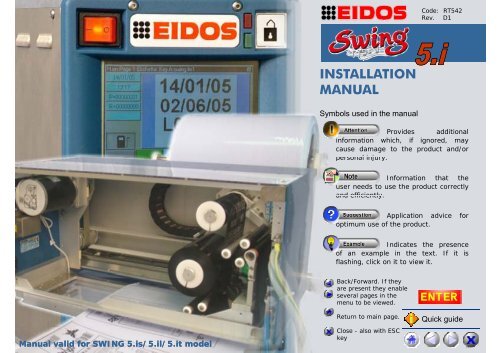

INSTALLATION MANUAL

INSTALLATION MANUAL

INSTALLATION MANUAL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Code: RT542<br />

Rev. D1<br />

<strong>INSTALLATION</strong><br />

<strong>MANUAL</strong><br />

Symbols used in the manual<br />

Provides additional<br />

information which, if ignored, may<br />

cause damage to the product and/or<br />

personal injury.<br />

Information that the<br />

user needs to use the product correctly<br />

and efficiently.<br />

Application advice for<br />

optimum use of the product.<br />

Indicates the presence<br />

of an example in the text. If it is<br />

flashing, click on it to view it.<br />

Back/Forward. If they<br />

are present they enable<br />

several pages in the<br />

menu to be viewed.<br />

Manual valid for SWING 5.is/5.il/5.it model<br />

Return to main page.<br />

Close - also with ESC<br />

key<br />

1<br />

Quick guide

General information<br />

Contacts<br />

Guide<br />

Contents<br />

t<br />

1. Contents t of standard d package<br />

2. Positioning printer<br />

3. Mechanical assembly<br />

4. System connections<br />

5. Pneumatic connections<br />

6. Setting up printer<br />

7. Switching on printer<br />

8. Creating labels and files management<br />

9. Connecting to computer and data exchange<br />

Swing 5.i - Installation manual<br />

2

General information<br />

Contacts<br />

Guide<br />

1. Contents t of standard d package<br />

PRINT UNIT<br />

with PRINT SURFACE<br />

+ roll of thermal test<br />

ribbon<br />

ELECTRONIC<br />

UNIT<br />

OPERATOR<br />

<strong>MANUAL</strong><br />

+ EASYCODE CD<br />

USB MEMORY<br />

KEY<br />

POWER CABLE<br />

CONNECTING<br />

CABLES<br />

CLEANING<br />

KIT<br />

Swing 5.i – Contents of standard package<br />

3

General information<br />

Contacts<br />

Guide<br />

2. Positioning i printer<br />

Recommended d installation ti positions:<br />

1) With print surface in position below<br />

2) With print surface in position above*<br />

(2*)<br />

• Increase in print pressure requested (+0.5 bar greater than value set with print surface on lower side).<br />

• If the packaging g film is dirty, these particles may be deposited on the print head, which will detract from<br />

print quality.<br />

• Through the force of gravity, the carriage may tend to jam the packaging film on its return from the home<br />

position. The film must therefore always be kept taut.<br />

Swing 5.i – Positioning printer<br />

4

General information<br />

Contacts<br />

Guide<br />

3) With the print carriage performing a vertical movement<br />

Assembly permitted but ONLY with the use of<br />

pneumatic balancing devices of the weight of the<br />

carriage.<br />

49KMS50 for Swing 5i.s<br />

49KMS49 for Swing 5i.l<br />

49KMS51 for Swing 5i.t<br />

Swing 5.i – Positioning printer<br />

5

General information<br />

Contacts<br />

Guide<br />

Permitted but not recommended d installation ti positions:<br />

1) With print surface in vertical position<br />

Ribbon loading reels– upper side-<br />

• The print head unit does not work in the most stable conditions because of its weight.<br />

