draft tower portfolio - Micro Matic USA

draft tower portfolio - Micro Matic USA

draft tower portfolio - Micro Matic USA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

96<br />

GLYCOL COOLED DISPENSE SYSTEMS<br />

GASCHECK<br />

Beverage Gas Leak Detector & Shut-Off<br />

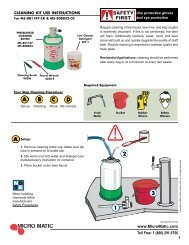

GasCheck automatically stops the flow of CO2 when it detects an excessive flow of gas, preventing CO2<br />

and revenue loss. GasCheck is simple to use:<br />

• Lever in the up (armed) position, the unit is armed and ready to stop a leak.<br />

• Gas flow has stopped which means GasCheck has stopped a leak. Identify the source of the leak, and<br />

repair or remedy.<br />

• Restart: flip the lever into the down (bypass) position and recharge system. Once system is recharged,<br />

simply flip the lever back into the up (armed) position.<br />

• System can be operated even with a leak occurring. Put lever in bypass position, and gas will flow<br />

through the unit unobstructed.<br />

1<br />

Gas Flow<br />

Read gauge when beer is NOT being poured.<br />

GASCHECK<br />

Gas Leak Detector & Shut-Off<br />

Grey Zone: Shut Down.<br />

Red Zone: Major Leak. Leaks in<br />

Potentially dangereous flow the system and require repair.<br />

of gas has been stopped. Reset<br />

detector before normal operation<br />

can resume.<br />

Gas Outlet<br />

Yellow Zone: Minor Leak.<br />

Green Zone: No Gas Leak.<br />

Gas Inlet<br />

2<br />

Lever Instructions<br />

Lever Up: Unit Armed.<br />

Ready to stop a dangereous gas leak.<br />

MOUNTING HOLES<br />

Lever Down: Unit bypassed.<br />

Gas leaks will be detected, but<br />

not stopped.<br />

Reset: First, repair leak(s). Second, flip the lever<br />

down, until the gauge is reading in the yellow<br />

or green zone. Third, flip the lever back up.<br />

For Service Call:<br />

866-327-4159 | www.micromatic.com Part No. MMGS-1 (Patent Pending)<br />

MMGS-1<br />

SAFETY<br />

FIRST!<br />

Features:<br />

• Stops beer and syrup pumps from pumping out-of-control.<br />

• Prevents costly down-time caused from running out of CO2.<br />

• Helps safeguard against potentially hazardous beverage gas leaks.<br />

• Effectively manage and reduce CO2 usage/costs.<br />

• Eliminate costly service calls associated with unexpected run-outs.<br />

• Works for both beer and soda systems.<br />

• Quickly and easily installed<br />

• Non-electric<br />

Part No.<br />

Description<br />

MMGS-1<br />

C02 Leak Detector & Shut Off<br />

IN-LINE LEAK DETECTOR<br />

MV035<br />

Determine gas leaks – save costs and employees from exposure to hazards.<br />

How it works: Chamber containing a small plastic float. If gas flows through the chamber the float will lift<br />

up. The larger the gas flow the higher the float lifts up. If no beer is being poured the float will remain at<br />

the bottom of the chamber. If floating, with no beer being poured a leak is present.<br />

Part No.<br />

MV035<br />

MV039<br />

Description<br />

Two Gas Lines<br />

Single Gas Line<br />

www.micromatic.com