tiles<br />

Porcelain stoneware<br />

Long service life combined with maximum cutting ability.<br />

Long service life and good cutting ability.<br />

41

CUTTING | PETROL CUTTING GRINDER<br />

AppliCAtion tAbles<br />

UP TO š 0 0<br />

stAndArd ★★<br />

material FAST CUT LONG LIFE<br />

Asphalt<br />

Abrasive concrete<br />

Concrete<br />

Concrete roofing tiles<br />

Hard concrete<br />

Lightly reinforced concrete<br />

Concrete blocks<br />

Pumice stone<br />

Floor pavement/plaster<br />

Soft fire-resistant bricks<br />

Gas concrete<br />

Fibreglass reinforced plastic<br />

Gneiss<br />

Granite<br />

Hard sand-lime brick<br />

Soft sand-lime brick<br />

Clinkers<br />

Marble<br />

Poroton<br />

Porphyry<br />

Sandstone<br />

Slate<br />

Slag concrete<br />

Clay bricks + slabs<br />

Washed-out concrete<br />

Ceramic tiles<br />

Porcelain stoneware<br />

Long service life combined with maximum cutting ability.<br />

Long service life and good cutting ability.

CUTTING | PETROL CUTTING GRINDER<br />

AppliCAtion tAbles<br />

UP TO š 0 0<br />

bAsiC ★<br />

material<br />

FAST CUT<br />

Asphalt<br />

Abrasive concrete<br />

Concrete<br />

Concrete roofing tiles<br />

Hard concrete<br />

Lightly reinforced concrete<br />

Concrete blocks<br />

Pumice stone<br />

Floor pavement/plaster<br />

Soft fire-resistant bricks<br />

Gas concrete<br />

Fibreglass reinforced plastic<br />

Gneiss<br />

Granite<br />

Hard sand-lime brick<br />

Soft sand-lime brick<br />

Clinkers<br />

Marble<br />

Poroton<br />

Porphyry<br />

Sandstone<br />

Slate<br />

Slag concrete<br />

Clay bricks + slabs<br />

Washed-out concrete<br />

Ceramic tiles<br />

Porcelain stoneware<br />

Long service life combined with maximum cutting ability.<br />

Long service life and good cutting ability.<br />

43

strAight grinder Cutting<br />

Resin 46<br />

Accessories 47<br />

45

CUTTING | STRAIGHT GRINDER<br />

Cutting | resin<br />

The innovative and economic advantages of our ultra-thin cut-off wheels<br />

can be seen especially when cutting thin metal sheets and thin-walled<br />

profiles. These are shown particularly by maximum performance,<br />

lifetime, clean cutting areas, the lowest burr formation and the low<br />

thermal load on the workpiece. Cut-off wheels in standard widths offer<br />

not only the most economical solution but also ultimate safety due to<br />

the maximum lifetime and stability. For cutting solid materials, pipes,<br />

and profiles made from steel and stainless steel, including cast iron.<br />

A thorough colour coding system enables you to always find the right<br />

product for your material or application.<br />

premium<br />

Construction/materials able to be machined: long life design.<br />

High-performance cut-off wheel for cutting metal sheets, profiles, pipes and rods.<br />

Details: Grit size 100 for particularly low-burr cutting.<br />

8 VHJ XDUGVI URP š P P <br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

699330 41 63x1x10 A100-BFM 100<br />

704198 41 63x2x10 A100-BFM 100<br />

325212 41 75x1x10 A100-BFM 100<br />

41<br />

46

CUTTING | STRAIGHT GRINDER<br />

premium<br />

Construction/materials able to be machined: aggressive design in R grade.<br />

High performance cut-off wheel for cutting.<br />

Details: for fast, convenient and low-burr cutting with maximum wheel life.<br />

