You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

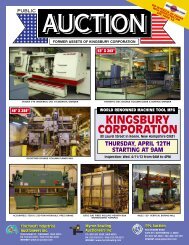

DUE TO BANKRUPTCY<br />

US BANKRUPTCY COURT EASTERN DISTRICT OF MI<br />

3 SALES•3 DAYS•3 LOCATIONS<br />

Tier 1 Stamping Facilities Including Welded<br />

Assembly Cells, Modules & Components,<br />

Full Manufacturing Support<br />

<strong>Oxford</strong> Automotive Inc.<br />

370 Manhattan Road, Greencastle, Indiana 46135 USA<br />

TUESDAY, JUNE 14<br />

AT 9:00 A.M. LOCAL TIME<br />

REBUILT<br />

><br />

MINSTER<br />

MDL. E2-400-96-48<br />

400-TON<br />

STRAIGHT-SIDE<br />

DOUBLE<br />

CRANK PRESS,<br />

w/FEED LINES, 1978<br />

CAN’T<br />

ATTEND?<br />

JUST CLICK<br />

& BID!<br />

Real Estate to Be<br />

Offered at Same Time<br />

VERSON MDL. S4-1000-144-84T 1,000-TON STRAIGHT-SIDE<br />

DOUBLE CRANK PRESS, 1986 REBUILT<br />

520 Republic Avenue, Alma, Michigan 48801 USA<br />

THURSDAY, JUNE 16 AT 9:00 A.M. LOCAL TIME<br />

<<br />

(2) VERSON MDL. LE4-800-108-72<br />

800-TON STRAIGHT-SIDE PRESSES,<br />

w/ 4 POINT ECCENTRIC GEARED<br />

PRESS LINE, RED LINE, 1990<br />

><br />

SMG SCHULER MDL. HZPUI-<br />

1400/900/3600/2500 2,300-TON<br />

DOUBLE ACTION TOP DRIVE<br />

HYDRAULIC PRESS, w/(4) SMG<br />

SCHULER 550 T STRAIGHT-SIDE<br />

HYDRAULIC PRESSES, ALL 1996<br />

1700 Short Drive, Prudenville, Michigan 48651 USA<br />

FRIDAY, JUNE 17 AT 9:00 A.M. LOCAL TIME<br />

(410) 654-7500 • (800) 722-3334 • http://www.michaelfox.com • email: info@michaelfox.com<br />

