Energy harvesting: a thin film approach - EE Times Europe

Energy harvesting: a thin film approach - EE Times Europe

Energy harvesting: a thin film approach - EE Times Europe

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

european<br />

business press<br />

www.electronics-eetimes.com<br />

September 2012<br />

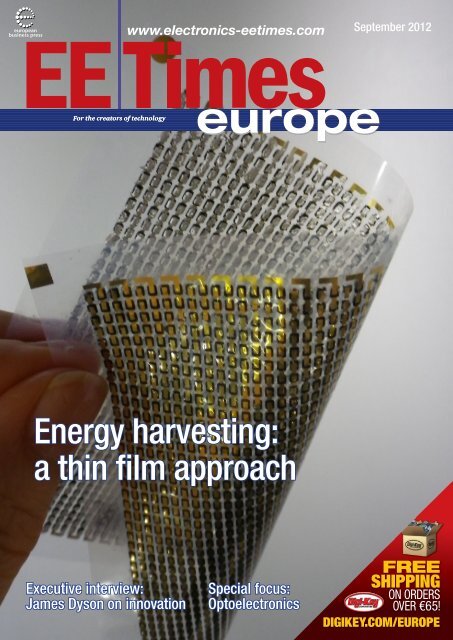

<strong>Energy</strong> <strong>harvesting</strong>:<br />

a <strong>thin</strong> <strong>film</strong> <strong>approach</strong><br />

Executive interview:<br />

James Dyson on innovation<br />

Special focus:<br />

Optoelectronics<br />

FR<strong>EE</strong><br />

SHIPPING<br />

ON ORDERS<br />

OVER €65!<br />

DIGIKEY.COM/ EUROPE

CONTENTS september 2012<br />

opinion<br />

DESIGN & PRODUCTS<br />

4<br />

50<br />

6<br />

8<br />

12<br />

13<br />

14<br />

Uncommon Market: Apple v. Samsung: rights and<br />

wrongs<br />

Last Word: Keeping open source software free<br />

news & TECHNOLOGY<br />

Investigating nano-electromechanical<br />

relay-based<br />

computing<br />

Optogan’s formula for<br />

success: Russian IP, German manufacturing<br />

In the globalized business of LED manufacturing,<br />

large Asian and American<br />

companies define the rules<br />

and set the pace. Unusually<br />

enough in the semiconductor<br />

business, Russian company<br />

Optogan does not only join in<br />

but it keeps growing.<br />

Patents drive innovation<br />

Despite all the legal battles<br />

between Samsung and<br />

Apple, patents are a key way<br />

of protecting investors and<br />

encouraging the exploitation<br />

of innovation, says the<br />

UK’s leading engineer, James<br />

Dyson.<br />

Wireless power outlets designed to support the<br />

IPv6 Internet protocol<br />

Lithium-ion battery pilot production line established<br />

by German research center<br />

Innovative LED geometry could increase light output<br />

by factor of ten<br />

Light-emitting foils could<br />

offer cost-effective OLED<br />

alternative<br />

Researchers from the university<br />

of umea (Sweden)<br />

have produced organic lightemitting<br />

electrochemical cells<br />

(LECs) using a roll-to-roll<br />

compatible process under ambient air conditions.<br />

18<br />

21<br />

23<br />

25<br />

26<br />

28<br />

31<br />

34<br />

36<br />

SPECIAL FOCUS:<br />

- ENERGY HARVESTING<br />

<br />

<strong>Energy</strong> harvesters: a <strong>thin</strong> <strong>film</strong> <strong>approach</strong><br />

During IDTechEx’ last<br />

energy <strong>harvesting</strong> and<br />

Storage <strong>Europe</strong> conference<br />

held in Berlin, <strong>thin</strong><br />

piezoelectric and low footprint<br />

thermoelectric materials<br />

were cited in many<br />

new energy <strong>harvesting</strong> research programs.<br />

Turning waste heat from<br />

industrial piping into<br />

electrical energy<br />

The EverGen PowerStrap<br />

thermoelectric-based<br />

energy <strong>harvesting</strong> solution<br />

produces multiple watts of<br />

power from industrial piping waste heat.<br />

Piezo wireless switch: No battery, no cable, no wear<br />

Self-charging piezo-power cell converts and stores<br />

energy chemically in a single unit<br />

UK leads in energy efficiency rankings as Germany<br />

pushes ahead<br />

- OPTOELECTRONICS<br />

Merging the benefits of CCD<br />

and CMOS for imaging<br />

Over the last decades, the<br />

imager world has seen<br />

numerous publications on<br />

the comparison of CCD and<br />

CMOS imaging technologies.<br />

Enhancing automotive safety through advanced IR<br />

sensor technology<br />

- DATA ACQUISITION<br />

Voice input processing<br />

for automotive speech<br />

recognition systems<br />

Low power system<br />

design optimizations with SAR A/D Converters<br />

15<br />

16<br />

First microwave laser to operate at room<br />

temperature<br />

Custom designed wireless links<br />

The 2012 VLSI Symposia which<br />

took place last summer in<br />

Honolulu came as an opportunity<br />

for researchers to unveil new<br />

short-range wireless link concepts.<br />

46<br />

49<br />

Reader offer<br />

This month, RTX is giving<br />

away 5 RTX4100 Wi-Fi<br />

development kits worth<br />

USD 399 each for <strong>EE</strong><strong>Times</strong><br />

<strong>Europe</strong>’s readers to win.<br />

distribution corner<br />

3 Electronic Engineering <strong>Times</strong> <strong>Europe</strong> September 2012 www.electronics-eetimes.com

UNCOMMON MARKET<br />

Apple v. Samsung: rights and wrongs<br />

By Rick Merritt<br />

BOTH APPLE AND SAMSUNG — are right—and wrong—and<br />

here’s what I <strong>thin</strong>k both sides ought to do to get some sanity<br />

back into the mobile industry and the patent process. There’s<br />

enough greatness and pettiness to go around in the cramped<br />

courtroom of Judge Lucy Koh of San Jose Federal Court where<br />

Apple and Samsung are suing each other for patent infringement.<br />

Apple deserves some kind of acknowledgement for creating<br />

some<strong>thin</strong>g unique with the iPhone, a distinctive looking<br />

handset that put Web access in your pocket along with a phone<br />

and music wrapped in easy to use software. In its own way, the<br />

equally distinctive iPad also was different from tablets that went<br />

before in its clear focus on consumer Web browsing with really<br />

easy-to-use software.<br />

But how do you express that in the arcane language of a<br />

patent? The patent system is encrusted with obtuse procedures<br />

and stiff, vague language. It needs a course with Strunk and<br />

White, the masters of crisp writing and <strong>thin</strong>king. As many have<br />