8 VHJ XDUGVI URP š P P <br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

323978 41 50x1x10 A60R-BFXA 100<br />

323970 41 50x2x6 A46R-BFXA 100<br />

299269 41 63x1x10 A60R-BFXA 100<br />

324404 41 63x1.6x10 A46R-BFXA 100<br />

711834 41 63x1.6x10 A60R-BFXA 100<br />

324402 41 63x2x6 A46R-BFXA 100<br />

324303 41 63x2x10 A46R-BFXA 100<br />

325228 41 75x1x8 A60R-BFXA 100<br />

299270 41 75x1x10 A60R-BFXA 100<br />

325222 41 75x1.6x10 A46R-BFXA 100<br />

327350 41 75x1.6x10 A60R-BFXA 100<br />

325224 41 75x2x8 A46R-BFXA 100<br />

325219 41 75x2x10 A46R-BFXA 100<br />

41<br />

ACCessories<br />

For mounting small cut-off wheels on straight grinders. Take note of max.<br />

permissible speed<br />

Details:<br />

S = diameter of mandrel<br />

H = bore attachment<br />

M = thread<br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

803404 100SS S6/H10/M10 SS171 1<br />

846441 100SS S10/H10/M10 SS173 1<br />

846442 100SS S6/H6/M6 SS174 1<br />

100 SS<br />

47

Angle grinder Cutting<br />

PREMIUM resin 50<br />

STANDARD resin 55<br />

BASIC resin 57<br />

49

CUTTING | ANGLE GRINDER<br />

Cutting | resin<br />

The innovative and economic advantages of our ultra-thin cut-off wheels<br />

can be seen especially when cutting thin metal sheets and thin-walled<br />

profiles. These are shown particularly by maximum performance,<br />

lifetime, clean cutting areas, the lowest burr formation and the low<br />

thermal load on the workpiece. Cut-off wheels in standard widths offer<br />

not only the most economical solution but also ultimate safety due to<br />

the maximum lifetime and stability. For cutting solid materials, pipes,<br />

and profiles made from steel and stainless steel, including cast iron.<br />

A thorough colour coding system enables you to always find the right<br />

product for your material or application.<br />

premium<br />

Construction/materials able to be machined: Long life design in S grade.<br />

High-performance cut-off wheel for cutting metal sheets, profiles, pipes, rods and<br />

solid materials.<br />

Details:<br />

maximum wheel life. 2.5 and 3.0mm cut-off wheels for maximum service life<br />

and stability.<br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

913181 41 115x1x22.23 A60S-BFXA 25 Long life<br />

867822 41 115x1.6x22.23 A46S-BFXA 25 Long life<br />

637066 41 115x2x22.23 A30S-BFXA 25 Long life<br />

913182 41 125x1x22.23 A60S-BFXA 25 Long life<br />

836979 41 125x1.6x22.23 A46S-BFXA 25 Long life<br />

637067 41 125x2x22.23 A30S-BFXA 25 Long life<br />

637068 41 150x2x22.23 A30S-BFXA 25 Long life<br />

183114 41 178x1.6x22.23 A46S-BFXA 25 Long life<br />

785339 41 178x2x22.23 A30S-BFXA 25 Long life<br />

637069 41 178x2.5x22.23 A30S-BFXA 25 Long life<br />

183113 41 230x1.9x22.23 A46S-BFXA 25 Long life<br />

785333 41 230x2x22.23 A30S-BFXA 25 Long life<br />

637070 41 230x2.5x22.23 A30S-BFXA 25 Long life<br />

41 42<br />

637071 42 115x2.5x22.23 A30S-BFXA 25 Long life<br />

637072 42 125x2.5x22.23 A30S-BFXA 25 Long life<br />

637073 42 178x3x22.23 A30S-BFXA 25 Long life<br />

637074 42 230x3x22.23 A30S-BFXA 25 Long life

CUTTING | ANGLE GRINDER<br />

premium<br />

Construction/materials able to be machined: soft, aggressive design in Q grade.<br />

High-performance cut-off wheel for cutting metal sheets, profiles, pipes, rods and<br />

solid material.<br />

Details: 1.0 and 1.6mm cut-off wheels for fast, convenient and low-burr cutting with<br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