• The ribbon could rewind with difficulty and incorrectly.<br />

• There could be creases on the printed surface.<br />

Swing 5.i – Positioning printer<br />

6

General information<br />

Contacts<br />

Guide<br />

FORBIDDEN installation ti positions:<br />

1) With the ribbon loading reels on the lower part of the printer<br />

Ribbon loading reels – lower side-<br />

Swing 5.i – Positioning printer<br />

7

General information<br />

Contacts<br />

Guide<br />

Remember !<br />

Positioning.<br />

If it is not possible to install the printer with the print surface integral with it, the print surface should be<br />

installed with the rubber at a maximum distance of 2.5-3mm from the head profile. Allow provision for<br />

setting the print surface with respect to the head so as to facilitate the search for the optimum print<br />

condition. Leave sufficient space for internal maintenance of the machine (rear cover). If this<br />

accessibility cannot be guaranteed, fit the machine to a support that enables the operator to rotate it or<br />

slide it to a comfortable position. To clean the head, the printer does not need to be moved away from<br />

the print head. This operation is on the other hand recommended if the print head has to be replaced.<br />

Support.<br />

The print unit support must be robust enough to minimize rocking or vibrations.<br />

Ambient temperature and humidity.<br />

The machine must also be installed in an environment where the temperature is not above 40°C (away<br />

from any drying kilns, etc.) and not below +5°C and with humidity not above 70%.<br />

Swing 5.i – Positioning printer<br />

8

General information<br />

Contacts<br />

Guide<br />

Obey these notices carefully to avoid creases forming on the printed surface<br />

A<br />

B<br />

The print unit print must be fixed to the packaging line. Position<br />

the two points [A] and [B] parallel. Check with a spirit level!<br />

The printer does not need to<br />

be in a completely horizontal<br />

position. But it is VERY<br />

important that the two sides<br />

are parallel to one another.<br />

Swing 5.i – Positioning printer<br />

9

General information<br />

Contacts<br />

Guide<br />

Recalibrate the print surface in relation to the line of the print<br />

head profile. Run the following tests on the points marked [C]<br />

and [D].<br />

D<br />

C<br />

Press the print<br />

head support<br />

manually in the<br />

central position<br />

until the profile of<br />

the head comes<br />

into contact with<br />

the print surface.<br />

To check that the print head profile and the print surface are parallel at point [C], adjust the 4 screws<br />

located on the right side that are used to fix the right side of the print surface to the printer. To check that<br />

the print head profile and the print surface are parallel atpoint[D],adjustthe4screws located on the left<br />

side that are used to fix the left side of the print surface to the printer.<br />

After setting, tighten the screws and check alignment on points [C] and [D] again.<br />

Swing 5.i – Positioning printer<br />

10

General information<br />

Contacts<br />

Guide<br />

3. Mechanical assembly<br />

The print unit needs to be fixed mechanically to an external support bracket (made and supplied by the<br />

customer). There are 10 fixing points so as to enable great configuration liberty.<br />

In particular, there are three standard ways of fixing to the machine (refer to overall dimension drawings):<br />

a) fixing upper face of printer by means of 4 screws in the threaded M6 holes<br />

b) fixing onto the two right and left sides of the printer by means of 4 screws in the threaded M6 holes<br />

c) fixing the printer on a rear crosspiece by means of 2 screws in the 6.5-mm diameter through holes.<br />

The printer must print only on the print surface supplied by EIDOS.<br />

Rules to be followed during the phase of installation of the printer and the print surface:<br />

a) the distance between the head profile and the print surface must be about 2.5 - 3mm. The maximum<br />

possible range for the head is 8 mm with respect to the rest position.<br />

b) Make sure that the film to be printed touches the print surface, thus reducing the so-called “suction”<br />

effects.<br />

It is advisable to maintain a distance of about 1mm between the film and the print surface.<br />

If the printer is going to be used in particularly humid environments (for example cheese<br />

factories) the electronic unit should be placed inside an IP65- grade sealed container to<br />

prevent ambient humidity from gradually reducing the reliability of the electronic parts.<br />

Swing 5.i – Mechanical assembly<br />

11

General information<br />

Contacts<br />

Guide<br />

4. System connections<br />

Connecting electronic unit and print unit<br />

• Power cable and controls<br />

print unit , 62-way HD<br />

• Print head signals cable, 44-way HD<br />

• Earth connection cable<br />

between the two units. DO NOT ground. 1<br />

3<br />

1<br />

2<br />

2<br />

3<br />

Swing 5.i – System connections<br />

12

General information<br />

Contacts<br />

Guide<br />

Connecting to main power supply<br />

• Main power cable<br />

Connectthepowercabletoalinethatcancarry400VAmaximumvoltage<br />

with voltage fluctuation that must never exceed 10% of nominal voltage.<br />

• Power: max 400 VA<br />

• Voltage and frequency: pay attention to the adhesive label on the rear of<br />

