Workshop Brochure - Society of Petroleum Engineers

Workshop Brochure - Society of Petroleum Engineers

Workshop Brochure - Society of Petroleum Engineers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Early Bird Registration Deadline:<br />

12 April 2013<br />

<strong>Society</strong> <strong>of</strong> <strong>Petroleum</strong> <strong>Engineers</strong><br />

27–29 May 2013 | Oryx Rotana | Doha, Qatar<br />

SPE Global Integrated <strong>Workshop</strong> Series<br />

Well Integrity: Current Challenges and Future Perspectives<br />

Who Should Attend<br />

• Drilling and Well Integrity<br />

Technology Providers<br />

• Production Technology <strong>Engineers</strong><br />

• Well Integrity Management<br />

• Well Completion <strong>Engineers</strong><br />

Committee Members<br />

Chairperson<br />

Ahmad Fakhroo<br />

Qatar <strong>Petroleum</strong><br />

Co-Chairperson<br />

Nigel Snow<br />

Maersk Oil Qatar AS<br />

Bipin Jain<br />

Schlumberger<br />

Ibrahim A. Ghamdi<br />

Saudi Aramco<br />

Inge Carlsen<br />

Weatherford<br />

Jean-Philippe Bedel<br />

Schlumberger<br />

Karim Shaikh<br />

Qatar Shell<br />

Ken Feather<br />

Archer<br />

Leozarin Morshidi<br />

RasGas<br />

Liane Smith<br />

Intetech Wells<br />

Malissa Boudreaux<br />

Baker Hughes<br />

Obadah Al Sawadi<br />

ZADCO<br />

Pierre Leschi<br />

TOTAL E&P Qatar<br />

Rana Shahzad Amin<br />

Qatar <strong>Petroleum</strong><br />

Sherif Refaat<br />

Archer<br />

Shri Kant Pandey<br />

Qatar <strong>Petroleum</strong><br />

Stuart Girling<br />

Girling and Company<br />

<strong>Workshop</strong> Description<br />

Well integrity is on a journey <strong>of</strong> realisation; together with the challenges <strong>of</strong> ageing wells and well<br />

life cycle extension, the verification <strong>of</strong> well integrity is a key area <strong>of</strong> interest for the oil and gas<br />

companies worldwide.<br />

Following industry incidents <strong>of</strong> uncontrolled outflow, there is an increase in public awareness<br />

<strong>of</strong> how effectively our industry manages well integrity. Together with recent challenges in zonal<br />

isolation to protect aquifers in USA and Australia’s onshore tight gas and coal bed methane<br />

development projects, there is increased focus on the management <strong>of</strong> well integrity. This puts<br />

increased demands on operators to provide assurance in safeguarding people and protecting the<br />

environment in order to acquire or retain the license to operate in compliance with standards and<br />

regulations.<br />

The importance <strong>of</strong> this is further elevated in view <strong>of</strong> large developments in unconventional gas and<br />

oil with well population growth that will result in more wells being drilled in the next decade than<br />

what we have drilled over the last hundred years to meet projected energy demands.<br />

In addition there is the fact that wells are getting older whilst new wells are increasingly complex<br />

with target reservoirs becoming more difficult to reach, requiring treatment, and interventions to<br />

enhance recovery <strong>of</strong> hydrocarbons.<br />

The surface and subsurface hazards with required mitigations and associated assurance tasks<br />

required to verify barrier integrity are not always fully understood nor is there always effective<br />

technology available to verify these barriers.<br />

The change in the requirements and the competency <strong>of</strong> industry to deal with these challenges is on<br />

a progressive journey but gaps exist to understand these new and complex issues.<br />