77965 41 115x1x22.23 A60Q-BFXA 25 2in1<br />

77963 41 115x1.6x22.23 A46Q-BFXA 25 2in1<br />

872338 41 115x2.5x22.23 A30Q-BFXA 25 2in1<br />

77966 41 125x1x22.23 A60Q-BFXA 25 2in1<br />

77964 41 125x1.6x22.23 A46Q-BFXA 25 2in1<br />

872339 41 125x2.5x22.23 A30Q-BFXA 25 2in1<br />

920351 41 150x1.6x22.23 A46Q-BFXA 25 2in1<br />

872340 41 150x2.5x22.23 A30Q-BFXA 25 2in1<br />

920352 41 178x1.6x22.23 A46Q-BFXA 25 2in1<br />

872341 41 178x2.5x22.23 A30Q-BFXA 25 2in1<br />

872342 41 178x3x22.23 A30Q-BFXA 25 2in1<br />

920353 41 230x1.9x22.23 A46Q-BFXA 25 2in1<br />

872343 41 230x2.5x22.23 A30Q-BFXA 25 2in1<br />

872344 41 230x3x22.23 A30Q-BFXA 25 2in1<br />

41 42<br />

42BN<br />

87215 42 115x1x22.23 A60Q-BFXA 25 2in1<br />

872346 42 115x2.5x22.23 A30Q-BFXA 25 2in1<br />

912603 42 115x3x22.23 A30Q-BFXA 25 2in1<br />

87216 42 125x1x22.23 A60Q-BFXA 25 2in1<br />

872347 42 125x2.5x22.23 A30Q-BFXA 25 2in1<br />

872348 42 125x3x22.23 A30Q-BFXA 25 2in1<br />

907800 42 125x3.5x22.23 A30Q-BFXA 25 2in1<br />

872349 42 150x3x22.23 A30Q-BFXA 25 2in1<br />

872350 42 178x3x22.23 A30Q-BFXA 25 2in1<br />

121878 42 230x2.5x22.23 A30Q-BFXA 25 2in1<br />

872351 42 230x3x22.23 A30Q-BFXA 25 2in1<br />

872352 42 230x3.5x22.23 A30Q-BFXA 25 2in1<br />

170795 42BN 100x1.2x22.23 A46Q-BFXA 25 2in1<br />

51

CUTTING | ANGLE GRINDER<br />

premium<br />

Construction/materials able to be machined: Long life design in R and P grades.<br />

High-performance cut-off wheel for cutting thin-walled metal sheets, profiles, pipes,<br />

rods and solid material.<br />

Details: 1.0 and 1.6mm cut-off wheels for fast, convenient and low-burr cutting with<br />