the printer and on the power supply.<br />

• 230V ONLY means min 200, max 260 Vac (50Hz)<br />

• 115V ONLY means min 100, max 130 Vac (60Hz)<br />

• The Electronic Unit model High power (EUHxx) is NOT autoranging.<br />

Swing 5.i – Connecting to main power supply<br />

13

General information<br />

Contacts<br />

Guide<br />

5. Pneumatic connections<br />

Compressed air supply<br />

• Compressed air pipe 8mm ø external<br />

• Pressure: 6 bar steady upstream of the adjuster<br />

• Filtered<br />

• Not lubricated or delubricated<br />

• Flow at least 15NL/min<br />

• Quick-fitting air pipe<br />

6 bar<br />

Adjust to<br />

3-4 bar<br />

max<br />

Swing 5.i – Pneumatic connections<br />

14

General information<br />

Contacts<br />

Guide<br />

6. Setting up printer<br />

Loading thermal ribbon roll<br />

see [operator manual]<br />

Swing 5.i – Setting up printer<br />

15

General information<br />

Contacts<br />

Guide<br />

7. Switching on printer<br />

Electronic Unit: operating area<br />

1. Title bar. The name of the active label file is<br />

described.<br />

2. Date, time, current number, previous number,<br />

type<br />

of emulation active, line-speed indicator.<br />

3. Image window of label to be printed.<br />

4. Tool bar<br />

ribbon reserve warning light<br />

5. Fault message and warning bar .<br />

6. Touch screen restore button. This is a<br />

protection to prevent unwanted operations<br />

being run because the screen has been<br />

unintentionally touched.<br />

7. Start key.<br />

7<br />

6<br />

automatic mode<br />

manual mode<br />

system information: sw release on<br />

board, head drift meter counter and<br />

actual print counter<br />

1<br />

2 3<br />

load new label/change batch<br />

go to operate menu<br />

4<br />

display label image<br />

5<br />

Fault warning.<br />

Press to release alarm<br />

Swing 5.i – Switching on printer<br />

16

General information<br />

Contacts<br />

Guide<br />

How to activate on-line Help window<br />

How to activate on-line zoom function<br />

The electronic unit is provided with Help on Line<br />

that gives information on all the tasks that can<br />

be performed, including configuration of the<br />

parameters.<br />

It can be displayed by pressing the bar of the<br />

title inside the desired page.<br />

Press on the right-hand side of the screen and<br />

when it appears drag the cursor up or down to<br />

alter zoom parameters.<br />

The enlarged image can be moved inside the<br />

display area in order to be able to see the part<br />

that is of interest.<br />

To override the zoom, drag the cursor down until<br />

OFF appears.<br />

Swing 5.i – Switching on printer<br />

17

General information<br />

Contacts<br />

Guide<br />

Manual mode (MAN)<br />

In MAN mode the printer does not run commands from outside (SYNC<br />

24) and enables access to the Operate menu.<br />

To enter the Set-up menu:<br />

1. Make sure that printer is in MAN position<br />

2. Press the key<br />

From this window the printer can be managed completely manually:<br />

• Service position<br />

Positions the carriage in the “service” zone, where the ribbon can be<br />

changedandtheheadcanbecleaned<br />

• Ribbon position<br />

Tensions thermal ribbon by rewinding it<br />

• Test print<br />

Runs a test print<br />

• Printer Parameters [see following pages]<br />

• Label parameters<br />

Checks dimensions, type of reprocessing, photocell threshold and<br />

space between labels<br />

• Print shift adjustment<br />

Adjusts shift of print image from set value<br />

• File management [see following pages]<br />

• Diagnosis [see maintenance manual]<br />

• Carriage position<br />

Repositions carriage onhomesensor<br />

Swing 5.i – Switching on printer<br />

18

General information<br />

Contacts<br />

Guide<br />

• Pi Printer Parameters<br />

• Printing speed<br />

• Intensity correction<br />

• Intelligence correction<br />

• Shift from home<br />

• Head fall delay<br />

• Head rest delay<br />

•Type of print step<br />

• Print number<br />

• Number of repetitions<br />

• Distance of repetitions<br />

• Print start delay<br />

• Movement speed<br />

