General machine brochure - Spiro International SA

General machine brochure - Spiro International SA

General machine brochure - Spiro International SA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.spiro.ch<br />

<strong>Spiro</strong> <strong>International</strong> S.A. is the undisputed world leader<br />

in the development and manufacture of <strong>machine</strong>s for the production<br />

of round ducting and fittings in sheet metal. <strong>Spiro</strong> ® is also a leading<br />

supplier of fittings and system solutions for the ventilation and airconditioning<br />

industr y.

THE<br />

O r i g i n a l<br />

SINCE 1956<br />

Our business principle is to support the improvement of indoor air quality by providing<br />

economical and environmentally-friendly solutions and innovations of <strong>machine</strong>ry and<br />

accessories used in the production and supply of air duct systems.<br />

<strong>Spiro</strong> <strong>International</strong> S.A. is the undisputed<br />

world leader in the development and<br />

manufacture of <strong>machine</strong>s for the production<br />

of round ducting and fittings in sheet metal.<br />

<strong>Spiro</strong> ® is also a leading supplier of fittings<br />

and system solutions for the ventilation<br />

and air-conditioning industry.<br />

With 80% of the world’s round ventilation<br />

components produced on <strong>Spiro</strong> ®<br />

<strong>machine</strong>s,<br />

the facts speak for themselves - we<br />

are truly the company to rely on<br />

when it comes to solutions<br />

concerning round ventilation<br />

systems. Consequently,<br />

users of <strong>Spiro</strong> ® <strong>machine</strong>s are<br />

found on all five continents.<br />

Ever since the company was<br />

founded in 1956, there has been maximum<br />

focus on quality and precision. Situated in<br />

Bösingen, Switzerland, quality comes naturally but<br />

<strong>Spiro</strong> ® ’s endeavors go beyond<br />

the traditional Swiss reliance on<br />

quality. <strong>Spiro</strong> ® has striven to raise<br />

the standards of production and<br />

support even higher. As a result<br />

of highly skilled employees,<br />

<strong>Spiro</strong> ®<br />

designs and produces an<br />

extensive range of sheet metal<br />

<strong>machine</strong>s. In addition to this core production, the<br />

company also markets a line of patented fittings<br />

based on the <strong>Spiro</strong> ® system sealing technology.<br />

We have always aimed at providing complete<br />

solutions as well as products. In our experience<br />

almost every project and installation is unique,<br />

which is why we present bespoke solutions. Having<br />

satisfied clients is undoubtedly every company’s<br />

goal and with experienced and qualified<br />

staff listening closely to the customers’<br />

needs, <strong>Spiro</strong> ®<br />

also succeeds<br />

in this area. We have an<br />

outstanding track-record of<br />

satisfying customers with<br />

problems solved - around<br />

the globe. This is based on our<br />

state-of-the-art <strong>machine</strong>ry, active<br />

service and support as well as our strict<br />

standards of precision and quality and overall<br />

world-class services.<br />

Many of the HVAC-industry’s<br />

leading companies are users of<br />

<strong>Spiro</strong> ® <strong>machine</strong>ry and equipment.<br />

With our continued emphasis on<br />

research and development, as<br />

well as user support and promotion,<br />

this is highly likely to be the<br />

case in the future too.<br />

SPIRO ®<br />

~ 2 ~<br />

www.spiro.ch

CONTENTS<br />

Tubeformers.................................................4<br />

Tubeformer PRO ........................................................ 4<br />

Tubeformer 2020........................................................ 6<br />

Tubeformer 1602 / 3600............................................. 7<br />

Tubeformer X-20 ........................................................ 8<br />

Tubeformer Alpha....................................................... 9<br />

Forming Heads / Decoiler / AROT .................................. 10<br />

PLC Corrugation Unit / Engraving / Other Applications......11<br />

Bend and Fitting Production..................... 12<br />

Introduction ............................................................. 12<br />

Plasmacutter Florett / SMART................................... 14<br />

Plasmacutter Cartridge Filtering Unit / Feeder ........... 15<br />

Curvecutter Delta 1500 / Rollformer AR 800.............. 16<br />

Stitchwelder PRO..................................................... 17<br />

Fittingshaper 1250 ................................................... 18<br />

<strong>Spiro</strong> ® Shaper........................................................... 19<br />

Gorelocker Combi-T.................................................. 20<br />

Gorelocker Beta 3..................................................... 21<br />

Complementary Machines......................... 22<br />

Ovalizer / Roval Roller................................ 23<br />

Special Welding Applications.................... 24<br />

Double-XX / SR Cutter............................... 26<br />

Rectangular SMART Line........................... 27<br />

<strong>Spiro</strong> ® System............................................ 28<br />

<strong>Spiro</strong> ® System .......................................................... 28<br />

Complete Range of Fittings and Accessories............. 29<br />

After Sales Support..........................................30<br />

Original Spare Parts / <strong>Spiro</strong> ® Service Agreement........ 30<br />

Upgrades................................................................. 30<br />

Real Quality, Real Value, Real Experience... 31<br />

<strong>Spiro</strong> <strong>International</strong> S.A. Industriestrasse 173 CH-3178 Bösingen Switzerland<br />

Tel +41 31 740 31 00 | Web www.spiro.ch | E-mail info@ spiro.ch<br />

info@spiro.ch<br />

~ 3 ~<br />

SPIRO ®

TUBEFORMERS<br />

TUBEFORMER PRO<br />

<strong>Spiro</strong> <strong>International</strong> S.A. is continuously working hard to improve the value for tubeformer users<br />

even more. We believe that we accomplished this goal by introducing the new edition of the<br />

Tubeformer PRO.<br />

The Tubeformer PRO is custom-tailored through its configurations that brings the user the<br />

comfort of producing only what he needs and provides the option to expand and adapt the<br />

<strong>machine</strong> functionality in the future.<br />

Built upon the highly successful Tubeformer 1602 we have finetuned and reinforced components<br />

that will result in more production capacity, material savings, and decreased changeover time.<br />

“ The world’s best<br />

tubeformer revolutionized<br />

an entire industry”<br />

Registered Design:<br />

2153601-0001/-0002<br />

Technical Data<br />

Diameter 80 - 1600 mm (3” - 64”)<br />

Strip Thickness<br />

Cutting System<br />

Slitter - Smooth and Noiseless Cut<br />

Basic Machine<br />

Performance Tested /<br />

Guaranteed (duct of 3 m length)<br />

0.4 - 1.5 mm (0.016”- 0.059”) galvanized steel<br />

0.4 - 0.8 mm (0.016”- 0.031”) stainless steel<br />

0.6 - 1.5 mm (0.024”- 0.059”) aluminium<br />

Super Slitter Model H<br />

High speed frequency controlled main drive<br />

Monitoring production output<br />

Hydraulically controlled drive roller pressure<br />

Hydraulically operated clinching roller<br />

Automatic length measurement system<br />

0.5 mm (0.020”) thickness – 100 mm (4”) diameter – Up to 250 Ducts/hour with AROT<br />

0.7 mm (0.028”) thickness – 500 mm (20”) diameter – Up to 85 Ducts/hour<br />

0.9 mm (0.035”) thickness – 1250 mm (50”) diameter – Up to 40 Ducts/hour<br />

1.25 mm (0.049”) thickness – 1600 mm (64”) diameter – Up to 24 Ducts/hour<br />

SPIRO ®<br />

~ 4 ~<br />

www.spiro.ch

Unique Features<br />

Configurable to your own needs<br />

AROT - Automatic Duct Receiving System<br />

Super Slitter<br />

“Bubblan” Reel<br />

Cassette System Quick-lock System State-of-the-art User Interface<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

BASIC<br />

STANDARD PERFORMANCE<br />

1 2 3<br />

m/min<br />

2Year<br />

Warranty<br />

Speed Options<br />

Unique Features<br />

Feature<br />

Your Value<br />

AROT - Automatic Duct<br />

Receiving System Increases production capacity by 38%<br />

Super Slitter<br />

Fastest Strip Speed in the<br />

No buckles<br />

Superior cutting with minimized maintenance and easy set-up<br />

Industry<br />

“Bubblan” Reel<br />

Fixed lock seam and assured duct quality<br />

Cassette System<br />

Fast set-up and ergonomic<br />

Quick-lock System<br />

Fast change of forming heads<br />

State-of-the-art User<br />

Interface<br />

Configurable Drive System<br />

2 Years Warranty Risk minimization<br />

PLC Corrugation Unit<br />

Risk Minimization<br />

PLC Corrugation Unit<br />

User-friendly display featuring interface to network and internet, diagnosis tool<br />

and multilingual function<br />

Fast acceleration/deceleration ability (60 - 100 m/min. available)<br />

Produce ducts with smooth inside surface at the ends but reinforced with<br />

corrugation<br />

TUBEFORMERS<br />

info@spiro.ch<br />

~ 5 ~<br />

SPIRO ®

TUBEFORMERS<br />

TUBEFORMER 2020<br />

<strong>Spiro</strong> <strong>International</strong> S.A. has succeeded with the<br />

