Smart Materials Solve Contradictions - Systematic Innovation

Smart Materials Solve Contradictions - Systematic Innovation

Smart Materials Solve Contradictions - Systematic Innovation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

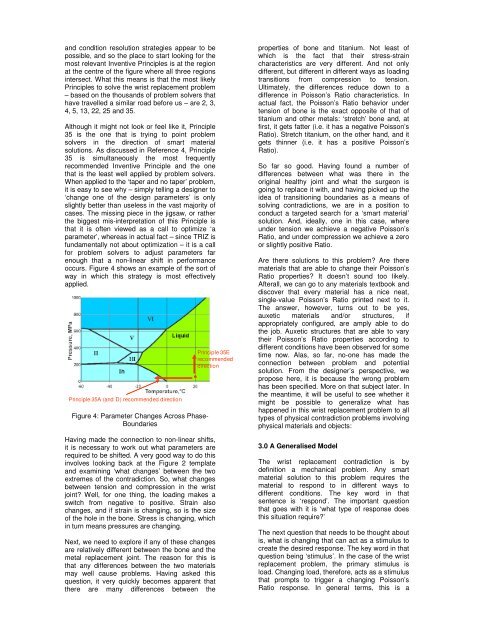

and condition resolution strategies appear to be<br />

possible, and so the place to start looking for the<br />

most relevant Inventive Principles is at the region<br />

at the centre of the figure where all three regions<br />

intersect. What this means is that the most likely<br />

Principles to solve the wrist replacement problem<br />

– based on the thousands of problem solvers that<br />

have travelled a similar road before us – are 2, 3,<br />

4, 5, 13, 22, 25 and 35.<br />

Although it might not look or feel like it, Principle<br />

35 is the one that is trying to point problem<br />

solvers in the direction of smart material<br />

solutions. As discussed in Reference 4, Principle<br />

35 is simultaneously the most frequently<br />

recommended Inventive Principle and the one<br />

that is the least well applied by problem solvers.<br />

When applied to the ‘taper and no taper’ problem,<br />

it is easy to see why – simply telling a designer to<br />

‘change one of the design parameters’ is only<br />

slightly better than useless in the vast majority of<br />

cases. The missing piece in the jigsaw, or rather<br />

the biggest mis-interpretation of this Principle is<br />

that it is often viewed as a call to optimize ‘a<br />

parameter’, whereas in actual fact – since TRIZ is<br />

fundamentally not about optimization – it is a call<br />

for problem solvers to adjust parameters far<br />

enough that a non-linear shift in performance<br />

occurs. Figure 4 shows an example of the sort of<br />

way in which this strategy is most effectively<br />

applied.<br />

Principle 35A (and D) recommended direction<br />

Figure 4: Parameter Changes Across Phase-<br />

Boundaries<br />

Principle 35E<br />

recommended<br />

direction<br />

Having made the connection to non-linear shifts,<br />

it is necessary to work out what parameters are<br />

required to be shifted. A very good way to do this<br />

involves looking back at the Figure 2 template<br />

and examining ‘what changes’ between the two<br />

extremes of the contradiction. So, what changes<br />

between tension and compression in the wrist<br />

joint? Well, for one thing, the loading makes a<br />

switch from negative to positive. Strain also<br />

changes, and if strain is changing, so is the size<br />

of the hole in the bone. Stress is changing, which<br />

in turn means pressures are changing.<br />

Next, we need to explore if any of these changes<br />

are relatively different between the bone and the<br />

metal replacement joint. The reason for this is<br />

that any differences between the two materials<br />

may well cause problems. Having asked this<br />

question, it very quickly becomes apparent that<br />

there are many differences between the<br />

properties of bone and titanium. Not least of<br />

which is the fact that their stress-strain<br />

characteristics are very different. And not only<br />

different, but different in different ways as loading<br />

transitions from compression to tension.<br />

Ultimately, the differences reduce down to a<br />

difference in Poisson’s Ratio characteristics. In<br />

actual fact, the Poisson’s Ratio behavior under<br />

tension of bone is the exact opposite of that of<br />

titanium and other metals: ‘stretch’ bone and, at<br />

first, it gets fatter (i.e. it has a negative Poisson’s<br />

Ratio). Stretch titanium, on the other hand, and it<br />

gets thinner (i.e. it has a positive Poisson’s<br />

Ratio).<br />

So far so good. Having found a number of<br />

differences between what was there in the<br />

original healthy joint and what the surgeon is<br />

going to replace it with, and having picked up the<br />

idea of transitioning boundaries as a means of<br />

solving contradictions, we are in a position to<br />

conduct a targeted search for a ‘smart material’<br />

solution. And, ideally, one in this case, where<br />

under tension we achieve a negative Poisson’s<br />

Ratio, and under compression we achieve a zero<br />

or slightly positive Ratio.<br />

Are there solutions to this problem? Are there<br />

materials that are able to change their Poisson’s<br />

Ratio properties? It doesn’t sound too likely.<br />

Afterall, we can go to any materials textbook and<br />

discover that every material has a nice neat,<br />

single-value Poisson’s Ratio printed next to it.<br />

The answer, however, turns out to be yes,<br />

auxetic materials and/or structures, if<br />

appropriately configured, are amply able to do<br />

the job. Auxetic structures that are able to vary<br />

their Poisson’s Ratio properties according to<br />

different conditions have been observed for some<br />

time now. Alas, so far, no-one has made the<br />

connection between problem and potential<br />

solution. From the designer’s perspective, we<br />

propose here, it is because the wrong problem<br />

has been specified. More on that subject later. In<br />

the meantime, it will be useful to see whether it<br />

might be possible to generalize what has<br />

happened in this wrist replacement problem to all<br />

types of physical contradiction problems involving<br />

physical materials and objects:<br />

3.0 A Generalised Model<br />

The wrist replacement contradiction is by<br />

definition a mechanical problem. Any smart<br />

material solution to this problem requires the<br />

material to respond to in different ways to<br />

different conditions. The key word in that<br />

sentence is ‘respond’. The important question<br />

that goes with it is ‘what type of response does<br />

this situation require?’<br />

The next question that needs to be thought about<br />

is, what is changing that can act as a stimulus to<br />

create the desired response. The key word in that<br />

question being ‘stimulus’. In the case of the wrist<br />

replacement problem, the primary stimulus is<br />

load. Changing load, therefore, acts as a stimulus<br />

that prompts to trigger a changing Poisson’s<br />

Ratio response. In general terms, this is a