• Carriage return speed<br />

• Carriage return wait<br />

• Character outline<br />

• Thermal coefficient<br />

•Drift<br />

• Saving backwards<br />

• Ribbon saving automatic<br />

calculation<br />

• Thermal head type<br />

• Mirror printing<br />

• Reverse printing<br />

• SATO emulation<br />

• SATO emulation mode<br />

• Number check in descending order<br />

• Consecutive number parameters<br />

• Consecutive line number<br />

parameters<br />

• Consecutive number<br />

• Consecutive line number<br />

• Absolute consecutive number<br />

•Number in descendingd order<br />

• Check STB-STA<br />

• STA only front<br />

• FAP pulsed<br />

• Reversed inputs<br />

•Only I/O print<br />

• Piece present<br />

• Enable I/O page<br />

• Serial parameters<br />

• Wait/ready protocol<br />

• Optical reader function<br />

• Barcode check function<br />

• Advanced parameters<br />

• Date<br />

•Time<br />

• Language<br />

• Enable password<br />

• Password<br />

• Enable sound<br />

• Rotate LCD by 180°<br />

• Enable capacity sensor<br />

• Enable operator Help<br />

• LCD contrast<br />

Swing 5.i – Switching on printer<br />

19

General information<br />

Contacts<br />

Guide<br />

Parameter setting<br />

Analogue parameter setting by means of numeric keyboard: print speed<br />

Main Page<br />

MAN<br />

Printer<br />

Parameters<br />

Set Printer Parameters Printer Parameters 1<br />

Minimum<br />

value<br />

Increase by 1<br />

unit<br />

Increase by10<br />

units<br />

Cancel<br />

operation and<br />

exit<br />

Unit of<br />

measurement<br />

Maximum value<br />

Decrease by 1<br />

unit<br />

Decrease by 10<br />

units<br />

Set default value<br />

Delete all<br />

entries<br />

Next<br />

page<br />

Confirm<br />

entries<br />

Cancel last entry<br />

Confirm entries and exit<br />

When there are white boxes on the display that contain values, click on the box to access<br />

a keyboard from which the values can be set.<br />

Swing 5.i – Switching on printer<br />

20

General information<br />

Contacts<br />

Guide<br />

ENABLE/DISABLE parameter setting: automatic application function<br />

Main Page<br />

MAN<br />

Printer<br />

Parameters<br />

Set Printer Parameters<br />

Application parameters1…<br />

When there is a checkbox<br />

on the display you can<br />

select ON (black)/OFF<br />

(white).<br />

Parameter setting with guided selection option: select language<br />

Main Page<br />

MAN<br />

Printer<br />

Parameters<br />

Set date-time-language<br />

Date, Time, Language<br />

When there is a “radio<br />

button” on the display<br />

(round box) you can<br />

make an exclusive<br />

selection.<br />

Swing 5.i – Switching on printer<br />

21

General information<br />

Contacts<br />

Guide<br />

• File management<br />

Main Page<br />

MAN<br />

File<br />

management<br />

Function unavailable<br />

Click on the menu items to display or hide<br />

the parameters list<br />

Swing 5.i – Switching on printer<br />

22

General information<br />

Contacts<br />

Guide<br />

8. Creating labels l and files management<br />

Load the label to be printed in one of the following ways:<br />

a) From hard disk<br />

Select TEMP label from hard disk [Flash disk C] and set desired parameters.<br />

b) From Easycode software<br />

Create the label on the PC using the previously installed Easycode software.<br />

-For label-creating operations, see Easycode guide – (Help on Line)<br />

If you are using the USB memory key, copy the label onto it and then call it up from the file<br />

management menu: load the new Flash A label (Flash Memory Key disk).<br />

See next chapter for information on exchanging computer data in other ways.<br />

c) From EIDOS libraries<br />

Eidos supplies the libraries (ELIB32) wich support the programmer, in the editing of custom<br />

programs for the data exchange and label files, between Pc and printer (by serial or network<br />

connection). These libraries are functions easily supplementable in programs drawn up in Visual<br />

Basic and Visual C++.<br />

It is advisable to ask Eidos the cd with the libraries functions and the use examples.<br />

