Dearborn Engineer, Fall 2005 - College of Engineering & Computer ...

Dearborn Engineer, Fall 2005 - College of Engineering & Computer ...

Dearborn Engineer, Fall 2005 - College of Engineering & Computer ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

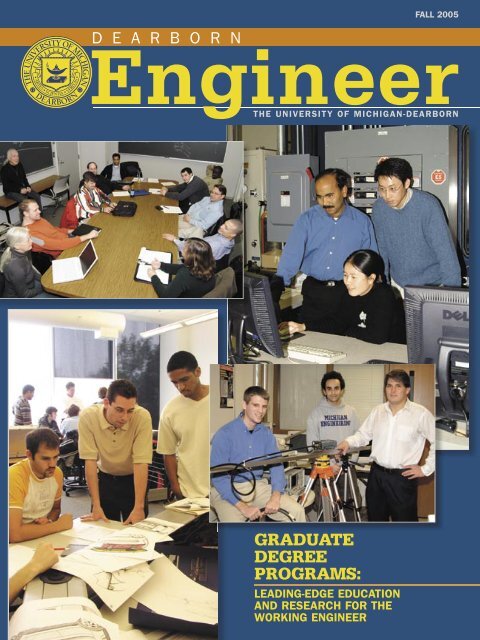

FALL <strong>2005</strong><br />

D E A R B O R N<br />

<strong>Engineer</strong><br />

THE UNIVERSITY OF MICHIGAN-DEARBORN<br />

GRADUATE<br />

DEGREE<br />

PROGRAMS:<br />

LEADING-EDGE EDUCATION<br />

AND RESEARCH FOR THE<br />

WORKING ENGINEER

The <strong>Dearborn</strong> <strong>Engineer</strong><br />

<strong>Fall</strong> <strong>2005</strong><br />

6<br />

IMSE GRADUATE PROGRAMS<br />

News from the <strong>College</strong> <strong>of</strong><br />

<strong>Engineer</strong>ing and <strong>Computer</strong> Science,<br />

University <strong>of</strong> Michigan-<strong>Dearborn</strong><br />

www.engin.umd.umich.edu<br />

Graduate Degree Programs at CECS 1<br />

CIS Graduate Degree Programs 2<br />

ECE Graduate Degree Programs 4<br />

IMSE Graduate Degree Programs 6<br />

ME Graduate Degree Programs 8<br />

Interdisciplinary Programs 10<br />

IAVS Offers Graduate Students Experience 11<br />

Ford Partnership with IAVS 12<br />

11 IAVS PROGRAMS<br />

Co-op Employer <strong>of</strong> the Year: DENSO 15<br />

DENSO Gift 13<br />

New Visiting Committee Members 14<br />

Scholarship Awards 15<br />

New Faculty Members 16<br />

Faculty Research Awards 17<br />

Student Robotics Activities 18<br />

<strong>2005</strong> Annual Alumni Awards 20<br />

Editorial Board<br />

Subrata Sengupta, Ph.D., Dean<br />

Keshav S. Varde, Ph.D., Associate Dean<br />

Editor: Kathryn Tamborino<br />

12 FORD MOTOR COMPANY FUND<br />

The <strong>Dearborn</strong> <strong>Engineer</strong> is published for the alumni<br />

and friends <strong>of</strong> the University <strong>of</strong> Michigan-<strong>Dearborn</strong><br />

<strong>College</strong> <strong>of</strong> <strong>Engineer</strong>ing and <strong>Computer</strong> Science.<br />

Send correspondence to the Editor, <strong>Dearborn</strong> <strong>Engineer</strong>,<br />

4901 Evergreen Road, <strong>Dearborn</strong>, MI 48128-1491.<br />

Regents <strong>of</strong> the University<br />

David A. Brandon, Laurence B. Deitch,<br />

Olivia P. Maynard, Rebecca McGowan,<br />

Andrea Fischer Newman, Andrew C. Richner,<br />

S. Martin Taylor, Katherine E. White,<br />

Mary Sue Coleman (ex <strong>of</strong>ficio)<br />

Citizens Advisory Committee<br />

Ismael Ahmed, Stephen T. Economy, Linda P. Kughn,<br />

Patricia Mooradian, Timothy J. O’Brien, Jon Pepper,<br />

Michael C. Porter, Maria Leonhauser Rosenau,<br />

Shirley R. Stancato<br />

18 ROBOTICS

FALL <strong>2005</strong><br />

Graduate Degree Programs at CECS<br />

In order to remain relevant, all major<br />

engineering schools cater to the needs <strong>of</strong> their<br />

students. The graduate programs at the <strong>College</strong><br />

<strong>of</strong> <strong>Engineer</strong>ing and <strong>Computer</strong> Science (CECS) go<br />

a step further and also work to meet the needs <strong>of</strong><br />

its stakeholders, the engineering companies and<br />

industries who benefit from the college’s research<br />

and highly qualified graduates.<br />

Over the past 40 years, the CECS graduate<br />

programs have sought to balance research and<br />

practice, a balance that pushes the boundaries<br />

<strong>of</strong> what is currently possible but stays rooted in<br />

practical application. This approach provides<br />

opportunities for full-time students to pursue<br />

leading-edge research while accommodating<br />

part-time students who need to solve daily problems<br />

facing them in their industry jobs. “I would<br />

say that we have succeeded in achieving this<br />

balance,” says Malayappan Shridhar, chair <strong>of</strong> the<br />

electrical and computer engineering department.<br />

More than 90 percent <strong>of</strong> the 800 graduate students<br />

enrolled at CECS are sponsored by their employers.<br />

To facilitate their education, courses are <strong>of</strong>fered in the<br />

evening or online. Some course <strong>of</strong>ferings<br />

are tailored directly to a specific company’s needs and<br />

<strong>of</strong>fered on site. “Our industry partners like to see this<br />

sort <strong>of</strong> flexibility in education, which helps to provide<br />

them with a very competent and productive technical<br />

workforce,” says Keshav Varde, associate dean <strong>of</strong> CECS.<br />

“And our students appreciate the ability to enhance their<br />

technical education without interruption <strong>of</strong> their careers.”<br />

CECS <strong>of</strong>fers both traditional and more unusual graduate<br />

programs. The traditional programs, including mechanical,<br />

electrical, and industrial and systems engineering,<br />

have been around since the 1960s, when graduate<br />

studies at CECS began. Newer programs have been added<br />

to reflect changes in industry and educational approach.<br />

“Our graduate programs in s<strong>of</strong>tware engineering, automotive<br />

systems engineering, and engineering management<br />

are nearly unique,” says Varde. “Very few institutions<br />

<strong>of</strong>fer these programs. The automotive systems program is<br />

interdisciplinary in nature in that students get exposure to<br />

important engineering disciplines that practicing engineers<br />

in automotive industry are expected to know. The s<strong>of</strong>tware<br />

engineering program blends unique and important aspects<br />

<strong>of</strong> s<strong>of</strong>tware engineering with exposure to computer science<br />

ASSISTANT PROFESSOR JIRACHAI BUDDHAKULSOMSIRI WITH HIS<br />

PROBABILITY AND STATISTICS CLASS<br />

and computer engineering. And the engineering management<br />

program is designed for engineers who need more<br />

background in management disciplines.”<br />

Graduate students in all the programs have the option to<br />

do research with faculty members, most <strong>of</strong> whom pursue<br />

multiple industry-based projects at any given time. “All<br />

<strong>of</strong> our graduate programs are staffed by faculty who are<br />

knowledgeable in the field, work in the discipline, and<br />

pursue research activities in the discipline,” says Varde.<br />

“The pr<strong>of</strong>essors at CECS are very familiar with working<br />

with industry and most have direct industry experience,”<br />

says Karl Kennedy, who received his master’s degree in<br />

electrical engineering in <strong>2005</strong>. “Most <strong>of</strong> the students are<br />

also industry pr<strong>of</strong>essionals. As a result, in the same way<br />

that the pr<strong>of</strong>essors can challenge students, the students<br />

can also challenge the pr<strong>of</strong>essors with ideas and issues<br />

from industry. It’s a good relationship.”<br />

Lisa Marie Floros, who received her master’s degree in<br />

industrial and systems engineering in 2000, concurs. “The<br />

programs <strong>of</strong>fer a wide scope <strong>of</strong> applicable study,” she<br />

says, “which translates into greater opportunities out in<br />

the workforce. You increase your skill set and become<br />

much more marketable. I really enjoyed my entire educational<br />

experience at UM-<strong>Dearborn</strong>. Looking back from<br />

where I am now, I wouldn’t change a thing.”