www.spe.org/events/12ado7

WORKSHOP<br />

Well Integrity: Current Challenges and Future Perspectives<br />

Sponsorship Support<br />

Sponsorship support helps <strong>of</strong>fset the<br />

cost <strong>of</strong> producing workshops and allows<br />

SPE to keep the attendance price within<br />

reach <strong>of</strong> operations-level individuals,<br />

those who benefit most from these<br />

technical workshops.<br />

Sponsors benefit both directly and<br />

indirectly by having their names<br />

associated with a specific workshop<br />

While SPE prohibits any type <strong>of</strong><br />

commercialism within the conference<br />

hall itself, the society recognises that<br />

sponsoring companies <strong>of</strong>fer valuable<br />

information to attendees outside the<br />

technical sessions.<br />

Sponsorship Categories<br />

Sponsorships are <strong>of</strong>fered on a first<br />

come basis. Please contact SPE to<br />

verify the availability <strong>of</strong> a particular<br />

sponsorship. Existing sponsors have<br />

the opportunity to renew the same level<br />

<strong>of</strong> sponsorship for annual workshops<br />

• Gold Sponsorship<br />

• Silver Sponsorship<br />

• Bronze Sponsorship<br />

• Welcome Reception and Dinner<br />

Sponsorship<br />

• Luncheon Sponsorship—Per Day<br />

• C<strong>of</strong>fee Break Sponsorship—Per Day<br />

Sponsorship Benefits<br />

In addition to onsite recognition; SPE<br />

will recognise sponsors on the SPE<br />

website and in all printed material<br />

for the workshop. Based on the<br />

sponsorship selected, sponsoring<br />

companies also receive logo visibility<br />

on promotional workshop items.<br />

For More Information<br />

For a detailed list <strong>of</strong> available<br />

sponsorships, including benefits and<br />

pricing, contact Loreen Nisha, event<br />

manager, at lnisha@spe.org<br />

Gold Sponsor<br />

Monday, 27 May 2013<br />

Silver Sponsor<br />

1600–1700 hours Final Committee Meeting<br />

1700–1800 hours Speaker/Session Chair Meeting<br />

1800–1900 hours Registration<br />

1900–2100 hours <strong>Workshop</strong> Reception and Dinner for all Delegates<br />

Tuesday, 28 May 2013<br />

0700–0800 hours Registration and Welcome C<strong>of</strong>fee Break<br />

0800–0830 hours Opening Remarks<br />

Bronze Sponsor<br />

0830–1000 hours Session 1: Well Integrity Challenges in Qatar—Case Histories<br />

Session Chairs: Ahmad Fakhroo, Qatar <strong>Petroleum</strong>; Pierre Leschi, TOTAL E&P Qatar<br />

In Qatar, several operators deal with oil and gas productions from both onshore and <strong>of</strong>fshore field developments. This session<br />

will provide a well integrity overview from these oil and gas companies (Qatar <strong>Petroleum</strong>, Maersk Oil Qatar AS, Shell, TOTAL,<br />

Occidental, etc.). Discussing actual well integrity case histories and work practices implemented by others will improve the<br />

overall management <strong>of</strong> the integrity <strong>of</strong> one’s wells.<br />

1000–1030 hours Morning C<strong>of</strong>fee Break and Posters<br />

1030–1200 hours Session 2: Well Integrity Challenges International—Breakout Session<br />

Session Chairs: Ahmad Fakhroo, Qatar <strong>Petroleum</strong>; Liane Smith, Intetech Wells;<br />

Pierre Leschi, TOTAL E&P Qatar<br />

Following the first session, hearing what well integrity challenges the local Qatari operators are facing, a breakout session will<br />

highlight the issues that arise in operations in the region. This session will focus on specific technical challenges that operators<br />

face. Do you share the same problems <strong>of</strong> this region or have some unique challenges? Do you operate ageing wells that are<br />

past their design life, but still have valuable production levels that demand continued operation, or high technology new wells<br />

that present major difficulties for intervention? Discuss and share your experience as the pooled list <strong>of</strong> challenges sets the<br />

scene not only for this workshop, but for the entire global series.<br />

1200–1300 hours Luncheon/Prayer Time and Posters<br />

Audio-Visual Equipment<br />

Sponsor<br />

1300–1430 hours Session 3: Barriers Verification<br />

Session Chairs: Rana Shahzad Amin, Qatar <strong>Petroleum</strong>; Stuart Girling, Girling and Company<br />