NORTH AMERICAN OFFICES: CALIFORNIA, CANADA, FLORIDA, ILLINOIS, MARYLAND, NEBRASKA, NEW YORK, OREGON, PENNSYLVANIA,<br />

TEXAS, WASHINGTON, ADDITIONAL OFFICES WORLDWIDE<br />

Indiana Auction Lic. Number: David S. Fox AU10300003<br />

BID<br />

ON-LINE<br />

www.michaelfox.com

OXFORD AUTOMOTIVE—JUNE 14, GREENCASTLE, INDIANA<br />

Machinery & Equipment Plus Real Estate<br />

370 MANHATTAN ROAD, GREENCASTLE, INDIANA, 57.64± SQ. FT.<br />

14<br />

AVAILABLE<br />

2<br />

AVAILABLE<br />

(2) MINSTER MDL. E2-400-96-48 400-TON STRAIGHT-SIDE DOUBLE<br />

CRANK PRESSES, w/FEED LINES, 1978<br />

Inspection: June 6–June 8<br />

By Appointment Only<br />

Open Inspections: June 9, 10, and 13.<br />

(10:00 A.M. to 4:00 P.M. local time)<br />

STRAIGHT-SIDE<br />

DOUBLE CRANK PRESSES<br />

(14) VERSON MDL. S2-250-96-48T 250-TON STRAIGHT-SIDE DOUBLE CRANK PRESSES, 1966–1980<br />

VERSON S4-1000-144-84T 1,000-Ton Capacity 4-Point Eccentric<br />

Geared Straight-Side Press, S/N 28394, Stroke 20", Shut Height<br />

60", Adjustment 14", SPM 13–26, Bed Area 144" x 84", Air Clutch,<br />

Air Counterbalance, Roll Out Bolster, w/Gull Wing Swing Down<br />

Transfer System, w/Allen-Bradley PLC Control, S/N GW1180,<br />

Sahlin Automated Parts Feed System, Spanco 1-Ton Press<br />

Mounted Jib Crane w/Electric Hoist, 1986, See Photo<br />

VERSON S4-1000-144-84T 1,000-Ton Capacity 4-Point Eccentric<br />

Geared Straight-Side Press, S/N 28393, Stroke 20", Shut Height<br />

60", Slide Adjustment 14", SPM 13–26, 53-1/2"W x 46"H Windows,<br />

Roll Out Bolster Area 144"LR x 84"FB, Bolster 12", Verson Twin<br />

Circuit Control, Banner Infrared Safety Curtain, Air Clutch,<br />

Counterbalance, Re-Built, Rolling Bolster, 1986<br />

MULTIPLE 250–600-TON PRESSES, SOME FLOOR STANDING, SOME WITH AIR CUSHIONS<br />

2<br />

SOME ITEMS MAY BE SUBJECT TO PRIOR SALE<br />

VERSON S4-1000-144-84T 1,000-Ton Capacity 4-Point Eccentric<br />

Geared Straight-Side Press, S/N 25972, Stroke 20", Shut Height<br />

60", Slide Adjustment 14", SPM 13–26, 53-1/2"W x 46"H Windows,<br />

Bolster Area 144"LR x 84"FB, Bolster 12", Toledo Transducer Die<br />

Try Digital Systems, Monitor, Smartpac Wintriss Press Automation<br />

Control w/Smartscreen Console, Air Clutch, Air Counterbalance,<br />

1978, See Photo<br />

VERSON S2-600-120-72T 600-Ton Capacity 2-Point Eccentric<br />

Geared Straight-Side Press, S/N 18469, Stroke 20", Shut Height<br />

46", Adjustment 10", SPM 10–20, Bed Area 120" x 72", 30"<br />

Windows, Air Clutch, Air Counterbalance, Link-Logic Brake<br />

Monitor, 1965

NEW<br />

2004<br />

COE MDL. CPR-60072 SERVO PRESS FEEDLINE, 60,00-LB. x 72"W. x 5/8", NEW 2004<br />

<<br />

VERSON<br />

MDL. S4-1000-144-84T<br />

1,000-TON<br />

STRAIGHT-SIDE<br />

DOUBLE CRANK PRESS,<br />

1986<br />

VERSON MDL. S4-1000-144-84T 1,000-TON STRAIGHT-SIDE<br />

DOUBLE CRANK PRESS, 1978<br />

CELL PHONE RECEPTION IS<br />

POOR INSIDE THESE PLANTS<br />

STRAIGHT-SIDE DOUBLE CRANK<br />

PRESSES, cont.<br />

(13) VERSON S2-500-96-48T 500-Ton Capacity 2 Point<br />

Eccentric Geared Straight-Side Presses, Stroke 18", Shut Height<br />

42-1/2", Slide Adjustment 8", SPM 13-26, 28-1/2"W x 35"H<br />

Windows, Bolster Area 96"LR x 48"FB, Bolster 6-1/2",<br />

Link-Logic Brake Monitors, Air Clutch, Air Counterbalance,<br />

1966–1980, See Photo<br />

(2) MINSTER Hevi Stamper E2-400-96-48<br />

400-Ton Straight-Side Presses, Stroke 8", Shut<br />

Height 30", Slide Adjustment 6", SPM 50–100,<br />

31"W x 18"H Windows, Bolster Area 96"LR x<br />

48"FB, Bolster 6", Air Clutch, Air Counterbalances,<br />

Belt Type Off Load Conveyor, Link Lite and<br />

Banner Infrared Safety Curtains, Smartpac Digital<br />

Wintriss Automation Controls, 1978, See Photo,<br />

Feed Lines<br />

13<br />

AVAILABLE<br />

VERSON MDL. S4-1000-144-84T 1,000-TON STRAIGHT-SIDE DOUBLE CRANK PRESS, 1986, ROLLING BOLSTER<br />

EAGLE PRESS SC2-400-84-60 400-Ton 2-Point<br />

Straight-Side Double Crank Press, S/N EP-97-<br />

082694, Stroke 12", Shut Height 30", Adjustment<br />

6", SPM 25–50, Bed Area 84" x 60", 42" Windows,<br />

Air Clutch, Air Counterbalance, Spectrum PLC<br />

Control, Infrared Light Curtain, w/Feedline, 1997<br />

(14) VERSON S2-250-96-48T 250-Ton Capacity<br />

2-Point Eccentric Geared Straight-Side Presses,<br />

Stroke 12", Shut Height 30-1/2", Slide Adjustment<br />

8", SPM 25, 28-3/4"W x 23-1/4"H Windows,<br />

Bolster Area 96"LR x 48"FB, Bolster 6-1/2",<br />

Link-Logic Brake Monitor, Allen-Bradley Digital<br />

Systems Monitor, Air Clutch, Air<br />

Counterbalance,1966–1980, See Photo<br />

VERSON SS2-250-144-48T 250-Ton Capacity, S/N<br />

24441, Stroke 12", Shut Height 30", Adjustment 6",<br />

SPM 30, Bed and Ram 48" x 144", Air Clutch, Air<br />

Counterbalance, Windows, See Photo<br />

(13) VERSON 500-TON STRAIGHT-SIDE DOUBLE CRANK<br />

PRESSES, MDL. S2-500-96-48T, 1966–1980<br />

VERSON MDL. SS2-250-144-48T 250-TON STRAIGHT-SIDE<br />

DOUBLE CRANK PRESS<br />

3

OXFORD AUTOMOTIVE—JUNE 14, GREENCASTLE, INDIANA<br />

Machinery & Equipment Plus Real Estate<br />

LEBLOND MAKINO LATHE 19" x 84", w/EXTRA TOOLING, 1985<br />

PRODO MAX LEFT HAND & RIGHT HAND WELDING CELLS, AS LATE AS 2004<br />

COIL FEED LINES<br />

COE Mdl. CPR-PO 60072 60,000-Lb. Uncoiler, S/N 34160-4, Max.<br />

Coil W 72", Max. Coil O.D. 72", w/Coil Loading Car; COE 2-Post<br />

Hydraulic Shear, w/Peeler Arm, Hold-Down Roll, and Exit Swing<br />

Up Threading Table; COE Mdl. SP6PS-562-72 5 Over 6 Roll, S/N<br />

34160-3, Capacity 5/8" x 72"W, w/Flip Down Threading Table; COE<br />

Mdl. CPRF-872, S/N 34160-1, 72"W w/Edge Guide, Console<br />

Control, 2004<br />

SESCO 55-602 50,000-Lb. x 54" Traveling Uncoiler, S/N 21974,<br />

w/Sesco Model 53-283 Peeler Straightener, Allen-Bradley Digital<br />

Microprocessor Controls, 1/4" x 54" Capacity, S/N 21978, Sesco<br />

Model 49-511 Leveler Feeder, S/N 219-80, Swing Down Thread Table<br />

COE CPR-CO-30048 30,000-Lb. x 48" 5 Over 6 Roll Uncoiler,<br />

S/N 12509-4, w/Shuttle, Coe Model 2062B 48" x .09" Straightener<br />

Peeler, Capacity 48" x .212", CPRF-548 Leveler Feeder, S/N 12509-1,<br />

Console Digital Control, Flip Up Thread Table<br />

(2) SESCO 55-576 30,000-Lb. x 30" Uncoilers, w/Sesco Model<br />

12-1066 30" x .030 to .090 Peller Straighteners, w/Peeler Arm and<br />

Threading Table, Sesco Mdl. 49-442 30" Leveler Feeder, Unico<br />

Digital Microprocessor Control<br />

PERFECTO 36-72-300 30,000-Lb. x 72" Uncoiler, S/N PR4638,<br />

w/Coil Loading Car, Perfecto Model 38-72-7 72" x .090" to .170"<br />

5-Over-6 Roll Straightener, S/N SS-4637, Perfecto Model 600-72-<br />

W60 Leveler Feeder, S/N F64636, Console Control<br />

(2) MECON Servo Coil Feed Line; MECON Mdl. 250BTJ 25,000-<br />

Lb. Uncoiler, S/N 209402, Max. W 48", Max. Coil O.D. 72", w/Coil<br />

Loading Car; MECON Mdl. 5STR42 Over 6 Roll, S/N STR127,<br />

Capacity 42" x .312" Thick, w/Peller Arm, Threading Table, and<br />

Swing Down Threading Table Over Looping; MECON Mdl. 600F42,<br />

S/N 6002, Capacity 42" x .312" w/Edge Guides and Control Console<br />

WELDING, ROBOTS, & CELLS<br />

GWI Engineering 262 KVA Multi Head Production Spot Welder,<br />

S/N 386200<br />

LINCOLN Idealarc Tig 300/300 300-Amp AC/DC Welder, S/N AC-<br />

662887<br />

FANUC Robotic Welding System Consisting of: FANUC Arc Mate<br />

100 Robot, w/System R-J2 Control, 1995; LINCOLN Electric Model<br />

Power Wave 450 Arc Welder, S/N U1971200589; (2) ESAB<br />

Pneumatic Wire Feed Units, w/Enclosed Crib<br />

HY-TEK SYSTEMS Production Welding System, w/(2) Miller Deltaweld<br />

452 Arc Welding Power Sources; (2) MILLER Automatic 1A Torch<br />

Controls; Pneumatic Clamping Fixture; Infrared Light Curtain<br />

PRODO MAX 360 Lowers RH Welding Cell, S/N 99427R/99011R,<br />

To Include:<br />

(10) FANUC Model ArcMate 100i Welding Robots, w/System R-J3<br />

Controls and Teaching Pendant, 2000; (3) FANUC Model S-430i-W<br />

Robots, w/System R-J3 Control and Teaching Pendant, 2000;<br />

FANUC Model S-430i-F Robot, w/System R-J3 Control and<br />

Teaching Pendant, 2000; (10) LINCOLN Model PowerWave 450<br />

Arc Welders, w/Robotic Interface, 2000; HAAS Model VF550 CNC<br />

Vertical Machining Center, S/N 24572, Table Size 23" x 52", Spindle<br />

Speed Range 0 to 7,500 RPM, Haas CNC Control, 2001; 6-Station<br />

Rotary Production Transfer Machine, w/(2) Vertical Machining<br />

Spindles, (2) Horizontal Machining Spindles, Gauging Station, w/(2)<br />

Marposs E3U Electronic Gauges, Robotic Load/Unload Station,<br />

Coolant System, Chip Conveyor; MILLER Model Deltaweld 450<br />

450-Amp CP DC Arc Welder, S/N JF889503, w/Model R-115 Wire<br />

Feeder, 1985; 5-Position Rotary Welding Fixture; 3-Position<br />

Welding Fixture, Allen-Bradley PLC Control, w/Touch Screen<br />

Controllers, Steel Belt Transfer Conveyors<br />

PRODO MAX 360 Lowers LH Welding Cell, S/N 99427L/99011L,<br />

To Include: (10) FANUC Model ArcMate 100i Welding Robots,<br />

w/System R-J3 Control and Teaching Pendant, 2000; (3) FANUC<br />

4<br />

Model S-430i-W Robots, w/System R-J3 Control and Teaching<br />

Pendant, 2000; FANUC Model S-430i-F Robot, w/System R-J3<br />

Control and Teaching Pendant, 2000; (10) LINCOLN Model<br />

PowerWave 450 Arc Welders, w/Robotic Interface, 2000; HAAS<br />

Model VF550 CNC Vertical Machining Center, S/N 24637, Table<br />

Size 23" x 52", Spindle Speed Range 0 to 7,500 RPM, Haas CNC<br />

Control, 2001; 6-Station Rotary Production Transfer Machine, w/(2)<br />

Vertical Machining Spindles, (2) Horizontal Machining Spindles,<br />

Gauging Station, w/(2) Marposs E3U Electronic Gauges, Robotic<br />

Load/Unload Station, Coolant System, Chip Conveyor; MILLER<br />

Model Deltaweld 450 450-Amp CP DC Arc Welder, S/N JF924928,<br />

w/Model R-115 Wire Feeder, 1985; 5-Position Rotary Welding<br />

Fixture; 3-Position Welding Fixture, Allen-Bradley PLC Control,<br />

w/Touch Screen Controllers, Steel Belt Transfer Conveyors<br />

PRODO MAX 360 Uppers RH Welding Cell, S/N 99426R, To<br />

Include: (9) FANUC Model ArcMate 100i Welding Robots,<br />

w/System R-J3 Controls and Teaching Pendant, 2000; FANUC<br />

Model S-430i Robot, w/System R-J3 Control and Teaching Pendant,<br />

1999; (9) LINCOLN Model PowerWave 450 Arc Welders,<br />

w/Robotic Interface, 2000; MILLER Model Deltaweld 450 450-Amp<br />

CP DC Arc Welder, S/N JH228482, w/Model R-115 Wire Feeder,<br />

1987; 5-Position Rotary Welding Fixture; 3-Position Welding<br />

Fixture, Allen-Bradley PLC Control, w/Touch Screen Controllers,<br />

Steel Belt Transfer Conveyors<br />

PRODO MAX 360 Uppers LH Welding Cell, S/N 99426L, To<br />

Include: (9) FANUC Model ArcMate 100i Welding Robots,<br />

w/System R-J3 Controls and Teaching Pendant, 2000; FANUC<br />

Model S-430i Robot, w/System R-J3 Control and Teaching Pendant,<br />

1999; (9) LINCOLN Model PowerWave 450 Arc Welders,<br />

w/Robotic Interface, 2000; MILLER Model Deltaweld 450 450-Amp<br />

CP DC Arc Welder, S/N JF784539, w/Model R-115 Wire Feeder;<br />

5-Position Rotary Welding Fixture; 3-Position Welding Fixture,<br />

Allen-Bradley PLC Control, w/Touch Screen Controllers, Steel Belt<br />

Transfer Conveyors<br />

PRODO MAX Twist Axle Welding Cell S/N 01402, To Include:<br />

150 KVA 2-Station Production Spot Welder, w/Medweld 3065<br />

Weld Control Op 10; (2) FANUC Model ArcMate 100i Welding<br />

Robots, w/System R-J3 Controls and Teach Pendant, 2001; (2)<br />

LINCOLN Model PowerWave 450 450-Amp Arc Welders;<br />

2-Position Vertical Carousel Type Work Holding Fixture, Op 20;<br />

(2) FANUC Model ArcMate 100i Welding Robots, w/System<br />

R-J3 Controls and Teach Pendant, 2001; CLOOS QUINTO Model<br />

503SD 50-Amp Arc Welders, w/KVM Controller and Wire<br />

Feeder, 2000; 2-Position Vertical Carousel Type Work Holding<br />

Fixture, Op 30; ROBOTIC SERVICES Welding Cell, w/Fanuc<br />

Model ArcMate 100i Welding Robot, w/System R-J2 Control, 1998;<br />

Lincoln Power Wave 450 450-Amp Arc Welder, 2-Position<br />

Horizontal Carousel Type Work Holding Fixture, PLC Control,<br />

Op 35; (5) FANUC Model R-2000i/165F Welding Robots, w/R-J3i<br />

Control and Teach Pendant; (7) FANUC Model ArcMate 100i<br />

Welding Robots, w/System R-J3 Control and Teach Pendant; (8)<br />

LINCOLN PowerWave 450 450-Amp Arc Welders; STARQUIP<br />

Floor Mounted Hydraulic Parts Handler; ADVANCED RESEARCH<br />

CO. Laser Marking Machine, w/Rofin-Sinar ND-YAG Laser,<br />

10-Watt Output, Wavelength 1064; Double End Deburring<br />

Machine; Double End Milling Machine, w/Chip Removal Conveyor;<br />

Free Standing Overhead Gantry Type Parts Transfer System, w/(3)<br />

Handlers; 2-Position Vertical Carousel Type Work Holding Fixtures;<br />

MILLER Model Deltaweld 450 450-Amp Arc Welder, w/Model<br />

R-115 Wire Feed Unit, Op 40–60, 80–120; 150 KVA 2-Station<br />

Production Spot Welder, w/Medweld 3065 Weld Control, Op 70<br />

HY-TEK SYSTEMS Production Welder, w/(2) Miller Deltaweld 452<br />

Arc Welders, (2) Miller Automatic 1A Torch Controllers, Work<br />

Clamping Fixture, Infrared Light Curtain<br />

Spot Welder, w/(8) Kirkhoff 150 KVA Power Supplies, (2) Robotron<br />

Series 400 Weld Controls, (4) 12" Vibratory Nut Feeders, 1994<br />

2-Station Production Spot Welder, w/(2) 120 KVA Power Supplies,<br />

Robotron Series 120 Weld Control<br />

FANUC MDL. 100I ARCMATE WELDING ROBOTS & FANUC<br />

MDL. S-430I ROBOTS, AS LATE AS 2005<br />

FEDERAL Model PA-2-112 PROJ 150 KVA Press Type Spot Welder,<br />

S/N 17547, Throat 12", Robotron Series 110 Weld Control, 1952<br />

2-Station Production Spot Welder, w/(2) 120 KVA Power Supplies,<br />

Robotron Series 120 Weld Control<br />

WELDERS & PRESSES 2-Station Production Spot Welder, S/N 033-<br />

2150B042, w/(2) 150KVA Power Supplies, Robotron Series 115 Weld<br />

Control, 14" Vibratory Bowl Feeder, 1998<br />

BRINKS MACHINE 2-Station Production Spot Welder, w/Approximately<br />

150 KVA Power Supply, Robotron Series 115 Weld Control, 12" Vibratory<br />

Bowl Feeder, Infrared Light Curtain<br />

NATIONAL ELECTRIC Model Type 100PTAO12P-OJ 150 KVA Press<br />

Type Spot Welder, S/N X-5687, Throat 18" w/Robotron Series 110 Weld<br />

Control, Infrared Light Curtain<br />

Welder, w/(2) Miller Deltaweld 450 CP DC Arc Welders, S/N’s JF858954<br />

and JF858977, w/(2) Miller Automatic 1D-DW Torch Controls<br />

AUTOMATION SERVICE EQUIPMENT Welding Cell, To Include:<br />

(2) AIRFLOAT 2-Station Rotary Tilt Indexing Tables, Max. Capacity Per<br />

Station 2,500-Lbs., Base Size 54" x 70"; (6) FANUC Model ArcMate 100i<br />

Welding Robots, w/System R-J3iB Controls and Teaching Pendant, 2003;<br />

(3) FANUC Model R-2000iA Robots, w/System R-J3iB Control and<br />

Teaching Pendant, 2003; (10) LINCOLN Model PowerWave 455 Arc<br />

Welders, w/Robotic Interface, (6) COOL-ARC 40 Cooling Systems, 2003;<br />

Custom Designed & Fabricated 100 KVA Spot Welder, w/Vibratory Bowl<br />

Feeder, Medweld 3015 Welding Control; Hydraulic Unit, w/(2) 15 HP<br />

Motors, M & S Stainless Steel Feed Hopper, Inclined Belt Conveyor,<br />

Vibratory Bowl Feeder, 42" x 12' Exit Conveyor, PLC Control w/Touch<br />

Screen Controller<br />

RPT Radius Arm RH Welding Cell, To Include: (3) FANUC Model ArcMate<br />

100i Welding Robots, w/System R-J2 Controls and Teaching Pendant,<br />

2000; (3) LINCOLN Model PowerWave 450 Arc Welders, w/Robotic<br />

Interface, 2000; Max. MOBILAIR Fume Collector, Horizontal Carousel<br />

Type Work Fixture, Welding Enclosure, PLC Control w/Touch Screen<br />

RPT Radius Arm LH Welding Cell, To Include: (3) FANUC Model ArcMate<br />

100i Welding Robots, w/System R-J2 Controls and Teaching Pendant,<br />

2000; (3) LINCOLN Model PowerWave 450 Arc Welders, w/Robotic<br />

Interface, 2000; Max. MOBILAIR Fume Collector, Horizontal Carousel<br />

Type Work Fixture, Welding Enclosure, PLC Control w/Touch Screen<br />

RPT Radius Arm Rework Welding Cell, To Include: (2) FANUC Model<br />

ArcMate 100i Welding Robots, w/System R-J2 Controls and Teaching<br />

Pendant, 2000; MILLER Model Maxtron 450 450-Amp CC CV DC<br />

Inverter Arc Welder, S/N KD364700, w/Robotic Interface, 1993; MILLER<br />

Model Invision 456P 450-Amp DC Inverter Arc Welder, S/N KJ060771,<br />

w/Robotic Interface, 1998; Horizontal Carousel Type Work Fixture,<br />

Welding Enclosure

MATTISON HYDRAULIC SURFACE GRINDER 18" x 60", 1977<br />

PAINT LINE<br />

BELCO Autophoretic Latex Coating Line, 1500' Overhead Monorail Conveyor w/(2) Drives,<br />