Tubeformer 2020 to cover the complete range<br />

of international standard sizes up to 2500 mm<br />

diameter.<br />

The Tubeformer 2020 is highly reliable, the<br />

strongest in the industry, and continues to live<br />

up to the history of durable quality <strong>machine</strong>s<br />

produced by <strong>Spiro</strong> ® .<br />

Unique Features<br />

» The outstanding flying slitter cuts the tubes<br />

to length without noise or hot sparks as<br />

known from the saws and provides smooth<br />

tube ends without deburring<br />

» The <strong>Spiro</strong> ® forming heads in combination<br />

with the clinching device represent the<br />

state-of-the-art to provide tubes in top<br />

quality concerning air-tight spiral lockseam<br />

and diameter tolerance<br />

» The corrugation unit allows a reduction<br />

in material costs and makes the bigger<br />

diameter tubes more rigid<br />

Tubeformer Plasmacutter<br />

Technical Data<br />

Diameter Range 80 - 2500 mm (4” - 100”)<br />

Strip Thickness<br />

Cutting System<br />

Slitter - Smooth and Noiseless Cut<br />

Other Applications<br />

Basic Machine<br />

Performance Tested /<br />

Guaranteed (duct of 3 m length)<br />

0.4 - 2.0 mm (0.016”- 0.079”) galvanized steel<br />

0.4 - 1.3 mm (0.016”- 0.051”) stainless steel<br />

0.4 - 2.0 mm (0.024”- 0.079”) aluminium<br />

High Performance Super Slitter Model H and/or Plasmacutter<br />

Voidforming / Mining ventilation / Jacketing<br />

Heavy duty frequency controlled main drive<br />

Hydraulically operated clinching roller<br />

Automatic length measuring system<br />

Motorized angle adjustment<br />

Hydraulically controlled drive roller pressure<br />

0.5 mm (0.020”) thickness – 100 mm (4”) diameter – 180 Ducts/hour<br />

0.7 mm (0.028”) thickness – 500 mm (20”) diameter – 53 Ducts/hour<br />

0.9 mm (0.035”) thickness – 1250 mm (50”) diameter – 23 Ducts/hour<br />

1.25 mm (0.049”) thickness – 1600 mm (64”) diameter – 19 Ducts/hour<br />

2.0 mm (0.079”) thickness – 2000 mm (80”) diameter - 15 Ducts/hour, with corrugation<br />

SPIRO ®<br />

~ 6 ~<br />

www.spiro.ch

TUBEFORMER 1602 / 3600<br />

The Tubeformer 1602 is the most sold Tubeformer model in the world!<br />

This state-of-the-art Tubeformer convinces with reliability, performance-driven approach, stability, and<br />

has the proven qualities for what <strong>Spiro</strong> ® stands for.<br />

The module technique gives the customer the possibility to choose between a number of options,<br />

allowing him to create a <strong>machine</strong> for his specific needs.<br />

Unique Features<br />

» Highly Reliable<br />

» Superior Lockseam<br />

» Combines Speed and Consistency<br />

» Hundreds of References Worldwide<br />

Technical Data<br />

Diameter Range 80 - 1600 mm (4” - 64”)<br />

Strip Thickness<br />

Cutting System<br />

Slitter - Smooth and Noiseless Cut<br />

Basic Machine<br />

Performance Tested /<br />

Guaranteed (duct of 3 m length)<br />

0.4 - 1.3 mm (0.016”- 0.051”) galvanized steel<br />

0.4 - 0.8 mm (0.016”- 0.031”) stainless steel<br />

0.4 - 1.3 mm (0.016”- 0.051”) aluminium<br />

Flying slitter<br />

Frequency controlled main drive<br />

Vertical decoiler & Run-off table<br />

Hydraulically operated clinching roller<br />

Hydraulically controlled drive roller pressure<br />

Automatic length measurement system<br />

0.5 mm (0.020”) thickness – 100 mm (4”) diameter – 195 Ducts/hour<br />

0.7 mm (0.028”) thickness – 500 mm (20”) diameter – 60 Ducts/hour<br />

0.9 mm (0.035”) thickness – 1250 mm (50”) diameter – 24 Ducts/hour<br />

1.25 mm (0.049”) thickness – 1600 mm (64”) diameter – 19 Ducts/hour<br />

TUBEFORMERS<br />

info@spiro.ch<br />

~ 7 ~<br />

SPIRO ®

TUBEFORMERS<br />

TUBEFORMER X-20<br />

This rigid and highly mobile tubeformer is ideal for on-site work and performs strongly in a rough<br />

environment. The compact design and selected technology allows for an easy relocation to a new<br />

worksite.<br />

The spiral duct <strong>machine</strong> captures the All-In-One approach, including the run-off table, decoiler,<br />

automatic discharge function, corrugation unit, <strong>Spiro</strong> ® flying slitter, and standard tooling up 1.0 mm.<br />

The Tubeformer X-20 design accomplishes the HVAC-industry requirements to produce in galvanized<br />

steel, stainless steel or aluminium, as well as fulfilling the DIN, EUROVENT, and SMACNA standards.<br />

Unique Features<br />

» Compact & Rigid Design<br />

» Reduced Maintenance<br />

Latest innovation by <strong>Spiro</strong> ®<br />

» High Mobility<br />

» FRU Cassettes For Quick Set-Up<br />

Registered Design:<br />

2153601-0001/-0002<br />

Technical Data<br />

Diameter Range 80 - 1250 mm (3” - 50”)<br />

Strip Thickness<br />

Cutting System<br />

Slitter - Smooth and Noiseless Cut<br />

Performance Tested /<br />

Guaranteed (duct of 3 m length)<br />

0.4 - 1.0 mm (0.016”- 0.039”) galvanized steel<br />

0.4 - 0.6 mm (0.016”- 0.024”) stainless steel<br />

0.6 - 1.0 mm (0.024”- 0.039”) aluminium<br />

Second Generation <strong>Spiro</strong> ® Flying Slitter<br />

0.5 mm (0.020’’) thickness – 100 mm (4”) diameter – 180 Ducts/hour<br />

0.7 mm (0.028’’) thickness – 500 mm (20”) diameter – 53 Ducts/hour<br />

0.9 mm (0.035’’) thickness – 1250 mm (50”) diameter – 23 Ducts/hour<br />

The new generation of<br />

SPIRO ® FLYING SLITTER,<br />

utilizing extra strong linear<br />

guides in combination with the<br />

strength of the toggle joint,<br />

results in the perfect cut.<br />

SPIRO ®<br />

~ 8 ~<br />

www.spiro.ch

TUBEFORMER ALPHA<br />

The Tubeformer Alpha is designed for<br />

automatic production of high quality spiral<br />

ducts from diameter 100 mm up to 1250 mm.<br />

Unique Features<br />

» Easy handling<br />

» User-friendly interface<br />

» High quality seam<br />

» Quick and easy set up<br />

Technical Data<br />

Diameter Range 100 - 1250 mm (4” - 50”)<br />

Strip Thickness<br />

Cutting System<br />

Slitter - Smooth and Noiseless Cut<br />

Basic Machine<br />

Performance Tested /<br />

Guaranteed (duct of 3 m length)<br />

0.5 - 1.0 mm (0.020” – 0.039”) galvanized steel<br />

0.5 - 0.6 mm (0.020” – 0.023”) stainless steel*<br />

*Production of stainless steel in consolidation with <strong>Spiro</strong> <strong>International</strong> S.A.<br />