DEARBORN <strong>Engineer</strong><br />

<strong>Computer</strong> and Information Science<br />

Graduate Programs: Developing<br />

S<strong>of</strong>tware Skills for Today’s Market<br />

The Department <strong>of</strong> <strong>Computer</strong> and<br />

Information Science (CIS) <strong>of</strong>fers two<br />

graduate degree programs, one in computer<br />

and information science and another in s<strong>of</strong>tware engineering.<br />

The computer and information science degree is a classic<br />

computer science degree; students can study in many <strong>of</strong> the<br />

traditional areas, including operating systems, networking,<br />

computer graphics, information systems, and databases.<br />

They can also study some <strong>of</strong> the newer cutting-edge areas<br />

such as web or multimedia information systems, web<br />

services, data mining, and automotive networking.<br />

The s<strong>of</strong>tware engineering program is jointly administered<br />

with the Department <strong>of</strong> Electrical and <strong>Computer</strong><br />

<strong>Engineer</strong>ing, with an emphasis on embedded systems.<br />

“That degree will, among other things, enable graduates to<br />

manage large s<strong>of</strong>tware projects,” says William Grosky, chair<br />

<strong>of</strong> CIS. The department also participates in a third program<br />

leading to a graduate degree in information systems technology,<br />

which is primarily run out <strong>of</strong> the Department <strong>of</strong><br />

Industrial and Manufacturing Systems <strong>Engineer</strong>ing.<br />

CIS graduate students concentrate in one <strong>of</strong> multiple<br />

areas, including computer graphics and geometric<br />

modeling, computer networks, database management,<br />

information systems, s<strong>of</strong>tware engineering, and system<br />

s<strong>of</strong>tware. Each program involves a mixture <strong>of</strong> core<br />

courses, concentration courses, cognates, and a project or<br />

thesis, which students conduct under the supervision <strong>of</strong> a<br />

faculty member. The core courses cover the principles <strong>of</strong><br />

the respective disciplines, while the concentration courses<br />

address the application <strong>of</strong> those principles.<br />

Every five years, both programs are critically evaluated by<br />

both internal and external entities in order to update <strong>of</strong>ferings<br />

to meet the demands <strong>of</strong> local industries and to incorporate<br />

major developments in the disciplines.<br />

“Our s<strong>of</strong>tware engineering degree program is unique<br />

in the metro area, and I would say in the country,” says<br />

Grosky. “There are few MS programs in s<strong>of</strong>tware engineering<br />

and even fewer programs with an emphasis<br />

in embedded systems. This is especially <strong>of</strong> interest to<br />

the auto companies and the U.S. Army Tank Command.<br />

Students with this training will gain the skills to manage<br />

large s<strong>of</strong>tware projects, a skill which, so far, has not been<br />

outsourced, and probably won’t be.”<br />

Grosky remains optimistic about CIS graduate students’<br />

career choices in spite <strong>of</strong> industry trends. “Many computing<br />

jobs have certainly been outsourced,” he says, “but<br />

these are mostly among low-level programming positions.<br />

If you believe government statistics, there will be a need<br />

for many, many people with the skills taught in our programs.<br />

This view has been echoed by Bill Gates, who is<br />

going around the country promoting this position. There<br />

are many different fields that a CIS graduate can enter.<br />

We’ve even had some more entrepreneurial students go<br />

on to start their own companies.”<br />

Austin Krauss, MS in S<strong>of</strong>tware <strong>Engineer</strong>ing, <strong>2005</strong><br />

Austin Krauss earned his graduate degree in s<strong>of</strong>tware engineering (SE),<br />

with a concentration in computer graphics and user interface design,<br />

with an eye toward going into computer game development. Although<br />

he had chosen an unusual choice for s<strong>of</strong>tware development research,<br />

Krauss found support and guidance from his pr<strong>of</strong>essors. “Overall, I felt<br />

that the pr<strong>of</strong>essors were receptive to students’ needs and were aware <strong>of</strong><br />

the changes in the job market. Their motivation excited me about the<br />

research I was doing.”<br />

Today he works at the California-based Treyarch, a leading developer <strong>of</strong><br />

video games best known for its Spiderman series <strong>of</strong> titles. Krauss credits<br />

his fledgling career to the work he did in CIS. “The program allowed me<br />

to study topics specific to my area <strong>of</strong> interest under the tutelage and advice<br />

<strong>of</strong> experienced pr<strong>of</strong>essors,” he says. “This education allowed me to obtain the dream job I have today. With my<br />

background, I was able to quickly come up to speed on Treyarch’s current processes. In the future, I hope to further<br />

shape our s<strong>of</strong>tware development processes based on the concepts and theories I learned in the SE program.”<br />

2

FALL <strong>2005</strong><br />

William Grosky, Pr<strong>of</strong>essor and Chair, CIS<br />

William Grosky’s primary area <strong>of</strong> research, multimedia<br />

information systems, is essentially an extension <strong>of</strong><br />

classical database technology. While classical databases<br />

concern themselves largely with textual information,<br />

Grosky’s work allows the management <strong>of</strong> multimedia<br />

information. “Of course, one can always attach<br />

textual annotations to images or video information,”<br />

says Grosky, “but an image or a video always seems to<br />

have more information than a single person can extract.<br />

After all, an image or video can be interpreted in<br />

multiple contexts and mean many different things.”<br />

Grosky is currently working on projects related to the<br />

bioinformatics field. “The project I’m working on right<br />

now, supported by the Michigan Life Science Corridor in<br />

collaboration with Wayne State University and UM-Ann<br />

Arbor, concerns the construction <strong>of</strong> optimal surgical paths<br />

in a patient’s brain so that a neurosurgeon can efficiently<br />

remove a tumor without damaging the patient.” The techniques<br />

used rely on various data structures and algorithms<br />

devised by Grosky and his research team. A previous project<br />

used data mining techniques to predict protein interactions<br />

and was supported by the National Institute for Health.<br />

“With the growth <strong>of</strong> technology, multimedia assets<br />

have proliferated,” says Grosky, “making their efficient<br />

management a quite important research topic. The<br />

techniques we use are many, including data mining<br />

and various statistical approaches. I really like the<br />

way different areas mesh in this field.”<br />

<strong>Computer</strong> and Information Science<br />

Graduate Degree Programs<br />

• MS in <strong>Computer</strong> and Information Science<br />

• MS in S<strong>of</strong>tware <strong>Engineer</strong>ing<br />

For more information, contact William Grosky<br />

at wgrosky@umich.edu or 313-436-9145.<br />

Qiang Zhu, Associate Pr<strong>of</strong>essor, CIS<br />

One <strong>of</strong> Qiang Zhu’s current projects, sponsored by<br />

the National Science Foundation (NSF), involves the<br />

development <strong>of</strong> techniques to support efficient<br />

similarity queries in non-ordered discrete data spaces<br />

(NDDS). This project is a collaborative research effort<br />

between Michigan State University and UM-<strong>Dearborn</strong>.<br />

“Similarity searches in NDDSs are becoming increasingly<br />

important in areas such as bioinformatics, biometrics,<br />

and E-commerce,” says Zhu. “But they require robust<br />

indexing techniques, and unfortunately existing<br />

methods can’t be directly applied to them or have<br />

suboptimal performance. At present, we have developed<br />

two novel index trees to address these problems. Our<br />

theoretical and empirical studies thus far show that these<br />

techniques show a lot <strong>of</strong> promise, and we expect that the<br />

research results from the project will have a significant<br />

impact on indexing techniques in the database field.”<br />

Zhu’s other research focuses on query optimization,<br />

multidatabases, self-managing databases, and data mining,<br />

which has been supported by sponsors that include NSF,<br />

IBM, and Ford Motor Company. He has received multiple<br />

awards, including the UM-<strong>Dearborn</strong> Distinguished Faculty<br />

Research Award, the IBM Partnership Research Award, and<br />

the IBM Faculty Award. “I like to choose research areas<br />

that are not only important from a theoretical point <strong>of</strong> view<br />

but are also valuable from a practical perspective,” he says.<br />

“I enjoy dealing with challenging issues that could lead to<br />

significant results in the field.”<br />

3

DEARBORN <strong>Engineer</strong><br />

Electrical and <strong>Computer</strong> <strong>Engineer</strong>ing<br />

Graduate Programs: Building<br />

Partnerships that Extend Knowledge<br />

The Department <strong>of</strong> Electrical and <strong>Computer</strong><br />

