Morpheus 611X and Agrios 413X - Flexo-Technic

Morpheus 611X and Agrios 413X - Flexo-Technic

Morpheus 611X and Agrios 413X - Flexo-Technic

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

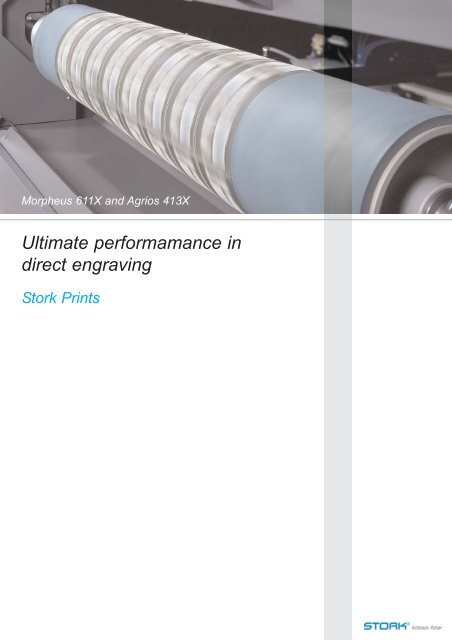

<strong>Morpheus</strong> <strong>611X</strong> <strong>and</strong> <strong>Agrios</strong> <strong>413X</strong><br />

Ultimate performamance in<br />

direct engraving<br />

Stork Prints

:: 2<br />

Better for your business<br />

Stork direct laser engraving<br />

systems are the ideal platform<br />

for taking your flexo plate or<br />

rotary screen engraving process<br />

to a higher level. Faster,<br />

more efficient, better quality,<br />

more economical, less environmental<br />

impact: there are<br />

many ways in which our laser<br />

engraving systems can improve<br />

your business. Furthermore,<br />

these systems are com-<br />

pletely digital, <strong>and</strong> will therefore<br />

provide cutting-edge engraving<br />

well into the future.<br />

Laser engraving, through constant<br />

development <strong>and</strong> improvement,<br />

is a technology which<br />

time has clearly arrived. There<br />

are a whole host of reasons<br />

why it is preferable to other<br />

engraving methods:<br />

Less process steps<br />

Some conventional processes<br />

require many different steps to<br />

create a flexo-printing form.<br />

With the Stork <strong>Morpheus</strong> <strong>611X</strong><br />

<strong>and</strong> <strong>Agrios</strong> <strong>413X</strong> direct laser<br />

engraving systems there is<br />

effectively only one; the laser<br />

engraving itself. This obviously<br />

simplifies <strong>and</strong> accelerates the<br />

production process.<br />

Faster<br />

The <strong>Agrios</strong> <strong>413X</strong> is the fastest<br />

laser engraver of flexo-printing<br />

forms on the market.<br />

More economical<br />

Consumable use is highly<br />

reduced. Stork laser engraving<br />

machines incorporate a<br />

sealed laser unit, so extra gas<br />

is not required. Naturally, there<br />

is no consumption of U.V.lights,<br />

ink or other chemicals.<br />

And the engraving process<br />

itself requires no water, so<br />

you don't have a 'wet area' in<br />

your production facility.<br />

Better quality<br />

An advanced laser control<br />

system <strong>and</strong> the precise focus<br />

of the beam leads to more<br />

sharply engraved edges <strong>and</strong><br />

extremely fine reproduction of<br />

detail. The <strong>Agrios</strong> <strong>413X</strong>'s<br />

patented triple-beam laser<br />

technology can achieved particularly<br />

high levels of accuracy.

otamesh fi<br />

The quality levels achieved<br />

by laser-based units are unparalleled<br />

in flexo engraving.<br />

Reduced chance of error<br />

Laser engraving is a largely<br />

automated process in which<br />

manual h<strong>and</strong>ling is reduced<br />

to a minimum. The possibility<br />

of human error is consequently<br />

much lower.<br />

Excellent repeatability<br />

Running repeat orders has<br />

never been easier. As it is a<br />

digital system, you simply<br />

load the appropriate data file<br />

<strong>and</strong> your system is ready to<br />

engrave. The potential for<br />

errors is virtually zero, <strong>and</strong><br />

consistency is guaranteed.<br />

Less environmental impact<br />

No U.V.-light is necessary, so<br />

the process does not produce<br />

any toxic run-off. All in all, the<br />

laser engraving process is<br />

considerably better for the<br />

environment <strong>and</strong> operator<br />

than traditional chemicalbased<br />

methods.<br />

Easy-to-use<br />

Stork laser engraving<br />

systems are simple to use.<br />

Process data can also be<br />

stored for future use.<br />

Save floorspace<br />

A conventional configuration<br />

would typically include separate<br />

units for UV exposure,<br />

chemical washing, drying <strong>and</strong><br />

after exposure. With Stork<br />

direct laser engraving, all<br />

these are replaced by a single<br />

engraving unit, which<br />

requires an average of 30%<br />

less floorspace. Space<br />

savings with the <strong>Morpheus</strong><br />

<strong>611X</strong> are even higher, because<br />

you have a rotary screen<br />

<strong>and</strong> flexo plate engraver rolled<br />

into one.<br />

Dedicated software for improved<br />

workflow<br />

The <strong>Agrios</strong> <strong>and</strong> <strong>Morpheus</strong> are<br />