Flying slitter<br />

Touch screen controller<br />

Vertical decoiler & Run-off table<br />

Profiling rolls for reinforced tubes<br />

0.5 mm (0.020”) thickness – 100 mm (4”) diameter – 98 Ducts/hour<br />

0.7 mm (0.028”) thickness – 500 mm (20”) diameter – 30 Ducts/hour<br />

0.9 mm (0.035”) thickness – 1250 mm (50”) diameter – 13 Ducts/hour<br />

TUBEFORMERS<br />

info@spiro.ch<br />

~ 9 ~<br />

SPIRO ®

TUBEFORMERS<br />

FORMING HEADS<br />

Original <strong>Spiro</strong> ® forming heads are made out of<br />

high quality aluminium and vitally contribute to<br />

consistently produce premium ducts.<br />

Technical Data<br />

DINØ<br />

Inside Diameter (mm)<br />

DINØ 80 / 90 / 100 / 125 / 160 / 180 / 200<br />

DINØ 224 / 250 / 280 / 300 / 315 / 355 / 400<br />

DINØ 450 / 500 / 560 / 600<br />

DINØ 630 / 710 / 800<br />

DINØ 900 / 1000 / 1120 / 1250<br />

DINØ 1400 / 1500 / 1600<br />

DINØ 1800 / 1900 / 2000<br />

DINØ 2100 / 2300 / 2500<br />

DECOILER DCH 3000<br />

The DCH-3000 decoiler is a horizontal decoiler for<br />

up to 3 coils. The design allows a quick change<br />

over time and serves to cope with thick material.<br />

Moreover, you achieve a high production capacity<br />

thanks to the formidable speed rate.<br />

Technical Data<br />

Max. Coil Weight Max. 3 Coils - 1000 kg each<br />

Max Speed<br />

100 m/min.<br />

Coil Dimensions Inside diameter min. 508 mm (20’’)<br />

Outside Diameter Max. 1400 mm (55’’)<br />

Strip Thickness 0.4 - 1.6 mm (0.016’’ - 0.063’’)<br />

Strip Width Max. 150 mm (6’’)<br />

Weight<br />

750 Kg<br />

AROT- AUTOMATIC DUCT RECEIVING SYSTEM<br />

The automatic duct receiving system increases<br />

production capacity and automatizes your<br />

process significantly. The combination of the<br />

duct receiving system with the Slitter MODEL<br />

H results in an up to 30% higher performance<br />

rate. The duct receiving system handles the full<br />

ranges of dimensions - Ø 80 - 2000 mm and<br />

can be retrofitted on most <strong>Spiro</strong> ® Tubeformers.<br />

Unique Features<br />

» No buckles<br />

» Increases production capacity<br />

» Ensures careful tube handling<br />

» Automizes your process<br />

» Possible to retrofit most <strong>Spiro</strong> ® Tubeformers<br />

SPIRO ®<br />

~ 10 ~<br />

www.spiro.ch

TUBEFORMER PRO / 1602 / 2020 -<br />

PLC CORRUGATION<br />

UNIT<br />

<strong>Spiro</strong> ® ’s uniquely featured “Controlled<br />

corrugation unit” enables you to produce<br />

ducts with a smooth inside surface at the<br />

ends but still reinforced with the corrugation.<br />

The result is a duct with considerable less<br />

amount of leakage and maintained rigidity.<br />

ENGRAVING & FIXED LOCK SEAM<br />

For the Tubeformer models PRO, 1602, and 2020 you can add additional value by making your own<br />

individual engraving and equip with a “Bubblan” option for a fixed lock seam and assured duct quality.<br />

Individual engraving possible<br />

Fixed lock seam and assured duct quality<br />

OTHER APPLICATIONS<br />

Mining Ventilation<br />

For the fast and reliable production of heavy duty<br />

manufactured steel ducts.<br />

» Ducts can be manufactured on-site<br />

» Up to 12 meters in length<br />

» Fully automated production<br />

» Low maintenance costs<br />

» Duct diameter from 80 - 2500 mm<br />

» Material thickness up to 2.0 mm<br />

» Meets all mining standards<br />

Voidforming<br />

Tubes for concrete structures.<br />

» <strong>Spiro</strong> ® Voidforming tubes meet the requirements of<br />

concrete structures for a highly rigid but light sheetmetal<br />

tube that can withstand being embedded<br />

without deformation.<br />

» Voidformers withstand reinforcement loads and<br />

transportation as well as fast casting.<br />

» Voidformers are sealed<br />

with end cones that<br />

are supplied fitted to<br />

the tubes.<br />

Jacketing<br />

Jacketed piping features a core pipe which is completely<br />

surrounded by a jacket pipe.<br />

» Pre-insulated pipes are commonly<br />

used for water piping systems<br />

and different types of energy<br />

applications (district energy).<br />

» Insulation is usually carried out with<br />

polyurethane foam and the outer<br />

casing material is galvanized or<br />

stainless steel which will withstand<br />

extreme climatic conditions.<br />

Post-Tensioning<br />

Post-Tensioning is another Tubeformer application used<br />

in the building industry, mainly for bridges, high rise<br />

buildings, and power plant buildings.<br />

» Duct production in 0.4 mm and 0.5 mm thickness<br />

» Duct diameter from 40 - 165 mm<br />

» Up to 12 meters in length<br />

» Saving raw material<br />

because of usage of<br />

strip width 78 mm<br />

TUBEFORMERS<br />

info@spiro.ch<br />

~ 11 ~<br />

SPIRO ®

BEND & FITTING PRODUCTION<br />

FLANGING &<br />

CLOSING<br />

GORELOCKER COMBI-T /<br />

BETA 3<br />

CURVECUTTER DELTA 1500<br />

PLASMACUTTER FLORETT / SMART<br />

CUTTING<br />

ROLLING<br />

ROLLFORMER AR800 /<br />

RME<br />

SEALING<br />

WELDING<br />

FITTINGSHAPER 1250 /<br />

SPIRO ® SHAPER<br />

STITCHWELDER PRO<br />

SPIRO ®<br />

~ 12 ~<br />

www.spiro.ch

1)<br />

Cutting of Segments<br />

Plasmacutter Florett 300 segments/hour - size 315 mm/90° (see page 14)<br />

Plasmacutter SMART 260 segments/hour - size 315 mm/90° (see page 14)<br />

Curvecutter Delta 1500 560 segments/hour - size 315 mm/90° (see page 16)<br />

The Plasmacutter Florett and SMART are delivered with a special HVAC software which<br />

provides a complete production control system for ductwork contractors. The Software includes<br />

libraries of round, rectangular and oval duct fittings which can be dimensioned and automatically<br />

manufactured. The Curvecutter Delta 1500 <strong>machine</strong> is a high production <strong>machine</strong> which delivers<br />

segments with smooth edges (4 roller – shear); thus extending the life of the rolls and guide<br />

plates on the Gorelocker and Stitchwelder considerably.<br />

2) Rolling of Segments<br />

Rollformer AR 800 1200 segments/hour - size 315 mm/90° (see page 16)<br />

Rollformer RME 60/128 400 segments/hour - size 315 mm/90° (see page 22)<br />

The AR 800 is equipped with an automatic feeding unit and can be linked to a Stitchwelder. This<br />

means that 1 operator can operate both <strong>machine</strong>s, without reducing the output of the Stitchwelder.<br />

3) Welding<br />

Stitchwelder PRO 700 segments/hour - size 315 mm/90° (see page 17)<br />

Spotwelder 200 segments/hour - size 315 mm/90° (see page 22)<br />

Usually, a spot welded fitting has to be treated (painted and sealed) after the welding operation to<br />

get the seam tight and prevent corrosion. In addition the melted zinc coats the electrode causing<br />

a bad weld. The <strong>Spiro</strong> ® Stitchwelders use a copper wire as an intermediate electrode which<br />

transports the zinc away and provides a constant small seam. This means no painting or sealing<br />

is needed after the welding process as the surface of the material remains intact.<br />

4) Sealing<br />

Fittingshaper 1250 2-gaskets (Ø300 mm) in less than 2 minutes (see page 18)<br />

<strong>Spiro</strong> ® Shaper 4-6 pcs/min. of 2-gasket fittings (Ø160 mm) (see page 19)<br />

The Fittingshaper and <strong>Spiro</strong> ® Shaper perfectly complement each other to achieve the full dimension<br />

range of rubber gasket on your fittings! Both <strong>Spiro</strong> ® <strong>machine</strong> innovations serve to incorporate a<br />

sealing strip of age-resistant EPDM rubber on the fitting, ensuring an air tight and lasting joint<br />

seal, immune to variations in temperature.<br />

5)<br />

Flanging / Closing of Segment Bends,<br />

End Caps, Offsets and Rainhats<br />

Gorelocker Combi-T 40 bends/hour (4 segments – Ø 200 mm bend) (see page 20)<br />

Gorelocker Beta 3 20 bends/hour (4 segments – Ø 200 mm bend) (see page 21)<br />

The Gorelocker Combi-T is always ready for flanging or closing as it is a two station <strong>machine</strong> (one<br />

flanging and one closing station). Two operators can work simultaneously. The Gorelocker Beta<br />

3 can be switched from flanging to closing by swivelling the table away and changing the rollers<br />

and arms for closing.<br />

BEND & FITTING PRODUCTION<br />

info@spiro.ch<br />

~ 13 ~ SPIRO ®

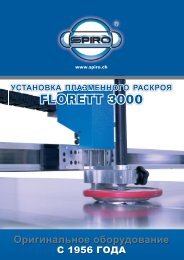

BEND & FITTING PRODUCTION<br />

PLASMACUTTER FLORETT<br />

The 3rd generation of the market leading Plasma Cutter is developed and designed with the HVAC<br />