<strong>Engineer</strong>ing (ECE) <strong>of</strong>fers rigorous programs<br />

where, as chair Malayappan Shridhar says, “hard work<br />

and conscientious effort are the only factors that affect<br />

our students’ progress.” The hard work is shared between<br />

faculty and students, he continues. “Ultimately, it is the<br />

interaction between the faculty, who try to extend the<br />

frontiers <strong>of</strong> knowledge, and students, with fresh and creative<br />

ideas, that contributes to new knowledge and discoveries.<br />

At the graduate level, it is always a partnership.”<br />

The department <strong>of</strong>fers two graduate degree programs<br />

that lead to a master <strong>of</strong> science in engineering: one<br />

focuses on electrical engineering, while the other<br />

concentrates on computer engineering. Currently, nearly<br />

140 graduate students are enrolled in the two programs.<br />

Since the field <strong>of</strong> electrical engineering is vast, students<br />

narrow their studies to one <strong>of</strong> four subcategories: control<br />

systems, which deals with the automated control <strong>of</strong><br />

processes; digital signal processing, including digital<br />

audio, filtering, and image processing; intelligent systems,<br />

which includes machine intelligence, neural networks,<br />

pattern recognition, and data mining; and automotive<br />

electronics, covering such subjects as sensors, actuators,<br />

and the control <strong>of</strong> electric vehicles.<br />

The computer engineering program <strong>of</strong>fers four concentrations<br />

as well, including s<strong>of</strong>tware development, hardware design<br />

and computer architecture, computer networks and data<br />

communications, and intelligent systems.<br />

“<strong>Computer</strong> engineering evolved out <strong>of</strong> the two fields<br />

<strong>of</strong> electrical engineering and computer science,” says<br />

Shridhar. “As a result, there can be significant overlap<br />

among electrical engineering, computer engineering, and<br />

computer science.”<br />

Students are encouraged to get involved in research with<br />

faculty who keep close ties to business. “We invite prominent<br />

practitioners from industry to be part <strong>of</strong> our teaching<br />

team,” says Shridhar. “We have been especially lucky<br />

to have some excellent adjunct faculty to help us here.”<br />

Research support comes from such industry giants as Ford<br />

Motor Company, Lear Corporation, and the U.S. military.<br />

The department <strong>of</strong>fers from 10 to 12 courses each term.<br />

Students complete 30 hours <strong>of</strong> course work, including projects<br />

and theses, but the department allows a fair amount <strong>of</strong><br />

flexibility within these constraints. “We use our requirements<br />

more as guidelines than as rigid rules,” says Shridhar.<br />

As with all the departments at CECS, ECE prizes a multidisciplinary<br />

approach to its graduate programs. “Overlap is very<br />

desirable in a learning environment,” says Shridhar, “and the<br />

synergy works to the advantage <strong>of</strong> all. For example, our course<br />

on embedded systems brings different engineers and scientists<br />

into one classroom, where each student focuses on one key<br />

aspect <strong>of</strong> embedded systems that includes real-time operating<br />

systems (computer scientists), hardware and s<strong>of</strong>tware<br />

compatibility (electrical and computer engineers), and s<strong>of</strong>tware<br />

development and maintenance (s<strong>of</strong>tware engineers). And<br />

when students from various disciplines work together on a<br />

project, their different<br />

perspectives<br />

enhance their<br />

overall experience.”<br />

Karl Kennedy, MSE in Electrical <strong>Engineer</strong>ing, <strong>2005</strong><br />

Karl Kennedy came to his graduate studies with a solid background in PC<br />

s<strong>of</strong>tware development, embedded s<strong>of</strong>tware development, and control systems, but<br />

he wanted to branch out and gain application experience in pattern recognition.<br />

While earning his master’s degree in electrical engineering, Kennedy worked full time<br />

as a senior engineer at Lear Corporation doing advanced product development for<br />

embedded systems “I appreciated the excellent balance that ECE <strong>of</strong>fered in terms <strong>of</strong><br />

subject theory, application, and research,” he says. “I also liked being able to interact<br />

with other students working in the industry. The program is geared toward the<br />

working student by <strong>of</strong>fering night and online classes, which was helpful.”<br />

“There are so many areas in which to do research and not enough students to do it all,” MALAYAPPAN SHRIDHAR AND KARL KENNEDY<br />

he says. “The pr<strong>of</strong>essors have such a broad range <strong>of</strong> research experience and interests. I<br />

especially enjoyed the opportunity to work on industry-related projects and being able to pursue research that related to my work.”<br />

4<br />

Kennedy’s time at CECS demonstrated to him the importance <strong>of</strong> continuing his education. “You’ll become a dinosaur as an<br />

engineer if you don’t,” he says. “ECE does a good job <strong>of</strong> keeping in touch with engineering advancements.”

FALL <strong>2005</strong><br />

Paul Richardson, Associate Pr<strong>of</strong>essor, ECE<br />

Paul Richardson is working closely with assistant<br />

pr<strong>of</strong>essor Weidong Xiang to study various issues related<br />

to wireless communications. “One new frontier we’re<br />

exploring is wireless networks in embedded systems with<br />

the aim <strong>of</strong> reducing infrastructure cost,” says Richardson.<br />

“Traditional wireless aims at moving voice and data<br />

for mobile users. We have much tighter reliability<br />

constraints, but our mobility issues are much simpler.”<br />

One area they are studying is “drive-by-wireless,”<br />

which would replace conventional wired communications<br />

in automotive systems with wireless links.<br />

Other research efforts include<br />

the development <strong>of</strong> a low-cost<br />

robotic sensor platform and a<br />

tracking system that uses radio<br />

signals to track the location <strong>of</strong><br />

pedestrians in the vicinity <strong>of</strong><br />

an autonomous vehicle. An<br />

additional project explores an<br />

innovative approach to achieve<br />

a flexible real-time network.<br />

Yi Lu Murphey,<br />

Pr<strong>of</strong>essor, ECE<br />

Yi Lu Murphey’s current research<br />

projects have spanned a wide range<br />

<strong>of</strong> areas, including developing<br />

computer vision systems for robotic<br />

vehicles, incremental learning in<br />

neural networks, hybrid learning<br />

systems with neural networks and<br />

genetic algorithms, support vector machine learning<br />

from large data sets, and data mining from text<br />

documents and time series data.<br />

Today her research concentrates primarily on computer<br />

vision and machine learning as they apply to robotic vehicle<br />

systems, vehicle diagnostics, health monitoring, and vehicle<br />

power management. “Right now, I’m applying my research<br />

in computer vision to unmanned ground vehicles in military<br />

applications as well as to intelligent commercial vehicle<br />

systems,” she says.<br />

Regarding her investigations, Murphey adds, “Graduate<br />

students are critical to my research success. They perform<br />

programming work and conduct all the experiments needed<br />

to validate ideas.”<br />

“It’s interesting to hear the<br />

views <strong>of</strong> people from different<br />

cultures and backgrounds,”<br />

says Richardson about working<br />

with graduate students<br />

and other faculty. “The nice<br />

thing about a university, and<br />

maybe about engineering in<br />

general, is that we can disagree<br />

and nobody has to be wrong.<br />

This creates an open<br />

environment where ideas flow freely. <strong>Engineer</strong>ing has<br />

taught me that the there are many solutions to a problem,<br />

each with numerous trade-<strong>of</strong>fs that have relative values<br />

dependent on environmental and contextual parameters.<br />

The key to making wise decisions—to being right, in other<br />

words—is to understand the environment and make wise<br />

trade-<strong>of</strong>fs. A good solution <strong>of</strong>ten emerges as we gain a<br />