supplied with <strong>Flexo</strong>POWER<br />

image preprocessing software.<br />

This soft-ware gives the user<br />

unprecedented levels of control<br />

in defining dot shape <strong>and</strong><br />

sharpness. The plateau,<br />

image area, shoulder angle,<br />

undercut, relief depth <strong>and</strong><br />

base size can be precisely<br />

specified in this powerful yet<br />

easy-to-use package.<br />

Leaders in laser engraving<br />

We were the first company to<br />

introduce laser engraving; a<br />

move that revolutionised the<br />

way screens are engraved.<br />

Today we can call on approximately<br />

two decades of experience<br />

in the development<br />

<strong>and</strong> manufacture of leading<br />

laser engraving systems such<br />

as the <strong>Morpheus</strong> <strong>611X</strong> <strong>and</strong><br />

the <strong>Agrios</strong> <strong>413X</strong>.

<strong>Agrios</strong> <strong>413X</strong>: high-quality <strong>and</strong> speed<br />

in flexo engraving<br />

The <strong>Agrios</strong> <strong>413X</strong> is the<br />

fastest laser engraver on the<br />

market, <strong>and</strong> also offers the<br />

best quality. It is a dedicated<br />

engraving unit for flexo material<br />

like rubber <strong>and</strong> polymer.<br />

The key to the excellent performance<br />

levels is a unique,<br />

patented triple-beam laser<br />

system. Three separate<br />

lasers passed over the plate<br />

in quick succession; the first<br />

creates a shallow track to<br />

Dimensions 1700 x 1350 x 4500 (HxWxD)<br />

Power supply 22 KVA<br />

Engraving depth operator controlled<br />

Plate compatibility all types<br />

Sleeve adapter 100 to 400 mm diameter<br />

Laser 3 * 250 W (3rd laser - 500 Watt possible)<br />

define the printing dot, <strong>and</strong><br />

the second <strong>and</strong> third further<br />

deepen <strong>and</strong> shape it. The<br />

result is an extremely welldefined<br />

flexo printing plate,<br />

achieved significantly faster<br />

than with conventional<br />

methods, <strong>and</strong> in a much<br />

more environmentally friendly<br />

way.<br />

Overview of key specifications (<strong>Agrios</strong> <strong>413X</strong>):<br />

4 ::

:: 5<br />

<strong>Morpheus</strong> <strong>611X</strong>: flexo printing forms<br />

<strong>and</strong> rotary screens form a single unit<br />

The <strong>Morpheus</strong> <strong>611X</strong> gives<br />

you the best of both worlds,<br />

enabling direct laser engraving<br />

of both flexo printingforms<br />

<strong>and</strong> rotary screen<br />

cylinders from a single unit.<br />

This all-purpose system<br />

engraves rubber <strong>and</strong> polymer<br />

with great accuracy, using a<br />

single laser beam to define<br />

the dot pattern. And it is also<br />

ideal for engraving Stork<br />

RotaMesh ® screens for narrow-web,<br />

packaging <strong>and</strong><br />

security printing, as well as<br />

Stork Special Screens ® for<br />

applications such as textile or<br />

wallcovering printing. The<br />

<strong>Morpheus</strong> can also be equiped<br />

with an aditional YAGlaser<br />

for LAM-technology.<br />

Overview of key specifications (<strong>Morpheus</strong> <strong>611X</strong>):<br />

Dimensions 1500/1950 x 1450 x 4500 (HxWxD)<br />

Power supply 7 KVA<br />

Engraving depth operator controlled<br />

Plate compatibility all types<br />

Sleeve adapter 50 to 500 mm diameter<br />

Laser 500 W

Stork Prints<br />

Stork Prints develops <strong>and</strong> produces (as the only company in the world to do so) rotary screen<br />

printing systems <strong>and</strong> digital systems for all process steps in the textile printing process. In addition<br />

the group supplies rotary screen printing systems <strong>and</strong> digital colour proofing systems for the<br />

graphic arts industry.<br />

Stork Prints is part of Stork NV, a global technology group comprising 60 companies, with a total<br />

workforce of around 13,000 <strong>and</strong> a turnover of € 1.9 billion.<br />