Industry in main focus.<br />

This <strong>machine</strong> offers the most efficient solution and highest output for any HVAC workshop. The latest<br />

version of the professional PC based controller <strong>Spiro</strong> ® HS comes with a whole range of new state of<br />

the art features.<br />

Our <strong>machine</strong> always includes the leading HVAC Software on the market, no compromise. Together<br />

with the rigid and accurate table design the <strong>Spiro</strong> ® Plasma Florett will serve your company for decades<br />

to come.<br />

Unique Features<br />

» <strong>Spiro</strong> ® HS Controller v.3<br />

» 50% faster traverse speed<br />

» Total production time reduced with up to 20%<br />

» Enforced high precision linear unit for the torch<br />

» Step forward/backward function<br />

» Free mode, select any part or contour<br />

» Optimized sheet utilization<br />

PLASMACUTTER SMART<br />

The Plasmacutter SMART is the perfect<br />

companion for any HVAC workshop. Easy<br />

accessible from all sides, the Plasmacutter<br />

is equipped with all necessary functions to<br />

execute the job. The <strong>machine</strong> comes with a<br />

large color touchscreen.<br />

Unique Features<br />

» <strong>Spiro</strong> ® cutting quality<br />

» Leading HVAC Software<br />

» Exhaust system moving with the bridge<br />

» PC-based control system with user-friendly<br />

interface and color touchscreen<br />

» Graphic display of the cutting process<br />

» Network connection and USB<br />

» X and y axis belt driven with servo-motors<br />

SPIRO ®<br />

~ 14 ~<br />

www.spiro.ch

PLASMACUTTER COMPARISON<br />

Technical Data<br />

PLASMACUTTER FLORETT SMART<br />

Work Area 1500 x 3000 mm (5’ x 10’) 1500 x 3200 mm (5’ x 10’)<br />

Traverse Speed<br />

40 m/min. (131 fpm)<br />

both X- and Y-axis<br />

20 m/min. (66 fpm)<br />

Plasma Unit 60 Amp 40 Amp<br />

PLASMACUTTER CARTRIDGE<br />

FILTERING UNIT<br />

Equip your Plasmacutter with a filtering unit to achieve a clean environment in your workshop<br />

and to ensure that the dust emissions are always guaranteed < 2 mg/m3. The perfectly filtered<br />

air could be ejected in the working area (in accordance with the local regulations) or directed into<br />

an exhaust chimney.<br />

The filtering unit prevents dust and metal particles to be<br />

exposed to the surrounding environment and thus contributes<br />

to an ecological responsible working approach while ensuring<br />

employee-friendly working conditions.<br />

Unique Features<br />

» Ensures Smoke-Free Environment<br />

» Produces Clean Air for Employees<br />

» Energy Saving Friendly<br />

PLASMAFEEDER<br />

Equip your workshop with a <strong>Spiro</strong> ® Plasma Feeder.<br />

Use the Plasma Feeder to increase your productivity and save material. Supply your Plasmacutter<br />

directly from a coil line (2 or 4 decoilers), including sheet selector!<br />

Unique Features<br />

» Increase your Productivity<br />

» Save Material<br />

» Comes with 2 or 4 Decoilers<br />

» Includes Sheet Selector<br />

BEND & FITTING PRODUCTION<br />

info@spiro.ch<br />

~ 15 ~ SPIRO ®

BEND & FITTING PRODUCTION<br />

CURVECUTTER DELTA 1500<br />

This <strong>machine</strong> is specially designed for cutting out<br />

segments of highest accuracy from a blank (i.e.<br />

bends, flat oval bends, domes and shapes for the<br />

insulation industry). The Curvecutter Delta 1500 is<br />

a suitable <strong>machine</strong> for a high production line together<br />

with the <strong>Spiro</strong> ® Rollformer, Stitchwelder and<br />

Gorelocker.<br />

Unique Features<br />

» Select up to 9 different program settings ranging from 100 to 1500 mm diameter<br />

» Simple input for circular or flat-oval bends, angle cuts and insulation fittings<br />

» Accurate cutting of segments with high repeatability due to high-tech servo motors<br />

» No burrs and no hardening of the edge as a result of cutting with 4 roller-shears<br />

» Efficiency: 1 elbow 200 mm with 4 segments is cutting in 1 path within 15 seconds<br />

Technical Data<br />

Maximum Sheet Width 1500 mm (60”)<br />

Material Thickness<br />

Cutting Speed<br />

Segment Angle<br />

0.4 - 1.1 mm (0.016”- 0.043”) galvanized steel<br />

0.4 - 0.6 mm (0.016”- 0.024”) stainless steel<br />

0.5 - 1.1 mm (0.020”- 0.043”) aluminium<br />

2 - 10 m/min. (6 – 32 fpm)<br />

5 - 46° (in steps of 1/10 degree)<br />

Elbow Diameter 100 - 1500 mm (in steps of 1 mm) (4”- 60”)<br />

Number of Cutters<br />

1 - 4 (selectable on control panel)<br />

ROLLFORMER AR 800<br />

The Rollformer AR 800 represents a new generation of<br />

Rollformers. Built to support high-speed production of<br />

round-shaped metal parts and perfectly complements<br />

the <strong>Spiro</strong> ® Stitchwelder and Litelocker family.<br />

Unique Features<br />

» Designed for fast and automatic rolling of bend<br />

segments, T-pieces, nipples, tubes etc.<br />

» The Rollformer can be operated in combination<br />

with the Stitchwelder PRO allocating only 1<br />

operator for both <strong>machine</strong>s<br />

» Equipped with remote control<br />

» Automatic feeding table<br />

Technical Data<br />

Diameter Range 100 - 1000 mm (4”- 40”)<br />

Maximum Width of Blank 800 mm (31”) (depending on thickness & Ø)<br />

Material Thickness<br />

Maximum Output<br />

Power Supply<br />

0.4 - 1.0 mm (0.016”- 0.039”) galvanized steel<br />

0.4 - 0.6 mm (0.016”- 0.024”) stainless steel<br />

0.4 - 1.0 mm (0.016”- 0.039”) aluminium<br />

1200 parts/hour<br />

1.5 kVA / 400V / 50 Hz (other voltage on request)<br />

SPIRO ®<br />

~ 16 ~<br />

www.spiro.ch

STITCHWELDER PRO<br />

The new generation of our Stitchwelder builds upon the most reliable and recognized Stitchwelder<br />

1000/1270/1540 in the industry.<br />

The guaranteed air-tight seam can be achieved through stitch welding or continuous welding<br />

application. Moreover, <strong>Spiro</strong> ® is emphasizing its leading role in the HVAC industry by equipping<br />

the Stitchwelder with a user-friendly touchscreen. This industrial novelty serves to facilitate the<br />

production set up and allows the user to save program settings.<br />

The Stitchwelder PRO also features<br />

the fastest welding speed in the<br />

industry with up to max. 15 m/<br />

min., underlining the continuous<br />

productivity and efficiency of the<br />

<strong>machine</strong>. Naturally, the welded seam<br />

is constant from the beginning to<br />

the end, sealing or paint cover is not<br />

required, no need to clean or rework<br />

the welding rolls, and eliminating<br />

burnt galvanized coating results in<br />

less finishing work. Finally, the 6 to<br />

8 mm overlap keeps your material<br />

costs at a minimum.<br />

Unique Features<br />

» New Design<br />

» Increased Welding Speed<br />

» Air-Tight Seam Guaranteed!<br />

Technical Data<br />

Welding Length 50 mm - 1000/1270/1540 mm (2” - 40”/ 50”/ 60”)<br />

Diameter Range 75 - 1000 mm (3”- 40”)<br />

Material Thickness 0.4 - 1.0 mm (0.016”- 0.039”)<br />

Overlap 6 mm (0.24”) for 1000, 8 mm (0.31”) for 1270 & 1540<br />

Wire Diameter 2 mm (0.078”)<br />

Adjustable Welding Speed<br />

2 - 15 m/min. (6.6 - 49.2 fpm)<br />

BEND & FITTING PRODUCTION<br />

info@spiro.ch<br />

~ 17 ~ SPIRO ®

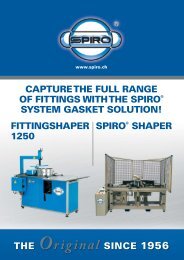

BEND & FITTING PRODUCTION<br />

Capture the full range of fittings with the<br />

<strong>Spiro</strong> ® System gasket solution!<br />

FITTINGSHAPER 1250<br />

The Fittingshaper contributes vitally to reduce the leakage rate in the ventilation system, resulting<br />

in reduced energy consumption costs!<br />

The Fittingshaper is a flexible <strong>machine</strong> made for mounting rubber gaskets to fittings in small<br />

volumes but with many different sizes.<br />

Technical Data<br />

Diameter Range 125 - 1250 mm (5”- 50”)<br />

Material Thickness<br />

Hydraulic System<br />

Power Supply<br />

0.5 - 0.9 mm (0.020”- 0.035”) galvanized steel<br />

0.5 - 0.8 mm (0.020”- 0.031”) stainless steel<br />

All drives & movements<br />

5 kVA / 400V / 50 Hz (other voltage on request)<br />

SPIRO ® SYSTEM (See Page 28)<br />

Patent No.: US 6,598,285 B1<br />

Patent No.: US 6,170,883 B1<br />

Unique Features<br />

» Fast and easy installation<br />

» Factory fitted gasket without any loose parts<br />

» Adjustable - twisting and fine adjustment<br />

result in no risk of leakage<br />

» Can be installed in all kinds of weather<br />

» Temperature resistant from -30˚C to +100˚C<br />

» Withstands positive pressure - 3000Pa<br />

» Environmentally Friendly - the system is<br />

fitted with solvent-free sealant<br />

<strong>Spiro</strong> ® System<br />

SPIRO ®<br />

~ 18 ~<br />

www.spiro.ch

SPIRO ® SHAPER<br />

The <strong>Spiro</strong> ® Shaper stands out with the efficiency to mount gaskets in a fast and accurate fashion<br />

on fittings. The focus on smaller diameter range (100 – 500 mm) results in a high output volume<br />

combined with consistency due to the precise <strong>machine</strong> set-up.<br />