better understanding <strong>of</strong> the environment and the real<br />

problem, as opposed to what we thought was the problem<br />

when we first started. In our meager way, we have added<br />

a few bricks to the vast wall <strong>of</strong> knowledge.”<br />

Electrical and <strong>Computer</strong> <strong>Engineer</strong>ing<br />

Graduate Degree Programs<br />

• MSE in Electrical <strong>Engineer</strong>ing<br />

• MSE in <strong>Computer</strong> <strong>Engineer</strong>ing<br />

For more information, contact Malayappan Shridhar<br />

at mals@umich.edu or 313-593-5420.<br />

5

DEARBORN <strong>Engineer</strong><br />

Industrial and Manufacturing Systems<br />

<strong>Engineer</strong>ing Graduate Programs:<br />

Tailoring Curriculum to <strong>Engineer</strong>s<br />

The Department <strong>of</strong> Industrial and<br />

Manufacturing Systems <strong>Engineer</strong>ing<br />

(IMSE) <strong>of</strong>fers three graduate programs:<br />

industrial and systems engineering (ISE), engineering<br />

management (EM), and information systems and technology<br />

(IST). IMSE also <strong>of</strong>fers a dual program with the School<br />

<strong>of</strong> Management that results in both an MSE in engineering<br />

in industrial and systems engineering and an MBA; this<br />

program is hosted by the School <strong>of</strong> Management.<br />

Industrial and systems engineering is the department’s<br />

oldest graduate program, dating back to the late<br />

1970s. The other two are joint programs: engineering<br />

management with the School <strong>of</strong> Management and<br />

information systems and technology with the Department<br />

<strong>of</strong> <strong>Computer</strong> and Information Science.<br />

“Our engineering management and information systems<br />

and technology programs developed out <strong>of</strong> the recognition<br />

that existing MBA and information technology programs<br />

weren’t meeting the needs <strong>of</strong> engineers in industry,” says<br />

Swatantra Kachhal, department chair. “For example, MBA<br />

programs include several accounting courses. But an<br />

engineer needs only sufficient accounting knowledge to<br />

be able to interpret financial statements and deal<br />

effectively with accounting departments. The EM program<br />

covers core areas <strong>of</strong> an MBA degree in a series <strong>of</strong> twoto<br />

three-credit-hour courses that contain the essentials.<br />

Industry representatives worked very closely with<br />

engineering and management faculty to develop the<br />

curricula for this program. That’s why we feel they’re very<br />

much in line with the needs in the market and in industry.<br />

Our engineering management program is now one <strong>of</strong> the<br />

ten largest in the country.”<br />

The information systems and technology program<br />

was also developed as a response to industry needs.<br />

“Typically,” says Kachhal, “we’ll have information science<br />

people who come out <strong>of</strong> a more technical, computer<br />

science background not knowing much about applications,<br />

and then we’ll have graduates <strong>of</strong> information system<br />

programs from business schools who know about<br />

application s<strong>of</strong>tware but do not have a strong background<br />

in IT. We realized we needed a program somewhere in<br />

the middle.” The IST program combines information<br />

technology courses with application courses<br />

incorporating enterprise systems, such as SAP. Students<br />

learn how to take s<strong>of</strong>tware available on the market and<br />

modify it to make it fit into any company’s processes.<br />

Each program consists <strong>of</strong> a combination <strong>of</strong> core courses,<br />

concentration courses, outside courses, electives, and,<br />

potentially, research and theses. In the ISE program,<br />

current topics range from human factors, ergonomics,<br />

and quality to statistics, mathematical and simulation<br />

modeling, and lean manufacturing.<br />

“Most <strong>of</strong> our students work full time,” says Kachhal.<br />

“What they learn here has a great deal <strong>of</strong> practical<br />

relevance. They learn, they read, they research, and<br />

then they apply what they’ve learned right away. This<br />

is important for them and for their companies.”<br />

Lisa Marie Floros, MSE in Industrial and Systems <strong>Engineer</strong>ing, 2000<br />

After earning her undergraduate degree from IMSE with a focus on manufacturing, Lisa Marie<br />

Floros decided to broaden her horizons. “My interest in more <strong>of</strong> a big-picture view <strong>of</strong> how<br />

a complete system comes together persuaded me to get a master’s in industrial and systems<br />

engineering,” says Floros. “Having a larger view, with a higher level <strong>of</strong> analysis, gave me<br />

the desire to head down the management path toward the business side <strong>of</strong> the industry.”<br />

Floros worked full time at Visteon while earning her degree, where she designed a new<br />

manufacturing assembly line for the Ford Focus front and rear fascias. She brought<br />

what she learned at IMSE to the job each day. “I had to consider everything from line<br />

balancing <strong>of</strong> operator tasks to ergonomics <strong>of</strong> the individual workstations,” she says.<br />

Currently a systems engineer in Visteon’s advanced engineering organization, Floros<br />

continues to draw from her education. “My education had an immediate impact<br />

on my job while I was in school,” she says, “and the general concepts I learned<br />

regarding problem solving, communication, and organization have<br />

continued to help me today.”<br />

6

FALL <strong>2005</strong><br />

Industrial and Manufacturing<br />

Systems <strong>Engineer</strong>ing Graduate<br />

Degree Programs<br />

• MS in <strong>Engineer</strong>ing Management<br />

• MS in Information Systems and Technology<br />

• MSE in Industrial and Systems <strong>Engineer</strong>ing<br />

• MSE/MBA in Industrial and Systems <strong>Engineer</strong>ing<br />

and Business Administration<br />

For more information, contact Swatantra Kachhal<br />

at kachhal@umich.edu or 313-593-5361.<br />

Armen Zakarian,<br />

Associate Pr<strong>of</strong>essor, IMSE<br />

In his current research projects, Armen Zakarian<br />

develops s<strong>of</strong>tware tools that serve both industry<br />

and the military. One project facilitates<br />

intelligent design in manufacturing through data<br />

mining, or extracting knowledge from large sets<br />

<strong>of</strong> data, in order to support process improvement.<br />

“Manufacturing and assembly plants currently<br />

capture millions <strong>of</strong> pieces <strong>of</strong> data and store them<br />

in databases,” says Zakarian. “But because there<br />

are no effective tools to extract knowledge from<br />

these databases, the information never gets used<br />

effectively. People are unable to look back historically<br />

at data and ask, what does this tell us? The tools<br />

we’re creating look to identify patterns and improve,<br />

for example, an assembly process based on what<br />

happened in the past.”<br />

Another project, in partnership with the U.S. military,<br />

was initiated to design s<strong>of</strong>tware that allows<br />

personnel in the field to reconstruct the original<br />

shape <strong>of</strong> a broken vehicle part. The part can then<br />

be created, using a spray forming process that is<br />

also currently under development in the college.<br />

Zakarian’s other major focus, working with<br />

automotive companies to develop methodologies,<br />

algorithms, and s<strong>of</strong>tware for modular product/<br />

architecture design, allows vehicle systems engineers<br />

to develop modular, low-cost vehicle architectures<br />

that can be shared across vehicle platforms (for<br />

OEMs) and across OEMs (for suppliers).<br />

He credits graduate students for much <strong>of</strong> his work.<br />

“Without them, we couldn’t even have done 15 percent<br />

<strong>of</strong> what we’ve been able to do,” he says. “You have<br />

ideas, but they’re the ones who bring them to life.”<br />

Ghassan Kridli, Associate Pr<strong>of</strong>essor, IMSE<br />

Ghassan Kridli’s interest in materials and manufacturing resulted<br />

from growing up on a poultry farm in Jordan, where replacement<br />

parts for farm machinery were in short supply. “I learned<br />

how to manufacture temporary parts that could be used until<br />

spare parts arrived,” he says. His early experience in sheet metal<br />

forming, welding, casting, and machining led him directly to the<br />

research projects on which he works today.<br />

One project involves collaborating with Ford Motor Company<br />

in developing its super-plastic forming technology. Kridli and<br />

his team <strong>of</strong> students have spent the past three years focusing<br />

on material characterization and process simulation with<br />

a goal <strong>of</strong> developing a material model that captures how the<br />

material would respond in various situations. With a more<br />

accurate model, Kridli’s team will be able to create a computer<br />

simulation that more accurately predicts results.<br />

Kridli has recently been involved with a number <strong>of</strong> other projects<br />

that involve studying the formability and behavior <strong>of</strong> materials,<br />

such as sheet metal and thermoplastic matrix composites,<br />

and their manufacturing feasibility for various uses. He has also<br />

worked on designing the body structure for the low-mass vehicle<br />

being created by the Institute for Advanced Vehicle Systems.<br />

7

DEARBORN <strong>Engineer</strong><br />

Mechanical <strong>Engineer</strong>ing Graduate<br />

Program: Designing the Future<br />

The mechanical engineering graduate studies<br />

program may begin with fundamentals, but<br />

the department’s ultimate goal is to produce engineers<br />

who can creatively apply those fundamentals to develop<br />

innovative mechanical systems. “We have a very exciting<br />

graduate program, which continues to evolve,” says Ben<br />

Li, chair <strong>of</strong> the department. “We teach our students to<br />

be more creative in order to become competitive in<br />

industry. Labor is very expensive. To keep manufacturing<br />

costs down, you have to find ways to be more innovative<br />

than the competition in order to stay ahead. We teach<br />

our students to find those ways, which in turn makes<br />

them more desirable to industry.”<br />

Mechanical engineering graduate students focus on one<br />

<strong>of</strong> three major areas: thermal and fluid sciences,<br />

mechanical systems, or manufacturing. Approximately<br />

half <strong>of</strong> their coursework emphasizes their chosen area <strong>of</strong><br />

study, while the other half is made up <strong>of</strong> classes from the<br />

other mechanical engineering disciplines as well as other<br />

departments. “We want our students to gain a wider<br />

exposure to other fields,” says Li, “so they’ll have a<br />

more diversified background from which to draw.”<br />

Students are given the option to do a research thesis as well.<br />

Opportunities for research currently include a wide variety<br />

<strong>of</strong> faculty projects dealing with such topics as hydrogen fuel<br />

cells, the manufacture <strong>of</strong> artificial bones, fundamental issues<br />

related to turbulence and its effect on vehicles, the effects<br />

<strong>of</strong> gravity and weightlessness on various materials, and<br />

improving fuel economy through the manufacture <strong>of</strong> better<br />

automotive powertrains. Sponsors include the Department<br />

<strong>of</strong> Defense, the Department <strong>of</strong> Energy, the National Science<br />