12' x 5' x 10' Shower Chamber, 7103 37' x 17' x 5' Single Zone Natural Gas Fired Pressure<br />

Wash, Clear Water Rinse, 1992<br />

CNC MACHINING CENTERS<br />

HURCO Hawk 5M CNC Vertical Milling Machine, S/N KM96B0654<br />

HAAS VF550 CNC Vertical Machining Center, S/N 24572, Table Size 23" x 52", Spindle Speed<br />

Range 0 to 7,500-rpm, Haas CNC Control, 2001<br />

HAAS VF550 CNC Vertical Machining Center, S/N 24637, Table Size 23" x 52", Spindle Speed<br />

Range 0 to 7,500-rpm, Haas CNC Control, 2001<br />

6-Station Rotary Production Transfer Machine, w/(2) Vertical Machining Spindles, (2)<br />

Horizontal Machining Spindles, Gauging Station w/(2) Marposs E3U Electronic Gauges, Robotic<br />

Load/Unload Station, Coolant System, Chip Conveyor<br />

MAZAK VTC-16B CNC Vertical Traveling Column Machining Center, S/N 119943, Table Size<br />

57-1/2"LR x 16-1/4"FB, 24-Position Tool Magazine, Mazatrol M Plus CNC Control, 1996<br />

MILLS<br />

ARBOGA A3008 Geared Head Floor Type Drill Press, S/N 333748E<br />

MAZAK M1000 Vertical Milling Machine, S/N 11724, 2-HP, 16-Spindle Speeds 58–1500 rpm,<br />

Table Size 67" x 12-1/4", #30 Taper Spindle, Power Table, Feed and Elevation, Pendant<br />

Control, 1975<br />

BRIDGEPORT Series II 4-HP Variable Speed Vertical Duplicating Milling Machine, S/N 2032,<br />

Table Size 60" x 11", w/Bridgeport Con-Trol-Scan Pendant Control, True Trace Model 1115<br />

Tracer Head, 5-HP Hydraulic and Pick Control, 1977<br />

EX-CELL-O 602 Vertical Milling Machine, S/N 60211208, 2-HP, Vari–Speed 85–4000 rpm,<br />

42" x 9" Powerfeed Table, 6" Swivel Base Vise<br />

BRIDGEPORT Series I 2-HP Variable Speed Vertical Milling Machine, S/N 12BR183343, Table<br />

Size 9" x 42", Spindle Speed Range 60–4200 rpm, Powerfeed Table, Sony Magnescale LF-200<br />

2-Axis Digital Readout, 1977<br />

DEFIANCE 25A-Mill 3" Horizontal Boring Mill 1259-42 Vertical Machine Head, Travel 42",<br />

T-Slot Table Size 64" x 36", Box Table, Anilam 2-Axis Digital Readout, 1942<br />

SHARP First 3-HP Vertical Milling Machine, S/N 72113146, Table Size 42" x 9" Variable Speed,<br />

