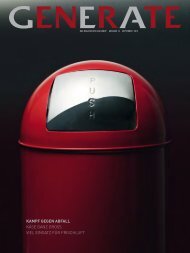

A BREATH OF FRESH AIR SAY CHEESE WAR ON ... - GEA Group

A BREATH OF FRESH AIR SAY CHEESE WAR ON ... - GEA Group

A BREATH OF FRESH AIR SAY CHEESE WAR ON ... - GEA Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The world’s deserTs<br />

receive more energy<br />

from The sun in<br />

six hours Than The<br />

planeT’s populaTion<br />

uses in a year. could<br />

harnessing The<br />

power of The deserT<br />

sun provide The<br />

long-Term soluTion<br />

To meeTing global<br />

energy needs?<br />

bu Dhabi in the United Arab Emirates is<br />

one place in the world that need not worry<br />

about its energy supply. Its 67,340 square<br />

kilometers holds eight per cent of global<br />

oil reserves and five per cent of natural gas<br />

reserves – enough to last for 100 years.<br />

Yet, despite this natural wealth, Abu Dhabi has<br />

embarked on a sustainable program to wean<br />

itself away from hydrocarbon dependence.<br />

Instead it wants to develop a more diverse<br />

economy and to become a beacon for<br />

renewable energy and sustainable technology.<br />

Masdar, a multi-faceted renewable energy<br />

company of the Abu Dhabi governmentowned<br />

Mubadala Development Company,<br />

is spearheading this sustainability drive. Its<br />

flagship project, Masdar City, is one of the<br />

world’s most sustainable developments,<br />

currently being built 17 kilometers from<br />

the city of Abu Dhabi. The low carbon, low<br />

waste city is a focused effort by Abu Dhabi<br />

to address the challenges of sustainable<br />

planning amid increasing urbanization.<br />

Masdar City achieves this by pioneering best<br />

practises in sustainable urban planning,<br />

design, development and operation. It<br />

has a pedestrian-friendly environment<br />

and is piloting several advanced cleantransportation<br />

systems and strategies,<br />

including personal rapid transit and electric<br />

vehicle point-to-point systems.<br />

The city is also reducing embodied carbon<br />

emissions and waste, increasing recycling,<br />

using local materials and timber from<br />

sustainable forests, and selecting products<br />

that have the greatest positive effect for<br />

indoor air quality.<br />

As it provides a unique test-bed platform that<br />

allows partners in cutting-edge technology<br />

and systems to pilot, demonstrate, refine,<br />

develop and commercialize technologies<br />

on a very fast-to-market platform, Masdar<br />

City has been chosen as the Middle East<br />

headquarters of renowned companies.<br />

In order to help the emirate reach its goal<br />

of moving towards a knowledge-based<br />

sustainable economy, Masdar operates<br />

across the full spectrum of the renewable<br />

energy and sustainable technology industry<br />

through its global and local projects.<br />

For the six years since its inception, Masdar<br />

has provided cutting-edge clean technology<br />

solutions by developing global and local<br />

solar and wind power projects. These include<br />

the unique concentrated solar power (CSP)<br />

plant Gemasolar in Spain; one of the world’s<br />

largest CSP plants, Shams One, in Abu<br />

Dhabi; and one of the world’s largest offshore<br />

wind farms, London Array in the UK.<br />

Shams Power Company is a joint venture<br />

between Masdar Power (60 per cent),<br />

Abengoa Solar (20 per cent) and Total (20<br />

per cent) and is the special purpose vehicle<br />

formed to build and operate Shams One, the<br />

100MW CSP plant in Abu Dhabi’s Western<br />

Region. The plant will provide electricity to<br />

20,000 homes and save 175,000 tonnes of<br />

CO 2. This is equivalent to planting 1.5<br />

million trees or taking 15,000 cars off Abu<br />

Dhabi roads.<br />

For the solar power industry, Shams One<br />

represents three significant milestones:<br />

it’s one of the largest projects of its kind in<br />

the world, covering 2.5 square kilometers,<br />

it’s the first utility-scale commercial solar<br />

power project in the Middle East; and, most<br />

significant of all, it’s the world’s first solar<br />

thermal power plant on desert sand. Shams<br />

One is currently under construction and is<br />

scheduled for completion by the end of 2012.<br />

Power from sunlight<br />

Like most commercial solar power plants,<br />

Shams One will convert sunlight into<br />

electricity using CSP technology. More<br />

than 258,000 thousand concave mirrors<br />

will be configured into 768 parabolic trough<br />

collectors. Each collector will concentrate<br />

the sunlight at between 30 and 60 times its<br />

normal intensity onto a receiver pipe that runs<br />

down the center of the trough. The pipe will<br />

be filled with thermal oil which then passes<br />

through a heat exchanger in the power plant,<br />

turning water into steam which then drives a<br />

turbine to generate electricity. Heat storage<br />

tanks will supply energy to the steam cycle at<br />

night and during times of peak demand.<br />

With the thermal oil reaching temperatures<br />

up to 400°C it partially degenerates and<br />

forms by-products, lowering the heat<br />

transfer. This means that it needs to be<br />

regenerated at regular intervals. <strong>GEA</strong><br />

Process Engineering developed fully<br />

automatic distillation plants for achieving<br />

this. Following the successful implementation<br />

at three solar thermal power stations in<br />

Spain this technology is set to be installed at<br />

Shams One.<br />

“Usually the oil has to be taken off site to<br />

a large distillery plant,” explains Sales &<br />

Marketing Manager at <strong>GEA</strong>, Norbert Streider.<br />

“But we came up with the idea of smaller<br />

units so that the oil could be regenerated on<br />

site. These units are also partially powered by<br />

solar energy.”<br />

He says that, although the distillation<br />

technology itself is not new, the difference is<br />

that these units can heat the oil to more than<br />

300°C for high temperature fractionation.<br />

Compared to conventional plants, the <strong>GEA</strong><br />

plant has a higher separation efficiency,<br />

allowing a recovery rate of 98-99 per cent and<br />

the reuse of thermal oil with the highest purity.<br />

Cooling first<br />

One of the main problems of locating Shams<br />

One in the desert is – unsurprisingly – the<br />

lack of water. This means that the exhaust<br />

steam from the power plant cannot be cooled<br />

conventionally, by condensation in a wet<br />

cooling tower. Instead a <strong>GEA</strong> Heat Exchangers<br />

air cooled condenser will be installed, the first<br />

at a solar thermal power plant.<br />

It was particle physicist Dr. Gerhard<br />

Knies, one of the founders of the Desertec<br />

Foundation, who calculated that the world’s<br />

deserts received more energy from the sun in<br />

six hours than the planet’s population used<br />

in a year. The Desertec Foundation is a nonprofit<br />

organization committed to promoting<br />

clean power from the deserts.<br />

It is part of the Desertec Industrial Initiative<br />

(Dii GmbH) – a consortium of European and<br />

Algerian companies – which plans to set up<br />

a vast network of solar and wind farms in<br />

the desert regions of northern Africa and<br />

transmit the electricity via high-voltage direct<br />

current cables. If successful, it could provide<br />

15 per cent of Europe’s electricity by 2050.<br />

Construction of the first Desertec solar farm<br />

is due to begin in Morocco in 2012. This,<br />

together with the Shams One project, is<br />

proving that the idea of capturing the power<br />

of the desert sun is no mirage.<br />

GENERATE MAGAZINE ISSUE 15 3