The Netherl<strong>and</strong>s<br />

Stork Prints B.V.<br />

P.O. Box 67<br />

5830 AB Boxmeer<br />

The Netherl<strong>and</strong>s<br />

Tel.: +31 485 58 82 00<br />

Fax: +31 485 58 83 63<br />

E-mail:<br />

info.storkprints@stork.com<br />

Internet: www.storkprints.com<br />

Stork Prints B.V.<br />

Dispensing Systems<br />

Mercuriusweg 17<br />

6971 GV Brummen<br />

The Netherl<strong>and</strong>s<br />

Tel.: +31 575 56 80 80<br />

Fax: +31 575 56 80 90<br />

Germany<br />

Stork Prints Germany GmbH<br />

Am Rain 53<br />

83088 Kiefersfelden<br />

Germany<br />

Tel.: +49 8033 69 05 0<br />

Fax: +49 8033 69 05 10<br />

Austria<br />

Stork Prints Austria GmbH<br />

Kufsteiner Strasse 4<br />

A-6336 Langkampfen<br />

Austria<br />

Tel.: +43 5372 69 93 0<br />

Fax: +43 5372 69 93 54<br />

Spain<br />

Stork Prints Iberia S.A.<br />

Polígono Industrial<br />

17412 Massanet de la Selva<br />

Gerona<br />

Spain<br />

Tel.: +34 972 16 52 52<br />

Fax: +34 972 16 51 51<br />

Turkey<br />

Stork Tekstil Sistemleri<br />

Tic Ltd Sti<br />

Kaya Sultan Sok.<br />

Huseyin Bagdatlioglu Is Merkezi<br />

No:97 Kat:4 D:8<br />

34742 Kozyatagi - Kadikoy<br />

Istanbul<br />

Turkey<br />

Tel.: +90 216 464 83 53<br />

Fax: +90 216 464 83 57<br />

U.S.A.<br />

Stork Prints America Inc.<br />

P.O. Box 26458<br />

Charlotte, N.C. 28221<br />

U.S.A.<br />

Tel.: +1 704 598 71 71<br />

Fax: +1 704 596 08 58<br />

Mexico<br />

Stork Mexico S.A. de C.V.<br />

P.O. Box 44-227<br />

03100 Mexico D.F.<br />

Mexico<br />

Tel.: +52 55 56 82 32 99<br />

Fax: +52 55 56 82 44 04<br />

Brazil<br />

Stork Prints Brasil Ltda.<br />

Av. Com. Leopoldo Dedini, 150<br />

CEP 13.422-210<br />

Piracicaba (SP)<br />

Brazil<br />

Tel.: +55 19 34 37 13 00<br />

Fax: +55 19 34 37 13 90<br />

Pakistan<br />

Stork Prints Pakistan (Pvt) Ltd.<br />

11, Bangalore Town<br />

Cooperative Housing Society<br />

Shahrah-e-Faisal<br />

KARACHI 75350<br />

Pakistan<br />

Tel.: +92 21 455 83 34<br />

Fax: +92 21 455 82 77<br />

India<br />

Stovec Industries Ltd.<br />

N.I.D.C. Near Lambha Village<br />

Post: Narol<br />

Ahmedabad 382 405<br />

Gujarat State<br />

India<br />

Tel.: +91 79 571 04 07<br />

Fax: +91 79 571 04 06<br />

Indonesia<br />

P.T. Stork Prints Indonesia<br />

Cikarang Industrial Estate<br />

Jl. Jababeka Raya<br />

Block C No. 1<br />

Bekasi 17550-Jawa Barat<br />

Indonesia<br />

Tel.: +62 21 893 41 36<br />

Fax: +62 21 893 41 35<br />

China<br />

Stork Textile Systems Wuxi<br />

Co. Ltd.<br />

No. 251, Xing Chuang Ba Lu<br />

Wuxi-Singapore Industrial Park<br />

Wuxi, Jiangsu 214028<br />

P.R. China<br />

Tel.: +86 510 528 22 25<br />

Fax: +86 510 528 22 41<br />

Japan<br />

Stork Prints Japan K.K.<br />

Daimei Building, 7F<br />

3-20-10, Toyosaki, Kita-Ku<br />

Osaka-City<br />

Osaka Pref. 531-0072<br />

Japan<br />

Tel.: +81 66 359 88 65<br />

Fax: +81 66 359 88 73<br />

The data in this brochure was valid at the time of publishing, <strong>and</strong> is subject to change without<br />

notice. Stork reserves the right to modify its products at any time without further obligation.<br />

100320504