Having competent barriers is a fundamental imperative <strong>of</strong> well integrity. In developing a barrier philosophy, consideration must<br />

be given to barrier envelopes and the individual barrier elements that make them up; which <strong>of</strong> these are safety critical and how<br />

their performance is managed; when some leakage is acceptable and whether different components can have different leak<br />

criteria. In reality few wells go through their operating life without material degradation, component failures or human error<br />

featuring. Because <strong>of</strong> this, the use <strong>of</strong> contingent (secondary, tertiary etc.) barriers is necessary in case failures happen. We<br />

also test, monitor, verify, and maintain barrier elements to minimise the likelihood <strong>of</strong> such failures and the resultant impact.<br />

However, standards are not the same across the industry as there are different regulatory regimes, variable understanding, and<br />

differing attitudes to risk. This session will encourage delegates to explain how barriers are managed in their own companies<br />

and to think about philosophy, standards, and practices related to barrier management.<br />

1430–1500 hours Afternoon C<strong>of</strong>fee Break and Posters<br />

SAVE USD 450<br />

BY REGISTERING<br />

BEFORE<br />

12 APRIL 2013<br />

1500–1630 hours Session 4: Risk Assessment—How to Manage Wells with Imperfect Barriers<br />

Session Chair: Karim Shaikh, Qatar Shell; Ken Feather, Archer<br />

Components fail in most wells resulting in imperfect barriers. Good designs, incorporating contingent barriers, can mitigate<br />

this, though even with such in-built safeguards, failures, and imperfect barriers introduce risks that need assessment and<br />

management. Traditionally, well integrity risk assessments have been done reactively, in response to an actual failure. The<br />

industry is using the concept <strong>of</strong> well failure models increasingly to consider failures that have not yet happened and determine<br />

actions to be taken should they occur. The recently published OGP describes the concept <strong>of</strong> well failure models and encourages<br />

their use to streamline the risk assessment process. A well failure model is, typically, a matrix that identifies the most common<br />

modes <strong>of</strong> failure with consideration for escalation to multiple failures, since the combined result <strong>of</strong> simultaneous failures<br />

can be more severe than failures occurring separately. Each mode <strong>of</strong> failure has an associated action plan and response time<br />

to repair; whether it is permissible to operate, close in or suspend a well during this period. The approach enables proper<br />

management <strong>of</strong> equipment, spares, resources, and contracts to meet the response times specified and is useful to categorise<br />

failures for the purpose <strong>of</strong> prioritisation and reporting. Some examples <strong>of</strong> well failure models will be presented and delegates<br />

will be encouraged to discuss the merits and pitfalls <strong>of</strong> this approach in comparison with other forms <strong>of</strong> risk assessment.

www.spe.org/events/12do7<br />

Wednesday, 29 May 2013<br />

0730–0800 hours Welcome C<strong>of</strong>fee Break<br />

0800–0930 hours Session 5: Well Abandonment—Securing and Restoring Well Integrity in a<br />

Long-Term Perspective<br />

Session Chairs: Inge Carlson, Weatherford; Jean-Phillipe Bedel, Schlumberger<br />

The increasing number <strong>of</strong> ageing wells reaching the end <strong>of</strong> their design lives and the need for final<br />

abandonment is a growing concern in the industry. The <strong>of</strong>ten uncertain status <strong>of</strong> existing well barriers is a<br />

challenge to both intervention safety and as a continued component <strong>of</strong> a permanent secured well. The original<br />

chemical and mechanical design envelopes <strong>of</strong> the well infrastructure need to be assessed and understood<br />

along with the degradation mechanisms. The <strong>of</strong>ten dynamic production history <strong>of</strong> the well may lead to tubular<br />

corrosion, well component wear, and fatiguing thermal loads. External casing corrosion from shallow aquifers<br />

is, to a considerable challenge but with few inspection and repair options. Also, potential deeper formation<br />

disturbance resulting from reservoir production activities need to be carefully assessed. Many fields are in<br />

a rejuvenation phase and continued production from neighbour wells may also interfere with the remaining<br />

infrastructure <strong>of</strong> the abandoned well. Even operations in other fields may recharge hydrocarbon flows if the<br />

formations are connected. Examples from the North Sea include challenges with tubular collapse and even<br />

parted casing strings restricting further reservoir access for the plugging and abandonment (P&A) phase.<br />