-See ELIB32 Libraries Manual.<br />

d) From Starcode software<br />

Use the serial connection to call up the label from the computer in which the software is installed.<br />

The Starcode software enables centralised management of production data.<br />

-See Starcode manual.<br />

Swing 5.i – Creating labels<br />

23

General information<br />

Contacts<br />

Guide<br />

9. Connecting to computer and data exchange<br />

Connection to the central computer (which has customized<br />

management software or Easycode or Starcode) can be achieved<br />

by serial port - RS232 to 115200 baud - or USB port.<br />

Connections by means of USB adapter devices for wireless<br />

802.11g, or Ethernet are also possible.<br />

Managing files and data exchange can occur in the following<br />

manner:<br />

EASYCOD<br />

E<br />

PC<br />

a) Exchanging data with USB memory<br />

b) Serial connection<br />

c) Connecting via Ethernet<br />

d) Connecting via Wireless network<br />

RS232<br />

USB-ETHERNET<br />

USB-WIRELESS<br />

Not all USB adapters are usable<br />

because there is no guarantee that the<br />

printer can manage their driver.<br />

Consult Eidos to create LAN and WLAN<br />

networks.<br />

USB MEMORY<br />

ELECTRONIC<br />

UNIT<br />

Swing 5.i – Connecting to computer and data exchange<br />

24

General information<br />

Contacts<br />

Guide<br />

a) Exchanging data with USB memory<br />

The label texts drawn up on a PC outside the printer by means of software (EASYCODE) are communicated<br />

to the Printess by means of the USB memory key, which can also be used as a local data archive. The USB<br />

memory key does not need to be installed and can be considered to be an extra hard disk.<br />

CONNECTOR<br />

FOR USB<br />

MEMORY<br />

Swing 5.i – Connecting to computer and data exchange<br />

25

General information<br />

Contacts<br />

Guide<br />

b) Serial connection<br />

With the printer in position and the serial cable connected:<br />

1) select printer parameters<br />

2) set communication parameters<br />

• External connection: enable COM<br />

• Serial parameters: set transmission speed of serial line. Recommended: 115200 (n,8,1,p) baud<br />

• Wait/Ready protocol: enable<br />

Wait/Ready protocol<br />

When the printer starts the print phase, send the character “W” to the serial line; at the end of the<br />

application cycle, send character "R". This occurs both in single print-cycle mode and in the double-print<br />

cycle.<br />

In the caseof the double cycle, the character “W” is senttothe startof the first cycle and the character<br />

“R” is sent to the end of the second application cycle. If the printer goes into fault status during the cycle,<br />

it sends the character “R” to the serial line. At this point it is possible to request (^?) status and check<br />

machine status.<br />

This W/R protocol management is also valid if the bar checker is enabled. The characters "W" and "R" are<br />

sent online only if the signals CTS and DSR are active. If these signals are missing, the characters are not<br />

sent.<br />

Swing 5.i – Connecting to computer and data exchange<br />

26

General information<br />

Contacts<br />

Guide<br />

c) Connecting via Ethernet t LAN 10/100<br />

By connecting the printer (Usb-Device port) to an Ethernet/USB adapter, it is possible to connect to an<br />

Ethernet network and then access the print data.<br />

Technical features of connection:<br />

Port: 30000<br />

Subnet mask: adjustable (default= 255.255.0.0)<br />

IP address: adjustable<br />

Communication mode: client/server<br />

EIDOS printer is acting like Server and is staying in stand-by<br />

(on the port) for the requirements from client .<br />

USB port<br />

RJ45<br />

Ethernet/USB<br />

adapter<br />

Company network<br />

LAN 10/100<br />

Ethernet – name of a protocol for local networks. Data travel at 100 Mbps over the Ethernet (100 million bits per<br />

second.<br />

Swing 5.i – Connecting to computer and data exchange<br />

27

General information<br />

Contacts<br />

Guide<br />

d) Connecting via Wireless networks<br />

CONSIDERATIONS ON THE SAFETY OF THE WI-FI NETWORKS:<br />

The EIDOS printers do not support the cryptography protocols (es. WEP, WPA) often used to increase the<br />

safety of the wireless networks against hackers.<br />

For the management of the EIDOS printers in WI-FI networks, EIDOS advises the following operations:<br />