6" Swivel Base Vise, R-8 Collets<br />

LATHES<br />

LEBLOND Makino 19" x 84" C.C. Engine Lathe, S/N<br />

14E-331, w/Taper Attachment, 2-Way Quick Change<br />

Tool Post, 3" Hole Thru Spindle, 12-Spindle Speeds 40<br />

to 1600 rpm, Metric and Standard Threading, 3 and<br />

4-Jaw Chucks, 1985, See Photo<br />

LEBLOND Regal 15" x 60" C.C. Engine Lathe, S/N<br />

7C2976, w/Taper Attachment, Aloris 2-Way Quick<br />

Change Tool Post, 1-1/2" Hole Thru Spindle, 12-Spindle<br />

Speeds 30 to 1200 rpm, Standard Threading, 3 and<br />

4-Jaw Chucks, 5C Collet Chucks<br />

GRINDERS<br />

BROWN & SHARPE 814U 8" x 14" Universal Cylindrical<br />

Grinder, S/N 525-8143-2259, 1-HP Wheelhead Motor<br />

MOORE #2 Jig Grinder, S/N 7598, Table Size 14" x 10",<br />

10" Vertical Headstock Travel, Collets, and Accessories,<br />

REID 618HA 6" x 18" Hand Feed Surface Grinder, S/N<br />

18744, w/Magna-Lock 6" x 18" Electromagnetic Chuck,<br />

1-HP Spindle Motor<br />

PARKER Majestic 6" x 18" Surface Grinder, S/N 2640-<br />

SCM-71, w/6" x 12" Permanent Magnetic Chuck, 1-HP<br />

Wheelhead Motor<br />

BROWN & SHARPE 1030 Micromaster 10" x 30"<br />

Surface Grinder, S/N 523-1030-361, 10" x 30"<br />

Electromagnetic Chuck, w/Neutrofier Control,<br />

Demagnetizer, Coolant Recirculation, 1974<br />

BROWN & SHARPE 1030 Micromaster 10" x 30"<br />

Surface Grinder, S/N 523-1030-310, 10" x 30"<br />

Electromagnetic Chuck, w/Neutrofier Control,<br />

Demagnetizer, Coolant Recirculation<br />

MATTISON 18" x 60" Hydraulic Feed Surface Grinder,<br />

S/N 23786, w/(2) 30" x 18" Magna-Lock HG<br />

Electromagnetic Chucks, w/Electromatic Chucktron<br />

Controls, Travatrol Remote Control, Wheel Dresser,<br />

15-HP Wheelhead Motor, Coolant Recirculation<br />

w/Filtration System, 1977, See Photo<br />

BOYAR-SCHULTZ #2 Profile Grinder, S/N 6-1123-SS,<br />

Tilting Table<br />

INSPECTION/TESTING<br />

HANSFORD Rapid Check Coordinate Measuring<br />

Machine, S/N H-729, Granite Plate Size 49" x 66" x<br />

9-1/2", w/Renishaw PH8 Probe Head, Clone PC<br />

UNITED LCH-10 Speedy Tester Digital Tensile Tester,<br />

S/N 186404, w/8149L B & L Model 2000 Recorder<br />

ELM SYSTEMS Coordinate Measuring/Layout Machine,<br />

S/N 6823, Granite Plate Size 72" x 120" x 16" Thick,<br />

Travels: X=96", Y=48", Z=60", Renishaw PH8 Probe<br />

Head, Series 6048, w/Dell 486 Personal Computer<br />

LK G-90C Coordinate Measuring Machine, S/N 56991,<br />

Granite Plate Size 83-1/2" x 139" x 19" Thick, Machine<br />

Size 2500mm x 1500mm x 1200mm, w/Renishaw<br />

PH10MQ Probe Head, Computer Control, Mounted<br />

on Air Isolation System, 2003, See Photo<br />

MITUTOYO PH-350 14" Optical Comparator,<br />

S/N 8170, Table Size 6" x 16"<br />

Height Gauges, Cubicles, Calipers, Gauge Blocks,<br />

Cabinets, Etc.<br />

HUPPERT Type ST Electric Oven, S/N 111, Capacity<br />

33-Amps, Size 18" x 18" x 30" Deep<br />

Q-Panel OGR Gravelometer 8008-263, w/8104 Freezer<br />

PRECISION 8105 Mechanic Convection Oven,<br />

S/N 21A11/7, Approximately 24"W x 20"H x 16" Deep<br />

ROLLING STOCK<br />

ECONOMY HJ-15-B 500-Lb. Portable Hydraulic Aerial<br />

Lift, S/N BD55524, Maximum Width 15'<br />

(8) CATERPILLAR T125D 12,500-Lb. LP Gas Forklift<br />

Trucks, S/N 5MB02234, Lift 133", Solid Tires, Overhead<br />

Guard, Sideshift Attachment, 1993<br />

(4) CATERPILLAR T100D 10,500-Lb. LP Gas Forklift<br />

Trucks, S/N 5MB02405, Lift 104", Solid Tires, Overhead<br />

Guard, Sideshift Attachment, 1993, See Photo<br />

CATERPILLAR GC45K 10,000-Lb. LP Gas Forklift<br />

Truck, S/N AT8800939, Lift 114", Solid Tires, Overhead<br />

Guard, Sideshift Attachment, 2001<br />

JLG 33HA Articulated Boom Type Aerial Lift, S/N<br />

0308811132, Dual Fuel, Max Lift 33', Max Capacity<br />

500-Lbs<br />

ELWELL-PARKER ERDH-40 40,000-Lb. Electric<br />

Stand-Up Riding Die Handler, S/N 27782, Lift 48",<br />

2003, See Photo<br />

CWF DH-FP-200 20,000-Lb. Electric Walk Behind Die<br />

Handler, S/N 11468, Lift 30"<br />

CWF DH-FP-300 30,000-Lb. Electric Walk Behind Die<br />

Handler, S/N 11467, Lift 30"<br />

(10) YALE MPB040ACN24C2748 4,000-Lb. Electric<br />

Walkie Type Pallet Trucks, 1999<br />

(8) YALE MPB040ACN24C2748 4,000-Lb. Electric<br />

Walkie Type Pallet Trucks, S/N A827N34604Y, 2001<br />

YALE MPW080LEN24T2796 4,000-Lb. Long Reach<br />

Electric Walkie Type Pallet Truck, S/N A891N01675Z,<br />

2002<br />

YALE MPB040EN24C2748 4,000-Lb. Electric Walkie<br />

Type Pallet Truck, S/N B827N03499Z, 2002<br />

TAYLOR-DUNN SS-5-35 3-Wheel Electric Cart,<br />

S/N 106393<br />

Factory Cat 29 Electric Walk Behind Floor Scrubber,<br />

S/N JK29-3036<br />

CLARKE AMERICAN-LINCOLN 7700 LP Gas Riding<br />

Type Floor Scrubber, S/N 750652<br />

FORD F-250XL Pickup Truck, S/N 1FTHF25H3SLB<br />

89059, 1995<br />

ELWELL-PARKER E31 40,000-Lb. Electric Stand Up Die<br />

Handler; CWF DH-FP-200 20,000-Lb. Electric Walk<br />

Behind Die Handler, S/N 10482; 20,000 Electric Walk<br />

Behind Die Handler; YALE MS30MS-071 3,000-Lb.<br />

Electric Walk Behind Forklift, S/N AK-134579;<br />

CALAVAR Condor 68 LP Gas Rough Terrain Boom<br />

Type Aerial Lift, S/N P252004970; 1999 CHRYSLER<br />

3000 4-Door Sedan<br />

4<br />

AVAILABLE<br />

LK MDL. G-90C CMM, NEW 2003,<br />

GRANITE PLATE SIZE 83 1/2" x 139"<br />

x 19" THICK<br />

ELWELL PARKER 40,000-LB. ELECTRIC DIE TRUCK<br />

(4) CATERPILLAR MDL. T100D 10,5000 LB. LP GAS FORK TRUCKS,<br />

AS LATE AS 1995<br />

A 10% BUYER’S PREMIUM APPLIES TO ALL ON-SITE PURCHASES<br />

5

OXFORD AUTOMOTIVE—JUNE 14, GREENCASTLE, INDIANA<br />

Machinery & Equipment Plus Real Estate<br />

SAWS<br />

KALAMAZOO 20" Abrasive Cut-Off Saw, 15-HP Motor<br />

GROB 4V-18 18" Vertical Band Saw, S/N 1147, Table Size 24"<br />

x 28", w/Blade Welder<br />

WELLSAW V-20 20" Vertical Band Saw, S/N 2051, Table Size<br />

26" x 26", Blade Speeds 45–3,000 fpm<br />

DRILLS<br />

BRINKS MACHINE 2-Station Upper Control Arm Drilling<br />

Machine, w/Deburring Spindle and Drilling Station, Infrared<br />

Red Light Curtain<br />

CINCINNATI GILBERT 5' x 9" Column Radial Drill,<br />

S/N 3A-103, 12-Spindle Speeds 42–1500 rpm, L-Shape T-Slot<br />

Base, w/Box Table<br />

CLAUSING 2223 20" Floor-Type Drill Press, S/N 105154,<br />

Taper Spindle, Power Downfeed<br />

MAS VO50 Box Column Radial Drill, S/N 2563, Base Size 39"<br />

x 72", Arm Length 5', Spindle Speed Range 28–2500 rpm,<br />

w/Drill Table, 1988<br />

NEW<br />

BREHOB 40-TON DOUBLE GIRDER 90' SPAN PENDANT BRIDGE CRANE, w/15-TON AUX., NEW 2003<br />

GARDNER-DENVER ROTARY COMPRESSORS, 50 HP, LATE<br />

MODELS<br />

(5) Scrap Removal Conveyors, Mounted Infloor w/Inclined<br />

Unload Section<br />

ROCKLINIZER 600 Electronic Carbide Metal Impregnator<br />

HAMMOND 72" Double-End Buffer, S/N 8059, 1-End w/3"<br />

Belt Sander<br />

AQUA BLAST High Pressure Pressure Washer<br />

RIDGID 535 Pipe and Bolt Threader, S/N 339178, w/Dies,<br />

Accessories, and Cart<br />

MISCELLANEOUS<br />

IRON WORKER<br />

PIRANHA P50 50-Ton Capacity Hydraulic Ironworker,<br />

S/N P505168, Punch, Angle Brake, Flat Bar and Notching<br />

Capacity, 1995<br />

CRANES<br />

ZENAR MILWAUKEE 10-Ton x 30' Double Girder Bridge<br />

Crane, S/N 7225, Top Running Cable Hoist, 6-Way<br />

Pendant Control<br />

ZENAR MILWAUKEE 15-Ton x 30' Double Girder Bridge<br />

Crane, S/N 7226, Top Running Cable Hoist, 6-Way<br />

Pendant Control<br />

DETROIT Hoist 10-Ton x 20' Double Girder Bridge Crane,<br />

S/N 30295, Top Running Cable Hoist, 6-Way Pendant Control<br />

BREHOB 40-Ton Double Girder 90' Span Pendant Crane,<br />

S/N 2518635, See Photo<br />

Approximately 30" Diameter Crane Lifting Magnet<br />

3-Ton Craneway System, w/Harrington 3-Ton Electric Hoist,<br />

Mounted on 30'L I-Beam<br />

WIRE EDM<br />

ELOX 8-2012-DR Ram Type Discharge Machine, S/N 093437<br />

(2) INGERSOLL-RAND RECIPROCATING AIR<br />

COMPRESSORS, 250 HP<br />

W. F. WELLS F16-1 Horizontal Band Saw, Capacity 16" x 24",<br />

Blade Speeds 100–400 fpm<br />

INGERSOLL-RAND 2475 5-HP Vertical Tank Mounted<br />

Reciprocating Air Compressor, S/N 4008583, w/Kaeser Model<br />

KRD025 Air Dryer<br />

(2) INGERSOLL-RAND 19.5" x 11.5" x 7" 250-HP<br />

Reciprocating Air Compressors, S/N JH7686, IR Tendamatic<br />

Systems Monitor, Coil Spring Type Anti-Vibration Base, 1985,<br />

See Photo<br />

GARDNER DENVER Rotary Compressor, S/N<br />

U14267, 1994, See Photo<br />

INGERSOLL-RAND 19.5" x 11.5" x 7" 250-HP XLE<br />

Cube Reciprocating Air Compressor, S/N JH8218, IR<br />

Tendamatic Systems Monitor, Coil Spring Type<br />

Anti-Vibration Base, 1989<br />

ULTRA FILTER SD 7000-60 Refrigerated Air Dryer,<br />

S/N 992/13096/01<br />

Centralized Air Compressor Coolant System, w/(3)<br />

Water Holding Tanks, Pumps, Control Panel, Bio-Max<br />

II Digital Monitoring System, All Fittings, Plumbing<br />

and Hardware<br />

MANCHESTER Approximately 12' x 4' Diameter<br />

Vertical Air Receiving Tank, S/N 466986, 1986<br />

MANCHESTER Approximately 18' x 6' Diameter<br />

Vertical Air Receiving Tank, S/N 409943, 1985<br />

GSE 574 5,000-Lb. Inground Digital Platform Scale,<br />

Platform, Size 7' x 10'<br />

EPCO Vertical Hydraulic Baler, Approximately 5' x 4'<br />

x 2' Bale Size<br />

PRODOMAX Twist Axle Assembly Cell Consisting of:<br />

Starquip Post Mounted Articulated Arm Type<br />

Pneumatic Part Handler, (4) Pneumatic Nut Runners<br />

w/Hanging Type Balancers, Knight Hanging Type<br />

Hydraulic Lift, w/Torque Gun Assembly, (2) Pneumatic<br />

Nut Runners, w/Hanging Type Balancers, (2) Test<br />

Stations, w/Hanging Type Balancers, Pallet Type Transfer<br />

Conveyor w/Bottom Return and Pallet Raise/Lower<br />

Stations, PLC Controls w/Touch Screen Interfaces<br />

ENERPAC 30-Ton H-Frame Hydraulic Press,<br />

w/Hydraulic Pump<br />

2-Station Pneumatic Assembly Press<br />

DAKE 907001 25-Ton Hydraulic H-Frame Shop Press,<br />

S/N 196480, Manual Pump, 33-1/2' Between Housing,<br />

Adjustable Bed (New), 1996<br />

TRINCO 1C-CB1 Dry Blast Sand Blast Cabinet,<br />

S/N 33638, w/Model CDB Collector<br />

JAPAX LU3B Wire Type Electrical Discharge Machine,<br />

w/Model Japt 3F Control, VH-02 Power Supply,<br />

Dielectric Fluid Tank<br />

(2) Prodomax 2-Station 360-Upper Assembly Cell Left<br />

Hand & Right Hand Cells, Each to Include: Pneumatic<br />

Assembly Press, Hydraulic Double End Bushing Press,<br />

Clamping Fixture, Burster Digiforce 9306 Electronic<br />

Force Indicator, Allen-Bradley PLC Control<br />

PRODOMAX 2-Station Assembly Cell, S/N 99013,<br />

to Include: Hydraulic Double End Bushing Press,<br />

Clamping Fixture<br />

(2) IFP 411-ACD, 411-2-ACD Salt Spray Cabinets,<br />

S/N 6047, w/Centralized D.I. Water Pumps<br />

Emerson 6'L x 3'D x 3'H Water Tank Heated, w/Pump<br />

MTS Hydraulic Test System, w/Model 505.07 Hydraulic<br />

Power Unit, S/N 1375078, (2) Model 407 Electronic<br />

Controllers, Model 293 Hydraulic Manifold, 10' x 10'<br />

T-Slotted Fixture Base<br />

Hydraulic Trash Compactor, w/Hydraulic Dumpster<br />

Dumping System<br />

20-Ton Capacity Die Trailer<br />

For more information, please contact<br />

the auctioneer or visit our website at<br />

www.michaelfox.com<br />

SOME ITEMS MAY BE SUBJECT TO PRIOR SALE<br />

6

OXFORD AUTOMOTIVE—JUNE 16, ALMA, MICHIGAN<br />

Machinery & Equipment Plus Real Estate<br />

Inspection: June 6–June 10 By Appointment Only<br />

Open Inspections: June 13–15. (10:00 A.M. to 4:00 P.M. local time)<br />

NEW<br />

1990<br />

520 REPUBLIC AVENUE, ALMA, MICHIGAN, 18.34± SQ. FT.<br />

ADDITIONAL PROPERTY LOCATED IN OSCODA, MICHIGAN<br />

TO BE SOLD FROM THIS LOCATION<br />

VERSON MDL. S2-1000-96-54 1,000-TON<br />

STRAIGHT-SIDE DOUBLE CRANK<br />

VARIABLE PRESS<br />

(2) VERSON MDL. LE4-800-72 800-TON STRAIGHT SIDE PRESSES,<br />

4-POINT ECCENTRIC GEARED PRESS LINE FOLLOWED BY<br />

(3) 500-TON LE4-500-108-72 BLUE LINE, 1990<br />

NEW<br />

1990<br />

USI CLEARING MDL. S4-144-84 600-TON STRAIGHT-SIDE<br />

DOUBLE CRANK FOUR POINT BLANKING PRESS & FEED<br />

LINE, PERFECTO 50"W. x .125" COIL FEED<br />

STRAIGHT-SIDE<br />

DOUBLE CRANK PRESSES<br />

VERSON S2-1000-96-54 1,000-Ton Capacity 2-Point Eccentric<br />

Geared Straight-Side Press, S/N 20700, 16" Stroke, 38" Shut<br />

Height, 10" Adjustment, 12–24 SPM Variable, w/54" x 96" Bed,<br />

36" Windows, Air Clutch, Air Cushion, Link Logic Brake<br />

Monitor, 8" Bolster Plate, Pit Mounted, 1968<br />

VERSON S2-800-108-60T 800-Ton Capacity 2-Point Eccentric<br />

Geared Straight-Side Press, S/N 2739, 16" Stroke, 56" Shut<br />

Height, 10" Adjustment, 20 SPM, w/60" x 108" Bed, 41"W<br />

Windows, Air Cushion, Air Counterbalance, Air Clutch, 8"<br />

Bolster Plate, Spra-Rite, Lubricant Injection System, Pit<br />

Mounted, Link Logic Brake Monitor, Data Instruments Smart<br />

PAC Wintress Press Automation Control, Autoset PAC<br />

Wintress Load Analyzer, Programmable Cam Outputs, 1979<br />

(2) VERSON LE4-800-108-72T 800-Ton Capacity 4-Point<br />

Eccentric Geared Straight-Side Presses, S/N 28895, Each w/24"<br />

Stroke, 75" Shut Height, 27" Adjustment, 6–20 SPM Variable,<br />

72" x 108" Bed, 78"W Windows, 24" Rolling Bolster, Link Logic<br />

Brake Monitors, Air Clutch, Air Cushion, Air Counterbalance,<br />

Verson Twin Circuit Clutch Control, Master Control Panel, Pit<br />

Mounted, 1990, See Photo<br />

2<br />

AVAILABLE<br />

(2) VERSON MDL. LE4-800-108-72 800-TON STRAIGHT-SIDE PRESSES, FOLLOWED BY (3) 500-TON LE4-500-108-72,<br />

RED LINE, 1990<br />

(3) VERSON LE4-500-108-72T 500-Ton Capacity 4-Point Eccentric Geared Straight-Side Presses, S/N 28902, Each<br />

w/24" Stroke, 75" Shut Height, 27" Adjustment, 6–20 SPM Variable, 72" x 108" Bed, 78"W Windows, 24" Rolling Bolster,<br />

Link Logic Brake Monitors, Air Clutch, Air Cushion, Air Counterbalance, Verson Twin Circuit Clutch Control, Master<br />

Control Panel, Pit Mounted, 1991<br />

(2) VERSON LE4-800-108-72T 800-Ton Capacity 4-Point Eccentric Geared Straight-Side Presses, S/N 28897, Each<br />

w/24" Stroke, 72" Shut Height, 27" Adjustment, 6–20 SPM Variable, 72" x 108" Bed, 78"W Windows, 24" Roll-In Bolster,<br />

Link Logic Brake Monitors, Air Clutch, Air Cushion, Air Counterbalance, Verson Twin Circuit Clutch Control, Master<br />

Control Panel, Pit Mounted, 1990<br />

(3) VERSON LE4-500-108-72T 500-Ton Capacity 4-Point Eccentric Geared Straight-Side Presses, S/N 28914, Each<br />

w/24" Stroke, 72" Shut Height, 27" Adjustment, 6–20 SPM Variable, 72" x 108" Bed, 78"W Windows, 24" Rolling Bolster,<br />

Link Logic Brake Monitors, Air Clutch, Air Cushion, Air Counterbalance, Verson Twin Circuit Clutch Control, Master<br />