Moreover, the <strong>Spiro</strong> ® Shaper can produce a rolled edge on non-gasket products. In addition, the <strong>machine</strong><br />

handles any type of fittings (e.g. saddle, bends, T-pieces). Also, to optimize the leakage tightness,<br />

<strong>Spiro</strong> ® implemented 5 different widths of rubber gaskets, covering the entire dimension range.<br />

Technical Data<br />

Diameter Range 100 – 500 mm (4”- 20”)<br />

Material Thickness<br />

Power Supply<br />

Pneumatic Connection<br />

Double lip gasket for <strong>Spiro</strong> ® System<br />

0.5 - 0.9 mm (0.020”- 0.035”) galvanized steel<br />

0.5 - 0.8 mm (0.020”- 0.031”) stainless steel<br />

400V / 50Hz / 3 Phases (other voltage on request)<br />

7 bar, 200 l/min. (as required minimum)<br />

Combine the Fittingshaper 1250 & <strong>Spiro</strong> ®<br />

Shaper to achieve the full dimension range<br />

of rubber gasket on your fittings!<br />

Double lip gasket ensures tightness class D<br />

BEND & FITTING PRODUCTION<br />

info@spiro.ch<br />

~ 19 ~ SPIRO ®

BEND & FITTING PRODUCTION<br />

GORELOCKER COMBI-T<br />

High production Gorelocker produce standing lockseam elbows and reducers. The high flexibility<br />

is achieved by means of 2 separate workstations: a flanging station and seam closing station.<br />

Thus the <strong>machine</strong> is always ready for operation without time-consuming conversion. The standing<br />

seam reduces welding to just one longitudinal seam and improves rigidity.<br />

Technical Data<br />

Diameter Range 125 - 1250 mm (5”- 50”)<br />

Material Thickness<br />

Flanging Speed<br />

Production Time<br />

Electrical Connection<br />

Unique Features<br />

0.4 - 1.5 mm (0.016”- 0.059”) galvanized steel<br />

0.4 - 1.0 mm (0.016”- 0.039”) stainless steel<br />

0.4 - 1.5 mm (0.016”- 0.059”) aluminium<br />

Max. 120 m/min. (394 fpm)<br />

» Dual working station<br />

» Maximum flexibility with no equipment<br />

change<br />

» Constant quality / High production speed<br />

» High capacity with material thickness up to<br />

1.5 mm<br />

» Virtually no maintenance, no lubrication<br />

necessary<br />

» High quality parts and all rotating tools are<br />

made of hardened steel<br />

» High quality seams<br />

90 sec. (bend ø 200 mm, 90° / 4 segments)<br />

3 x 400 V / 50 Hz / 4 kVA (other connections on request)<br />

SPIRO ®<br />

~ 20 ~<br />

www.spiro.ch

GORELOCKER BETA 3<br />

This is an original lockseam <strong>machine</strong> manufactured of high quality <strong>machine</strong> parts. A genuine<br />

product from the world’s leading manufacturer of <strong>machine</strong>s for the HVAC-industry.<br />

Technical Data<br />

Diameter Range 125 - 1000 mm (5”- 40”)<br />

Material Thickness<br />

Flanging Speed<br />

Production Time<br />

Electrical Connection<br />

Switching from single flange to double flange<br />

operation requires a mere move of a handle.<br />

Changing from flanging operation to lockseaming<br />

operation requires only a few minutes. The<br />

<strong>machine</strong> can easily produce segment bends,<br />

reducers, end caps, offsets, etc.<br />

Single Flange<br />

Double Flange<br />

0.4 - 1.25 mm (0.016”- 0.049”) galvanized steel<br />

0.4 - 0.8 mm (0.016”- 0.031”) stainless steel<br />

0.4 - 1.25 mm (0.016”- 0.049”) aluminium<br />

Max. 80 m/min. (262 fpm)<br />

120 sec. (bend ø 200 mm, 90° / 4 segments)<br />

3x 400 V / 50 Hz / 4 kVA (other connections on request)<br />

Closed Seam<br />

Gorelocker Beta 3 / Combi-T<br />

BEND & FITTING PRODUCTION<br />

info@spiro.ch<br />

~ 21 ~<br />

SPIRO ®

COMPLEMENTARY MACHINES<br />

LITELOCKER<br />

The <strong>Spiro</strong> ® Litelocker is a sturdy and advanced button lock <strong>machine</strong>.<br />

It enables up to 3 plates of sheet metal to be firmly joined together<br />

(cold forming) without incurring any damages to the sheet metal surface.<br />

The press force is made by using a pneumo-hydraulic system.<br />

Unique Features<br />

» No heating of material<br />

» No need to make holes for rivets<br />

» Low energy consumption and minimal maintenance<br />

» No damage to galvanized or prepainted surfaces<br />

» Usable for all kind of connections (rectangular and round)<br />

» Laser point to seam a straight line<br />

» Various types of dies & punches<br />

» Low maintenance costs and noise level<br />

Technical Data<br />

Length of Arm 400 mm (15”)<br />

Minimum Tube Diameter 80 mm (3”)<br />

Maximum Material<br />

Thickness<br />

Capacity<br />

80 stroke/min.<br />

Pre Stroke 52 mm (2”)<br />

Press Stroke 8 mm (0.31”)<br />

Total Stroke 60 mm (2.4”)<br />

Air Supply<br />

6 bar<br />

SPOTWELDER<br />

Spotwelder for welding of fittings,<br />

where the Stitchwelder cannot be<br />

used.<br />

Technical Data<br />

Galvanized steel 2 x 1.5 mm (2 x 0.059”)<br />

3 x 1.0 mm (3 x 0.039”)<br />

Stainless steel 2 x 0.8 mm (2 x 0.031”)<br />

Various types of dies<br />

and punches<br />

ROLLFORMER<br />

RME 60/128<br />

To get round shape of parts cut in one of<br />

the <strong>Spiro</strong> ® Plasmacutters you need a <strong>Spiro</strong> ®<br />

Rollformer.<br />

Welding Power<br />

Max. 55 kVA<br />

Diameter Range 75 - 1000 mm (3” - 40”)<br />

Air Pressure<br />

6 Bar<br />

Stroke of Electride 10 - 60 mm (0.39” - 2.36”)<br />

Depth of Arm 380 - 700 mm (14.96” - 27.55”)<br />

Technical Data<br />

Material Thickness Max. 1.2 mm (0.047”)<br />

Roller Length 1280 mm (50”)<br />

Working Diameter 100 - 1000 mm (4” - 40”)<br />

EDGEFORMER<br />

SME 63<br />

The Edgeformer has an arm length of<br />

250 mm and includes 6 sets of rolls<br />

with different available profiles, underlining<br />

the high-quality <strong>machine</strong> parts.<br />

Technical Data<br />

Material Thickness<br />

Arm Length 250 mm (10”)<br />

Diameter<br />

Working Speeds<br />

Max. 1.7 mm (0.067”) mild steel<br />

63 mm (2.48”) (Rolls)<br />

6 m/min. (20 fpm) or<br />

12 m/min. (39 fpm)<br />

SPIRO ®<br />

~ 22 ~<br />

www.spiro.ch

OVALIZER 36 / 10<br />

From Round<br />

to Flat Oval<br />

The Ovalizer transforms smooth and corrugated<br />

round spiral ducts into flat-oval ducts. Machine<br />

control is by PLC and the Ovalizer is equipped<br />

with superior hydraulic unit to ensure the<br />

required force.<br />

Technical Data<br />

Size<br />

Tube Length 3000 mm (10’)<br />

ROVAL ROLLER 48/20<br />

Roval-Roller shapes round and flat-oval<br />

segments and reducers as well as many other<br />

forms common to the sheet-metal industry.<br />

With its programmable controller, it is designed<br />

to duplicate shapes at the high level of accuracy<br />

critical for mating parts.<br />

Technical Data<br />

Material Width Max. 1220 mm (48”)<br />

Material Thickness Max. 1.0 mm (0.039”)<br />

Oval Fittings<br />

Advantages of oval compared to<br />

rectangular ductwork<br />

» Better airflow<br />

» Easier to install<br />

» Less joints<br />

» Less hangers<br />

150 x 435 mm - 915 x 2650 mm<br />

(6” x 7” - 36” x 106”)<br />

Oval Ducts<br />

» Often requires less space<br />

» Corrugation for added strength<br />

» Modern design<br />

OVALIZER / ROVAL ROLLER<br />

info@spiro.ch ~ 23 ~<br />

SPIRO ®

SPECIAL WELDING APPLICATIONS<br />

STITCHWELDER SWA 400<br />

The Stitchwelder SWA 400 reduces labor cost significantly. The <strong>machine</strong> produces couplings, bend<br />