Foundation, and automotive companies.<br />

“In southeastern Michigan, our two main industries are<br />

automotive and manufacturing,” says Tariq Shamim, associate<br />

pr<strong>of</strong>essor <strong>of</strong> mechanical engineering and chair <strong>of</strong> the department’s<br />

graduate studies committee. “Most <strong>of</strong> our research,<br />

although widely diversified, is somehow related to issues<br />

relevant to those two industries. We have unique expertise.”<br />

With the oldest graduate program at UM-<strong>Dearborn</strong>, the<br />

mechanical engineering department has long accommodated<br />

the working student. Its courses are primarily<br />

<strong>of</strong>fered in the evening hours, and the students’ pr<strong>of</strong>essional<br />

expertise is highly valued in the classroom. “When<br />

students bring their industry experience to the classroom,<br />

they enrich the discussion,” says Shamim. “They bring<br />

practical problems they encounter at work, and we help<br />

them solve them. It’s definitely one <strong>of</strong> the more positive<br />

aspects <strong>of</strong> the program.”<br />

“Teaching here is exciting,” says Li. “There’s a certain<br />

fulfillment in helping students apply what they learn,<br />

then come back and share with us what they encounter.<br />

You have the opportunity to help them enhance their<br />

knowledge and their careers, and at the same time you<br />

get to keep up with developments in industry. This kind<br />

<strong>of</strong> interaction is beneficial and unique for our graduate<br />

program. And by providing them with the tools to make<br />

themselves and the region competitive, you’re helping<br />

the next generation <strong>of</strong> engineers design the future.”<br />

Vahram Avagyan, MS in <strong>Computer</strong> and Information Science, <strong>2005</strong><br />

Through his research with mechanical engineering associate pr<strong>of</strong>essor Pravansu<br />

Mohanty, Vahram Avagyan has been able to apply his interest in computer science<br />

to challenging, real-world mechanical engineering and manufacturing problems.<br />

Avagyan helped Mohanty develop s<strong>of</strong>tware for rapid manufacturing systems.<br />

“There are a lot <strong>of</strong> mathematical problems involved in supporting rapid<br />

manufacturing,” says Avagyan. “You have to look at a damaged part from<br />

various angles and try to work with the mathematical properties <strong>of</strong> that part,<br />

like its symmetry, in order to project its complete shape.”<br />

8<br />

Avagyan came to UM-<strong>Dearborn</strong> primarily to work with Mohanty and was funded<br />

through the project. “I’m interested in applying interesting new theories <strong>of</strong><br />

computer science to very practical problems,” he says. “That was the most<br />

exciting aspect <strong>of</strong> this project, and it’s why I came here.”

FALL <strong>2005</strong><br />

Mechanical <strong>Engineer</strong>ing<br />

Graduate Degree Program<br />

• MSE in Mechanical <strong>Engineer</strong>ing<br />

For more information, contact Ben Li at<br />

benqli@umich.edu or 313-593-5241.<br />

Pravansu Mohanty, Associate Pr<strong>of</strong>essor, ME<br />

Pravansu Mohanty’s research deals primarily with<br />

on-demand custom manufacturing. A few years ago, he<br />

started working on this technology to develop custom<br />

components for military vehicles that break down in<br />

the field. This rapid manufacturing process looks at an<br />

incomplete or broken part and figures out how to<br />

complete it so that it can be rebuilt quickly and deployed<br />

immediately. Applications for his work now include tank<br />

components, missile defense system components, human<br />

prosthetics, and rapid prototyping <strong>of</strong> fuel cell components.<br />

“We have developed a deposition system that can consolidate<br />

two or more widely varying materials into a net shape based<br />

on a predetermined composition pr<strong>of</strong>ile,” says Mohanty.<br />

“The materials are called functionally gradient materials<br />

(FGM), and there’s great demand for this technology.”<br />

One critical component in Mohanty’s research has been<br />

the translation <strong>of</strong> CAD data into useful manufacturing<br />

information. Over the past three years, graduate students<br />

have worked with him to develop s<strong>of</strong>tware to do this.<br />

“The most meaningful interactions that I’ve had with<br />

students have come through research projects,” says<br />

Mohanty. “Research makes university life exciting for<br />

faculty as well as for the students.”<br />

Oleg Zikanov, Associate Pr<strong>of</strong>essor, ME<br />

Most <strong>of</strong> Oleg Zikanov’s various research projects deal with the<br />

turbulent flows <strong>of</strong> fluids. “These kinds <strong>of</strong> flows are difficult to<br />

analyze,” says Zikanov. “They are nonlinear and chaotic. You<br />

have to do either experiments or computations.” He develops<br />

computer models to predict the flows <strong>of</strong> liquid metals, such<br />

as steel or aluminum, and manufactured or cast materials like<br />

melted silicone.<br />

The main applications for Zikanov’s work are in steel<br />

casting and aluminum manufacturing. “If you optimize the<br />

process,” he says, “if you make better materials, you can<br />

avoid extra steps in the manufacturing. With aluminum,<br />

this is particularly important because you have to spend a<br />

tremendous amount <strong>of</strong> electrical energy to make it. If we<br />

can provide a better predicting tool, we can help industry<br />

optimize the process, save some energy, and produce<br />

better-quality, stronger materials.”<br />

Zikanov’s model was introduced at some Alcoa plants,<br />

helping its engineers to rearrange the electrical conductive<br />

wire in aluminum reduction cells in order to optimize the<br />

shape <strong>of</strong> the magnetic field. “Optimizing the shape <strong>of</strong> the<br />

magnetic field provides the lowest consumption <strong>of</strong> electrical<br />

energy,” he says, “and the lowest emission <strong>of</strong> one particular<br />

greenhouse gas. They are using our model today. Every day,<br />

we continue to discover something really exciting.”<br />

9

DEARBORN <strong>Engineer</strong><br />

Interdisciplinary Programs:<br />

Seeing the Bigger Picture<br />

Recognizing the importance <strong>of</strong> breadth<br />

across multiple engineering and<br />

business fields as well as depth in the area <strong>of</strong><br />

automotive engineering, the <strong>College</strong> <strong>of</strong> <strong>Engineer</strong>ing<br />

and <strong>Computer</strong> Science’s interdisciplinary programs<br />

(IDP) were developed to take advantage <strong>of</strong> resources<br />

from departments throughout the school. The<br />

interdisciplinary graduate degrees include a master<br />

<strong>of</strong> science in engineering in automotive systems<br />

engineering (ASE) and a master <strong>of</strong> science in engineering<br />

in manufacturing systems engineering (MSE). A<br />

doctor <strong>of</strong> engineering in manufacturing engineering,<br />

<strong>of</strong>fered through the Ann Arbor campus, is also a part<br />

<strong>of</strong> IDP. Each <strong>of</strong> these programs provides industrially<br />

relevant engineering design or research experience<br />

through coursework and projects or thesis.<br />

The graduate degree in automotive systems engineering<br />

is particularly unusual. “I can think <strong>of</strong> only two universities<br />

in the country that <strong>of</strong>fer this degree,” says P. K.<br />

Mallick, pr<strong>of</strong>essor <strong>of</strong> mechanical engineering and director<br />