noted, patents have become a quantity game, not a quality<br />

metric.<br />

Apple did a reasonable job trying to write patents on all the<br />

neat little ideas it put<br />

into its casings and<br />

coded into software.<br />

But they should not<br />

have been written as<br />

a few dozen patents,<br />

rather they should<br />

have been written as<br />

a few dozen claims in<br />

one iPhone patent.<br />

Imagine an iPhone<br />

patent with claims<br />

on the shape of the<br />

device, the metal<br />

bezel, the big screen,<br />

the colorful, well-lit<br />

icons on a black<br />

background that<br />

bounce back and snap to the screen. Imagine them written in<br />

plain English rather than fusty patent-ese.<br />

There would be no problem for a jury of average San Jose<br />

Joes and Janes determining whether or not such a patent was<br />

violated.<br />

Excuse me, now, while I proceed to take Apple off its holierthan-thou<br />

pedestal. I am as touched by anyone by the emotional<br />

language of Steve Jobs that still lives on at Apple and has<br />

been invoked often in Judge Koh’s courtroom, but let’s tell the<br />

other side of that story.<br />

The lofty language of Steve Jobs also acts as a drug to dupe<br />

talented Apple employees into overworking and living unbalanced<br />

lives. It has been used to brainwash Apple employees<br />

into believing they are somehow better than other people that<br />

put their pants on one leg at a time.<br />

Get real, Apple! You don’t own the rectangle with rounded<br />

corners. You didn’t invent the smartphone, capacitive touch<br />

screen displays or browsers on handsets.<br />

You aren’t the only creators of beauty on Planet Earth.<br />

Compared to Samsung you don’t do much work on forwarding<br />

the fundamental technologies that give us the LCDs, batteries,<br />

communications networks and microprocessors we need to<br />

make cool gadgets of all kinds.<br />

That said, you used all those components damn well. So give<br />

yourself a pat on the back, and take that chip off your shoulder<br />

while you are doing it.<br />

And while you’re getting humble, let’s hear a little more<br />

candor about how the electronics industry uses lowcost labor. It<br />

didn’t start with you by any means, but maybe you can use your<br />

clout and fat bankroll to bring some meaningful reforms to labor<br />

practices. After all, your complex designs that require lots of<br />

hand assembly have certainly pushed the edge of this dark side<br />

of the Industrial Revolution 2.0.<br />

Samsung’s side of the street<br />

Samsung’s documents (displayed in court) showing featureby-feature<br />

comparisons of its unreleased S1 handset and the<br />

iPhone are shameful. Each page makes nearly explicit recommendations<br />

for aping features on which Apple has patents.<br />

This is aggressive competition gone way overboard. It is<br />

copying patented<br />

technology. You did<br />

it. You gained the<br />

lead in the smartphone<br />

market in part<br />

because you did it,<br />

and you deserve<br />

to be reined in with<br />

some sort of punishment.<br />

We expected to<br />

see clunky no-name<br />

clones of the iPhone<br />

come out of China<br />

a month after the<br />

iPhone was released,<br />

and we did. We<br />

didn’t expect this<br />

slavish professionalized copying from Samsung.<br />

Still, the lights stay on pretty late in Seoul where they develop<br />

some of the world’s finest chip technology, displays, batteries<br />

and much more. There are hundreds of hard working engineers<br />

in this company and they deserve their due. In becoming one of<br />

its largest customers, Apple has already paid Samsung a form<br />

of silent respect.<br />

When this trial is over, Samsung probably owes Apple a<br />

check, though it may not be for as much as $2.5 billion. Indeed,<br />

Samsung showed some pretty compelling evidence of how the<br />

iPhone appears to infringe some of pretty broad mobile patents<br />

it owns.<br />

Speaking of what’s owed in all this, Apple could write one to<br />

the diligent workers at Foxconn who help it amass its “iFortune”<br />

along with Apple’s retail staff that reportedly works for an average<br />

of about $12 an hour.<br />

After observing the maneuvering in a San Jose court, one<br />

<strong>thin</strong>g seems clear: It’s time to put an end to this patent madness.<br />

4 Electronic Engineering <strong>Times</strong> <strong>Europe</strong> September 2012 www.electronics-eetimes.com

NEWS & TECHNOLOGY<br />

Investigating nano-electro-mechanical<br />

relay-based computing<br />

By Julien Happich<br />

A consortium led by IBM has been awarded €2.44M by the<br />

<strong>Europe</strong>an commission to investigate nano-electro-mechanical<br />

relay based computing for ultra-low power computing applications.<br />

The goal wi<strong>thin</strong> the NEMIAC project (Nano-Electro-<br />

Mechanical Integration And Computation) is to build the world’s<br />

first ever miniaturised electro-mechanical relay based processor.<br />

Nano-electro-mechanical (NEM) relays have practically zero<br />

leakage, an abrupt turn-on transient and a high on-current, and<br />

can also be integrated with CMOS at the<br />

die or wafer level. This makes them promising<br />

candidates for digital logic implementation<br />

in ultra-low power applications,<br />

explains Dinesh Pamunuwa, Lecturer<br />

in Nanotechnology in the Engineering<br />

Department of the Lancaster University<br />

and also in charge of the project’s communication.<br />

“Building a functioning NEM relay<br />

based processor, one would go the full<br />

circle, effectively using electro-mechanical<br />

switches as the basic building block some<br />

200 years after Babbage proposed his<br />

original fully mechanical calculator continues<br />

Pamunuwa.<br />

Several research initiatives have been<br />

pursuing NEM relay based logic, and<br />

many innovative relay architectures have<br />

been proposed that realise logic functionality<br />

in widely different ways, ranging from<br />

combining a basic 3-terminal switching<br />

element in the manner of MOSFETs to<br />

multi-terminal relays and multiple-valued logic implementations.<br />

However the main stumbling block in this technology is<br />

limited switching cycles due to contact material failure. Stiction<br />

caused by surface forces, and material transfer is the main<br />

cause. The relay architecture is also key in ensuring structural<br />

reliability and ensuring scalability. NEM relays that operate on<br />

multiple voltage levels to realise complex logic functionality,<br />

require multiple contacts to be made and have complex timing<br />

sequences are generally not conducive to manufacturability and<br />

repeatability.<br />

The <strong>approach</strong> to be explored wi<strong>thin</strong> NEMIAC - www.nemiac.<br />

