High-speed Angular Contact Ball Bearings New 9 Series for ... - NTN

High-speed Angular Contact Ball Bearings New 9 Series for ... - NTN

High-speed Angular Contact Ball Bearings New 9 Series for ... - NTN

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>NTN</strong> TECHNICAL REVIEW No.782010<br />

<strong>New</strong> Product <br />

<strong>High</strong>-<strong>speed</strong> <strong>Angular</strong> <strong>Contact</strong> <strong>Ball</strong> <strong>Bearings</strong><br />

<strong>New</strong> 9 <strong>Series</strong> <strong>for</strong> Machine Tool<br />

Futoshi KOSUGI<br />

Many 9 series angular contact ball bearings are used <strong>for</strong> the main spindles of machine tools in<br />

Europe. However, demand <strong>for</strong> them has risen also in Japan recently. We improved the current<br />

design and developed new 9 series high-per<strong>for</strong>mance angular contact ball bearings.<br />

We introduce the features and the per<strong>for</strong>mance test data of these new 9 series high-<strong>speed</strong><br />

angular contact ball bearings in this report.<br />

1. Introduction<br />

In order to shorten lead time by addition of process<br />

integration capability, an increasing number of machine<br />

tool models have recently been adopting unique main<br />

spindles whose angle can be varied during machining<br />

operation, and examples of such main spindles include<br />

milling main spindles on 5-axis machine tools and<br />

combined machine tools.<br />

Main spindles on these machines swing to change<br />

their angle, and a sufficiently large space is needed on<br />

these machine tools to accommodate the motion of<br />

main spindles. There<strong>for</strong>e, any main spindle in these<br />

machines needs to be compact in size, and the main<br />

spindle bearing also needs to be compact in size. For<br />

this reason, 9 series bearings are used because of<br />

their low cross-sectional heights and smaller width.<br />

This article hereunder describes the features and<br />

per<strong>for</strong>mance of the <strong>NTN</strong>’s newly developed “high<strong>speed</strong><br />

angular contact ball bearing 9 series” products.<br />

2. Advantages of 9 <strong>Series</strong> bearings<br />

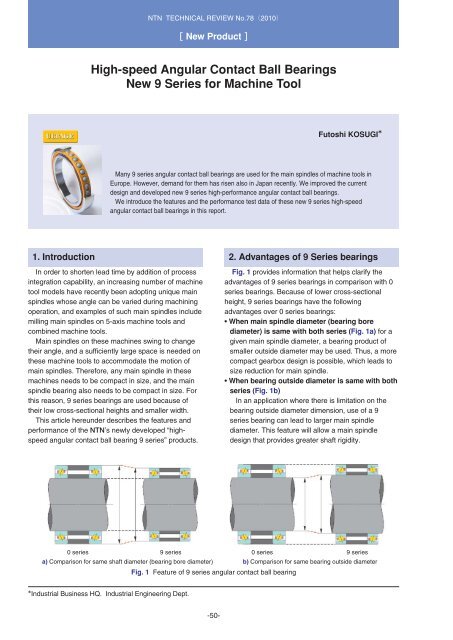

Fig. 1 provides in<strong>for</strong>mation that helps clarify the<br />

advantages of 9 series bearings in comparison with 0<br />

series bearings. Because of lower cross-sectional<br />

height, 9 series bearings have the following<br />

advantages over 0 series bearings:<br />

• When main spindle diameter (bearing bore<br />

diameter) is same with both series (Fig. 1a) <strong>for</strong> a<br />

given main spindle diameter, a bearing product of<br />

smaller outside diameter may be used. Thus, a more<br />

compact gearbox design is possible, which leads to<br />

size reduction <strong>for</strong> main spindle.<br />

• When bearing outside diameter is same with both<br />

series (Fig. 1b)<br />

In an application where there is limitation on the<br />

bearing outside diameter dimension, use of a 9<br />

series bearing can lead to larger main spindle<br />

diameter. This feature will allow a main spindle<br />

design that provides greater shaft rigidity.<br />

0 series 9 series 0 series<br />

9 series<br />

a) Comparison <strong>for</strong> same shaft diameter (bearing bore diameter) b) Comparison <strong>for</strong> same bearing outside diameter<br />