1) to create a local Wlan EIDOS network (SSID=EIDOS) independent from the network (LAN/WLAN)<br />

already existing in the company.<br />

2) to enable the “Mac Filtering” option in the Access Point parameters. This filter will avoid that other wi-fi<br />

devices with MAC address not presents in the list could communicate with the EIDOS Wlan network,<br />

reducing the risk of hackers attack.<br />

AP (Access point) – device of a local wireless network in which the data converge that come from the devices connected<br />

by the specified protocol (e.g:WI-FI).<br />

LAN (Local Area Network) - a LAN consists of a series of devices that are connected together that share resources and<br />

peripherals.<br />

MAC Address (Media Access Control address) - in computer networking is a unique identifier attached to most forms of<br />

networking equipment.<br />

SSID (Service Set IDentifier) – the wireless network has its own identifying address called SSID, that the wireless cards<br />

have to recognise in order to be able to be connected. A device that has no SSID cannot log into the network.<br />

WI-FI (Wireless Fidelity) – certification of the products for wireless networks that conform to Ethernet compatibility<br />

specifications. WI-FI technology, which is also known as 802.11b IEEE wireless technology, uses the same Ethernet<br />

standards (cabled networks).<br />

WLAN – network consisting of wireless devices.<br />

Swing 5.i – Connecting to computer and data exchange<br />

28

General information<br />

Contacts<br />

Guide<br />

NOTES ON ALL RECOMMENDED CONFIGURATIONS:<br />

• The PC does not need to be connected to the company network; it can also be stand-alone<br />

• If the PC is connected to the company network, EASYCODE, STARCODE and other programmes can use<br />

the customer database or the archive of labels resident in a disc of the company network.<br />

• Assigning the SSID isolates the local EIDOS WLAN network from any other WI-FI networks current in the<br />

company or to be installed in future. Even if IP addresses that are already in use on other WLAN networks<br />

are assigned to the EIDOS printers the different SSID will make the network units separate from one<br />

another.<br />

• Using a laptop and a USB to WI-FI converter (configured with the same network SSID and an IP address<br />

that is not assigned to another - PC, AP unit EIDOS printers – of the network) it is possible to<br />

communicate in WI-FI with the different connected printers without any need to connect via cable or to<br />

use other APs.<br />

• In order to increase the communication distance between AP and EIDOS printers, it is possible to fit the AP<br />

with higher-performance direction or bipolst antennas instead of the 2 antennas provided. In this way,<br />

(theoretical) distances of 100-150m can be reached.<br />

IP –unique numeric address of the device connected to the network. The numbers of an IP address are used to identify a<br />

network and a particular host (each terminal connected to the network that hosts application level programmes).<br />

Swing 5.i – Connecting to computer and data exchange<br />

29

General information<br />

Contacts<br />

Guide<br />

Configuration 1<br />

Recommended in the following cases:<br />

• Company PC housed in a room thatt can act as a screen for the radiofrequency. The Ethernett cable thatt<br />

connects the PC and the Access Point enables radiofrequency filtering barriers to be overcome.<br />

Network features:<br />

• The WLAN network is a local network and is isolated from other networks by means of the SSID identifier<br />

that is settable both on the printers and on the Access Point. The IP WLAN addresses of the printers, of the<br />

Access Point and of the company PC can be defined by the EIDOS installer without any need to request<br />

free company IP addresses. It is recommended that 10.0.y.x IP addresses be used (where 0 x 255 and<br />

1 y 254).<br />

• If the PC is also connected to the company network it will therefore have 2 IP addresses. One will be the<br />

network address assigned by the company (e.g. 192.168.0.39) for the LAN connection, the other will be<br />

an IP address of the type 10.0.0.2 with SSID = EIDOS for the WI-FI connection to the local EIDOS<br />

connection.<br />

• Access Point connected to the PC by “crossed” Ethernet cable. In order to intervene on the customer’s PC<br />

to add a second Ethernet LAN card, an external USB – Ethernet converter should be used.<br />

• On the company PC the following management programmes of the EIDOS printers can be installed:<br />

a) EASYCODE<br />

b) STARCODE<br />

c) a custom programme that uses the EIDOS E-LIB libraries<br />

d) programmes for creating different labels that interface with the EIDOS printer by means of the SATO<br />

driver.<br />

Swing 5.i – Connecting to computer and data exchange<br />

30

General information<br />

Contacts<br />

Guide<br />

• The Access Point should be positioned at the point of gravity with relation to the printers.<br />