Control Panel, Pit Mounted, 1991<br />

SOME ITEMS MAY BE SUBJECT TO PRIOR SALE<br />

7

OXFORD AUTOMOTIVE—JUNE 16, ALMA, MICHIGAN<br />

Machinery & Equipment Plus Real Estate<br />

STRAIGHT-SIDE DOUBLE CRANK PRESSES, Cont.<br />

USI CLEARING S4-600-144-84-HB 600-Ton Capacity 4-Point<br />

Eccentric Geared Straight-Side Press, S/N 10-4064, 24" Stroke, 48"<br />

Shut Height, 12" Adjustment, 17-18 Vari SPM, w/84" x 144" Bed, 51"W<br />

Windows, Air Cushion, Air Counterbalance, Air Clutch, Pit Mounted,<br />

Programmable Cam Outputs, Spra-Rite Lubricant Injection System,<br />

Data Instruments Smart PAC Wintress Press Automation Control<br />

System, 24" Rolling Bolster, 1968<br />

(9) VERSON S2-500-96-60T 500-Ton Capacity 2-Point Eccentric<br />

Geared Straight-Side Presses, S/N 25944, 18" Stroke, 42.5" Shut<br />

Height, 14" Adjustment, 13–26 SPM Variable, w/60" x 96" Bed, 48"W<br />

Windows, Air Counterbalance, Air Clutch, Pit Mounted, Link Logic<br />

Brake Monitor, (2) Data Instruments Autoset 1500 Wintress Load<br />

Analyzers, 6.5" Bolster Plate, 1978, See Photo<br />

VERSON MDL. S2-500-96-48 500-TON STRAIGHT-SIDE<br />

DOUBLE CRANK BLANKING LINE, w/30,000-LB. x 72"W. x .080"<br />

THICK CAPACITY<br />

(5) VERSON S2-500-96-48T 500-Ton<br />

Capacity 2-Point Eccentric Geared<br />

Straight-Side Presses, 18" Stroke, 42.5"<br />

Shut Height, 8" Adjustment, 13–26 SPM<br />

Variable, w/48" x 96" Bed, 24" Windows,<br />

Air Clutch, Air Counterbalance, Link Logic<br />

Brake Monitor, 8" Bolster Plate, 1978<br />

(3) VERSON S2-500-96-48T 500-Ton<br />

Capacity 2-Point Eccentric Geared<br />

Straight-Side Presses, 12" Stroke, 30.5"<br />

Shut Height, 8" Adjustment, 25 SPM,<br />

w/48" x 96" Bed, 28"W Windows, Air<br />

Cushion, Air Clutch, Air Counterbalance,<br />

Pit Mounted, 6.5" Bolster Plate, Link Logic<br />

Brake Monitor, Allen-Bradley PLC<br />

Control, 1964–1980<br />

(7) VERSON S2-250-96-48T 250-Ton<br />

Capacity 2-Point Eccentric Geared<br />

Straight-Side Presses, 12" Stroke, 30.5"<br />

Shut Height, 8" Adjustment, 25 SPM,<br />

w/48" x 96" Bed, 29"W Windows, Air<br />

Counterbalance, Air Clutch, 6" Bolster<br />

Plate, Link Logic Brake Monitor,<br />

1964–1980, See Photo<br />

BLISS 200-Ton Capacity 2-Point Double<br />

Crank Straight-Side Press, 12" Stroke,<br />

w/48" x 84" Bed, 25" Windows, 6" Bolster<br />

Plate, Link Logic Brake Monitor Air Clutch<br />

VERSON 200-B2-84 200-Ton Capacity<br />

2-Point Straight-Side Press, S/N 27055,<br />

12" Stroke, 30" Shut Height, 8"<br />

Adjustment, 30 SPM, w/54" x 84" Bed, 54"<br />

x 84" Ram, 32"W Windows, Air Cushion,<br />

Air Counterbalance, Air Clutch, 6" Bolster<br />

Plate, Link Logic Brake Monitor, 1978<br />

VERSON C2-200-84-48T 200-Ton<br />

Capacity 2-Point Straight-Side Press, S/N<br />

14681, 12" Stroke, 24" Shut Height, 8"<br />

Adjustment, 26 SPM, w/48" x 84" Bed,<br />

48" x 84" Ram, 30" Windows, Air<br />

Counterbalance, Air Clutch, 8" Bolster<br />

Plate, Link Logic Brake Monitor<br />

9<br />

AVAILABLE<br />

(9) VERSON MDL. S2-500-96-60T 500-TON STRAIGHT-SIDE<br />

DOUBLE CRANK PRESSES, 1978 TO 1998<br />

GAP FRAME PRESSES<br />

(5) VERSON 150-GP2-72 150-Ton Capacity 2-Point Open Back<br />

Gap Frame Press, w/36" x 84" Bed, 36" x 84" Ram, 8" Stroke, 30"<br />

Shut Height, 5" Adjustment, 40-spm, Link Logic Brake Monitor, Air<br />

Clutch, Air Cushion, Air Counterbalance, 1977–1980<br />

5<br />

AVAILABLE<br />

9<br />

AVAILABLE<br />

(5) VERSON MDL. GP2-72 150-TON DOUBLE<br />

CRANK PRESSES<br />

(1 OF 9) VERSON MDL. S2-500-96-48T 500-TON<br />

STRAIGHT-SIDE DOUBLE CRANK PRESS<br />

VERSON MDL. S2-800-108-60T 800-TON STRAIGHT-SIDE DOUBLE<br />

CRANK PRESS, 1979<br />

8<br />

A 10% BUYER’S PREMIUM APPLIES TO ALL ON-SITE PURCHASES

HYDRAULIC<br />

PRESSES<br />

SMG SCHULER HZPUI-1400/900/3600/2500<br />

2,300-Ton Double Action Top Drive Hydraulic<br />

Press, See Photo; (1) ATLAS TECHNOLOGIES<br />

Blank Destacker, S/N G115.00, 1996; w/ALLEN-<br />

BRADLEY Panel View 900 PLC Control; SYRON<br />

Multi-Channel Double Blank Analyzer; 12" x 48"<br />

Min. Blank Size; 72" x 120" Max. Blank Size;<br />

.020"–.125" Max. Blank Thickness; 12" Max.<br />

Stack Height; 30,000 Lb.; (1) SMG SCHULER<br />

2,300 US Ton Capacity, 4-Point Eccentric<br />

Geared Straight-Side Press, S/N 7/5046, 1996,<br />

61.02" Stroke w/98.4" x 141" Bed; 6–8 Spm,<br />

Variable, Pit Mounted; (4) SMG SCHULER Mdl.<br />

HPU500-3600/2150 550 US Ton Capacity,<br />

4-Point Eccentric Geared Straight-Side Presses,<br />

1996 Each w/84.64" x 141" Bed; (7) KAWASKI<br />

Mdl. UT-150 6-Axis Overhead Mounted Robotic<br />

Pick-N-Place Arm, 1996, Each w/PLC Controller<br />

Quick Change Tooling Lindgren 6-Station Quick<br />

Change Bolster System w/6 Rail Die Transfer<br />

Carts, CNC Controlled, 1996, See Photo<br />

(3) TESCO ENGINEERING Approx. 75-Ton<br />

Capacity 4-Post Downacting Hydraulic Press,<br />

w/36" x 96" Between Posts, Approximately<br />

40-HP Hydraulic Power Supply Downacting<br />

VERSON 100-HD2-156-84T 100-Ton Capacity<br />

Hydraulic Spotting Press, S/N 12653, w/84" x<br />

156" Bed, 84" x 156" Ram, 60" Stroke, 78" Shut<br />

Height, 20" Adjustment, 0–156"/Min. Operating<br />

Speed, No Windows, Pit Mounted, 6" Rolling<br />

Bolster, 1956, See Photo<br />

OTC 55-Ton Capacity H-Frame Shop Press,<br />

Unknown, w/36" Between Uprights<br />

DAKE 6-482 82-Ton Capacity H-Frame Shop<br />

Press, S/N 161243, w/44" Between Uprights,<br />

Dake Air Hydraulic Power Supply<br />

COIL FEED LINES<br />

SESCO, Mdl. 55-601 60,000 Lb. x 74" W.<br />

Motorized Coil Reel, S/N 2159, Rail Mounted<br />

w/Coil Car; SESCO Mdl. 53-287 74" W. x .250"<br />

Thick Coil Straightener, S/N 21963, 3 over 4<br />

Roll, Looping Fit Peeler; SESCO Mdl. 49-508 74"<br />

W. Coil Feeder, .250" Thick S/N 21965<br />

CULLEN-FRIEDSTADT 200 20,000-Lb.<br />

Capacity Coil Upender SB-T1, w/48" x 56" Bed,<br />

Air Clamping, Power Rotation<br />

SESCO 47-272 40,000-Lb. x 42"W Motorized<br />

Coil Cradle, S/N 21970, w/Coil Feed Table<br />

SESCO 56-247 40,000-Lb. x 42"W Straightener<br />

/Leveler, S/N 21971, w/3-Over 4-Roll<br />

Straightener, Sesco Smart Screen Control<br />

Coe Servo Feed Line<br />

COE CPR-PO-300-72 30,000-Lb. x 72"W<br />

Capacity Motorized Coil Reel, S/N 24863-4,<br />

w/Rail Mounted Coil Car, See Photo; COE<br />

CPP6-305-72 72"W Coil Straightener, S/N<br />

24863-3, w/3-Over 4-Roll Straightener, Peeler,<br />

Looping Pit and Feed Table; COE CPRF-672<br />

72"W Servo Coil Feed, S/N 24863-1, w/Servo<br />

Master PLC Control<br />

Littell Feed Line<br />

LITTELL 30,000-Lb. x 72"W Capacity Motorized<br />

Coil Reel, S/N 77880-70, w/Rail Mounted Coil<br />

Car; LITTELL No. 676 72"W x .080 Thick Coil<br />

Straightener S/N 86987-82, w/3-Over 4-Roll<br />

Straightener, Peeler, Looping Pit, Feed Table,<br />

1982; LITTELL No. 772 DLC 72"W Coil Feed,<br />

S/N 86985-82, w/Control Panel, 1982<br />

Perfecto Servo Feed Line<br />

PERFECTO RS40550B 40,000-Lb. x 50"W<br />

Motorized Coil Reel, S/N RS-77153, w/Rail<br />

Mounted Coil Car, 72" Maximum Coil O.D.,<br />

Snubber Arm; PERFECTO 38-50-7 50"W x .125"<br />

Thick Coil Straightener, S/N S5-77152, w/3-<br />

Over 4-Roll Straightener, Looping Pit, Feed<br />

Tables; PERFECTO 50"W Coil Feed,<br />

w/Control Panel<br />

Perfecto Feed Line<br />

PERFECTO 30-72-300 30,000-Lb. x 72"W<br />

Motorized Coil Reel, S/N PR-4325, w/Rail<br />

Mounted Coil Car; PERFECTO 38-72-7 72"W x<br />

.170" Thick Coil Straightener, S/N SS-4324,<br />

w/3-Over 4-Roll Straightener, Looping Pit, Feed<br />

Table; PERFECTO 72"W Coil Feed<br />

ATLAS TECHNOLOGIES Blank Destacker, S/N<br />

G115.00, w/Allen-Bradley PanelView 900 PLC<br />

Control, Syron Multi-Channel Double Blank<br />

Analyzer, 12" x 48" Min. Blank Size, 72" x 120"<br />

Max. Blank Size, .020" - .125" Max. Blank<br />

Thickness, 12" Max. Stack Height, 30,000-Lb.<br />

Max. Blank Stack Weight, 1996<br />

ATLAS TECHNOLOGIES Blank Destacker, S/N<br />

G083.00, w/Controls, 12" x 36" Min. Blank Size,<br />

60" x 96" Max. Blank Size, .020" - .125" Blank<br />

Thickness Capacity Range, 16" Max. Stack<br />

Height, 15,000-Lb. Max. Stack Weight, 1996<br />

INNOVATION GROUP Blank Destacker, S/N<br />

414/415, w/Automated Feed System, Controls,<br />

12" x 30" Min. Blank Size, 60" x 84" Max. Blank<br />

Size, .020"–.100" Blank Thickness Capacity, 16"<br />

Max. Blank Stack Height, 15,000-Lb. Max. Blank<br />

Capacity, 1998<br />

WELDING, ROBOTS,<br />

& CELLS<br />

Weld Control, (3) 12"D Vibratory Type Nut<br />

Feeders; (2) NACHI Model SA-160F 6-Axis<br />

Articulated Arm Pick & Place Robots, s/n<br />

B78G400, Each w/Nachi Type AR Controls,<br />

Teach Pendant, Allen-Bradley PanelView, 900<br />

PLC Control, 1998, See Photo<br />

Throughout Department #64, Building #11,<br />

To Include: Lockers; Miscellaneous Conveyor<br />

Sections; Carts; Wall Mounted Fans; Die Stands;<br />

Eye Bolts; Self-Dumping Hoppers; Fire<br />

Extinguishers; Bench Grinders; Double Door<br />

Supply Cabinets; Foreman Stations; Cribbing;<br />

Welding Curtains; Etc.<br />

Automated Spot Welding Assembly Line, 1992:<br />

11-Station Fully Automated Spot Welding<br />

