Supradisc II Depth Filter Modules with Seitz Media - Pall Corporation ...

Supradisc II Depth Filter Modules with Seitz Media - Pall Corporation ...

Supradisc II Depth Filter Modules with Seitz Media - Pall Corporation ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

USD 2304a (1)<br />

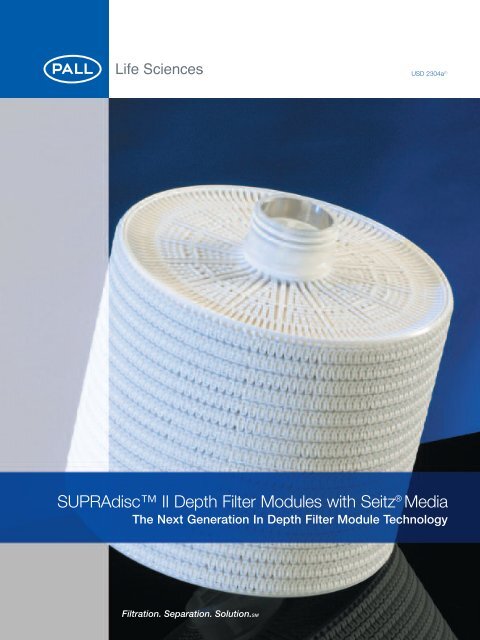

SUPRAdisc <strong>II</strong> <strong>Depth</strong> <strong>Filter</strong> <strong>Modules</strong> <strong>with</strong> <strong>Seitz</strong> ® <strong>Media</strong><br />

The Next Generation In <strong>Depth</strong> <strong>Filter</strong> Module Technology

<strong>Pall</strong> SUPRAdisc <strong>II</strong> <strong>Depth</strong> <strong>Filter</strong> <strong>Modules</strong> <strong>with</strong> <strong>Seitz</strong> <strong>Media</strong><br />

The Next Generation In <strong>Depth</strong> <strong>Filter</strong> Module Technology<br />

Constantly increasing process demands in the Biopharmacuetical industry has<br />

driven <strong>Pall</strong> <strong>Corporation</strong> to develop the new SUPRAdisc <strong>II</strong> depth filter modules. The<br />

SUPRAdisc <strong>II</strong> design combines the filtration performance of <strong>Seitz</strong> media and the<br />

structural robustness of interlocking dual drainage plates. This provides the most<br />

robust design available in the market today.<br />

The dual drainage plate design of the SUPRAdisc <strong>II</strong> modules optimizes the flow<br />

distribution by providing unobstructed process flow. These advancements in module<br />

design also enhance module integrity as well as superior resistance to back pressure<br />

failures of the filter media.<br />

<strong>Pall</strong> SUPRAdisc <strong>II</strong> features<br />

• Highest structural robustness due to<br />

dual drainage plates.<br />

◆ Interlocking and welded drainage<br />

plates provide similar structural<br />

integrity as found <strong>with</strong> most filter<br />

cartridge cage and core assemblies.<br />

• Optimized flow distribution upstream<br />

and downstream of the filter sheets<br />

maximizes filter utilization.<br />

◆ <strong>Filter</strong> media is less susceptible to<br />

blinding from media to media<br />

contact <strong>with</strong>in the module assembly.<br />

◆ Unobstructed process flow.<br />

• Fully supported filter sheets inhibit the<br />

rupturing of filter media frequently<br />

associated <strong>with</strong> back pressure.<br />

• Shipping and handling damage is<br />

significantly reduced through the very<br />

same interlocking and welded drainage<br />

plates.<br />

• Highest packing density<br />

minimizes hold up volume.<br />

• SUPRAdisc <strong>II</strong> modules are steam<br />

sterilizable at 125 °C (257 °F) for 30<br />

minutes.<br />

• All plastic components used in<br />

construction meet the specifications<br />

for the biological test listed in the<br />

current version of the USP Class VI<br />

121 °C.<br />

• SUPRAdisc <strong>II</strong> modules and all their<br />

components are fully traceable by<br />

serial number.<br />

The filter sheets meet the specifications<br />

set forth in the US Code of Federal<br />

Regulations Title 21, parts 177.2260 e, f, g,<br />

h, i, j, k, l. The materials for all plastic<br />

components are listed in US Code of<br />

Federal Regulations Title 21, part 177.1520.<br />

With regard to food law conformity, the<br />

manufacture of depth filter sheets is also<br />

subject to ongoing analysis by the German<br />

ISEGA Forschungs- und Untersuchungsgesellschaft<br />

mbH, Aschaffenburg.<br />

Technical Service<br />

For best possible support and maximum<br />

reliability, we recommend performing filter<br />

evaluations utilizing your process and<br />

process conditions. <strong>Pall</strong>’s specialists can<br />

provide valuable support, either at your<br />

facility or in our SLS (Scientific and<br />

Laboratory Services) laboratories, providing<br />

hands-on assistance and placing its<br />

extensive technical resources at your<br />

disposal in the form of worldwide technical<br />

advice, including problem solving, process<br />

review and cost reduction programs.<br />

Inside<br />

Outside

<strong>Pall</strong> SUPRAdisc <strong>II</strong> <strong>Depth</strong> <strong>Filter</strong> <strong>Modules</strong><br />

Technical Specifications<br />

Technical Specifications<br />

Operating Characteristics*<br />

Maximum Operating Temperature<br />

Maximum Operating Pressure<br />

80 °C (176 °F)<br />

2.4 bard (35 psid)<br />

* With compatible fluids, which do not soften, swell or adversely affect the products or its material of construction.<br />

Materials of Construction<br />

<strong>Pall</strong> SUPRAdisc <strong>II</strong> Components<br />

O-rings<br />

Polypropylene<br />

Platinum Cured Silicone Elastomer<br />

Sterilization<br />

Steam in Place<br />

125 °C (257 °F) for 30 minutes at 0.3 bard (4.3 psid) maximum<br />

Nominal Dimensions<br />

Total Length (Nominal)<br />

Double O-ring<br />

Flat Gasket<br />

Nominal Total Diameter<br />

<strong>Filter</strong> Area<br />

332 mm (13.1 in.)<br />

272 mm (10.7 in.)<br />

284 mm (12 in.) in 232 design<br />

410 mm (16 in.) in 440 design<br />

1.8 m 2 (19.4 ft 2 ) in 232 design<br />

5.0 m 2 (53.8 ft 2 ) in 440 design

<strong>Pall</strong> SUPRAdisc <strong>II</strong> <strong>Depth</strong> <strong>Filter</strong> <strong>Modules</strong> <strong>with</strong> <strong>Seitz</strong> <strong>Media</strong><br />

Technical Specifications<br />

<strong>Filter</strong> <strong>Media</strong> Specifications<br />

Code <strong>Depth</strong> <strong>Filter</strong> Type Typical Water in Nominal Retention Ash Content Endotoxin Level<br />

Permeability Rating in % in EU/ml<br />

L/min/m 2 @ ∆p 1 bar in µm before Rinsing<br />

(14. 5 psid)<br />

PEKS EKSP 29 0.1 - 0.3 58