segments and several other products at high speed.<br />

Unique Features<br />

» Assured high-quality welding result<br />

» Easy welding parameter adjustment for<br />

galvanized, coated or stainless steel<br />

» Quick seaming of tube length and easy<br />

material thickness adjustments<br />

» Easy accessibility for maintenance<br />

» Low maintenance costs<br />

» DISCON mercury free cooling solution<br />

Machine with coil line<br />

Punching<br />

Technical Data<br />

Stand alone solution<br />

Control panel<br />

Welding Length 50 - 400 mm (2” - 15”)<br />

Diameter Range 100 - 400 mm (4” - 15”)<br />

Welding<br />

DISCON mercury free cooling solution<br />

Material Thickness 0.3 - 1.0 mm (0.011” - 0.039”)<br />

Overlap 6.0 mm (0.24”)<br />

Copper Wire 2.0 mm round (0.078”)<br />

Welding Speed<br />

Standard Machine<br />

Option<br />

3 - 12 m/min. (10 - 39 fpm)<br />

400 Volt 50 Hz or 460 Volt 60 Hz (other voltage on request)<br />

One set of clamping tools<br />

Remote operating panel<br />

DISCON mercury free cooling solution<br />

SPIRO ®<br />

~ 24 ~<br />

www.spiro.ch

STITCHWELDER SWB i/o (inside and outside)<br />

The combination of SWB i/o allows the welding of pressed half-shells (inside and outside),<br />

covering the diameter range 80 - 315 mm (3 - 12”). It provides the possibility to weld both<br />

galvanized and stainless steel.<br />

Unique Features<br />

» Simple operation<br />

» High reliability<br />

» Good accessibility of the components for<br />

fine adjustment<br />

» Variable welding speed<br />

Technical Data<br />

Bend Diameter 80 - 315 mm (3“ - 12“)<br />

Material Thickness 0.4 - 1.0 mm (0.015” - 0.039”)<br />

Seam Overlap<br />

Variable<br />

Copper Wire Diameter 2.0 mm (0.078”)<br />

Welding Speed<br />

Power Supply<br />

Cooling System<br />

Compressed Air<br />

Variable between 2 and 9 m/min. (10 - 30 fpm)<br />

3 x 400 V, 50 Hz, 100 A (adapt to requirements)<br />

Water cooling 12 liters/min. (3 gallons/min.)<br />

Water pressure at least 4 bar (58 PSI)<br />

Maximum water temperature for supply 15°C (59° F)<br />

6 bar (87 PSI) clean and dry air<br />

STITCHWELDER SWR<br />

The radial welder SWR is a multipurpose<br />

<strong>machine</strong>, designed to produce a high quality<br />

welded seam on circular parts and other<br />

shapes.<br />

Technical Data<br />

Welding Arm Length 60 - 250 mm (2.36” - 9.84”)<br />

Welding Diameter 75 - 1000 mm (2.95” - 39.37”)<br />

Material Thickness 0.3 - 1.0 mm (0.012” - 0.039”)<br />

Overlap<br />

Copper Wire<br />

Welding Speed<br />

Variable<br />

2.0 mm (0.078”) round<br />

2 - 9 m/min. (10 - 30 fpm)<br />

» High safety level for operator and <strong>machine</strong><br />

» Constant welding seam thanks to an<br />

intermediate copper wire electrode<br />

» Shortest possible change over times<br />

» Precise start and end welding points<br />

SPECIAL WELDING APPLICATIONS<br />

info@spiro.ch ~ 25 ~<br />

SPIRO ®

DOUBLE-XX / SR CUTTER<br />

DOUBLE-XX<br />

Principle: The Double-XX works with a 67 mm wide<br />

coil, which is stretched up to 137 mm, resulting in<br />

50% material savings compared to conventional<br />

perforated systems!<br />

Made for Silencer and Double Wall Applications!<br />

For Expanded-Metal Spiral tube production, the Double-<br />

XX eliminates the need to make or purchase pre-expanded or<br />

perforated material. It reduces material thickness by over 50% thanks<br />

to the Liner’s Spiral solid lockseam. It produces ultra clean end cut Liners<br />

with 62% open area, at high output, and with accurate diameters and lengths.<br />

Unique Features<br />

» Over 50% material savings<br />

» High output volume<br />

» No cutting, rolling and welding blanks. No inventory of<br />

blanks for each diameter and length size<br />

» One single coil size for all diameter and length sizes<br />

» Tight tube length and diameter tolerances<br />

» Compact design<br />

» A fully automatic one-man operated <strong>machine</strong>, with fast<br />

and easy tube size changeover<br />

» All tube sizes and production data kept in memory<br />

» Ideal for in-line production<br />

Technical Data<br />

Diameter Range 75 - 630 mm (3” - 24”)<br />

Strip Thickness 0.38 - 0.65 mm (0.016” - 0.024”)<br />

Diameter Changeover Time<br />

Max. 10 min.<br />

Lockseam<br />

Inside or Outside<br />

SR CUTTER<br />

With the new SR Cutter you get a precise and<br />

clean cut of ducts every time. Fast, simple<br />

and safe to use, the SR Cutter also means<br />

ergonomically correct cutting. The SR Cutter is<br />

fully portable and easy to get on and off site.<br />

Unique Features<br />

» Easy and fast to use<br />

» Ergonomically correct cutting<br />

» Perpendicular cutting<br />

» No sparks from angle grinder and less noise<br />

» Easy to handle and transport<br />

» Cuts ducts up to 0.7 mm thickness and up to<br />

3 meters in length to within Ø80 - 315 mm<br />

SPIRO ®<br />

~ 26 ~<br />

www.spiro.ch

RECTANGULAR SMART LINE<br />

Underlining <strong>Spiro</strong> ® ’s full product range the rectangular SMART line is the perfect starting kit for<br />

your workshop. <strong>Spiro</strong> ® offers a fully automatic and integrated solution that includes 3 decoilers,<br />

sheet selectors, and features 5 different product programs.<br />

Unique Features<br />

» Rectangular duct with allowances for double seam<br />

» L-section with variable allowances<br />

» Z-Profile and/or Trapez-Profile available<br />

» Rectangular duct with allowances for corner or Pittsburgh lock<br />

» U-duct with variable allowances - also prepared for inner standing seam<br />

Technical Data<br />

Processable Sheet<br />

0.5 - 1.25 mm (0.020“ - 0.049“)<br />

Thickness<br />

Max. Coil Width 1500 mm (59”)<br />

Max. Coil Weight<br />

3 x 5 tons<br />

Duct Dimension for Box Min. 125 x 125 mm (4.9“ - 4.9“)<br />

Sessions<br />

Feeding Speed<br />

Up to 15 m/min<br />

RECTANGULAR<br />

DUCT FORMING<br />

RECTANGULAR SMART LINE<br />

info@spiro.ch ~ 27 ~<br />

SPIRO ®

SPIRO ® SYSTEM<br />

SPIRO ® SYSTEM<br />

The Leakproof and Energy Efficient Air Duct<br />

System<br />

<strong>Spiro</strong> <strong>International</strong> S.A. is a leading supplier of fittings and system solutions for the ventilation<br />

and air conditioning industry, marketed under the “<strong>Spiro</strong> ® system” trademark. We offer owners<br />

of <strong>Spiro</strong> ® Tubeformers a complete range of pressed fittings and accessories.<br />