SCREENED<br />

AREA<br />

"crossed" Ethernet<br />

cable<br />

max 15m<br />

+<br />

USB to Ethernet<br />

adapter<br />

Access Point<br />

max 15m<br />

max 15m<br />

EIDOS WLAN<br />

Swing 5.i – Connecting to computer and data exchange<br />

31

General information<br />

Contacts<br />

Guide<br />

Configuration 2<br />

Recommended in the following cases:<br />

• Company PC thatt is nofurther than 15 m from the “Access Point” (Fig. 2.1)<br />

• Between the company PC and the Access Point there must not be any barriers screening the<br />

radiofrequency.<br />

• If the PC and the printers are more than 15m away (but less than 100m) from the Access Point provide<br />

the Access Point with 2 dipolar antennas (Fig. 2.2) that enable a distance up to 100m to be covered.<br />

max 15m<br />

max 15m<br />

max 15m<br />

+<br />

Access Point<br />

max 15m<br />

Fig 2-1<br />

max 15m<br />

Swing 5.i – Connecting to computer and data exchange<br />

32

General information<br />

Contacts<br />

Guide<br />

+<br />

USB WI-FI<br />

adapter<br />

max 100m<br />

max 100m<br />

+ USB WI-FI<br />

adapter<br />

max 100m<br />

max 100m<br />

+<br />

+ USB WI-FI<br />

adapter<br />

USB WI-FI<br />

adapter<br />

Access Point<br />

max 100m<br />

+<br />

USB WI-FI<br />

adapter<br />

Fig 2-2<br />

• The Access Point should be positioned at the point of gravity in relation to the printers and to the PC.<br />

• This configuration can also be used by the technician who wishes to communicate in radiofrequency with<br />

the EIDOS printers that he is installing.<br />

Swing 5.i – Connecting to computer and data exchange<br />

33

General information<br />

Contacts<br />

Guide<br />

How to configure the Eidos printer<br />

IP address :<br />

Printer Parameters> Set communication Parameters> Communication parameters 2 > IP Wireless LAN.<br />

SSID:<br />

Printer Parameters> Set communication Parameters> Communication parameters 2 > Name Lan Wireless<br />

(ESSID)<br />

Search function of AP:<br />

Printer Parameters> Set communication Parameters> Communication parameters 2 > Scanning WLAN<br />

Swing 5.i – Connecting to computer and data exchange<br />

34

General information<br />

Contacts<br />

Guide<br />

Installation recommendations<br />

• How to find optimal network configuration<br />

Preliminary operations (before embarking on installation on site):<br />

Request a scale plan of the premises on which the network will be installed that specifies:<br />

- the position of the PC and of the EIDOS printers to be connected to the network<br />

- the presence and location of metal obstacles on the company premises.<br />

In this way an approximate configuration of the WLAN network can already be made.<br />

Equipment required to carry out installation:<br />

1laptopPC<br />

1 Access Point device.<br />

n USB-TO-WI-FI converters for all the printers (more than 1 may have to be used on the company PC)<br />

1 Ethernet cable harness, connectors and pliers for crimping cable<br />

2 direction antennas<br />

2 dipolar omnidirectional antennas<br />

2 coaxial cables measuring 3 metres to connect the antennas to the Access Point<br />

1 Devolo converter with USB port.<br />

1 Devolo converter with Ethernet port (RJ-45).<br />

Swing 5.i – Connecting to computer and data exchange<br />

35

General information<br />

Contacts<br />

Guide<br />

• Proceeding with installation<br />

Position and switch on the Access Point at the centre of gravity with the printers.<br />

With the laptop PC and a USB to Wireless converter installed on board, check Link Quality and signal<br />

strength in the zones where the printers will be installed and in the zone where the PC is located.<br />