eu - is based on an in-plane curved cantilever architecture proposed<br />

by IBM that optimises the electrostatic field distribution<br />

and beam stiffness and allows miniaturisation.<br />

The inclined cantilever design also prevents the beam landing<br />

on the gate due to the different angles of motion of the drain<br />

electrode and the beam. The relay is fabricated using a sacrificial<br />

layer, which ensures precise control of the air gap, with<br />

uniformity throughout the length of the beam.<br />

It also makes possible air gaps smaller than the lithographically<br />

defined limit, which in turn allows precise control of the<br />

electric fields and reduced footprints. In this case, the contact is<br />

realised with platinum silicide and gold.<br />

So far, several functioning microscale switches have been<br />

demonstrated with various footprints, showing “on” resistances<br />

in the order of 5kohm. The target wi<strong>thin</strong> the project is to achieve<br />

a device footprint of 3μm×3μm, a mechanical latency of 50ns<br />

with an operating voltage of 5V, and a reliability of 10 billion<br />

switching cycles.<br />

Using this 3-terminal relay as a primitive, digital logic can<br />

SEM image of a 15.5-μm-long curved cantilever switch.<br />

be realised by adopting a complementary style <strong>approach</strong>, with<br />

pull-up and pull-down networks connecting the output to Vdd<br />

or ground. Both networks are required as the relay can only be<br />

configured to pass a ‘0’ or ‘1’ depending on whether the common<br />

source terminal (beam) is grounded or connected to Vdd,<br />

as NEM relays are ambipolar, and the actuation depends on the<br />

voltage difference between the gate and beam.<br />

A design library of combinational and sequential gates will<br />

be constructed using circuit architectures that are tailored to<br />

the NEM relay characteristics. For example, one way to take<br />

advantage of the ohmic contact and relatively low output impedance<br />

is to have a higher fan-out than would be possible with<br />

minimum-sized CMOS devices. The intended final demonstrator<br />

is a 4-bit microprocessor with a reliability of 1 million switching<br />

cycles.<br />

Researchers from several universities and labs are taking<br />

part in this project, including from the University of Bristol and<br />

the University of Lancaster (UK), from IBM Research in Zurich<br />

and from the Nanoelectronic Device Laboratory (NanoLab) of<br />

École Polytechnique Fédérale de Lausanne (Switzerland), from<br />

ST Microelectronics in Agrate (Italy), and from the KTH Royal<br />

Institute of Technology, Stockholm (Sweden).<br />

6 Electronic Engineering <strong>Times</strong> <strong>Europe</strong> September 2012 www.electronics-eetimes.com

a real BroaDsiDe!<br />

low ohmic precision anD power resisTors<br />

Top performance on small surface areas wiTh low-ohmic precision resisTors<br />

By reversal of the length to width ratio, our Vlx series resistors have larger soldering and contact pads, giving them:<br />

_ better heat dissipation, rthi < 20 K/w<br />

_ higher power rating: 2 w for size 1020, 1 w for size 0612<br />

_ significant increase in mechanical stability<br />

Innovation by Tradition<br />

isabellenhütte heusler Gmbh & co. KG<br />

eibacher weg 3 – 5 · 35683 Dillenburg · phone +49 (0) 2771 934-0 · fax +49 (0) 2771 23030<br />

sales.components@isabellenhuette.de · www.isabellenhuette.de

NEWS & TECHNOLOGY<br />

OPTOELECTRONICS<br />

Optogan’s formula for success: Russian IP,<br />

German manufacturing<br />

By Christoph Hammerschmidt<br />

In the globalized business of LED manufacturing, large<br />

Asian and American companies define the rules and set the<br />

pace. <strong>Europe</strong>an competitors such as Osram and Philips<br />

struggle to keep up. Unusually enough in the semiconductor<br />

business, Russian company Optogan does not only join in but it<br />

keeps growing. With Optogan General Manager Global Sales &<br />

Marketing, Markus Zeiler, <strong>EE</strong> <strong>Times</strong> <strong>Europe</strong> discussed the company’s<br />

recipe for success in this highly competitive market.<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: It is rather uncommon that a company with<br />

Russian roots succeeds in Western <strong>Europe</strong>’s high tech markets.<br />

What is the story behind Optogan?<br />

Markus Zeiler: The company has been launched 2004 in Helsinki<br />

by three Russian physicists and entrepreneurs who formerly<br />

worked at the Joffe Institute, one of the world’s leading institutes<br />

in the field of solid state physics. At the Joffe institute<br />

where Nobel laureate Zhores Ivanovich Alferov worked at the<br />

professorship, they conducted breakthrough research on epitaxy<br />

for LED crystals. They also worked for Western companies<br />

and were involved in the development of epitaxy processes<br />

for blue LEDs. From there, they filed for their first patents and<br />

launched their first company.<br />

As early as 2005 they moved to Dortmund, Germany. In the beginning,<br />

the company was funded by a Finnish venture capital.<br />

Later, they also received financial support from Denmark and<br />

the EU. After a couple of years, the first large investors joined in.<br />

One of them was Unixim, a Russian VC fund; another was the<br />

Russian nanotechnology fund Rusnano. Thus, the seat of the<br />

company moved to St. Petersburg from where it staged market<br />

entry in Russia. About one and a half year ago, I accepted the<br />

task of shaping Optogan’s international market appearance.<br />

We are a <strong>Europe</strong>an company with locations in Russia, Finland<br />

and Germany; we run our semiconductor production in<br />

Landshut in Bavaria. This is a clear differentiator against our<br />

competitors in Asia, and our customers reward this <strong>approach</strong>.<br />

Wi<strong>thin</strong> twelve months we received more then 500 inquiries from<br />

distributors across <strong>Europe</strong>, enabling us to select the ones that<br />

best suit us. Recently we launched operations in Italy, Romania<br />

and Turkey. We’re making progress.<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: It is certainly not easy to assert oneself against<br />