Features of the <strong>Spiro</strong> ® System<br />

» Fast and easy installation<br />

» Factory fitted gasket without any loose parts<br />

» Adjustable - twisting and fine adjustment<br />

result in no risk of leakage<br />

» Environmentally Friendly - the system is<br />

fitted with solvent-free sealant<br />

» Can be installed in all kinds of weather<br />

» Temperature resistant from -30˚C to +100˚C<br />

<strong>Spiro</strong> ® System<br />

» Withstands positive pressure - 3000Pa<br />

Some Advantages of Spiral Ductwork<br />

Lower Heating /<br />

Cooling Energy Use<br />

Lower Fan Energy<br />

Use<br />

Lower Air Leakage Less Material Cost /<br />

Shorter Installation<br />

Time<br />

TIGHTNESS CLASS A<br />

TIGHTNESS CLASS C<br />

TIGHTNESS CLASS A<br />

TIGHTNESS CLASS C<br />

TIGHTNESS CLASS X<br />

q l [l/s]<br />

TIGHTNESS CLASS X<br />

0.75 • q l [l/s]<br />

E [kWh]<br />

0.85 • 5 E [kWh]<br />

E [kWh]<br />

0.7 • E [kWh]<br />

Note!<br />

The same tightness<br />

class for both systems.<br />

t [min]<br />

0.8 • t [min]<br />

SPIRO ®<br />

~ 28 ~<br />

www.spiro.ch

S DE SPIRO<br />

SPIRO®System/ SPIRO®System/ Vent<br />

SPIRO®System/ Vent sin junta de goma SPIRO®System/<br />

sin junta Vent de sin junta de goma<br />

Vent<br />

goma<br />

sin junta de goma<br />

BSL45˚<br />

XCL<br />

DE LOS<br />

XL BSL45˚<br />

S DE SPIRO<br />

BL90˚<br />

BL60˚ BL45˚ BL30˚<br />

PSVL<br />

TSTL<br />

TSTCL<br />

BSL45˚<br />

BSL90˚<br />

BSFL90˚<br />

Complete XCL Range of Fittings and Accessories<br />

Transfer<br />

Transfer Transfer<br />

XCL<br />

<strong>Spiro</strong> ® System<br />

XL<br />

TCPL<br />

TCPL<br />

SRTR<br />

TCPL<br />

XCL<br />

SRTR<br />

LRTR<br />

PSL<br />

XL<br />

BKCL90˚<br />

PSL<br />

LRTR SRTR<br />

TSRTR<br />

OTRTH<br />

LRTRTCPL<br />

PSL<br />

TSRTR<br />

OTRTH<br />

BTR30˚<br />

BL90˚<br />

BL60˚ BL45˚ BL30˚<br />

PSVL<br />

TSTL<br />

TSTCL<br />

BSL90˚<br />

BSFL90˚<br />

BKCL90˚ BSL90˚<br />

BL90˚<br />

BL60˚ BL45˚ BL30˚<br />

PSVL<br />

TSTL<br />

TSTCL<br />

BSL45˚<br />

BSL90˚<br />

BSFL90˚<br />

PSL<br />

BFL90˚ BFL60˚ BFL45˚ BFL30˚ BFL15˚ ILRL<br />

BTR90˚ BSTR90˚ BSFTR90˚ TVTR30˚<br />

YVTR30˚<br />

ILTR<br />

XL<br />

BKCL90˚ BTR90˚ BBKCL90˚ BSTR90˚ BSFTR90˚ REL<br />

RFL TVTR30˚ RCPL YVTR30˚ RCFPL ILTR<br />

BTR60˚<br />

BKCL90˚<br />

PSTR<br />

TSRTR<br />

Dampers & Measuring<br />

OTRTH<br />

BTR30˚<br />

SRTR<br />

BTR60˚ PSTR<br />

SKPTR<br />

BTR30˚ LRTR<br />

BTR60˚ PSTR<br />

DRL<br />

DSL<br />

BL90˚<br />

BL60˚ BL45˚ BL30˚<br />

PSVL RCLL TSTLRLL<br />

TSTCL TCL<br />

BBKCL90˚ BSFL90˚ REL<br />

RFL<br />

RCPL RCFPL<br />

RCLL<br />

RLL<br />

TCL<br />

BBKCL90˚ REL<br />

RFL<br />

RCPL RCFPL<br />

BFL90˚ BFL60˚ BFL45˚ BFL30˚ BFL15˚ ILRL<br />

ILL<br />

NPL ESL ILF<br />

RCLL<br />

RLL<br />

TCL<br />

BBKCL90˚ REL<br />

RFL<br />

RCPL RCFPL<br />

BFL90˚ BFL60˚ BFL45˚ BFL30˚ BFL15˚ ILRL<br />

ILL<br />

NPL ESL ILF<br />

ILRTR PTR BTR45˚ BSTR60˚<br />

BTR90˚ BSTR90˚ BSFTR90˚<br />

BFL90˚ BFL60˚<br />

ILRTR PTR BTR45˚<br />

BSFTR60˚<br />

TVTR30˚<br />

BFL45˚ BFL30˚<br />

BSTR60˚ BSFTR60˚ BSTR30˚<br />

BSTR30˚ BSFTR30˚<br />

YVTR30˚<br />

BFL15˚<br />

BSFTR30˚<br />

BTR15˚<br />

ILTR<br />

ILRL<br />

BTR15˚<br />

ILL<br />

RCLL<br />

MFK<br />

ILL<br />

MFK<br />

BSTR15˚ BSFTR15˚ BSTR45˚ BSFTR45˚ OUTR EPTR OTR MFTR<br />

ILRTR PTR BTR45˚ BSTR60˚ BSFTR60˚ BSTR30˚ BSFTR30˚ BTR15˚ MFK<br />

BSTR15˚ BSFTR15˚ BSTR45˚ BSFTR45˚ OUTR EPTR OTR MFTR<br />

BTR90˚ BSTR90˚ BSFTR90˚ TVTR30˚<br />

YVTR30˚<br />

ILTR<br />

BSTR15˚ BSFTR15˚ BSTR45˚ BSFTR45˚ OUTR EPTR OTR MFTR<br />

SKHTR<br />

FML<br />

KLL<br />

TATBL<br />

KLTPL<br />

KLTEL<br />

NPL ESL ILF<br />

TLTR<br />

PSVTR30˚<br />

TLTR<br />

RLL PSVTR30˚ TCL<br />

LORTR<br />

TLTR<br />

NPL<br />

LORTR<br />

SHTR<br />

LORTR<br />

SHTR<br />

TLTR<br />

SH<br />

PSVTR30˚<br />

ESL SH ILF<br />

SB SHSB-2<br />

SB SB-2<br />

PSVTR30˚<br />

SHTR<br />

TATL SB TASL SB-2<br />

Registros Registros y medidores y medidores<br />

Registros Transfer y medidores<br />

<strong>Spiro</strong> Accesorios <strong>Spiro</strong> Accesorios<br />

<strong>Spiro</strong> Accesorios Registros y medidores<br />

Silenciadores Silenciadores circulares circulares<br />

Silenciadores <strong>Spiro</strong> circulares Accesorios<br />

Silenciadores circulares<br />

DRL<br />

OTRTH<br />

DTBL NMF<br />

DRL<br />

BTR30˚<br />

DTBL NMF<br />

DTBL LMF<br />

DTBL NMF<br />

DTBL LMF<br />

DRL<br />

DTBL LMF<br />

SVK<br />

BTR60˚<br />

DTL<br />

DTBCL AF<br />

DSL<br />

TSRTR<br />

PSTR<br />

DRUI<br />

FL<br />

ILRTR PTR<br />

SKHTR<br />

BSLL 50<br />

BTR45˚<br />

FML<br />

SLGL 100 LRBCB<br />

SLGL 150<br />

IRIS-M<br />

info@spiro.ch ~ 29 ~<br />

DLD<br />

BSTR60˚ BSFTR60˚ BSTR30˚<br />

KLL<br />

TATBL<br />

MBL<br />

GISOL<br />

HN<br />

GISOL<br />

BSFTR30˚<br />

KLTPL<br />

BTR15˚<br />

BSTR15˚ BSFTR15˚ BSTR45˚ BSFTR45˚ OUTR EPTR OTR MFTR<br />

FMDRL<br />

FMDL<br />

PSDRL<br />

KL2EL<br />

TDSL<br />

TDRL<br />

DTHL<br />

SKHTR<br />

DTPL<br />

FML<br />

DTBCL LF<br />

KLL<br />

DTBL NMF DTL<br />

DRUI<br />

FMDRL<br />

FMDL<br />

SVK ILKNL50 ILKNL100 ILKNF50 ILKNF100 EPF EPFH<br />

SVK SR<br />

DTBL LMF<br />

SR<br />

KC<br />

SVK<br />

SLL SR 50<br />

KC<br />

KC<br />

SLL 50<br />

SLBL 100<br />

SLBGU 100<br />

SLL 50<br />

SLBL 100<br />

KC<br />

SLBGU 100<br />

SLBL 100<br />

SLBGU 100<br />

DSL<br />

DTL<br />

DSL<br />

DTBCL AF<br />

DTL<br />

Accessories<br />

SR<br />

DTBCL AF<br />

DTBL AM<br />

DTHL<br />

DTPL<br />

DTBCL LF<br />

EP<br />

FL<br />

UVH UV<br />

IN<br />

ILKNL50 ILKNL100 ILKNF50 ILKNF100 EPF EPFH<br />

EP<br />

FL<br />

SLL 100FA<br />

SLKNL SLL 50 50 SLKNL SLL 100 100<br />

BSLL 100<br />

SLKNL 50 SLKNL 100<br />

DRUI<br />

DTBL AM<br />

DRUI<br />

FMDRL<br />

SKHTR<br />

DTHL<br />

FMDRL<br />

UVH<br />

STR<br />

BSLL 50<br />

LRCA<br />

UV<br />

SLGL 100<br />

SLGL 150<br />

UV<br />

FMDL<br />

FML<br />

DTPL<br />

FMDL<br />

DTBCL AF DTBL AM DTHL<br />

DTPL DTBCL LF<br />

ILKNL50 ILKNL100 ILKNF50 ILKNF100 EPF EPFH<br />

ILKNL50 ILKNL100 FA ILKNF50 STRILKNF100 EPF EPFHRGS<br />

EP<br />

EP<br />

DTBL AM<br />

FA<br />

FL<br />

SLL 100<br />

Circular Silencers<br />

FA<br />

BSLL 100<br />

SLL 100<br />

BSLL 100<br />

SLBL 100 SLKNL 50 SLKNL 100<br />

SLBGU 100<br />

BSLL 100<br />

SLKNL 50 SLKNL 100<br />

UVH<br />

UVH<br />

STR<br />

STR<br />

BSLL 50<br />

LRCA<br />

BSLL 50<br />

LRCA<br />

LRCA<br />

UV<br />

SLGL 100<br />

SLGL 150<br />

SLGL 100<br />