41<br />

42<br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

610935 41 115x0.75x22.23 A60R-BFXA 25<br />

41502 41 115x1x22.23 A60R-BFXA 25<br />

384142* 41 115x1.2x22.23 TA60P-BFXA 25<br />

35952 41 115x1.6x22.23 A46R-BFXA 25<br />

41489 41 115x2x22.23 A30R-BFXA 25<br />

41491 41 115x2.5x22.23 A30R-BFXA 25<br />

610937 41 125x0.75x22.23 A60R-BFXA 25<br />

41503 41 125x1x22.23 A60R-BFXA 25<br />

384143* 41 125x1.2x22.23 TA60P-BFXA 25<br />

35954 41 125x1.6x22.23 A46R-BFXA 25<br />

41492 41 125x2x22.23 A30R-BFXA 25<br />

41493 41 125x2.5x22.23 A30R-BFXA 25<br />

41494 41 125x3x22.23 A30R-BFXA 25<br />

401205* 41 150x1.2x22.23 TA60P-BFXA 25<br />

41495 41 150x2x22.23 A30R-BFXA 25<br />

291584 41 178x1.6x22.23 A46R-BFXA 25<br />

41499 41 178x2x22.23 A30R-BFXA 25<br />

35946 41 178x2.5x22.23 A30R-BFXA 25<br />

41500 41 230x2x22.23 A30R-BFXA 25<br />

35950 41 230x2.5x22.23 A30R-BFXA 25<br />

41501 41 230x3x22.23 A30R-BFXA 25<br />

42BN<br />

282149 42 115x0.75x22.23 A60R-BFXA 25<br />

472863* 42 115x1.2x22.23 TA60P-BFXA 25<br />

35937 42 115x2x22.23 A30R-BFXA 25<br />

41504 42 115x2.5x22.23 A30R-BFXA 25<br />

282150 42 125x0.75x22.23 A60R-BFXA 25<br />

458870* 42 125x1.2x22.23 TA60P-BFXA 25<br />

35944 42 125x2x22.23 A30R-BFXA 25<br />

41505 42 125x2.5x22.23 A30R-BFXA 25<br />

41506 42 125x3x22.23 A30R-BFXA 25<br />

458874* 42 125x3.5x22.23 TA30P-BFXA 25<br />

458871 42 150x1.2x22.23 TA60P-BFXA 25<br />

41507 42 150x2x22.23 A30R-BFXA 25<br />

41508 42 150x3x22.23 A30R-BFXA 25<br />

458876* 42 150x3.5x22.23 TA30P-BFXA 25<br />

291588 42 178x1.6x22.23 A46R-BFXA 25<br />

41509 42 178x2.5x22.23 A30R-BFXA 25<br />

41510 42 178x3x22.23 A30R-BFXA 25<br />

458878* 42 178x3.5x22.23 TA30P-BFXA 25<br />

41511 42 230x2.5x22.23 A30R-BFXA 25<br />

41513 42 230x3.5x22.23 A30R-BFXA 25<br />

170797 42BN 100x1.2x22.23 A46R-BFXA 25

CUTTING | ANGLE GRINDER<br />

premium<br />

Construction/materials able to be machined: High-performance cut-off wheel in<br />

S grade for cutting metal sheets, profiles, pipes and rods (small cross-section).<br />

Details: 1.0 and 1.6mm cut-off wheels for fast, convenient and low-burr cutting.<br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

337383 41 115x1x22.23 C46S-BFXA 25 2in1<br />

342978 41 125x1x22.23 C46S-BFXA 25 2in1<br />

320335 41 178x1.6x22.23 C46S-BFXA 25 2in1<br />

41<br />

premium<br />

Construction/materials able to be machined: High-performance cut-off wheel in<br />

N grade for cutting metal sheets, profiles, pipes and solid material.<br />

Details:<br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

840247 41 115x1.0x22.23 A60N-BFXA 25<br />

623553 41 115x1.6x22.23 A46N-BFXA 25<br />

257533 41 125x1.0x22.23 A60N-BFXA 25<br />

739982 41 125x1.6x22.23 A46N-BFXA 25<br />

39624 41 115x2.5x22.23 A30N-BFXA 25<br />

39321 41 150x2.5x22.23 A30N-BFXA 25<br />

62726 41 115x2.5x22.23 A30N-BFXA 25<br />

525355 41 178x2.0x22.23 A30N-BFXA 25<br />

32141 41 178x2.5x22.23 A30N-BFXA 25<br />

32142 41 230x2.5x22.23 A30N-BFXA 25<br />

41 42<br />

82646 42 115x2.5x22.23 A30N-BFXA 25<br />

366888 42 125x2.5x22.23 A30N-BFXA 25<br />

468182 42 150x2.5x22.23 A30N-BFXA 25<br />

5485 42 178x3.0x22.23 A30N-BFXA 25<br />

651544 42 178x3.5x22.23 A30N-BFXA 25<br />

30741 42 230x3.0x22.23 A30N-BFXA 25<br />

53

CUTTING | ANGLE GRINDER<br />

premium<br />

Construction/materials able to be machined: High-performance cut-off wheel in<br />

R grade for cutting all cast materials, in P grade free from iron, sulphur or chlorine<br />