Asian competitors who produce in very high quantities, driving<br />

price levels down, sometimes with politics coming into play.<br />

M. Zeiler: Sure, it is a challenge. We build our strategy on innovation<br />

and quality. Customers increasingly find out that not<br />

all LEDs are equal and that quality makes a difference. And we<br />

combine quality with slim, cost-effective manufacturing processes.<br />

Being cost-conscious is a precondition if you manufacture<br />

in Germany, but we also offer modular product concepts to<br />

make <strong>thin</strong>gs easy for our customers.<br />

Stages the international expansion for LED manufacturer<br />

Optogan: Markus Zeiler, General Manager Global Sales &<br />

Marketing<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: Innovation is not sufficient in itself. Could you<br />

elaborate your <strong>approach</strong>?<br />

M. Zeiler: Our chip technology is based on IP from the professorship<br />

of professor Alferow – nobel award technology, if you<br />

will. With this basis we can well compete in the market, and<br />

we further develop it with subsidies from Skolkovo, in a sense<br />

the Russian pendant of the Silicon Valley. Our unit there, “New<br />

Technologies of Light”, is conducting research and development<br />

for a kind of “People’s LED lamp” – a highly integrated solution<br />

at a low price level.<br />

In this context it is certainly a relevant factor that in Russia the<br />

so called “energy saving lamp”, the CCFL, never was a market<br />

success, its market share never climbed above 4 percent. For<br />

this reason, the Russians migrate from the incandescent bulb<br />

directly to the LED. This is a huge open market, in particular for<br />

highly integrated solutions.<br />

8 Electronic Engineering <strong>Times</strong> <strong>Europe</strong> September 2012 www.electronics-eetimes.com

DESIGNSPARK<br />

UNIQUE<br />

RESOURCES FROM<br />

COMING SOON<br />

A NEW ENGIN<strong>EE</strong>RING<br />

ECO-SYSTEM<br />

www.designspark.com

NEWS & TECHNOLOGY<br />

OPTOELECTRONICS<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: Highly integrated<br />

– does this mean that you<br />

integrate the driver circuitry onto<br />

the LED chip?<br />

M. Zeiler: Yes, for instance. This is<br />

one option. Also the connecting<br />

technology is designed to be as<br />

slim as possible. We always have<br />

solutions that are different. In addition,<br />

we have many promising<br />

contacts with large OEMs which<br />

are interested in our technology.<br />

If you look at the details, in the<br />

high-volume retrofit market it even<br />

makes sense to run a production<br />

in <strong>Europe</strong> – if you have a high<br />

degree of automation.<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: Where are your<br />

manufacturing locations?<br />

M. Zeiler: Every<strong>thin</strong>g but the chips<br />

are produced in St. Petersburg.<br />

In Dortmund we have R&D and a<br />

pilot production. Our high volume<br />

production is here in Landshut<br />

where we can use existing infrastructure<br />

(from LFoundry), clean rooms etc. We can rent the<br />

infrastructure with an option for further enlargement, ideal for<br />

mass production.<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: What’s your estimate of the LED market development<br />

for the future? Do you <strong>thin</strong>k LEDs will quickly displace<br />

CFLs?<br />

M. Zeiler: Yes and no. Quickly in the sense of the traditional<br />

lighting business, yes. This could happen in a time frame of<br />

three to five years while it took some 25 years for the CFL to<br />

gain significant market share in conventional lighting. But one<br />

should not expect a complete changeover. In certain market<br />

segments such as automotive or laptop display backlighting,<br />

LEDs conquered the markets very quickly. In general lighting,<br />

this won’t happen at the same speed. The established lighting<br />

companies do not move that fast. This is a clash of the cultures<br />

– conventional lighting and the fast-moving semiconductor<br />

industry.<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: Which market segments do you expect to<br />

grow the fastest? In which applications do LEDs gather acceptance<br />

most rapidly?<br />

Slim, cost effective processes and leading solid-state IP are the two main pillars of Optogan’s<br />

technology strategy.<br />

M. Zeiler: The automotive market is almost saturated with LEDs.<br />

Therefore, we are not active in automotive lighting. We have a<br />

clear focus on general lighting and see the highest potential in<br />

industrial lighting. In this segment, customers can achieve an<br />

ROI in less than three years in some cases. In the consumer<br />

segment we are not so present but we prepare our first concepts.<br />

Here the focus is high lumen per watt and more specifically,<br />

high lumen per dollar.<br />

To address the outdoor lighting market, we have launched a<br />

joint venture with Philips which covers the market for street<br />

lighting in Russia, Belarus and Kazahkstan. In this joint venture,<br />

R&D is in the hands of our partner. For this reason, street lighting<br />

is a “dead spot” on our R&D map.<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: Which technology trends in the LED lighting<br />

segments do you find most interesting at the current point of<br />

time?<br />

M. Zeiler: We bet very strongly on modular concepts that embrace<br />

the entire product chain from components to the complete<br />

lamp. In these concepts, complete solutions with tiered<br />

drivers and heat sinks play a major role. In addition, we see a<br />

trend to ever-higher integration. The customers are increasingly<br />

looking for reduced component count through higher integration.<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: Is the ability to control dimming a factor in the<br />

market acceptance?<br />

M. Zeiler: Yes – for example in the markets for home lighting<br />

where dimming is a popular feature for retrofit lamps. We also<br />

see an increasing interest for dimming in industrial applications:<br />

it enables users to dim down the lighting in storage halls as long<br />

as nobody works in there and when an employee with a fork<br />

lift enters the place the illumination is turned up. This is also<br />

relevant for dynamic sports areas lighting. End users can save a<br />

lot of money with dimming solutions.<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: Are there any standard interfaces and industrial<br />

standards that will gain importance in lighting technology?<br />

M. Zeiler: Of course, for us the Zhaga standard is relevant. We<br />

offer all components and interfaces necessary to position ourselves<br />

in this environment. In industrial markets, it is important<br />

to comply with the DMX / DALI standards. When it comes to<br />

retrofits, however, the Zhaga standard does not help you along;<br />

in this field we need to drive the integration by ourselves and<br />

develop our own ideas.<br />

10 Electronic Engineering <strong>Times</strong> <strong>Europe</strong> September 2012 www.electronics-eetimes.com

NEWS & TECHNOLOGY<br />

EXECUTIVE INTERVIEW<br />

Patents drive innovation<br />

By Nick Flaherty<br />

Despite all the legal battles between Samsung and<br />

Apple, patents are a key way of protecting investors and encouraging<br />

the exploitation of innovation, says the UK’s leading<br />

engineer, James Dyson. More has to be done to generate more<br />

engineers, more patents and more innovation in <strong>Europe</strong> over the<br />