Fig. 1 Feature of 9 series angular contact ball bearing<br />

Industrial Business HQ. Industrial Engineering Dept.<br />

-50-

<strong>High</strong>-<strong>speed</strong> <strong>Angular</strong> <strong>Contact</strong> <strong>Ball</strong> <strong>Bearings</strong> <strong>New</strong> 9 <strong>Series</strong> <strong>for</strong> Machine Tool<br />

On the disadvantage side, having balls smaller than<br />

those of 0 series, 9 series bearings are inferior to 0<br />

series bearings in terms of their radial load capacity<br />

and maximum allowable axial load. To eliminate this<br />

problem, <strong>NTN</strong> has developed 9 series bearing variants<br />

that boast greater load capacity.<br />

3. Improved functions on <strong>New</strong> 9 <strong>Series</strong><br />

products<br />

3.1 Load rating and allowable axial load<br />

Our newly developed high-<strong>speed</strong> angular contact<br />

ball bearing products—new 9 series—feature improved<br />

internal design that include rolling elements of<br />

increased diameter as shown in Fig. 2, thereby the<br />

load rating has been improved by a maximum of 50%<br />

and the allowable axial load has been increased by<br />

<strong>New</strong> design<br />

Old design<br />

Fig. 2 Design of new product<br />

20% (Fig. 3). Consequently, the new 9 series bearing<br />

products boast longer life and increased allowance<br />

against axial load that occurs during tool change<br />

process on machine tools; thus, these bearings will be<br />

used in a larger scope of applications.<br />

Fig. 4 provides axial rigidity graph and radial rigidity<br />

graph with high-<strong>speed</strong> angular contact ball bearings<br />

(new design and old design), internal bore diameter<br />

100 mm, with constant pressure preload (GN preload).<br />

3.2 Result of operation test<br />

The result of operation test with the high-<strong>speed</strong><br />

angular contact ball bearings (new design and old<br />

design) is described below.<br />

Fig. 5 schematically illustrates the construction of<br />

the test rig (main spindle type test rig) used <strong>for</strong> the test.<br />

Fig. 6 summarizes a result of temperature rise test<br />

on the new and old bearing design variants with<br />

ceramic balls, air-oil lubricated, and with fixed position<br />

preload.<br />

The pattern of heat rise on the outer ring of our new<br />

design, up to dmn = 1.4510 6 (12,000 min -1 ) is<br />

identical to that of the old design. However, at higher<br />

<strong>speed</strong> range, the temperature with the new design is<br />

somewhat higher (1 to 2˚C). A possible cause is a<br />

larger ball size, which leads to greater PV value<br />

(contact surface pressure x slip velocity).<br />

140<br />

Basic dynamic load rating Basic static load rating Allowable axial load<br />

120<br />

100<br />

<strong>New</strong> design<br />

Old design<br />

kN<br />

80<br />

60<br />

40<br />

20<br />

0<br />

50<br />

100 150 50 100 150 50 100 150<br />

Fig. 3 Basic load ratings and allowable axial load (steel ball, contact angle 20˚)<br />

15<br />

6<br />

Axial displacement μm<br />

10<br />

5<br />

<strong>New</strong> design<br />

Old design<br />

Radial displacement μm<br />

5<br />

4<br />

3<br />

2<br />

1<br />

<strong>New</strong> design<br />

Old design<br />

0<br />

0 500 1000 1500 2000 2500 3000<br />

Axial load N<br />

0<br />

0 500 1000 1500 2000 2500 3000<br />

Radial load N<br />

Fig. 4 Rigidity graph (bearing bore dia. 100 mm, constant pressure preload)<br />

-51-

<strong>NTN</strong> TECHNICAL REVIEW No.782010<br />

Fig. 7 graphically plots the variation in bearing<br />

preload in this test: the diagram shows that the new<br />

design helps reduce possible increase in preload by<br />

approximately 15% compared with the old design. To<br />

sum up, the temperature on outer ring on our new<br />

design is somewhat higher compared with the old<br />

design: nevertheless, our new design boasts improved<br />

anti-seizure property because temperature difference<br />

across its inner ring and outer ring is smaller,<br />

minimizing the increase in preload.<br />

Fig. 8 illustrates test result with constant pressure<br />

preload type bearing specimens.<br />

The temperature on the outer ring of our new design<br />

is higher by 1˚C compared with the old design:<br />

nevertheless, our new design is capable of stable<br />

operation up to ultrahigh-<strong>speed</strong> region of dmn = 2.40<br />

10 6 (20,000 min -1 ).<br />

Drive<br />

system<br />

Test bearing<br />

Preload N<br />

Temperature rise on outer ring ˚C<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