<strong>of</strong> interdisciplinary programs. The ASE program is geared<br />

toward the automotive industry, providing in-depth knowledge<br />

on the technology that goes into making automobiles,<br />

including vehicle dynamics, energy systems, lightweight<br />

materials, electric and hybrid vehicles, and electronics. “The<br />

program is very interdisciplinary in nature because a car is an<br />

interdisciplinary product,” says Mallick. “Students have the<br />

opportunity <strong>of</strong> looking at a vehicle as a system; we look at the<br />

big picture first and then delve deeper.”<br />

While the ASE program emphasizes design, the master’s<br />

program in manufacturing emphasizes bringing designs to<br />

life. “There are overlapping courses between the two fields,”<br />

says Mallick. “You don’t just design something; you also<br />

manufacture it. The manufacturing program also goes beyond<br />

automobiles. It takes a systems approach, where students<br />

look at not only the machinery <strong>of</strong> manufacturing products<br />

but also how to design the product that gets manufactured.”<br />

Interdisciplinary Graduate<br />

Degree Programs<br />

GRADUATE STUDENTS BRENT RAJANIEMI, GARUN AGARWAL,<br />

ASHWIN DHARAP, AND SANGEETA GUPTA<br />

Supporting these programs is a handful <strong>of</strong> leading-edge<br />

centers, including the Institute for Advanced Vehicle Systems<br />

(IAVS) and the Center for Lightweight Automotive Materials<br />

and Processing (CLAMP). When it was founded in 1998<br />

with grants from the U.S. Department <strong>of</strong> Energy’s Graduate<br />

Automotive Technology Education program, UM-<strong>Dearborn</strong>’s<br />

CLAMP was the first center in the country devoted to the<br />

study <strong>of</strong> lightweight materials. Today the center provides<br />

research fellowships and assistantships to graduate students<br />

interested in learning about not just lightweight materials<br />

themselves but how to apply them in a real-world context, in<br />

particular through the IAVS low-mass vehicle project.<br />

The center also <strong>of</strong>fers courses on lightweight materials such<br />

as aluminum and magnesium alloys, composite materials, and<br />

plastics. More recently, the center is also starting to study<br />

materials for fuel cells and materials for “green” or environmentally<br />

conscious engineering design. One <strong>of</strong> its most<br />

important activities involves compiling the latest research<br />

on lightweight materials into its web-based automotive<br />

materials database so that information is easy to find and<br />

accessible to both academia and industry.<br />

• MSE in Automotive Systems <strong>Engineer</strong>ing<br />

• MSE in Manufacturing Systems <strong>Engineer</strong>ing<br />

• Doctor <strong>of</strong> <strong>Engineer</strong>ing in Manufacturing<br />

For more information, contact P. K. Mallick at<br />

pkm@umich.edu or 313-593-5582.<br />

“One <strong>of</strong> the great strengths <strong>of</strong> the center is that it provides<br />

students with the opportunity to work on problems really<br />

related to the automotive industry,” says Mallick. “They get<br />

to interact with engineers and researchers with automotive<br />

companies and apply what they learn to major issues facing<br />

the industry today.”<br />

10

FALL <strong>2005</strong><br />

IAVS Offers Graduate Students Interdisciplinary,<br />

Real-World Research Experience<br />

The Institute for Advanced Vehicle Systems<br />

(IAVS) was created to advance education and<br />

research related to systems issues in the automotive<br />

industry. “It became clear as technology moved out to the<br />

supplier community,” says Dean Subrata Sengupta, “that<br />

systems integration skills and the ability to think in a<br />

systemic way, especially with regard to OEMs and applied<br />

technologies, were skill sets that simply were not being<br />

developed in most institutions. So we created IAVS to ensure<br />

that students and faculty would be challenged to think<br />

about entire systems rather than just in individual pieces.”<br />

To that end, IAVS maintains a strong interdisciplinary<br />

approach to applied research, ensuring that students and<br />

faculty from multiple disciplines work together and with<br />

industry representatives on each project. The institute<br />

<strong>of</strong>fers the opportunity to take a fresh look at the way<br />

automobiles are designed, developed, manufactured,<br />

and marketed as well as the infrastructure used in these<br />

processes, including supply base, prototyping and<br />

engineering services, enterprise and financial systems,<br />

and distribution networks.<br />

“IAVS also <strong>of</strong>fers an environment for all levels <strong>of</strong> the<br />

auto industry to explore the application <strong>of</strong> the latest<br />

technological advances and novel ideas that may lead to<br />

meeting project objectives,” says Roger Shulze, director<br />

<strong>of</strong> IAVS. “Right now, we’re focusing on how to design,<br />

develop, build, and manufacture a low-mass vehicle,<br />

so we’re especially looking at issues such as reduced<br />

weight, reduced energy consumption, reduced environmental<br />

impact, and low-volume manufacturing.”<br />

The low-mass vehicle, the foundational project <strong>of</strong> IAVS, aims<br />

to be 30 percent lower in mass than vehicles like the Ford<br />

Focus and the Toyota Echo.<br />

The low-mass vehicle<br />

will be aerodynamic,<br />

with an efficient body and chassis design and affordable<br />

manufacturing alternatives. To that end, IAVS explores<br />

issues such as auto body design and manufacturing; lightweight<br />

materials; rapid prototyping; energy management;<br />

safety concerns and crash-worthiness; ride, handling, and<br />

stability; aerodynamics; modular construction; and supply<br />

chain management.<br />

“We aim to provide a place where industry can conduct<br />

projects and develop concepts in conjunction with faculty<br />

and students in a low-risk environment,” says Shulze.<br />

“Graduate students can take advantage <strong>of</strong> this opportunity<br />

to work on real-world problems and solve real-world issues,<br />

much like those they will encounter when they enter the<br />

industrial workforce. They can work with other graduate<br />

students from a broad spectrum <strong>of</strong> disciplines who may be<br />

working on their own research projects but are nevertheless<br />

tied together in a common theme—the design and<br />

development <strong>of</strong> a low-mass vehicle.”<br />

As part <strong>of</strong> its mission to focus on the big picture, IAVS also<br />

<strong>of</strong>fers students and faculty the opportunity to collaborate<br />

not only with industry but also with other institutions, such<br />

as the <strong>College</strong> for Creative Studies in Detroit and RWTH<br />

Aachen University in Germany. Through IAVS’s Automotive<br />

Design Studio, engineering students work with industrial<br />

design students to flesh out each other’s expertise and<br />

create more fully developed automotive design concepts.<br />

Graduate students from throughout CECS may participate<br />

in IAVS projects. “IAVS <strong>of</strong>fers students the opportunity<br />

to participate in cutting-edge automotive<br />

research,” says Shulze, “and the chance<br />

to gain experience in the design and<br />

development <strong>of</strong> complex automotive<br />

systems, experience that will make<br />

them more in demand as they<br />

seek jobs following graduation.”<br />

11

DEARBORN <strong>Engineer</strong><br />

Ford Continues Its Partnership<br />

with IAVS through Generous Pledge<br />

DANIEL LITTLE, UM-D CHANCELLOR; ROMAN KRYGIER, GROUP VICE PRESIDENT OF GLOBAL MANUFACTURING AND QUALITY, FORD MOTOR<br />

COMPANY; AND SUBRATA SENGUPTA, DEAN, AT THE SITE OF THE NEW BUILDING THAT WILL HOUSE IAVS<br />

With a generous pledge through its Ford<br />

Motor Company Fund, Ford has reaffirmed its<br />

commitment to the Institute for Advanced Vehicle<br />

Systems (IAVS) and its cross-disciplinary, systemic<br />

approach to automotive design and development.<br />

Ford’s pledge <strong>of</strong> $800,000 over the next five years will<br />

help ensure the permanence <strong>of</strong> IAVS and its objectives<br />

<strong>of</strong> supporting research and education in complex vehicle<br />

systems. The first pledge installment took place this year.<br />

“I’m delighted about Ford’s gift,” says Roger Shulze,<br />

director <strong>of</strong> IAVS. “Ford has been with IAVS almost from<br />

its beginning, and this gift means that it will continue to<br />

be a partner for years to come. This gift will go a long way<br />

to help assure the continued success <strong>of</strong> the institute.”<br />

Approximately three quarters <strong>of</strong> the money will fund<br />

projects related to the institute’s keystone project, the<br />

low-mass vehicle, an experimental car roughly the size<br />

<strong>of</strong> the Ford Focus but with 30 percent less mass. Current<br />

projects include a parametric model that will reduce the<br />

time required to design a new vehicle; a parametric<br />

analysis <strong>of</strong> the low-mass vehicle’s seat structure; design<br />

and analysis <strong>of</strong> its brake system, including brake-by-wire<br />

(or wireless) reliability; and a capstone design project<br />

involving analysis <strong>of</strong> its dual sliding doors.<br />

The rest <strong>of</strong> the gift will support continued collaborative<br />

learning among the University <strong>of</strong> Michigan-<strong>Dearborn</strong><br />