next 20 years.<br />

“I get very depressed and alarmed when I hear people have<br />

copied technology, infringed the patent and got away with it<br />

because I know it will encourage plagiarism and discourage<br />

innovation,” he said. “If you don’t have patents you won’t have<br />

innovation.”<br />

Patents do not stifle<br />

innovation, he says. “I see<br />

patents as a way of increasing<br />

competition not least<br />

because when someone has<br />

discovered a way of doing<br />

some<strong>thin</strong>g and patented it,<br />

if you want to compete with<br />

them you have to develop<br />

your own way of competing<br />

and develop your own<br />

technology, not copy theirs,“<br />

he said. “If someone takes<br />

the risk of spending lots of<br />

time and lots of money in<br />

developing technology and<br />

a lot of money going into<br />

production and making a<br />

success of it, if people are<br />

able to copy it then no one<br />

will conduct innovation, no<br />

one will do research and<br />

development.”<br />

The defence of “prior art” isn’t necessarily helpful, he says,<br />

as a patent is just as much about making the ideas work in<br />

practice, not just protecting the idea.<br />

Dyson, who founded his consumer electronics company in<br />

1992 and now employs 1000 engineers in the UK, sees <strong>Europe</strong><br />

as falling behind countries like China and India in innovation.<br />

“If you look at the number of patents filed in the UK and in<br />

Germany, it’s not that we are filing fewer patents,” he said. “The<br />

problem is that our competitors like China, Korea and India are<br />

filing an increasing number of patents, so the problem is that we<br />

will be left behind.”<br />

While the quality of patents in the US and <strong>Europe</strong> is higher,<br />

this will change with countries like China producing very large<br />

numbers of engineers. “We can’t stay as we are, we have to redouble,<br />

more than re-double, our efforts to develop new technology,<br />

train new engineers and scientists in order to maintain<br />

our position,” he said.<br />

“There are several <strong>thin</strong>gs we need to do. The first is to<br />

increase the number of engineers. We are under-producing the<br />

numbers we need in Britain by 50% and the same is true in<br />

Germany. Iran and Mexico produce twice as many engineering<br />

graduates as Britain so we are under-producing and industry is<br />

short of engineers.<br />

“The second problem is that governments need to recognise<br />

that in order to win world markets you have to produce better<br />

technologies than your competitors because if you can’t you<br />

have no<strong>thin</strong>g to export,” he said.<br />

Part of this comes from providing the right environment for<br />

innovation to thrive, he says, from training engineers to backing<br />

innovation and research. “Developing new technology is very<br />

risky and you have to acknowledge that and incentive people to<br />

develop it,” he said. “You have to have the right sort of structure<br />

to encourage it but you do have to encourage individuals. A lot<br />

of new technology and risk taking happens because an individual<br />

wants to do it and drives the business through, so I <strong>thin</strong>k<br />

you need to encourage that as well.”<br />

One example of this is the James Dyson Awards, which run<br />

every year to find the best young engineers. The 2012 awards<br />

were announced last week (30th August) and includes projects<br />

from 18 countries, from a retrofit LED bulb, that due to its innovative<br />

heatsink, reaches a light output equivalent to 175W and<br />

an eye-controlled camera to earplugs with built-in alarms.<br />

“Innovation is innate,” said Dyson. “We employ a lot of<br />

graduates and you just allow them to develop their technology,<br />

develop their ideas and when you see them, take them and run<br />

with them. We want to change <strong>thin</strong>gs.<br />

It’s not hard to inspire young engineers, he says. “Allowing<br />

them to take risks and making sure it goes into production,<br />

that’s all you have to do as young people have that innovation<br />

and desire to change the world, you just have to use it,” he said.<br />

Dyson is also looking at long term research that will generate<br />

innovation and patents over the next 15 to 20 years.<br />

“We are investing in new materials, <strong>thin</strong>gs that can be substrates<br />