20<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

<strong>New</strong> design<br />

Old design<br />

0<br />

0 5000 10000 15000<br />

Bearing running <strong>speed</strong> min -1<br />

5S-2LA-HSE920UDBP4 (<strong>New</strong> design)<br />

5S-2LA-HSE920DBP4 (Old design)<br />

Air-oil lubricated<br />

Air supply rate: 40 NL/min<br />

Oil supply rate: 0.03 mL/5 min<br />

Fixed position preload: 1800 N<br />

w/ jacket cooling<br />

<strong>New</strong> design<br />

Old design<br />

0<br />

0 5000 10000 15000 20000<br />

Bearing running <strong>speed</strong> min -1<br />

Approx. 15%<br />

reduction<br />

in increase<br />

in preload<br />

Fig. 7 Correlation between <strong>speed</strong> and preload<br />

Fig. 5 Test spindle<br />

Fig. 8 Test results (Constant pressure preload, Air-oil)<br />

Temperature rise on outer ring ˚C<br />

20<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

<br />

<strong>New</strong> design<br />

Old design<br />

5S-2LA-HSE920UDBP4 (<strong>New</strong> design)<br />

5S-2LA-HSE920DBP4 (Old design)<br />

Air-oil lubricated<br />

Air supply rate: 40 NL/min<br />

Oil supply rate: 0.03 mL/5 min<br />

Preload on mounted bearing: 49 N<br />

w/ jacket cooling<br />

0<br />

0 5000 10000 15000 20000<br />

Bearing running <strong>speed</strong> min -1<br />

Fig. 6 Test results (Fixed position preload, Air-oil)<br />

Temperature rise on outer ring ˚C<br />

<br />

20<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

<strong>New</strong> design<br />

Old design<br />

2LA-HSE920UDBP4 (<strong>New</strong> design)<br />

2LA-HSE920DBP4 (Old design)<br />

Grease lubrication<br />

Prefilled grease: SE-1<br />

Fixed position preload: 49 N<br />

w/ jacket cooling<br />

0 5000 10000 15000<br />

Bearing running <strong>speed</strong> min -1<br />

Fig. 9 Test results (Fixed position preload, Grease)<br />

-52-

<strong>High</strong>-<strong>speed</strong> <strong>Angular</strong> <strong>Contact</strong> <strong>Ball</strong> <strong>Bearings</strong> <strong>New</strong> 9 <strong>Series</strong> <strong>for</strong> Machine Tool<br />

Fig. 9 summarizes test result with grease-lubricated<br />

specimens having steel balls, with fixed position<br />

preload setting. Even under these conditions, heat rise<br />

on the outer ring of the new bearing design remains<br />

low up to dmn = 1.4410 6 (12,000 min -1 ).<br />

4. Conclusion<br />

Compared with old products, our newly developed<br />

high-<strong>speed</strong> angular contact ball bearing 9 series<br />

products boast greater radial load capacity and<br />

allowable axial load, and longer life and increased load<br />

capacity during tool change process on machine tools.<br />

In terms of functions, the bearing temperature on our<br />

new design is 1 to 2˚C higher compared with old<br />

design. Nevertheless, the temperature gradient across<br />

the inner ring and outer ring on our new design is low<br />

and increase in preload in high-<strong>speed</strong> bearing<br />

operation is also low. Thus, our new design excels in<br />

anti-seizure property.<br />

<strong>NTN</strong> will add its “high-<strong>speed</strong> angular contact ball<br />

bearing new 9 series” products, which boast compact<br />

size and enhanced functionality, to its ULTAGE <strong>Series</strong><br />

line of products, and will actively market these novel<br />

products.<br />

Photo of author<br />

Futoshi KOSUGI<br />

Industrial Business HQ<br />

Industrial Engineering Dept.<br />

-53-

![[New Product] Unit Products for Office Equipment - NTN](https://img.yumpu.com/27154451/1/184x260/new-product-unit-products-for-office-equipment-ntn.jpg?quality=85)

![[New Product] Development of Oil-impregnated Sintered ... - NTN](https://img.yumpu.com/27154427/1/184x260/new-product-development-of-oil-impregnated-sintered-ntn.jpg?quality=85)