(≤ 0.1%) aggressive and good cutting ability.<br />

Details: 2.5 and 3.5mm for maximum service life and stability.<br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

929885 42 115x2.5x22.23 ZA30R-BFXA 25 Focur Extra<br />

929886 42 125x2.5x22.23 ZA30R-BFXA 25 Focur Extra<br />

904019 42 178x3.5x22.23 ZA30P-BFXA 25 Focur Extra<br />

929887 42 178x3.5x22.23 ZA30R-BFXA 25 Focur Extra<br />

855818 42 230x3.5x22.23 ZA30P-BFXA 25 Focur Extra<br />

929889 42 230x3.5x22.23 ZA30R-BFXA 25 Focur Extra<br />

42<br />

54

CUTTING | ANGLE GRINDER<br />

stAndArd<br />

Construction/materials able to be machined: Powerful cut-off wheel for cutting<br />

solid material.<br />

Details: 2.5 and 3.0mm cut-off wheels for long service life, suitable for universal use.<br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

367565 41 115x2.5x22.23 A30-BF 25<br />

367569 41 125x2.5x22.23 A30-BF 25<br />

367574 41 150x2.5x22.23 A30-BF 25<br />

367578 41 178x3x22.23 A30-BF 25<br />

367583 41 230x3x22.23 A30-BF 25<br />

368010 42 100x2.5x16 A30-BF 25<br />

367781 42 115x2.5x22.23 A30-BF 25<br />

367785 42 115x3x22.23 A30-BF 25<br />

367786 42 125x2.5x22.23 A30-BF 25<br />

367789 42 125x3x22.23 A30-BF 25<br />

367800 42 178x3x22.23 A30-BF 25<br />

367803 42 230x3x22.23 A30-BF 25<br />

41 42<br />

stAndArd<br />

Construction/materials able to be machined: Powerful cut-off wheel for cutting<br />

thin-walled metal sheets, profiles, pipes and solid material.<br />

Details:<br />

2.5mm cut-off wheels for long service life, suitable for universal use.<br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

367562 41 115x1x22.23 A60-BFINOX 25<br />

367561 41 115x1.6x22.23 A46-BFINOX 25<br />

367568 41 125x1x22.23 A60-BFINOX 25<br />

367567 41 125x1.6x22.23 A46-BFINOX 25<br />

367776 41 150x2x22.23 A30-BFINOX 25<br />

367575 41 150x2.5x22.23 A30-BFINOX 25<br />

367576 41 178x1.6x22.23 A46-BFINOX 25<br />

367777 41 178x2x22.23 A30-BFINOX 25<br />

367577 41 178x2.5x22.23 A30-BFINOX 25<br />

367581 41 230x1.9x22.23 A46-BFINOX 25<br />

367780 41 230x2x22.23 A30-BFINOX 25<br />

367582 41 230x2.5x22.23 A30-BFINOX 25<br />

41 42<br />

368017 42 100x2x16 A30-BFINOX 25<br />

367783 42 115x2x22.23 A30-BFINOX 25<br />

367788 42 125x2x22.23 A30-BFINOX 25<br />

367791 42 178x2.5x22.23 A30-BFINOX 25<br />

367802 42 230x2.5x22.23 A30-BFINOX 25<br />

55

CUTTING | ANGLE GRINDER<br />

stAndArd<br />

Construction/materials able to be machined: Powerful cut-off wheel for cutting<br />

solid material.<br />

Details: 2.5 and 3.0mm cut-off wheels for long service life, suitable for universal use.<br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

367566 41 115x2.5x22.23 C30-BF 25<br />

367572 41 125x2.5x22.23 C30-BF 25<br />

367580 41 178x3x22.23 C30-BF 25<br />

367585 41 230x3x22.23 C30-BF 25<br />

367782 42 115x2.5x22.23 C30-BF 25<br />

367787 42 125x2.5x22.23 C30-BF 25<br />

367801 42 178x3x22.23 C30-BF 25<br />

367804 42 230x3x22.23 C30-BF 25<br />

41 42<br />

56

CUTTING | ANGLE GRINDER<br />

bAsiC<br />

Construction/materials able to be machined: Universal cut-off wheel for cutting<br />

metal sheets, profiles, pipes, rods and solid material.<br />

Details:<br />

cut-off wheels for long service life, suitable for universal use.<br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