Assuring well integrity and securing reservoir access are key issues for many <strong>of</strong> these <strong>of</strong>fshore P&A projects.<br />

Both new diagnostic tools and cost efficient rig solutions and downhole repair tools are high on the wish<br />

list. Understanding the dynamics <strong>of</strong> the subsurface is a key requirement for plugging material selection<br />

and qualification processes. The regulators on the Norwegian continental shelf focus a lot on the status <strong>of</strong><br />

temporary abandoned wells and make higher demands for risk assessment and compliance with the safety<br />

regulations. This workshop session will present current global experiences, and discuss other perspectives <strong>of</strong><br />

well integrity in the context <strong>of</strong> safe well abandonment.<br />

0930–1000 hours Morning C<strong>of</strong>fee Break and Posters<br />

1000–1130 hours Session 6: Technology Gaps<br />

Session Chairs: Bipin Jain, Schlumberger; Karim Shaikh, Qatar Shell<br />

As we all strive to reach a point where we can manage the integrity <strong>of</strong> our whole well stock, while satisfying<br />

both our internal and external standards, guidelines, recommended practices for the whole well life cycle, will<br />

have gaps. These gaps may be technology gaps, failings in well or equipment design or application, gaps in our<br />

processes or gaps in our own understanding and knowledge <strong>of</strong> the complex issues that we face.<br />

This session will explore some <strong>of</strong> these gaps by example, and discuss possible ways in which these gaps could<br />

be filled. These gaps will form the basis <strong>of</strong> an active discussion with new ideas and concepts being brought to<br />

the table.<br />

1130–1230 hours Luncheon/Prayer Time and Posters<br />

1230–1400 hours Session 7: Automating the Management <strong>of</strong> Well Integrity Data<br />

Session Chairs: Leozarin Morshidi, RasGas; Nigel Snow, Maersk Oil Qatar AS<br />

Automating well integrity data requires solving the issue <strong>of</strong> consolidating data in one place and then automating<br />

its evaluation in order to achieve a consistent approach to the decisions taken when faced with specific well<br />

data. In an ideal situation, an integrated data management system provides decision support which can be<br />

tailored to match ISO requirements and any local policies or regulations in different regions. This session<br />

explores how well integrity data review can be automated and how it can achieve consistent treatment <strong>of</strong> data<br />

and identification <strong>of</strong> well problems through approaches like a built-in well failure model, exception based<br />

surveillance, and other concepts embodied within the new ISO standard for well integrity management.<br />

1400–1430 hours Afternoon C<strong>of</strong>fee Break and Posters<br />

1430–1600 hours Session 8: What are the Priorities for Well Integrity Data Management?—<br />

Breakout Session<br />

Session Chairs: Leozarin Morshidi, RasGas; Liane Smith, Intetech Wells;<br />

Nigel Snow, Maersk Oil Qatar AS; Stuart Girling, Girling and Company<br />

At the heart <strong>of</strong> analysing any well integrity problem is access to data. We all have faced experiences <strong>of</strong> unreliable<br />

and incomplete data being stored in separate silos. Great effort is required to pull it all together. There is a<br />

revolution in data management technology, and systems which support well integrity data management already<br />

exist. But what do we expect these systems to provide? What is the minimum specification for a useful data<br />

system? What are the essential aspects and the nice-to-have extras? Where do we want to push this technology<br />

in the future? Share your thoughts and ideas, and discuss potential implementation challenges with others in<br />