SLGL 150<br />

DLD<br />

DLD<br />

LRBCB<br />

DLD<br />

LRBCB<br />

LRBCB<br />

DTBCL LF IRIS-M<br />

PSDRL<br />

IN<br />

IN<br />

IN<br />

PSDRL<br />

KLL<br />

RGS<br />

RGS<br />

RGS<br />

PSDRL<br />

MF<br />

FB 40<br />

IRIS-M<br />

TATBL<br />

IRIS-M<br />

MF<br />

FB 40<br />

MF<br />

FB 40<br />

Isol productos Isol productos Isol productos<br />

MF<br />

FB 40<br />

Isol productos<br />

KL2EL<br />

TATBL<br />

MBL<br />

KL2EL<br />

KL2EL<br />

GISOL<br />

GISOL<br />

HN<br />

HN<br />

HN<br />

MBL<br />

MBL<br />

TDSL<br />

KLTPL<br />

MBFL<br />

TDSL<br />

KLTPL<br />

TDSL<br />

VHP<br />

VHP<br />

MBFL<br />

MBFL<br />

MBFL<br />

VHP<br />

HF<br />

HF<br />

HF<br />

VHP<br />

TCUI<br />

TCUI<br />

TCUI<br />

HF<br />

TCUI<br />

MFK<br />

KLTEL<br />

TDRL<br />

KLTEL<br />

TDRL<br />

IRIS<br />

KLTEL<br />

TDRL<br />

IRIS<br />

IRIS<br />

BFUI30°<br />

BFUI30°<br />

BFUI30°<br />

BFUI30°<br />

H<br />

LORTR TATL<br />

RCLTR LÖMOK<br />

SHTR<br />

RCLTR<br />

HKOMR<br />

HKOMR<br />

IRIS<br />

HKOMR<br />

H<br />

H<br />

H<br />

HKOMR<br />

RCLTR<br />

TATL<br />

RCLTR LÖMOK<br />

VREDF<br />

LÖMOK<br />

TATL<br />

VREDF<br />

VREDF<br />

LÖMOK<br />

VREDF<br />

TASL SH<br />

IK<br />

TASL<br />

DRHTG IK<br />

SB SB-2<br />

DRHTG IK<br />

KOMHY<br />

DRHTG<br />

KOMHY<br />

TASL<br />

KOMHY<br />

IK<br />

LHR<br />

DRHTG<br />

LHR<br />

KOMHY<br />

LHR<br />

VHL<br />

VHL<br />

VHL<br />

LHR<br />

NPUI<br />

VHL<br />

NPUI<br />

SVK<br />

NPUI<br />

SVK<br />

SVK<br />

NPUI<br />

SVK<br />

18.12.2005 13:49:39 Uhr<br />

18.12.2005 13:49:39 Uhr<br />

18.12.2005 13:49:39 Uhr<br />

SPIRO ®<br />

SPIRO ® SYSTEM

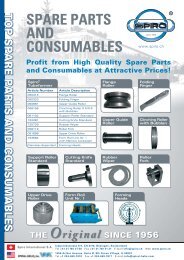

AFTER <strong>SA</strong>LES SUPPORT<br />

ORIGINAL SPARE PARTS<br />

Unique Features<br />

» Original parts produced by <strong>Spiro</strong> ®<br />

» The right spare parts at the right time, for the<br />

right price<br />

» Fast and reliable delivery service<br />

» Replacement components for obsolete parts<br />

Visit www.spiro.ch/shop to purchase original spare parts and consumables online<br />

SPIRO ® SERVICE AGREEMENT<br />

Unique Features<br />

» Annual inspection visit<br />

» Special discount on spare parts and work<br />

» Warranty on spare parts<br />

» Priority service on breakdown<br />

UPGRADES<br />

Tubeformer<br />

» Condition report on your <strong>machine</strong><br />

» Telephone support free of charge<br />

» Certificate certified <strong>Spiro</strong> ® producer<br />

» Receive your <strong>Spiro</strong> ® Webshop Log-in that<br />

includes your special discount on spare parts<br />

Lubrication Solution<br />

Production of grease-free and<br />

clean ducts<br />

Narrow Lock Seam<br />

Solution<br />

Material savings up to 3%<br />

Bubblan Reel<br />

Fixed lock seam and assured<br />

duct quality<br />

Gorelocker<br />

Flanging Roller - <strong>Spiro</strong> ® Gorelocker Combi-T owners can<br />

upgrade their <strong>machine</strong> with a newly developed flanging roller!<br />

Mastic Kit<br />

Mastic Kit Solution - Invaluable for every ventilation workshop<br />

to provide your customers with an airtight class D system!<br />

Spotwelder<br />

Deburring cleaning device - Maintain your Spotwelder<br />

with a deburring cleaning device - Fast and clean outcome!<br />

Visit our website to see the full range of our available upgrades; www.spiro.ch<br />

SPIRO ®<br />

~ 30 ~<br />

www.spiro.ch

LET’S TALK SPIRO ®<br />

REAL QUALITY!<br />

Always Class D<br />

Complete System Tested (SITAC)<br />

Easy to Mount - Always fits<br />

Exact Tolerance - Always measured<br />

Patented Rubber Gasket<br />

Always fixed and not movable<br />

Material Quality<br />

Always highest quality and consistent<br />

Full Range<br />

Always same quality<br />

Technical Support<br />

We have provided support for 50 years<br />

REAL VALUE!<br />

Best Output Quality<br />

Products certified and tested<br />

Highest Capacity and Productivity<br />

Superior Up-time and Longest Life Time<br />

Swiss Quality<br />

CE-Certified and EMC directive<br />

Compliance verified<br />

Patented Solutions<br />

Own drawings and own engineering<br />

Spare Parts - 20 years guaranteed<br />

2 Years Warranty and Service Package<br />

Support - Whenever, wherever, forever!<br />

Know How - Invented It<br />

REAL EXPERIENCE!<br />

Global Business Experience<br />

Thousands of References World-wide<br />

Complete Solutions<br />

Production Experience<br />

R&D Department<br />

Support and Service Department<br />

Demonstration and Training Centre<br />

Solid and Credit-Worthy<br />

REAL QUALITY, REAL VALUE, REAL EXPERIENCE<br />

info@spiro.ch ~ 31 ~<br />

SPIRO ®

We welcome you to visit<br />

our demonstration centre<br />

to see the <strong>machine</strong>s in<br />

action.<br />

<strong>Spiro</strong> <strong>International</strong> S.A.<br />

I n d u s t r i e s t r a s s e 173<br />

C H - 3178 B ö s i n g e n S w i t z e r l a n d<br />

Web www.spiro.ch<br />

Spiral-Helix<br />

1450 Arthur Avenue<br />

Suite B Elk Grove Village IL 60007<br />

Web www.spiral-helix.com<br />

<strong>Spiro</strong> LLC<br />

P o z h a r s k o g o S t r. 7 3<br />

R U - 1 5 0 0 6 6 Ya r o s l a v l R u s s i a<br />

Web www.spiro.ch<br />

<strong>Spiro</strong> Havalandırma<br />

Limited Şirketi<br />

M e r m e r c i l e r S a n a y S i t e s i 8 . C a d .<br />

N o : 11 / B B ü y ü k c e k m e c e / Ya k u p l u<br />

I s t a n b u l Tu r k e y<br />

Web www.spiro.ch<br />

THE COMPLETE SOLUTION<br />

MACHINES<br />

<strong>Spiro</strong> ® can provide you with a complete<br />

set of superior quality <strong>machine</strong>s for the<br />

production of circular ducts and fittings.<br />

AIR DUCT SYSTEMS<br />

<strong>Spiro</strong> ®<br />

has an extensive range of<br />

pre-fabricated fittings, ventilation<br />

and air-conditioning accessories<br />

that make a great addition to the<br />

products your business can offer.<br />

SERVICES<br />

<strong>Spiro</strong> ® have the experience, in depth<br />

knowledge, support and aftermarket<br />

services that ensure your production is<br />

continuous and efficient.<br />

Subject to technical improvements and changes without prior notice. <strong>Spiro</strong> ® is a registered trademark.<br />

© 07.2009 <strong>Spiro</strong> <strong>International</strong> S.A. Any form of reprinting and copying is prohibited without written permission.<br />

The products, systems and product names of <strong>Spiro</strong> <strong>International</strong> S.A. are protected by intellectual property rights.