222996 41 100x2.5x16 A30-BF 25 2in1<br />

222899 41 115x1.6x22.23 A46-BF 25 2in1<br />

222997 41 115x2.5x22.23 A30-BF 25 2in1<br />

222900 41 125x1.6x22.23 A46-BF 25 2in1<br />

222998 41 125x2.5x22.23 A30-BF 25 2in1<br />

222999 41 150x2.5x22.23 A30-BF 25 2in1<br />

633506 41 178x1.6x22.23 A46-BF 25 2in1<br />

223000 41 178x3x22.23 A30-BF 25 2in1<br />

633509 41 230x1.9x22.23 A46-BF 25 2in1<br />

291949 41 230x2x22.23 A30-BF 25 2in1<br />

223002 41 230x3x22.23 A30-BF 25 2in1<br />

41 42<br />

223020 42 100x2.5x16 A30-BF 25 2in1<br />

223021 42 115x2.5x22.23 A30-BF 25 2in1<br />

223022 42 125x2.5x22.23 A30-BF 25 2in1<br />

291948 42 125x3x22.23 A30-BF 25 2in1<br />

223023 42 178x3x22.23 A30-BF 25 2in1<br />

222044 42 230x3x22.23 A30-BF 25 2in1<br />

291947 42 230x3.5x22.23 A30-BF 25 2in1<br />

bAsiC<br />

Construction/materials able to be machined: Universal cut-off wheel for cutting<br />

thin-walled metal sheets, profiles, pipes and rods (small cross-section).<br />

Details: 1.0mm cut-off wheels for fast, convenient and low-burr cutting.<br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

222893 41 100x1x16 A60-BFINOX 25<br />

222894 41 115x1x22.23 A60-BFINOX 25<br />

222896 41 125x1x22.23 A60-BFINOX 25<br />

41<br />

57

CUTTING | ANGLE GRINDER<br />

bAsiC<br />

Construction/materials able to be machined: Universal cut-off wheel for cutting<br />

solid material.<br />

Details: 2.5 and 3.0mm cut-off wheels for long service life, suitable for universal use.<br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

223010 41 100x2.5x16 C30-BF 25<br />

223012 41 115x2.5x22.23 C30-BF 25<br />

223015 41 125x2.5x22.23 C30-BF 25<br />

223016 41 150x2.5x22.23 C30-BF 25<br />

222042 41 178x3x22.23 C30-BF 25<br />

223019 41 230x3x22.23 C30-BF 25<br />

223024 42 100x2.5x16 C30-BF 25<br />

223025 42 115x2.5x22.23 C30-BF 25<br />

223027 42 125x2.5x22.23 C30-BF 25<br />

223029 42 178x3x22.23 C30-BF 25<br />

223031 42 230x3x22.23 C30-BF 25<br />

41 42<br />

ACCessories<br />

Construction/materials able to be machined: Special accessory made from<br />

tempered tool steel for angle grinders with M14 drive screw; accessory for<br />

Increases lateral stability, enables even more precise wheel guidance, improves<br />

section performance.<br />

XOWUD WK LQF XW RIIZ HHOVLQV WUDLJK WGHVLJQ VK DSH š DQGš P P <br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