Assembly Line, w/Approximately (6) Roman<br />

50kva Weld Transformers Per Station, 3-Axis<br />

Overhead Pick & Place Rail Mounted Robotic<br />

Arm, Medar Medweld 1000S Weld Controls;<br />

(5) Manual Spot Welding Assembly Stations,<br />

w/Approximately (4) Roman 50kva Weld<br />

Transformers Per Station, Medar Medweld<br />

1000S Weld Controls; (2) Check Stands;<br />

(2) Pneumatic Scissor Lift Tables; Entrance<br />

Conveyor Section; Exit Conveyor Section;<br />

(2) Allen-Bradley PLC Line Control Panels<br />

Automated Spot Welding Assembly Line,<br />

1992:11-Station Fully Automated Spot Welding<br />

Assembly Line, w/Approximately (6) Roman<br />

50kva Weld Transformers Per Station, 3-Axis<br />

Overhead Pick & Place Rail Mounted Robotic<br />

Arm, Medar Medweld 1000S Weld Controls;<br />

(5) Manual Spot Welding Assembly Stations,<br />

w/Approximately (4) Roman 50kva Weld<br />

Transformers Per Station, Medar Medweld<br />

1000S Weld Controls; (2) Check Stands;<br />

(2) Pneumatic Scissor Lift Tables; Entrance<br />

Conveyor Section; Exit Conveyor Section;<br />

(2) Allen-Bradley PLC Line Control Panels<br />

SMG SCHULER MDL. HZPUI-1400/900/3600/2500 2,300-TON DOUBLE<br />

ACTION TOP DRIVE HYDRAULIC PRESS, w/(4) SMG SCHULER 550 T<br />

STRAIGHT-SIDE HYDRAULIC PRESSES, LINDGREN 6-STATION QUICK<br />

CHANGE BOLSTER SYSTEM, ALL 1996<br />

VERSON MDL. 100-HD2-156-84 100-TON HYDRAULIC SPOTTING PRESS,<br />

w/ROLL OUT BOLSTER 60" STR<br />

(50) NACHI MDL. SA-160-01-6 AXIS ROBOTS,<br />

AS LATE AS 2004<br />

NEW<br />

<<br />

COE MDL.<br />

CPR-PO-300-72<br />

SERVO PRESS<br />

FEED LINE,<br />

30,000-LB.,<br />

72"W. x 72" OD,<br />

2000<br />

NACHI MDL.<br />

6-AXIS ROBOT<br />

SA-160F-01, 1999<br />

NEW<br />

1996<br />

9

OXFORD AUTOMOTIVE—JUNE 16, ALMA, MICHIGAN<br />

Machinery & Equipment Plus Real Estate<br />

WELDING, ROBOTS, & CELLS, Cont.<br />

Automated Spot Welding Assembly Line, 1998, To Include:<br />

(3) Semi-Automatic Multi Head Spot Welders, Each w/Allen-<br />

Bradley Panelmate Power Pro PLC Controls, (4) 150kva<br />

Weld Transformers, Medar Medweld 3000S AC Weld<br />

Control; (8) NACHI Model SA-160F-01 6-Axis Articulated<br />

Arm Pick & Place Robots, Each w/Nachi Type AR Robotic<br />

Controller, Teach Pendant, 1997; (9) Approximately 50kva<br />

Single & Dual Head Spot Welders, w/Medar Medweld 3000S<br />

AC Weld Controls; (2) Multi-Head Spot Welders, Each w/(5)<br />

150kva Welding Transformers, Medar Medweld 3000S AC<br />

Weld Controls, TESCO ENGINEERING Approximately<br />

75-Ton Capacity 4-Post Downacting Hydraulic Press, w/36"<br />

x 96" Between Posts, Approximately 40 HP Hydraulic Power<br />

Supply; JOHNSTONE Model “Auto-Stream” Adhesive Pump,<br />

S/N 9800538/4-397AA, 1998; (2) IDT Model Cutler<br />

Panelmate Power Series PLC Line Control Panels<br />

Automated Spot Welding Assembly Line, 1998, To Include:<br />

(3) Semi-Automatic Multi Head Spot Welders, Each w/Cutler<br />

Hammer Panelmate Power Pro PLC Controls, (4) 150kva<br />

Weld Transformers, Medar Medweld 3000S AC Weld Controls;<br />

(10) NACHI Model SA160F-01 6-Axis Articulated Arm Pick<br />

& Place Robots, Each w/Nachi Type AR Robotic Controls,<br />

Teach Pendant; (12) Approximately 50kva Single & Dual<br />

Head Spot Welders, w/Medar Medweld 3000S AC Weld<br />

Controls; (2) Multi Head Spot Welders, Each w/(5) 150kva<br />

Welding Transformers, Medar Medweld 3000S Weld Controls;<br />

TESCO ENGINEERING Approximately 75-Ton Capacity<br />

4-Post Downacting Hydraulic Press, w/36" x 96" Between<br />

Posts, Approximately 40 HP Hydraulic Power Supply;<br />

JOHNSTONE Model “Auto Stream” Automated Adhesive<br />

Pump, S/N 9800837/4-396AA, w/Barrel Pump, 1998; (2)<br />

CUTLER HAMMER Model IDT Panelmate Power Series<br />

PLC Control Panels<br />

Hand Cowl Side 3-Head Spot Welder, w/(3) Roman<br />

Approximately 50kva Transformers, Robotron Series 400<br />

Weld Control, (2) Dengensha 12"D Vibratory Bowl Type<br />

Nut Feeders<br />

Multi Head Spot Welder, w/(2) Roman 45kva Weld<br />

Transformers, (2) Roman 60kva Weld Transformers,<br />

Dengensha 12"D Vibratory Bowl Type Nut Feeder,<br />

Robotron Series 115 Weld Control<br />

VERSON Model 150-GP2-72 150-Ton Capacity 2-Point<br />

Open Back Gap Frame Press, S/N 27007, w/36" x 84" Bed,<br />

36" x 72" Ram, 12" Stroke, 30" Shut Height, 8" Adjustment,<br />

40 SPM, Air Clutch, Air Cushion, 8" Bolster Plate, Air<br />

Counterbalance, Link Logic Brake Monitor, 1979<br />

Throughout Department #74, Building #4, To Include: Die<br />

Racks; Foreman Stations; Miscellaneous Conveyor Sections;<br />

Banding Outfits; Wall Mounted Fans; Chairs; Slings; Electric<br />

Walk Behind Pallet Jacks; Self-Dumping Hoppers; Foreman<br />

Stations; Microwave Oven; Etc.<br />

Robotic Spot Welding Cell, To Include: FANUC Model<br />

S-420iF 6-Axis Articulated Arm Spot Welding Robot, S/N<br />

F-26209, w/Fanuc System R-J2 Robotic Controls, Robotron<br />

Series 115 Weld Control, Hand Held Teach Pendant, 50kva<br />

Weld Transformer; (2) Welding Fixtures; ALLEN-BRADLEY<br />

Model PanelView 550 PLC Control, 1995<br />

Spot Welding Cell, w/Roman 80kva Weld Transformer,<br />

Knight 350-Lb. Jib Crane, Tool Balance, Johnstone Barrel<br />

Pump, Welding Fixture<br />

Welding Cell, S/N 97094, w/ABB Robotics Model Type<br />

IRB-4400-M97A 6-Axis Spot Welding Robot, S/N 64-05269,<br />

w/ABB Robotic Control, Hand Held Teach Pendant,<br />

Centerline 50kva Weld Transformer, 1997; Rotary Indexing<br />

Dual Position Welding Fixture, w/Allen-Bradley PanelView<br />

550 PLC<br />

10<br />

Cell S/N 9-3367, ABB Robotics Model IRB-4400 6-Axis<br />

Articulated Arm Spot Welding Robot, S/N L9941-8504-001,<br />

w/ASEA Controls, Medar Medweld 500S Weld Control, Roman<br />

50kva Weld Transformer; Dual Position Welding Fixture<br />

S/N 4553, (5) ASEA Model Type 90 6-Axis Articulated Arm<br />

Spot Welding Robots, Each w/ASEA Type NY-200-05-A<br />

Robotic Control Panels, 50kva Weld Transformers, Medar<br />

Medweld 500s Weld Controls, Medar 3000s Weld Controls<br />

or Pertron Weld Controls, (2) Rotary Indexing Multi Station<br />

Welding Fixture Tables, Allen-Bradley Model Panel View 550<br />

PLC Control<br />

Robotic Welding Cell, S/N 8110, ASEA Model Type 90 6-Axis<br />

Articulated Arm Spot Welding Robot, w/ASEA Robotic Weld<br />

Control Panel, S/N L6095.0022-001, Pertron Paragon Series<br />

TIM 4000 Resistance Weld Control, 50kva Weld Transformer;<br />

Fabricated Welding Fixture; ALLEN-BRADLEY Model<br />

PanelView 550 PLC Control<br />

Welding Cell, S/N 8-4145D, (2) ASEA Model Type 90 6-Axis<br />

Articulated Arm Spot Welding Robots, Each w/ASEA Type<br />

7637-710 Robotic Control Panels, Medar Medweld 500s<br />

Weld Controls, 50kva Weld Transformers; Fabricated<br />

Rotary Weld Fixture<br />

SCIAKY Model Type SP-1-12-50-30 50kva Press Type Spot<br />

Welder, S/N 6037, w/Weltronic Weld Controls, 30" Throat<br />

SCIAKY Model Type SP-1-12-50-30 50kva Press Type Spot<br />

Welder, S/N 6323, w/Weld Controls, 30" Throat<br />

TECHNITRON Model T3415/V8 120kva Press Type Spot<br />

Welder, S/N 02374037, w/Robotron Series 400 Weld<br />

Control, Seiki Kogyo Nut Feeder, 16" Throat<br />

AUTOMATION BY DESIGN Wheel House Rotary Mig<br />

Welder, S/N 97098, w/Welding Fixture<br />

KIMURA DENYOKI, LTD. Model SW-608 SPA 60kva Press<br />

Type Spot Welder, S/N 57404, w/Medar Medweld 500s<br />

Weld Control, Dengensha Nut Feeder, 16" Throat, 1988<br />

TAYLOR WINFIELD Model Type NB-12-75 75kva Press<br />

Type Spot Welder, S/N 261102, w/Medar Medweld 500S<br />

Weld Controls, 16" Throat, 1953<br />

Spot Welder, w/Robotron Weld Controls, (2) 75kva Weld<br />

Transformers, (2) Owoso Automation Nut Feeders, Each<br />

w/16"D Vibratory Bowls<br />

Type Spot Welder, w/Robotron Series 115 Weld Controls,<br />

(2) 50kva Weld Transformers, (2) Welding Fixtures, Allen-<br />

Bradley Model PanelView 550 PLC Control<br />

Assembly Cell, (7) NACHI Model SA160F-01 6-Axis<br />

Articulated Arm Pick & Place Robots, w/Nachi Type AR<br />

Robotic Controls, Hand Held Teach Pendants; (4) GARDNER-<br />

DENVER Model M-Pro-93 Process Control Monitors;<br />

(8) Multi Head Spot Welders, Each w/(2–5) 50kva Weld<br />

Transformers, Robotron Series 115 Weld Controls<br />

(3) ASE INDUSTRIES Multi Head Spot Welders, Each<br />

w/Approximately (4) 50kva Weld Transformers, Allen-<br />

Bradley PanelView 1400e PLC Controls, Approximately<br />

(3) Dengensha 12"D Vibratory Bowl Type Nut Feeders<br />

(2) Single Head Press Type Spot Welders, Each w/Robotron<br />

Series 400 Weld Controls, 50kva Weld Transformer,<br />

Dengensha 12" Vibratory Bowl Type Nut Feeder<br />

(2) Dual Head Press Type Spot Welders, Each w/Robotron<br />

Series 400 Weld Controls, (2) 35kva Weld Transformers,<br />

Dengensha 12 Vibratory Bowl type Nut Feeders<br />

Dual Station Spot Welder, w/Robotron Series 400 Weld<br />

Control, (2) 50kva Weld Transformers, Allen-Bradley<br />

PanelView 1400e PLC Control<br />

6-Station Spot Welder, w/Medar Mercury Weld Control,<br />

(6) 23kva Weld Transformers<br />

MULTIPLE NACHI & TESCO WELD CELLS &<br />

SPOT WELDERS AS LATE AS 2003<br />

Spot Welding Assembly Cell, S/N 8016R, (4) NACHI Model<br />