for chips, looking 15 to 20 years into the future because<br />

you have to,” he said. “Electric motors are a very interesting<br />

area of development, as are robotics, batteries and sound, but<br />

electronics is only an enabler. The technology that goes with it<br />

is much harder,” he said.<br />

12 Electronic Engineering <strong>Times</strong> <strong>Europe</strong> September 2012 www.electronics-eetimes.com

POWER DESIGN<br />

Wireless power outlets designed to<br />

support the IPv6 Internet protocol<br />

By Paul Buckley<br />

A new Internet-enabled power outlet was developed by<br />

researchers at the Fraunhofer Institute for Communication<br />

Systems ESK in Munich will allow users to control household<br />

appliances via their smartphone, and reduce their energy costs<br />

into the bargain.<br />

The smart socket was developed in collaboration with the<br />

Fraunhofer Institute for Industrial Mathematics<br />

ITWM in Kaiserslautern and the industrial<br />

partner embedded brains GmbH.<br />

The solution means that soon there will be<br />

no need for special timers to switch lighting<br />

on and off or operate household appliances<br />

when the homeowner is absent. In<br />

future, all this can be done by means of a<br />

smartphone or PC, thanks to Internet-enabled<br />

wireless power outlets that support<br />

the new IPv6 Internet protocol.<br />

“We have been able to connect the<br />

power outlets wirelessly using the IPv6 protocol,” said ESK research<br />

engineer Günter Hildebrandt. “All household appliances<br />

plugged in one of the sockets can be switched on and off remotely<br />

using an IPv6-compatible device such as a smartphone<br />

or laptop PC – from anywhere.”<br />

The wireless power outlets are a component of the HexaBus<br />

home automation system that was developed by the ITWM as<br />

part of the mySmartGrid project - www.mysmartgrid.de.<br />

“The HexaBus components make the smart home of the<br />

future a reality. They enable household appliances to be<br />

controlled intelligently, thus optimizing or reducing electricity<br />

consumption. For example, the householder can start the<br />

washing machine during cheap-rate off-peak hours, or run<br />

the dishwasher when the photovoltaic panels on the roof are<br />

generating sufficient power,” said industrial engineer Mathias<br />

Dalheimer of the ITWM, who leads the SmartGrid project and is<br />

its chief programmer.<br />

In addition to the wireless power outlets,<br />

the HexaBus system employs a specially<br />

designed USB stick that plugs into any<br />

compatible, off-the-shelf router. The user<br />

enters the command to switch on an appliance<br />

via a standard web browser or an<br />

Android-compatible smartphone app. The<br />

router and stick then forward the data to<br />

the power outlet.<br />

The two-way communication function<br />

also allows the wireless power outlet to<br />

send data to the smartphone, informing<br />

the user how much power various appliances are consuming<br />

at any given time. Because the HexaBus system is based on<br />

the IPv6 data communication protocol, a separate IP address is<br />

assigned to each power outlet, and thereby to each connected<br />

appliance, enabling them to be accessed directly. But how did<br />

the researchers go about integrating Internet functionality in the<br />

wireless power outlets and USB sticks? To do so, Hildebrandt<br />

and his team developed special protocol software and an extension<br />

to the Contiki operating system that enables it to handle<br />

the 6LoWpan (IPv6 over Low power Wireless Personal Area<br />

Network) communication protocol.<br />

Lithium-ion battery pilot production line<br />

established by German research center<br />

By Christoph Hammerschmidt<br />

German research center ZSW (Zentrum für Sonnenenergieund<br />

Wasserstoff-Forschung) will install a test production line for<br />

lithium-ion batteries for electric vehicles. The goal of the project<br />

is the development and test of prismatic Li-ion batteries with a<br />

capacity of 20 Ah and more. Such batteries will be used as drive<br />

batteries in electric cars. The pilot production line is scheduled<br />

to start its activities in 2014.<br />

The project has been initialized by industry network KLiB<br />

(Kompetenznetzwerk Lithium-Ionen-Batterien). KLiB counts<br />

numerous companies along the entire battery production value<br />

chain to its members, including BASF, BMW, Bosch, Daimler,<br />

Dow, SB Limotive, Siemens and Varta.<br />

The project aims at industrial-grade production processes<br />

for large Li-ion batteries. At the same time, it offers the chance<br />

to validate new materials and production techniques as well as<br />

methods for quality assurance. “This research production line<br />

will close the gap between manufacturing at the laboratory level<br />

and serial production,” explained KLiB chairman Hubert Jäger.<br />

“This is a central requirement of the German Electromobility<br />

Platform. Wi<strong>thin</strong> the KLiB a number of working groups have<br />

been formed with focus on each stage of the value chain - for<br />

instance materials for anode, cathode, separator and electrolytes,<br />

automation technology, cell production, and battery<br />

production. According to a joint press release of ZSW and KLiB,<br />

the project represents the first opportunity in Germany for all<br />

companies involved to access a value chain-spanning R&D<br />

platform that completes in-house R&D efforts. The project is<br />

funded in part by the federal German research ministry with<br />

23.5 million euros.<br />

www.electronics-eetimes.com Electronic Engineering <strong>Times</strong> <strong>Europe</strong> September 2012 13

NEWS & TECHNOLOGY<br />

LED LIGHTING<br />

Innovative LED geometry could increase<br />

light output by factor of ten<br />

By Christoph Hammerschmidt<br />

New three-dimensional assembly of LEDs could dramatically<br />

multiply the light output compared to today’s planar<br />

devices, <strong>Europe</strong>an scientists hope. The EU research project<br />

GECCO aims at vertically oriented LEDs with much higher efficiency.<br />

Already now, modern high-performance LEDs provide a<br />

bright light output at high efficiency and are meanwhile applied<br />

for automobile headlights, for example. At present, the production<br />

process for these kinds of LEDs is still not cost efficient<br />

enough and also the efficiency of these LEDs needs further<br />

improvement.<br />

The international team of the GECCO project with their partners<br />

from Madrid, Bristol, Lodz, as well as LED manufacturer<br />

Osram is working on achieving their ambitious objectives.<br />

Up to now, LEDs are being constructed in a planar way,<br />

meaning in layers and completely flat. The more light is being<br />

required, the more wafer area has to be produced - an expensive<br />

and laborious <strong>approach</strong>. The idea of the GECCO project is<br />

to assemble LEDs in a three-dimensional way so that actually<br />

every LED consists of a ‘light emitting tower’ from which the entire<br />

vertical surface is emitting light. Obviously the surface of the<br />

tower is much larger compared to the ground area of a planar<br />

LED. And in fact, it is exactly the gain of light emitting area that<br />

leads to a higher<br />

light output.<br />

Thus, the manufacturing<br />

of an LED<br />

becomes much<br />

more cost-effective<br />

and as a result replacing ancient electric bulbs, halogen lamps<br />

as well as energy saving bulbs to LEDs is getting significantly<br />

more profitable. Considering the fact that currently 20% of<br />

electrical energy worldwide is being utilized for illumination, this<br />

innovation provides an enormous potential as far as cost-effectiveness<br />

is concerned. In addition, LED lighting is particularly<br />

important for future electric mobility. <strong>Energy</strong> saving is of utmost<br />

importance in electric cars.<br />

The dimensions of the ‘light emitting towers’ are wi<strong>thin</strong> the<br />