614644 100SFL 76 mm 1<br />

58

petrol sAW Cutting<br />

PREMIUM resin 60<br />

STANDARD resin 62<br />

BASIC resin 64<br />

59

CUTTING - PETROL SAW CUTTING<br />

Cutting | resin<br />

For the various cutting jobs encountered in industry and handicrafts,<br />

TYROLIT always provides the right tools for both portable and<br />

stationary machines.<br />

Whether for use on steel, stainless steel (INOX), stone or slate, the clear<br />

colour coding system and the application tips always enable you to find<br />

the right product for your application and the material to be cut.<br />

TYROLIT guarantees optimum cutting results and the ultimate safety<br />

in all situations.<br />

premium<br />

Construction/materials able to be machined: Special tool for cutting large<br />

cross-sections.<br />

Details: For use on portable cut-off machines with electric motors or petrol<br />

engines (off-hand and guided off-hand applications) or on powerful stationary<br />

machines. (≥ 5KW)<br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

255451 41H 300x3.5x20 A30O-BF02A2 10 Easy cut<br />

75020 41H 300x3.5x20 A30P5BF71A2 10<br />

307876 41H 300x3.5x20 A30Q-BF02A2 10 Easy cut<br />

181071 41H 300x3.5x22.2 A30O-BF02A2 10 Easy cut<br />

141512 41H 300x3.5x22.2 A30Q-BF02A2 10 Easy cut<br />

83618 41H 300x3.5x22.2 A30Q4BF71A2 10<br />

514745 41H 300x3.5x22.2 M85A30P4BF91A2 10<br />

363478 41H 300x3.5x25.4 A30O-BF02A2 10 Easy cut<br />

351693 41H 300x3.5x30 A30N-BF02A2 10 Easy cut<br />

366794 41H 300x3.5x30 A30Q-BF02A2 10 Easy cut<br />

419688 41H 350x4x30 A30N-BF02A2 10 Easy cut<br />

623097 41H 400x4.5x40 MA30Q4BF97M2 10<br />

41H

CUTTING - PETROL SAW CUTTING<br />

premium<br />

Construction/materials able to be machined: long life design in Q grade.<br />

High-performance cut-off wheels for cutting profiles, solid material and large<br />

cross-sections.<br />

Details: Special specification for cutting rails, easy cutting ability and optimised<br />

lifetime. For use on portable cut-off machines with electric motors or petrol<br />

engines (off-hand and guided off-hand applications) or on powerful stationary<br />

machines. (≥ 5KW)<br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

665900 41H 300x3.2x22.2 A24Q-BF 10<br />

676423 41H 300x3.5x22.2 A24Q-BF100 10<br />

671093 41H 350x3.8x22.2 A24Q-BF100 10<br />

671108 41H 350x3.8x25.4 A24Q-BF100 10<br />

671090 41H 400x4.3x22.2 A24Q-BF100 10<br />

676428 41H 400x4.3x25.4 A24Q-BF100 10<br />

41H<br />

premium<br />

Construction/materials able to be machined: Powerful cut-off wheel with<br />

2 external reinforcements for cutting solid material and large cross-sections.<br />

Details: For use on portable cut-off machines with electric motors or petrol<br />

engines (off-hand and guided off-hand applications) or on powerful stationary<br />

machines. (≥ 5KW)<br />

TYPE NO. SHAPE DImENSIONS SPECIFICATION PU CLASSIFICATION<br />

255450 41H 300x3.5x20 C24O-BF02A2 10<br />

183592 41H 300x3.5x22.2 C24O-BF02A2 10<br />

9292 41H 300x4x20 C30P4BF71A2 10<br />

410277 41H 300x4x22.2 1C24R6BF38A2 10<br />

732088 41H 300x4x25.4 C247O4BF33A2 10<br />

668570 41H 350x4x20 C24O-BF02A2 10<br />

548170 41H 350x4x25.4 C24O-BF02A2 10<br />

41H<br />

61

CUTTING - PETROL SAW CUTTING<br />

stAndArd<br />

Construction/materials able to be machined: Powerful cut-off wheel with<br />

2 external reinforcements for cutting profiles, solid material and large<br />

cross-sections.<br />

Details: For use on portable cut-off machines with electric motors or petrol<br />

engines (off-hand and guided off-hand applications) or on powerful stationary<br />

machines. (≥ 5KW)<br />