The Link Quality and Signal Strength bars indicate the quality of the wireless section. The minimum<br />

acceptable values of these two parameters are around 60-70%<br />

Swing 5.i – Connecting to computer and data exchange<br />

36

General information<br />

Contacts<br />

Guide<br />

• In order to check the quality of the link the command “ping nnn.nnn.nnn.nnn – t” should also be run from<br />

the Ms-Dos prompt of Windows. nnn.nnn.nnn.nnn is the IP address of the Access Point and enables the<br />

send/receive test of 32-byte packets between the PC and the Access Point to be tested, showing dispatch<br />

and return times.<br />

The monitor displays the result of each ping command prompt:<br />

Ping (Packet InterNet Groper i.e. "Internet package searcher") is a programme that is available in the main operating<br />

systems that measures the time, expressed in milliseconds taken by one or more ICMP packets (transmission protocols)<br />

to reach another computer or network server (whether Internet or LAN) and return to the origin.Itisinfactaservice<br />

run by the server, locally or via Internet, to find out whether the server is operating.<br />

Swing 5.i – Connecting to computer and data exchange<br />

37

General information<br />

Contacts<br />

Guide<br />

• Key in Ctrl-C to interrupt the operation and obtain statistical data on the test:<br />

•Average acceptable durations of pings are 0 - 20 ms.<br />

•If after these tests some devices do not have good transmission quality, replace the antennas with which<br />

the Access Point are provided, in order to expand their capacity. The choice between omnidirectional<br />

antennas and directional antennas depends on the number of printers to be installed and on their<br />

arrangement.<br />

If the number of printers is reduced and it is possible to arrange them at a short distance from one another,<br />

direction antennas are recommended. If on the other hand there is a large number and/or the printers are<br />

arranged on an extended surface, it is preferable to use a pair of dipolar antennas.<br />

Attachments:<br />

• Configuring g the Access Point<br />

• Configuring the WI-FI<br />

Swing 5.i – Connecting to computer and data exchange<br />

38

General information<br />

General information<br />

All rights to this manual are reserved. The reproduction, even partial, of this manual in any form is forbidden unless<br />

express written permission is given by Eidos S.p.A.<br />

The contents of this manual may be modified and improved without prior notice.<br />

Every effort has been made to ensure the accuracy of the contents.<br />

Please report any errors and/or inaccuracies to Eidos S.p.A. in order to make the manual as exhaustive as possible.<br />

Eidos S.p.A. accepts no liability for any accidental error or for any consequent harm arising from the supply,<br />

performance or use of this manual.<br />

Documentation supplied<br />

A series of tool that are supplied with the product and that simplify its use are an integral part of this manual:<br />

Help on Line and Error Messages – on machine. Help on Line provides information on the specific selected<br />

operations. Display must be enabled by the printer’s setup menu. The error messages provide an immediate<br />

explanation of the error that has occurred and indicate the measures that must be taken to eliminate it.<br />

Operator Manual – This is the paper document and it is designed to inform and assist the machine operator in matters<br />

of routine operation and maintenance.<br />

System Description and Configuration Manual – It is in hypertext format and contains the description of the<br />

system and basic instructions on its operation.<br />

Installation Manual – It is written for the installation technician in hypertext format. It indicates the procedures to be<br />

carried out for correct installation and commissioning of the machine.<br />

Maintenance Manual – It is written for electricians and fitters in hypertext form. It provides the information required<br />

to perform special maintenance, diagnostics, updating and all the tasks that are not part of normal operation.<br />

Easycode Programme – The demonstration version of the label management software is provided.<br />

39

Contacts<br />

How to contact t<br />

us<br />

Via dell’Industria, 11<br />

ZI Z.I. Fontaneto<br />

10023 Chieri (TO) ITALY<br />

Tel. +39 011 947 781<br />

Fax +39 011 947 7865<br />

E-mail: eidos@eidos.eueu<br />

Web: www.eidos.eu<br />

40

Guide<br />

Guide<br />

Surfing<br />

Contents<br />

t From the contents t page youcanchoose a topic orsection of this manual.<br />

Forwards/backwards if there are several pages in the menu.<br />

Return to main page.<br />

Close – also with ESC.<br />

How to print<br />

Use the right mouse key to open the menu from which it is possible to set and carry out printing.<br />

Connecting<br />

Events link: Text in green indicates an event that is active on the page.<br />

Active links: The underlined green text indicates an active connection to a different page.<br />

Animation: [show] starts animation.<br />

Press this flashing symbol to start an animation.<br />

This symbol invites the reader to contact EIDOS for greater information on solutions and particular products.<br />

41