micrometer range. This means approximately one million LEDs<br />

fit on an area of one square millimeter. This process requires<br />

utmost precision which can only be achieved by applying nanotechnology<br />

manufacturing techniques.<br />

The GECCO project is coordinated by Prof. Andreas Waag<br />

from the Institute of Semiconductor Technology of the Braunschweig<br />

Technical University.<br />

Light-emitting foils could offer<br />

cost-effective OLED alternative<br />

By Christoph Hammerschmidt<br />

Researchers from the university of umea (Sweden)<br />

have produced organic light-emitting electrochemical cells<br />

(LECs) using a roll-to-roll compatible process under ambient<br />

conditions. The manufacturing technology developed by the<br />

Swedish team opens the perspective on producing extremely<br />

<strong>thin</strong> light emitting foils in an inexpensive<br />

process.<br />

Applications for the LEC foils could<br />

be informative displays. At a later stage<br />

of development, the foils could also be<br />

used for lighting applications, offering a<br />

cheaper alternative to today’s OLEDs, said<br />

Physics Professor Ludvig Edman from the<br />

Umea university. Edman’s group at Umea<br />

University is focusing on novel organic<br />

compounds (such as light-emitting and<br />

conducting polymers and graphene) and<br />

develops LECs based on such materials. The researchers say<br />

they have dramatically improved the energy efficiency and lifetime<br />

of LECs. They have demonstrated the unique physics and<br />

chemistry behind their operation and recently they enhanced<br />

the performance of LECs to a point where lifetime and efficiency<br />

make LECs useful for signage applications.<br />

The next step in the development was to ensure that the<br />

manufacturing costs can be attractive for commercial applications.<br />

According to a report of the team, published in Nature<br />

Communications, the team managed to deposit a light-emitting<br />

layer and a PEDOT-PSS anode on top of a<br />

flexible cathode-coated substrate mounted on<br />

a roll by means of a slot-die head, using solely<br />

air-stable materials in a roll-coater apparatus.<br />

The layers in the produced LEC device were<br />

found to be highly uneven, and the layer thickness,<br />

for both active layer and anode, was<br />

very thick at approximately 1µm. However,<br />

due to the unique self-doping operation of the<br />

LEC, the light emitted did not suffer from the<br />

rough interfaces, and was in fact found to be<br />

very uniform. This feature is ideal for roll-toroll<br />

processes, as the demands of the coating quality can be<br />

relaxed thus lowering the costs substantially. The researchers<br />

point out that all the steps involved, i.e. preparation of inks,<br />

the subsequent coating of the constituent layers, and the final<br />

device operation all could be carried out under ambient air.<br />

14 Electronic Engineering <strong>Times</strong> <strong>Europe</strong> September 2012 www.electronics-eetimes.com

MATERIAL SCIENCES<br />

First microwave laser to operate<br />

at room temperature<br />

By Nick Flaherty<br />

Scientists in the uk have developed the first solid-state<br />

MASER to operate at room temperature, paving the way for its<br />

widespread adoption.<br />

The researchers from the National<br />

Physical Laboratory (NPL) and Imperial<br />

College London suggest that roomtemperature<br />

MASERs could be used<br />

to make more sensitive medical instruments<br />

for scanning patients, improved<br />

chemical sensors for remotely detecting<br />

explosives; lower-noise read-out<br />

mechanisms for quantum computers<br />

and better radio telescopes for potentially<br />

detecting life on other planets. The<br />

microwave equivalent of a laser, masers<br />

deliver a concentrated beam of microwaves<br />

by amplifying microwaves using<br />

hard inorganic crystals such as ruby. But<br />

they have always required extreme conditions<br />

such as extremely low pressures<br />

or temperatures close to absolute zero<br />

(-273.15°C), as well as strong magnetic<br />

fields from large magnets.<br />

The team have demonstrated pulse<br />

masing in a solid-state device working in<br />

air at room temperature with no applied<br />

magnetic field. This could dramatically<br />

reduce the cost to manufacture and<br />

operate a MASER, which could lead to<br />

them becoming as widely used as laser<br />

technology in a wide range of applications.<br />

“For half a century the MASER has<br />

been the forgotten, inconvenient cousin<br />

of the laser. Our design breakthrough<br />

will enable MASERs to be used by<br />

industry and consumers,” said Dr Mark<br />

Oxborrow, co-author of the study at<br />

NPL. The team used a completely different<br />

type of crystal, namely p-terphenyl<br />

doped with pentacene, to replace ruby<br />

and replicate the same masing process<br />

at room temperature. As a curious twist,<br />

the pentacene dopant turns the otherwise<br />

colourless p-terphenyl crystal an<br />

intense reddish pink.<br />

The first device only works in pulsed<br />

mode for fractions of a second at a time.<br />

They aim to get it to operate continously<br />

over a range of microwave frequencies,<br />

instead of its current narrow bandwidth,<br />

which would make the technology more<br />

useful. In the long-term, the team has a<br />

range of other goals including the identification<br />

of different materials that can<br />

While the world benefi ts<br />

from what’s new, I<strong>EE</strong>E can<br />

focus you on what’s next.<br />

Request a Free Trial<br />

www.ieee.org/tryieeexplore<br />

11-PIM-0544d_Xplore_WhatsNext_5x7.875_FINAL..indd 1<br />

mase at room temperature while consuming less power than<br />

pentacene-doped p-terphenyl.<br />

Develop for tomorrow with<br />

today’s most-cited research.<br />

Over 3 million full-text technical documents<br />

can power your R&D and speed time to market.<br />

• I<strong>EE</strong>E Journals and Conference Proceedings<br />

• I<strong>EE</strong>E Standards<br />

• I<strong>EE</strong>E-Wiley eBooks Library<br />

• I<strong>EE</strong>E eLearning Library<br />

• Plus content from select publishing partners<br />

I<strong>EE</strong>E Xplore ® Digital Library<br />

Discover a smarter research experience.<br />

12/16/11 9:30 AM<br />

www.electronics-eetimes.com Electronic Engineering <strong>Times</strong> <strong>Europe</strong> September 2012 15