today’s breakout session<br />

1600–1615 hours <strong>Workshop</strong> Closing Remarks<br />

General Information<br />

<strong>Workshop</strong> Venue<br />

Oryx Rotana<br />

P.O. Box 29922, Doha, Qatar<br />

Tel: +974.4402.3333 | Fax: +974.4402.3300<br />

Web: www.rotana.com<br />

<strong>Workshop</strong> Guidelines<br />

Format<br />

Two (2) days <strong>of</strong> informal discussions prompted by<br />

selected keynote presentations and discussions.<br />

<strong>Workshop</strong>s maximise the exchange <strong>of</strong> ideas among<br />

attendees and presenters through brief technical<br />

presentations followed by extended Q&A periods.<br />

Focused topics attract an informed audience eager to<br />

discuss issues critical to advancing both technology<br />

and best practices. The majority <strong>of</strong> the presentations<br />

are in the form <strong>of</strong> case studies, highlighting engineering<br />

achievements, and lessons learnt. In order to stimulate<br />

frank discussion, no proceedings are published and the<br />

press is not invited to attend.<br />

Breakout Sessions<br />

Attendees will be assigned to discussion groups on a<br />

random basis for the breakout sessions to maximise the<br />

opportunity to interact with other participants.<br />

Documentation<br />

• Proceedings will not be published; therefore, formal<br />

papers and handouts are not expected from<br />

speakers.<br />

• Work in progress, new ideas, and interesting<br />

projects are sought.<br />

• Pr<strong>of</strong>essionally-prepared visual-aids are not required;<br />

PowerPoint presentations are most commonly used.<br />

• Note-taking by participants is encouraged.<br />

Attendance<br />

Registrations will be accepted on a first-come, first-serve<br />

basis. The Steering Committee encourages attendance<br />

from those who can contribute to the workshop most<br />

effectively either in discussions or with posters. A mix <strong>of</strong><br />

attendees in terms <strong>of</strong> geographic origin, companies, and<br />

disciplines will be encouraged.<br />

<strong>Workshop</strong> Deliverables<br />

• The Steering Committee will appoint a “scribe”<br />

to record the discussions and to produce the full<br />

workshop report for SPE.<br />

• This report will be circulated to all attendees as the<br />

workshop deliverable within 4–6 weeks following the<br />

workshop. The copyright <strong>of</strong> the report is with SPE.<br />

• PowerPoint presentation materials will be posted<br />

on a specific SPE URL address after the workshop.<br />

Provision <strong>of</strong> the materials by the speakers will signify<br />

their permission for SPE to do so.<br />

Commercialism<br />

In keeping with workshop objectives and the SPE<br />

mission, commercialism in posters or presentations will<br />

not be permitted. Company logos must be limited to the<br />

title slide and used only to indicate the affiliation <strong>of</strong> the<br />

presenter and others involved in the work.<br />

Attendance Certificate<br />

All attendees will receive an attendance certificate<br />

attesting to their participation in the workshop. This<br />

certificate will be provided in exchange for a completed<br />

<strong>Workshop</strong> Questionnaire.<br />

Continuing Education Units<br />

Attendees at this workshop qualify for SPE Continuing<br />

Education Units (CEU) at the rate <strong>of</strong> 0.1 CEU per hour <strong>of</strong><br />

the workshop.

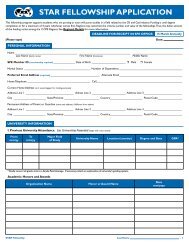

REGISTRATION FORM<br />

Well Integrity: Current Challenges and Future Perspectives<br />

27–29 May 2013 | Oryx Rotana | Doha, Qatar<br />

Important: Attendance is limited and is not guaranteed. Early registration is recommended. Please print or type in black ink.<br />

Registration Fee MUST be paid in advance for attending the workshop.<br />

First Name/Forename__________________________________________________ Middle Name___________________________________________________<br />