and other schools worldwide, such as the <strong>College</strong> for<br />

Creative Studies (CCS) in Detroit. Students and staff at<br />

UM-<strong>Dearborn</strong> and CCS currently work together to design<br />

a variety <strong>of</strong> automotive components, including doors, ro<strong>of</strong><br />

modules, and center consoles.<br />

Key to making this gift happen was Roman Krygier, group<br />

vice president <strong>of</strong> global manufacturing and quality at<br />

Ford. Krygier, a member <strong>of</strong> the <strong>College</strong> <strong>of</strong> <strong>Engineer</strong>ing<br />

and <strong>Computer</strong> Science Visiting Committee, has been a<br />

longtime champion <strong>of</strong> UM-<strong>Dearborn</strong> and IAVS. “He has<br />

a truly strong dedication to the education <strong>of</strong> engineers,”<br />

says Dean Subrata Sengupta, “and to the continued<br />

development <strong>of</strong> facilities and people within the<br />

automotive industry, both in automotive manufacturing<br />

and in product development.” Doug Szopo, executive<br />

director <strong>of</strong> manufacturing and business strategy at Ford,<br />

also played a significant role bringing about this gift.<br />

“IAVS was created to address systems integration skills<br />

and the ability to think in a systemic way, a skill set<br />

that simply was not being developed in most institutions,”<br />

says Sengupta. “We wanted to ensure that students and<br />

faculty would be challenged to think about entire systems<br />

rather than pieces. Ford believes in this. Its gift will<br />

help keep a very fundamental trust <strong>of</strong> this college<br />

alive and well for the future.”<br />

12

FALL <strong>2005</strong><br />

DENSO Gift Provides<br />

New Climate Control Lab<br />

Through its North America Foundation,<br />

DENSO, a global supplier <strong>of</strong> automotive technology,<br />

systems, and components, has given $250,000<br />

to the <strong>College</strong> <strong>of</strong> <strong>Engineer</strong>ing and <strong>Computer</strong> Science.<br />

The gift, which will be delivered over a five-year<br />

period, will build the school’s new DENSO Climate<br />

Control Education and Research Laboratory.<br />

“As a strategy, we try to create the best<br />

instructional environment for functioning in the<br />

automotive industry,” says Dean Subrata Sengupta.<br />

“One <strong>of</strong> the areas we deal with involves automotive<br />

climate control. Equipment that will be purchased<br />

through DENSO’s significant gift will allow us to<br />

have one <strong>of</strong> the best automotive climate control<br />

facilities in any university.”<br />

Largely responsible for this donation are John<br />

Voorhorst, DENSO’s vice president <strong>of</strong> external<br />

affairs and president <strong>of</strong> the DENSO North America<br />

Foundation, and Barbara Wertheimer, secretary<br />

and program <strong>of</strong>ficer <strong>of</strong> the foundation.<br />

“This gift adds depth to our relationship with a<br />

major engineering program involved in teaching<br />

and research that’s right <strong>of</strong>f our song sheet,” says<br />

Voorhorst. “DENSO is a world leader in manufacturing<br />

car air conditioners. Additionally, we’re excited to<br />

have DENSO staff involved in development <strong>of</strong> the new lab.”<br />

Pat Bassett, DENSO’s director <strong>of</strong> climate control<br />

engineering, will be coordinating development <strong>of</strong><br />

the laboratory with Eric Ratts, CECS associate<br />

pr<strong>of</strong>essor <strong>of</strong> mechanical engineering.<br />

“I’m very excited about the generous contribution from the<br />

DENSO North America Foundation,” says Ratts. “The lab<br />

will only add to the excellent mechanical engineering<br />

education at the University <strong>of</strong> Michigan-<strong>Dearborn</strong> and<br />

provide additional learning experiences both through<br />

research and through instruction. It will now be possible<br />

to obtain the equipment we’ve needed for a long time and<br />

to develop the laboratory to enhance the mechanical<br />

engineering curriculum. Students will benefit from this gift<br />

for years to come.”<br />

The new lab will be used to facilitate research and other<br />

educational opportunities in the field <strong>of</strong> automotive climate<br />

control, which addresses the heating, air conditioning,<br />

defogging, and defrosting <strong>of</strong> vehicles. Students will be able<br />

ASSOCIATE PROFESSOR ERIC RATTS, DENSO PROGRAM OFFICER<br />

BARBARA WERTHEIMER, DEAN SUBRATA SENGUPTA, AND DENSO<br />

DIRECTOR OF CLIMATE CONTROL ENGINEERING PAT BASSETT<br />

to perform heat exchanger studies with a new wind tunnel,<br />

which will provide the necessary steady uniform airflow to<br />

measure heat exchanger performance. A thermal imaging<br />

camera will allow students to measure things like the<br />

temperature distribution <strong>of</strong> a heat exchanger in order to<br />

determine unwanted hotspots and make design corrections.<br />

Mechanical engineering core courses will use the<br />

new equipment to demonstrate external flow and heat<br />

transfer principles, and both students and faculty will<br />

be able to use the equipment for student design projects,<br />

guided studies, and faculty research.<br />

Development <strong>of</strong> the lab, which will be located in the<br />

<strong>Engineer</strong>ing Laboratory Building, has already begun<br />

and is expected to be completed within the coming year.<br />

13

DEARBORN <strong>Engineer</strong><br />

Welcome, New Visiting Committee Members<br />

ANGELO DIMITRIOU<br />

Vice President, Technology,<br />

Smiths Aerospace Systems<br />

Angelo Dimitriou is vice<br />

president <strong>of</strong> technology at<br />

Smiths Aerospace Systems,<br />

where he has worked since<br />

1967. His previous<br />

positions at Smiths<br />

Aerospace include vice<br />

president <strong>of</strong> engineering<br />

technology, electronic<br />

systems, where he<br />

was responsible for<br />

developing the core computing system for the Boeing<br />

787, and vice president <strong>of</strong> engineering and development<br />

programs, where he worked on the flight management<br />

system for Air Force One and the Airbus A320.<br />

Prior to joining Smiths Aerospace, Dimitriou held engineering<br />

positions at Honeywell and Ford Motor Company.<br />

Dimitriou received his bachelor’s degree in electrical<br />

engineering from UM-<strong>Dearborn</strong> in 1965 and his master’s<br />

degree in electrical engineering from Michigan State<br />

University in 1970. He is married with two sons and<br />

two grandchildren.<br />

KEVIN S. GAGNON<br />

Vice President,<br />

Automotive Business Unit,<br />

STMicroelectronics<br />

As vice president <strong>of</strong><br />

STMicroelectronics’<br />

automotive business unit<br />

since 2002, Kevin Gagnon<br />

maintains responsibility<br />

for that company’s North<br />

American automotive<br />

marketing, sales, business<br />

operations, quality, and<br />

technical services.<br />

guided his unit to become the company’s first field <strong>of</strong>fice<br />

to pass a third-party audit <strong>of</strong> their processes with no<br />

non-conformances.<br />

Gagnon graduated with a bachelor’s degree in mechanical<br />

engineering from UM-<strong>Dearborn</strong>.<br />

GARRICK HU<br />

Vice President, Advanced<br />

<strong>Engineer</strong>ing and Product<br />

Strategy, Commercial<br />

Vehicle Systems,<br />

ArvinMeritor, Inc<br />

Garrick Hu is vice<br />

president, advanced<br />

engineering and<br />

product strategy, for<br />

the commercial vehicle<br />

systems business<br />

group <strong>of</strong> ArvinMeritor<br />

Inc. In this position, he<br />

leads a consortium <strong>of</strong> advanced engineers and is<br />

responsible for creating a competitive advantage for<br />

the company through the mechanical and electronic<br />

integration <strong>of</strong> heavy-duty axles, drivelines, trailer systems,<br />

suspensions, brakes, and transmissions.<br />

With more than 30 years <strong>of</strong> experience in research, new<br />

product development, and advanced engineering with<br />

heavy truck OEMs, Hu joined ArvinMeritor in 2002. Prior<br />

to that, he was vice president, advanced engineering, for<br />

the Volvo Global Trucks Group in Gothenburg, Sweden.<br />

Before that, Hu held senior engineering positions with<br />

Mack Trucks, International Truck and Engine Company,<br />

Kenworth Truck Company, and PACCAR.<br />

A graduate <strong>of</strong> the University <strong>of</strong> Michigan with a bachelor’s<br />

degree in mathematics and computer science, as well as a<br />

master’s degree in mechanical engineering, Hu also holds<br />

an MBA from Chapman <strong>College</strong> in Orange, California.<br />

Prior to his current appointment, Gagnon held a variety <strong>of</strong><br />

management positions in sales and business operations at<br />

STMicroelectronics, which he joined as a quality engineer<br />

in 1995. During his time in the automotive business unit,<br />

he has presided over an organization that has consistently<br />

achieved double-digit growth each year. Additionally,<br />

in support <strong>of</strong> STMicroelectronics’ recent achievement <strong>of</strong><br />

attaining ISO/TS 16949 certification, Kevin successfully<br />

14

FALL <strong>2005</strong><br />

<strong>2005</strong> Co-op Employer<br />

<strong>of</strong> the Year: DENSO<br />

International America, Inc.<br />

DENSO International America, Inc. was named Cooperative<br />

Education Employer <strong>of</strong> the Year at the annual Cooperative<br />

Education Employer-Student Recognition Breakfast in May <strong>2005</strong>.<br />