SA160F-01 6-Axis Articulated Arm Robots, w/(2) Pick &<br />

Place Heads, (2) Spot Welding Heads, Nachi Type AR<br />

Robotic Controls, Medar Medweld 3000s AC Welding<br />

Controls, Teach Pendants; (3) Custom Designed &<br />

Fabricated Single Head Spot Welders, w/50kva Weld<br />

Transformers, Dengensha Vibratory Bowl Type Nut<br />

Feeders, Medar Medweld 3000S AC Welding Controls;<br />

Dual Station Rotary Welding Fixture; ALLEN-BRADLEY<br />

Model PanelView 1000 PLC Control; ALLEN-BRADLEY<br />

Model PanelView 550 PL Control<br />

Spot Welding Assembly Cell, S/N 8016L, (4) NACHI Model<br />

SA160F-01 6-Axis Articulated Arm Robots, w/(2) Pick &<br />

Place Heads, (2) Spot Welding Heads, Nachi Type AR<br />

Robotic Controls, Medar Medweld 3000s AC Welding<br />

Controls, Teach Pendants; (3) Single Head Spot Welders,<br />

w/50kva Weld Transformers, Dengensha Vibratory Bowl<br />

Type Nut Feeders, Medar Medweld 3000S AC Welding<br />

Controls; Dual Station Rotary Welding Fixture;<br />

ALLEN-BRADLEY Model PanelView 1000 PLC Control;<br />

ALLEN-BRADLEY Model PanelView 550 PL Control<br />

PICO Model FP360241001 Stud Welder, S/N 3186-96-0001,<br />

w/Weltronic V60 Weld Controls, (2) 75kva Weld<br />

Transformers<br />

Throughout Old Paint Room Building #2, to Include:<br />

Dollies; Tables; Chairs; Benches; Carts; Fans; Desks; Self-<br />

Dumping Hoppers; Electric Pallet Jacks; Conveyor<br />

Sections; Racks; Wall Mounted Fans; Etc.<br />

STORAGE ROOM<br />

SCIAKY Model SP1-12-100-30 100kva Press Type Spot<br />

Welder, S/N 7539, w/30" Throat, Weltronic Weld Controls<br />

HOBART Model RC-256 250-Amp Arc Welder, S/N<br />

8RT-13634, w/Hobart 2410 Wire Feed, Cart, Leads<br />

CNC MACHINING CENTER<br />

HURCO HAWK 5M 3-Axis CNC Vertical Milling Machine,<br />

S/N H55M92005038B, w/Hurco Ultimax 3 CNC Control,<br />

10" x 36" Table, Auto Speed Attachment, 70–3,500-rpm<br />

Spindle Speed Range, 1996<br />

MILLS<br />

TREE 2UV 1-HP Vertical Milling Machine, w/10" x 42" Bed,<br />

140–3,500-rpm Spindle Speed Range<br />

TREE 2UVR 1-1/2-HP Vertical Milling Machine, w/10" x 42"<br />

Table 60–3,300-rpm Spindle Speed Range<br />

BRIDGEPORT Series I 2-HP Variable Speed Vertical Milling<br />

Machine, S/N 12BR-246124, w/9" x 48" Table, 4" Column<br />

Riser, Bridgeport Rapid 8 Power Draw Bar, Acu-Rite III<br />

2-Axis Digital Readout, 1986<br />

BRIDGEPORT Series II Special 3-HP Variable Speed<br />

Vertical Milling Machine, S/N 7041-S, w/11" x 60"<br />

Power Table, 6" Column Riser, Acu-Rite III 2-Axis<br />

Digital Readout, Bridgeport Power Draw Bar, 1989

GRINDERS<br />

MATTISON 18" x 60" Hydraulic Surface Grinder,<br />

S/N 23811, w/18" x 60" Electromagnetic Chuck,<br />

Coolant, Incremental Downfeed, Sludge Recovery<br />

Tank, 1977<br />

BOYAR-SCHULTZ No. 2 Profile Grinder,<br />

S/N 2955, w/Overarm Attachment<br />

BROWN & SHARPE 1030 Micromaster 10" x 30"<br />

Hydraulic Surface Grinder, 523-1030-407, w/10"<br />

x 30" Electromagnetic Chuck, Coolant, 1977<br />

TAFT-PIERCE 5" x 10" Hand Feed Surface Grinder,<br />

w/5" x 10" Electromagnetic Chuck<br />

TAFT-PIERCE 5" x 10" Hand Feed Surface Grinder,<br />

w/5" x 10" Electromagnetic Chuck<br />

BROWN & SHARPE No. 5 8" x 24" Hand Feed<br />

Surface Grinder, w/8" x 24" Electromagnetic Chuck<br />

BROWN & SHARPE No. 5 8" x 24" Hand Feed<br />

Surface Grinder, w/8" x 24" Electromagnetic Chuck<br />

WCI MACHINE TOOL GROUP 6" x 18" Hand<br />

Feed Surface Grinder, S/N 22385, w/6" x 18"<br />

Permanent Magnetic Chuck<br />

BROWN & SHARPE 814U 8" x 24" Universal<br />

ID/OD Cylindrical Grinder, S/N 525-8143-2588<br />

INSPECTION<br />

JAPAX LU3B Wire Type Electrical Discharge<br />

Machine, S/N 462-00-539, w/Japax JAPT 3F Controls,<br />

Japax VH-02 Interface, Dell Optiplex Personal<br />

Computer, Japax PW20X Coolant System, 1984<br />

48" x 72" x 9" 4-Ledge Black Granite Surface Plate,<br />

w/Steel Stand<br />

HE Check Master 850-251 3-Axis Coordinate<br />

Measuring Machine, S/N 1823, w/Starrett 60"<br />

x 120" x 16" Grey Granite Surface Plate, Personal<br />

Computer System, Printer, Renishaw PH8 Probe<br />

Head, 1982<br />

LK LY90 Type 40.16.20 Dual Column Coordinate<br />

Measuring Machine, S/N 15680, w/Trimuk Model<br />

TLD-MAN-CNC 10' x 20' x 14" Cast Iron Layout<br />

Plate, S/N 2103 (1998), Renishaw Probe Heads,<br />

Personal Computer System, 1998<br />

MORA 0119 3-Axis Layout Machine, S/N<br />

8442/0586, w/60" x 120" x 4" Cast Iron Layout<br />

Plate, Heidenhain 3-Axis Digital Readout, Renishaw<br />

PH-8 Probe Head, Personal Computer System, 1986<br />

LATHES<br />

ROCKWELL 16" x 36" Geared-Head Engine Lathe,<br />

w/Collet Chaser, 40–1,600-rpm Spindle Speed<br />

Range, 1" Spindle Bore<br />

LEBLOND 17" x 48" Dual Drive Geared-Head Engine<br />

Lathe, S/N HC1867, w/3-Jaw Chuck, 1.25" Spindle<br />

Bore, 28–1,800-rpm Spindle Speed Range, 1967<br />

LEBLOND Makino Regal 20" x 84" Geared-Head<br />

Engine Lathe, S/N 14E-288, w/3-Jaw Chuck,<br />

40–1,600-rpm Spindle Speed Range, 3" Spindle<br />

Bore, 1984<br />

LEBLOND 18" x 72" Geared-Head Engine Lathe,<br />

w/4-Jaw Chuck, 1.25" Spindle Bore, 20–425-rpm<br />

Spindle Speed Range<br />

DIVINE BROTHERS 5-HP Double-End Pedestal Buffer<br />

ROLLING STOCK<br />

CATERPILLAR T125D 12,500-Lb. Capacity LPG<br />

Forklift Truck, S/N 5MB02212, w/117" Maximum<br />

Lift Height, Solid Tires, Overhead Guard, Lights,<br />

2-Stage Mast, Side Shift, 1993<br />

(15) CATERPILLAR T125D 12,500-Lb. Capacity<br />

LPG Forklift Truck, w/117" Maximum Lift Height,<br />

Solid Tires, Overhead Guard, Lights, 2-Stage Mast,<br />

Side Shift, 1995<br />

CWF Approx. 30,000-Lb. Capacity Electric Walk<br />

Behind Die Lift, w/64" x 72" Bed, Battery Charger<br />

TAYLOR TE-300M 30,000-Lb. Capacity Diesel<br />

Forklift Truck, S/N S-H6-18037, w/Overhead Guard,<br />

Cab, 2-Stage Mast, Cushion Tires, Lights, 1987<br />

ALLIS-CHALMERS ACC60CLPS 6,000-Lb. Capacity<br />

LPG Forklift Truck, S/N AKD10029C, w/106" Max.<br />

Lift Height, Overhead Guard, 2-Stage Mast, Solid<br />

Tires, Side Shift<br />

ALLIS-CHALMERS 5,000-Lb. Capacity LPG Forklift<br />

Truck, w/2-Stage Mast, Solid Tires, Overhead Guard<br />

Electric Scissor Type Platform Lift, w/48" x 96"<br />

Platform, 750-Lb. Capacity, Cushion Tires,<br />

Battery Charger<br />

JLG 33HA Basic LPG Aerial Lift, S/N 0308915236,<br />

w/Cushion Tires, 32" x 50" Platform, 30' Max. Lift<br />

Height, 1989<br />

JLG 450A Series II LPG Aerial Lift, w/500-Lb.<br />

Maximum Lift Capacity, Cushion Tires, 30" x 72"<br />

Operator Bucket<br />

CATERPILLAR T125D 12,500-Lb. Capacity LPG<br />

Forklift Truck, S/N 5MB02647, w/117" Maximum<br />

Lift Height, Solid Tires, Overhead Guard, Lights,<br />

2-Stage Mast, Side Shift, 1995<br />

VERSATILE 256 Type 2360 Rubber Tire<br />

Articulating Front End Loader, S/N 008833,<br />

w/Bucket, Enclosed Cab, Lights, Cummins 3.9L<br />

Diesel Engine, 1985 TENNANT 7400 Electric Sit<br />

Down Rider Type Floor Scrubber, S/N 3745,<br />

w/Overhead Guard, Battery Charger<br />

TENNANT 527 Electric Sit Down Rider Type Floor<br />

Scrubber, S/N 2374, w/Overhead Guard,<br />

Battery Charger<br />

ADVANCE RETRIEVER 5600G LPG Sit Down Rider<br />

Type Floor Scrubber, S/N 846446, w/Overhead<br />

Guard, 1981<br />

GMC 2500SL Sierra 3/4-Ton Capacity Regular Cab<br />

Pickup Truck, S/N 1GTGC24K9KES27201, w/Auto<br />

Transmission, 8' Extended Bed, Bed Liner, 1989<br />

FORD Taurus 4-Door Sedan Automobile, S/N<br />

1FACP5247PG289326, w/Auto Transmission,<br />

Cloth Seats, 1990<br />

SAWS<br />

MARVEL 8/M1/M4 18" Vertical Metal Cutting Band<br />

Saw, S/N 88034<br />

GROB Type S24U 24" Vertical Metal Cutting Band<br />

Saw, S/N 265, w/30" x 30" Table<br />

KASTO 12" Power Hack Saw<br />

KALAMAZOO H8AW 8" x 24" Horizontal Metal<br />

Cutting Band Saw, S/N 540<br />

TANNEWITZ 16" Table Saw<br />

DRILLS<br />

DOALL DG-17 18" Variable Speed Floor-Type Drill<br />

Press, S/N 47-8503, w/16" x 18" Table, 150–1,200-rpm<br />

CINCINNATI GILBERT 8" Column x 60" Arm<br />

Radial Drill, S/N 6050, w/L-Base, (2) Box Tables,<br />

50–1,800-rpm Spindle Speed Range, 1956<br />

CLAUSING 1875 18" Floor-Type Drill Press, S/N<br />

006487, w/16" x 22" Table<br />

SHEAR<br />

COLUMBIA Type 0410 10' x 1/4" Power Squaring<br />

Shear, S/N W182-80, w/Back Gage, 1980<br />

MATTISON HYDRAULIC HORIZONTAL SURFACE GRINDER 18" x 60", 1977<br />

(2) INGERSOLL-RAND MDL. SSR-EPE350-25 ROTARY SCREW AIR<br />

COMPRESSORS, 350 HP, 1998<br />

CELL PHONE RECEPTION<br />

IS POOR INSIDE THESE PLANTS<br />

(15) CATERPILLAR MDL. T1250 12,500-LB.<br />

LPG FORK TRUCKS, AS LATE AS 1998<br />

15<br />

AVAILABLE<br />

ROLL FORMER<br />

PIRANHA P3 50-Ton Capacity Hydraulic Ironworker, S/N 3505 1-1/2" Round<br />

Bar Capacity, 5/8" x 12" Shearing Capacity, 5" x 5" x 3/8" Angle Capacity,<br />

2-3/4" x 4" x 50-Ton Coping/Notching Capacity, 10" x 17" Table, 15" x 15"<br />

Coping Surface, 1991<br />

PRESS BRAKE<br />

VERSON 206 60-Ton Capacity x 8' Power Press Brake, S/N 11686-206-F,<br />

w/12" Shut Height, 3" Stroke, 4" Adjustment<br />

For more information, please contact the auctioneer or visit our website at www.michaelfox.com<br />