Last/Family Name________________________________________________________________________________________ SPE Member? ❒ Yes ❒ No<br />

Member No.__________________________________________ Job Title_____________________________________________________________________<br />

Company/Organisation_______________________________________________________________________________________________________________<br />

Street or P.O. Box Number_____________________________________________________________________ City___________________________________<br />

State/Province___________________________________ Zip/Postal Code___________________________ Country___________________________________<br />

Telephone____________________________________________ Facsimile<br />

Email (required)____________________________________________________________________________________________________________________<br />

<strong>Workshop</strong> Fee: Before 12 April 2013 ❒ USD 1,150 for SPE Members ❒ USD 1,350 for Nonmembers<br />

WORKSHOP<br />

After 12 April 2013 ❒ USD 1,600 for SPE Members ❒ USD 1,800 for Nonmembers<br />

<strong>Workshop</strong> Fee includes: Technical sessions, c<strong>of</strong>fee breaks, luncheons, and welcome reception (if applicable).<br />

Accommodation is NOT included in the workshop registration fee.<br />

IMPORTANT: All SPE Middle East rates are net <strong>of</strong> taxes. The fees in this form do not include any local or withholding taxes. All such taxes will be added to<br />

the invoice.<br />

Do you wish to present a poster? (subject to selection) ❒ Yes ❒ No<br />

Do you wish to be considered a Discussion Leader? (subject to selection) ❒ Yes ❒ No<br />

If yes, please indicate which subject you would like to present on: _______________________________________________________________________<br />

Credit Card (Check One): ❒ American Express ❒ MasterCard ❒ Visa<br />

NO REFUNDS will be granted on cancellations on or after 20 May 2013.<br />

Card Number (will be billed through <strong>Society</strong> <strong>of</strong> <strong>Petroleum</strong> <strong>Engineers</strong>) Expiration Date (mm/yy) Security Code<br />

Name <strong>of</strong> Credit Card Holder (printed) _________________________________________________________________________________________________<br />

Signature (required)___________________________________________________________________________ Date_______________________________<br />

Please inform us <strong>of</strong> mobility or special dietary needs_____________________________________________________________________________________<br />

Payment by Bank Transfer: IMPORTANT—For reference: Please quote “12ADO7” and name <strong>of</strong> delegate<br />

Make Payment to: HSBC Bank Middle East Ltd, Jebel Ali Branch, P.O. Box 66, Dubai, UAE<br />

Account Name: SPE Middle East DMCC Account Number: 036-217131-100 Swift Code: BBMEAEAD<br />

IBAN Code: AE180200000036217131100<br />

Cancellation and Refund Policy:<br />

• A processing fee <strong>of</strong> USD 100 will be charged for cancellations received before the registration deadline 27 April 2013.<br />

• For cancellations received after the registration deadline, 27 April 2013, 25% refund will be made to the registrant.<br />

• No refund on cancellations received within seven (7) days prior to the workshop date, i.e. on or after 20 May 2013.<br />

• No refund will be issued if a registrant fails to attend the workshop.<br />

Not an SPE Member?<br />

Join SPE when you register and<br />

save money by paying the lower<br />

member registration fee.<br />

A portion <strong>of</strong> your dues is<br />

allocated to a JPT subscription<br />

and is not deductible or refundable.<br />

Visa:<br />

SPE Middle East, North Africa, and India will assist in providing a visa invitation letter, upon request in writing, to confirmed registrants after receiving full payment <strong>of</strong> registration<br />

fees. Visa invitation letters take five days to issue from the date <strong>of</strong> request and it is the course attendee’s responsibility to obtain their own visa. SPE cannot issue the visa nor can we<br />

guarantee it will be obtained.<br />

For questions or additional information contact: Loreen Nisha, event manager, at lnisha@spe.org.<br />

12ADO7<br />

To submit your registration online, please visit the event website at: www.spe.org/events/12ado7.<br />

Alternatively, you can email this form to: formsdubai@spe.org, or fax it to: +971.4.457.3164.