The <strong>College</strong> <strong>of</strong> <strong>Engineer</strong>ing and <strong>Computer</strong> Science honored the<br />

DENSO organization for its long-time support and assistance in<br />

promoting and sustaining a quality cooperative education program.<br />

Subrata Sengupta, dean, presented the award to John<br />

Voorhorst, vice president <strong>of</strong> external affairs, DENSO International<br />

America Inc., and president, DENSO North America Foundation.<br />

“DENSO provides exceptionally high-quality, hands-on engineering<br />

learning experiences for our students and exemplifies the necessary<br />

commitment to student learning for pr<strong>of</strong>essional growth,” says<br />

cooperative education director Anthony DeLaRosa. “We are very<br />

grateful to DENSO for its support.”<br />

GEE PYE, HR RECRUITING SPECIALIST, DENSO; CHERYL SROKA,<br />

HR ADMINISTRATOR, DENSO; ANTHONY DELAROSA, COOPERATIVE<br />

EDUCATION DIRECTOR, CECS; AND JOHN VOORHURST, VICE PRESIDENT<br />

OF EXTERNAL AFFAIRS, DENSO<br />

For more information about the <strong>Engineer</strong>ing Cooperative Education Program at UM-<strong>Dearborn</strong>, go<br />

online to www.engin.umd.umich.edu/student_services/coop/ or contact Anthony DeLaRosa at<br />

delaroan@umich.edu or 313-593-5078.<br />

<strong>2005</strong>-2006 Scholarship Awards<br />

Detroit Edison Minority<br />

and Women Scholarship<br />

Rose Chambers<br />

Samantha Longfield<br />

Jennifer Ng<br />

David Roose<br />

Frederick P. and Violet<br />

Sharpe Endowed Scholarship<br />

Mohannad Abdulrahim<br />

Bilal Alasry<br />

Jeffrey Bremer<br />

Hyunwook Cho<br />

Shawn Kowaleski<br />

Eric Lammers<br />

Mehdi Paul Mazloom<br />

Fatwan Munaser<br />

Michael Ramey<br />

Daniel Strimpel<br />

DaimlerChrysler Minority<br />

and Women Scholarship<br />

Stephanie Askew<br />

Rimma Isayeva<br />

Anna Lee<br />

Lauren Marzolf<br />

Eva Moussa<br />

Robert L. Husak<br />

Memorial Scholarship<br />

Philip Gerrity<br />

Yuhan Li<br />

Henry W. Patton<br />

Endowed Scholarship<br />

Nicholas Asciutto<br />

Andrew Averhart<br />

Ali Ayoub<br />

Adam Bass<br />

Albert Borrego<br />

Daniel Bowden<br />

Chelsea Calderone<br />

Nicholas Calus<br />

Diana Cameron<br />

Kyle Cesarz<br />

Rachel Crouse<br />

Sean Cwiek<br />

Mark Davis<br />

Jason Earl<br />

Michael Evich<br />

William Filipski<br />

Stephen Frost<br />

Travis Gage<br />

Kushal Gargesh<br />

Robyn Gutman<br />

Iman Haghgooie<br />

Michael Hampton<br />

Johnny Jackson<br />

Jessica Lowe<br />

Melissa Masters<br />

Daniel McClure<br />

Malek Musleh<br />

Ryan Pacheco<br />

Aaron Romain<br />

Kory Schonsheck<br />

Scott Shaw<br />

Russell Shirey<br />

Joshua Smith<br />

Matthew Sturges<br />

Nathan Styles<br />

Mark Valentin<br />

William Weidendorf<br />

Patrick Yee<br />

Matthew Zierau<br />

DaimlerChrysler<br />

Freshman Scholarship<br />

Ashley Axford<br />

Nicole Berry<br />

Albert Borrego<br />

Melissa McLeod<br />

Ashley Taylor<br />

Inga Yuditsky<br />

General Motors Minority/<br />

Women Scholarhip<br />

Velerie Borza<br />

Tiffany Klupacs<br />

Sean Williams<br />

CECS/Ford Freshman<br />

Minority Scholarship<br />

Alyssa Chambers<br />

Jonathan Contreras<br />

Amanda Davison<br />

Michael Mixon<br />

Uzoma Okeke<br />

Kristina Rembisz<br />

Shawna Stratton<br />

Heather Velliky<br />

Nicole Witkowski<br />

Matthew Woodford<br />

Lindsay Yaros<br />

15

DEARBORN <strong>Engineer</strong><br />

New CECS Faculty Members<br />

Vehicle, Power Electronics, and Motor Drive Laboratory.<br />

He was granted both his bachelor’s and master’s degrees<br />

in electrical engineering from Korea University, Seoul,<br />

Korea, in 1994 and 1998, respectively.<br />

BEN LI<br />

Pr<strong>of</strong>essor and Chair<br />

Department <strong>of</strong> Mechanical <strong>Engineer</strong>ing<br />

His research interests include sensorless control <strong>of</strong> AC<br />

motor drives, power conversion systems, design and control<br />

<strong>of</strong> hybrid electric vehicles, inverter topology for AC<br />

motor drives, and DSP-based power electronics and motor<br />

drives system control. To date, he has contributed more<br />

than 15 technical publications and holds one pending patent<br />

in the motor drives and power electronics area. Kim is<br />

a member <strong>of</strong> the IEEE Power Electronics Society and a full<br />

member <strong>of</strong> Sigma Xi (the scientific research society).<br />

Ben Q. Li, pr<strong>of</strong>essor and chair <strong>of</strong> the Department <strong>of</strong><br />

Mechanical <strong>Engineer</strong>ing, received his doctoral degree at<br />

the University <strong>of</strong> California, his master’s degree at the<br />

Colorado School <strong>of</strong> Mines, and his bachelor’s degree at<br />

Central South University <strong>of</strong> Technology, Hunan, China.<br />

He previously taught at Washington State University<br />

and Louisiana State University, and served as associate<br />

director <strong>of</strong> the Center for Advanced Multiphase Materials<br />

Processing at Washington State from 2000 to 2002.<br />

Li’s research interests include fluid flow, heat and mass<br />

transfer, hydrodynamic and microscale phenomena in thermal<br />

fluids, materials processing and manufacturing systems;<br />

computational fluid flow and heat transfer; multiscale<br />

modeling; and integrated model-guided design for thermal<br />

fluids systems and materials and their processing systems.<br />

NAEEM SELIYA<br />

Assistant Pr<strong>of</strong>essor<br />

Department <strong>of</strong> <strong>Computer</strong> and Information Science<br />

Naeem Saliya, assistant pr<strong>of</strong>essor <strong>of</strong> computer and<br />

information science, received his master’s degree in<br />

computer science and his Ph.D. in computer engineering<br />

from Florida Atlantic University in 2001 and <strong>2005</strong>,<br />

respectively. He earned his bachelor’s degree in civil<br />

engineering from the University <strong>of</strong> Bombay, India, in 1995.<br />

TAEHYUNG KIM<br />

Assistant Pr<strong>of</strong>essor<br />

Department <strong>of</strong> Electrical and <strong>Computer</strong> <strong>Engineer</strong>ing<br />

Taehyung Kim received his Ph.D. degree in electrical<br />

engineering in 2003 from Texas A&M University, where<br />

he was also employed as a researcher in the Advanced<br />