11

OXFORD AUTOMOTIVE—JUNE 16, ALMA, MICHIGAN<br />

Machinery & Equipment Plus Real Estate<br />

CRANES<br />

ZENAR 40-Ton Capacity x 128' Span Double Girder Top<br />

Riding Overhead Bridge Crane, S/N 1997, w/40-Ton Hoist,<br />

Class D Rated, Radio Controlled, 1997<br />

ZENAR MILWAUKEE 30-Ton Capacity x 35' Span Double<br />

Girder Top Riding Overhead Bridge Crane, S/N 2279,<br />

w/30-Ton Hoist, Pendant Control<br />

ZENAR MILWAUKEE 10-Ton Capacity x 40' Span Double<br />

Girder Top Riding Overhead Bridge Crane, S/N 6818,<br />

w/10-Ton Hoist, Pendant Control<br />

ZENAR MILWAUKEE 20-Ton Capacity x 40' Span Double<br />

Girder Top Riding Overhead Bridge Crane, S/N 0817,<br />

w/20-Ton Hoist, Pendant Control<br />

ZENAR MILWAUKEE 10-Ton Capacity x 30' Span Double<br />

Girder Top Riding Overhead Bridge Crane, S/N 6820,<br />

w/10-Ton Hoist, Pendant Control<br />

ZENAR MILWAUKEE 5-Ton Capacity x 30' Span Single Girder<br />

Top Riding Overhead Bridge Crane, S/N 6819, w/5-Ton Hoist,<br />

Pendant Control<br />

5-Ton Capacity x 20' Span Single Girder Top Riding Overhead<br />

Bridge Crane, w/5-Ton Hoist, Pendant Control<br />

DETROIT HOIST 25-Ton Capacity x 25' Span Double Girder<br />

Top Riding Overhead Bridge Crane, w/25-Ton Hoist, Pendant<br />

Control<br />

ZENAR 5-Ton x 40' Span Single Girder Underslung Overhead<br />

Bridge Crane, S/N 2003, w/5-Ton Hoist, Pendant Control<br />

15-Ton Capacity x 60' Span Double Girder Top Riding<br />

Overhead Bridge Crane, w/Pendant Control<br />

AIR COMPRESSORS<br />

& RELATED EQUIPMENT<br />

INGERSOLL-RAND SSR-EPE350-25 350-HP Package Type<br />

Rotary Screw Air Compressor, S/N EE1674U93217, w/1,740-cfm<br />

Capacity, Ingersoll-Rand Intellisys PLC Control, 1993<br />

INGERSOLL-RAND SSR-EPE350-25 350-HP Package Type<br />

Rotary Screw Air Compressor, S/N EE1675U98217, w/1,740-cfm<br />

Capacity, Ingersoll-Rand Intellisys PLC Control, 1998<br />

ROLLAIR 200 200-HP Pallet Type Rotary Screw Air<br />

Compressor<br />

INGERSOLL-RAND DXR10000W Compressed Air Dryer,<br />

S/N 98FDX1829, w/PLC Control, 1998<br />

INGERSOLL-RAND F500 Compressed Air Dryer, S/N 894F164,<br />

1989<br />

(2) Vertical Air Receiving Tanks<br />

Water Chiller, w/BAC Heat Exchangers, (15) 20-HP Process<br />

Water Pumps<br />

Throughout Air Compressors & Related Equipment,<br />

To Include: Lockers, Benches, Vises, Double-End Grinder,<br />

Vertical Band Saw, Drill Press, Miller Welder, MEP Cut-Off<br />

Saw, Die Lift, Repair Parts, File Cabinets, Racks, Etc.<br />

Scrap Removal System, w/(4) 180'L x 48"W Conveyor<br />

Sections, (4) 40'L x 48"W Incline Conveyor Sections<br />

MISCELLANEOUS<br />

Throughout Department #64 Building #11, To Include:<br />

Lockers, Miscellaneous Conveyor Sections, Carts, Wall<br />

Mounted Fans, Die Stands, Eye Bolts, Self-Dumping Hoppers,<br />

Fire Extinguishers, Bench Grinders, Double Door Supply<br />

Cabinets, Foreman Stations, Cribbing, Welding Curtains, Etc.<br />

Throughout Department #66 Building #10, To Include:<br />

Foreman Stations, File Cabinets, Self-Dumping Hoppers, Allen<br />

Bradley Dataline Digital Readout Line Displays, Fire<br />

Extinguishers, Bench Grinders, Pedestal Fans, Cribbing, Weld<br />

Curtains, Lockers, Miscellaneous Conveyor Sections, 2-Wheel<br />

Dollies, Benches, Chairs, Stools, Etc.<br />

Throughout Department #74 Building 4, To Include: Die<br />

Racks, Foreman Stations, Miscellaneous Conveyor Sections,<br />

Banding Outfits, Wall Mounted Fans, Chairs, Slings, Electric<br />

Walk Behind Pallet Jacks, Self-Dumping Hoppers, Foreman<br />

Stations, Etc.<br />

(3) ALLEN-BRADLEY PanelView 550 PLC Control<br />

12<br />

ZENAR 40-TON OVERHEAD BRIDGE CRANE, w/15-TON AUX HOIST., 128" SPAN, RADIO CONTROLLED, 1998<br />

Throughout Department #74 Building #3,<br />

To Include: Wall Mounted Fans, Nederman<br />

Portable Fume Collector, Workbenches,<br />

Detroit Testing Machine Model NST 20,000-psi<br />

Sample Press, S/N 908, Detroit Testing<br />

Machine Model LPT 3,000-psi Sample Press,<br />

S/N 152, Foreman Stations, Pedestal Fans,<br />

Halogen Work Lights, Lunch Table, Chairs,<br />

Self-Dumping Hoppers, File Cabinets,<br />

Double Door Supply Cabinets, Tilt Master<br />

Bin Tilters, Buffing Jack, Racks, Etc.<br />

Hydraulic Trash Compactor<br />

Throughout Department #76 Building #6,<br />

To Include: Miscellaneous Conveyor<br />

Sections, Self-Dumping Hoppers, Wall<br />

Mounted Fans, Pedestal Fans, Racking, Etc.<br />

(4) Custom Designed and Fabricated Door<br />

Flange Piercing Cells, S/N 83035R, Each<br />

w/Allen-Bradley PanelView 900 PLC Controls,<br />

Dual C-Frame Pneumatic Piercing Cylinders<br />

Throughout Old Paint Room Building #2,<br />

To Include: Dollies, Tables, Chairs, Benches,<br />

Carts, Fans, Desks, Self-Dumping Hoppers,<br />

Electric Pallet Jacks, Conveyor Sections,<br />

Racks, Wall Mounted Fans, Etc.<br />

5-HP Double-End Pedestal Buffer<br />

Throughout Storage Room, To Include: Racking,<br />

Miscellaneous Repair Parts, Lincoln Idealarc<br />

Tig 300 Welder, Peer 100-Kva Press Type<br />

Spot Welder, Peer 100-Kva Press Type Spot<br />

Welder, Kawasaki VT 150 6-Axis Robot,<br />

Miscellaneous Conveyor Sections, Miscellaneous<br />

Hobart Welders Electric Pallet Jacks, Forklift<br />

Boom, Miller Deltaweld 451 Welder,<br />

Pedestal Fans, Self-Dumping Hoppers, Wall<br />

Mounted Jib, Dollies, Supply Cabinets, Fanuc<br />

Robot, Die Lift, Portable Steam Heated<br />

Pressure Washer, Portable Cement Mixer,<br />

Hilti Jack Core Boaring Machine, Shop Vac, Etc.<br />

Throughout Building #8, To Include:<br />

Kawasaki UX120 6-Axis Robot, Barrel Racks,<br />

Lube Tanks, Racks, Supply Cabinets, Etc.<br />

K.H. HUPPERT Type ST Style 19FMPC1FHT<br />

22" x 22" x 24" Electrical Furnace, 95<br />

K.H. HUPPERT Type ST Style 21PCOTH<br />

TDOEL 36" x 24" x 36" Electrical Furnace, 86<br />

ROCKFORD 20" Toolroom Shaper, 111HB92<br />

Throughout 020 Department Machine Shop,<br />

To Include: Epps Steam Heated Pressure<br />

Washer, Shop Vacs, Racks, Carts, Saw Horses,<br />

Benches, Chairs, Vises, Fans, Lockers,<br />

Lincoln Invertec V200T Welder, Chairs,<br />

Slings, Atlas No. 3 Mandrel Press, Double-<br />

End Grinders, Drill Sharpeners, Self-Dumping<br />

Hoppers, Welding Tables, Hold Downs,<br />

Machine Vises, Cast Iron Layout Plates,<br />

Height Gages, Abrasive Cut-Off Saw, Mag<br />

Drill, Anvil, Acetylene Torch Outfits, Etc.<br />

Throughout Department 90 Building #13,<br />

To Include: Clausing Drill Press, Roll-In Band<br />

Saw, Workbenches, Pedestal Fans, Bench<br />

Vises, Abrasive Cut-Off Saw, Buffing Jack,<br />

Self-Dumping Hoppers, Pipe Threaders,<br />

Flammable Storage Cabinets, Double Door<br />

Storage Cabinets, Arbor Press, Barrel<br />

Dollies, Chain Falls, Come-A-Longs, Rigid<br />

1822-1 Pipe Threader, Racks, Chains, Slings,<br />

MISCELLANEOUS HAND, AIR, & POWER TOOLS<br />

LARGE ASSORTMENT MISCELLANEOUS GAGES & HAND TOOLS<br />

Acetylene Torch Outfits, Pneumatic Hose Reels, Portable Air<br />

Compressor, Electric Pallet Jacks, Aeroquip Hydraulic Hose Clamp,<br />

Battery Chargers, Etc.<br />

(3) JOHNSTONE Auto Stream Adhesive Pump, 1998<br />

(6) CUTLER HAMMER IDT Panelmate Power Series PLC Control Panels<br />

Throughout Basement Areas, To Include: Pumps, Solamander Heater,<br />

Welder, Carts, Fans, Etc.<br />

Throughout Outside Areas, To Include: Racks, Self-Dumping Hoppers,<br />

Transport Carts, Diesel Fuel Tank, Pump, Etc.<br />

Throughout Warehouse Areas, To Include: Self-Dumping Hoppers, Carts,<br />

Racks, Dock Plates, Cribbing, Fire Extinguishers, Dollies, Lunch Tables,<br />

Banding Outfits, Pallet Jacks, Forman Stations, Etc.<br />

Throughout Quality Control, To Include: Desks, Chairs, Bookcases,<br />

Bench Top Drill Press, Speedaire 5-HP VTM Air Compressor, Ladders,<br />

Dollies, Drafting Tables, Hewlett Packard 1055CM Plus Color Plotter,<br />

File Cabinets, Double Door Supply Cabinets<br />

Throughout Office Areas, To Include: Desks, Chairs, Computers,<br />

Printers, Etc.<br />

Miscellaneous Equipment Throughout Department #54 Building #1,<br />

To Include: Grinder, Blanker Conveyor, Blanker Conveyor,<br />

Maintenance Cart, Lathe, FH Welder, Welder, (11) ASEA Robots, (8)<br />

Fanuc Arc Mate 100 Robots, Hone, Miscellaneous Robots, Welders and<br />

Fixtures Saturn Door Line Racking, Etc.<br />

Miscellaneous Equipment Throughout Department #54 Building #2,<br />

To Include: Allis Chalmers 100C Forklift Truck, Verson Coston OBI<br />

Press, S/N 16478, (2) Moto Truck Die Carts, (3) Ingersoll-Rand Air<br />