NEWS & TECHNOLOGY<br />

VLSI report<br />

Custom designed wireless links:<br />

what the 2012 VLSI Symposia had on offer<br />

By Julien Happich<br />

sponsored by the electron devices Society, the Solid<br />

State Circuits Society and the Japan Society of Applied Physics,<br />

the 2012 VLSI Symposia which took place last summer<br />

in Honolulu came as an opportunity for researchers to unveil<br />

new short-range wireless links and design concepts. Striking<br />

examples include inductive RF coupling solutions for in-chip<br />

communications or through-skull neural sensing data collection.<br />

A team of researchers from the Department of Electrical Engineering<br />

and Computer Sciences at the University of California,<br />

Berkeley, presented a 260GHz fully integrated CMOS transceiver<br />

for wireless chip-to-chip communication. Designed in<br />

65nm CMOS, the OOK modulation (On/Off Key) transceiver was<br />

demonstrated to transmit 10Gb/s over a range of 40mm.<br />

The Tx/Rx dual on-chip antenna array is implemented with<br />

half-width leaky wave antennas. Each transmitter consists of<br />

a quadrupler driven by a class-D-1 PA with a distributed OOK<br />

modulator, and outputs +5 dBm of EIRP. The receiver uses a<br />

double balanced mixer to down-convert<br />

to a Vband IF signal that is amplified with<br />

a wideband IF driver and demodulated<br />

on-chip.<br />

Another team from the same department<br />

presented a 65nm CMOS-integrated<br />

wireless neural sensor with a footprint<br />

of 0.125mm 2 for minimally invasive<br />

surgery, drawing only 10.5μW.<br />

This brain-machine interface consists<br />

of an array of electrodes that extend<br />

vertically to reach relevant neurons, the<br />

wirelessly powered 65nm CMOS IC integrating<br />

four 1.5μW amplifiers (6.5μVrms<br />

input-referred noise for a 10kHz bandwidth)<br />

with power conditioning and<br />

communication circuitry, and an inductive<br />

coupling receiver (RX) coil placed on<br />

top of the active circuitry to minimize the<br />

device’s total footprint.<br />

This neural sensor is claimed to be<br />

able to record action potentials with<br />

enough resolution to<br />

control a complex robotic<br />

prothesis. Data is<br />

then transmitted through<br />

the brain’s dura to a subcutaneous<br />

interrogator.<br />

The four 10-bit, 20kHz<br />

ADCs generate 800kbps<br />

of neural data, which<br />

is backscattered after<br />

each sample is taken.<br />

The interrogator initiates<br />

sampling and communication<br />

by sending a<br />

20kHz beacon.<br />

Fig. 2: Conceptual system diagram of a<br />

wireless neural sensor.<br />

Fig. 1: Sub THz wireless data-link setup.<br />

Fig. 3: ThruChip interface (TCI): (a) inductive coupling, (b) coil by multi-layer wires.<br />

A paper from the Keio University,<br />

Japan, disclosed the use of inductive<br />

coupling, dubbed ThruChip Interface<br />

(TCI) for inter-chip communication. In effect,<br />

the idea is to use near-field wireless<br />

connections between different 3D-chip<br />

levels, instead of silicon vias. Designed<br />

as part of the digital CMOS circuit<br />

integration, this solution is claimed to<br />

be less expensive than using through<br />

silicon vias (TSVs) while offering similar<br />

bandwidth. The researchers listed various<br />

issues with TSVs, including their<br />

excessive footprint or the open failures<br />

they cause due to thermal stress.<br />

They looked at near-field communication<br />

at 50GHz in the 1mm range. The<br />

ThruChip Interface is described as being<br />

surge-tolerant, thermally resilient, while<br />

imposing no restrictions on the circuit<br />

position wi<strong>thin</strong> multi-layer stacks. This<br />

multi-layer interconnection is said to<br />

require only 3% of the footprint of conventional<br />

CMOS I/Os. It<br />

was tested with stacks<br />

of 128 dies, supporting<br />

a data rate per coil of<br />

11Gb/s/ch and aggregating<br />

a data rate of<br />

8Tb/s by arranging 1000<br />

channels wi<strong>thin</strong> 6.4mm 2<br />

while drawing two orders<br />

of magnitude less power<br />

than conventional highspeed<br />

memory links<br />

such as DDR.<br />

This inter-chip, intrastack<br />

communication<br />

16 Electronic Engineering <strong>Times</strong> <strong>Europe</strong> September 2012 www.electronics-eetimes.com

smart system integration 2012<br />

technology could find use not only<br />

in large memory stacks that make<br />

up solid-state drives but also for<br />

multiple processor packages or<br />

for non-contact wafer-level testing<br />

as well as for debugging by probing<br />

internal bus data wirelessly<br />

through a device’s package.<br />

A student in the Department<br />

of Electrical Engineering at the<br />

National Tsing Hua University in<br />

Taiwan, Chang-Ming Lai presented<br />

an ultra-wideband (UWB)<br />

impulse radio timed-array radar<br />

implemented in 0.18μm CMOS<br />

technology.<br />

Using a time-shifted directsampling<br />

architecture, the 4-channel<br />

transmitter array generates<br />

and sends a variety of 10GS/s pulses towards targets while the<br />

receiver array samples the reflected signal in RF domain directly<br />

by time interleaved sampling at 20GS/s. The radar system can<br />

Fig. 4: Human brea<strong>thin</strong>g as seen over a distance of 3m by<br />

the UWB impulse radio timed-array radar.<br />

determine time of arrival (TOA) and<br />

direction of arrival (DOA) through<br />

time-shifted sampling edges which<br />

are generated by on-chip digital-totime<br />

converters (DTC).<br />

According to the student, the<br />

proposed architecture has range<br />

and azimuth resolution of 0.75cm<br />

and 3 degree respectively - see<br />

figure 4.<br />

This UWB impulse radio timedarray<br />

radar system can identify<br />

multiple targets by measuring simultaneously<br />

both direction of arrival<br />

(DOA) and time of arrival (TOA) of<br />

the radio waves scattered by several<br />

objects.<br />

What’s more, for high-fidelity<br />

detection, the scattering waveform of<br />

UWB pulses from the radio interaction<br />

between the radar and the detected objects can be reconstructed<br />

through the analogue signal processing array (ASP) of<br />

the radar receiver.<br />

Game Changer<br />

A Winning Strategy for All your Product Needs!<br />

The LPKF ProtoLaser U3 creates applications for product development that were previously only possible with the help<br />

of large, industrial systems. The machine’s UV laser processes nearly all materials, including laminated substrates.<br />

Visit www.lpkf.com to learn more about the new LPKF ProtoLaser U3.<br />

<strong>Europe</strong>an Microwave Week: 29. – 31.10.2012, Halle 3, Stand B425<br />

electronica: 13. – 16.11.2012, Halle B1, Stand 319<br />

LPKF Laser & Electronics AG Phone +49 (0) 5131-7095-0<br />

www.electronics-eetimes.com Electronic Engineering <strong>Times</strong> <strong>Europe</strong> September 2012 17

DESIGN & PRODUCTS<br />

<strong>Energy</strong> <strong>harvesting</strong><br />

<strong>Energy</strong> harvesters: a <strong>thin</strong> <strong>film</strong> <strong>approach</strong><br />

By Julien Happich<br />

during idtechex’last energy <strong>harvesting</strong> and Storage<br />

<strong>Europe</strong> conference held in Berlin, <strong>thin</strong> piezoelectric and<br />

low foot-print thermoelectric materials were cited in many new<br />

energy <strong>harvesting</strong> research programs and design implementations.<br />

The ultimate goal, as for many electronic applications,<br />

is to replace bulky energy <strong>harvesting</strong> units by lower cost and<br />

conformable <strong>film</strong>-like solutions that are easier to integrate or to<br />

wear.<br />

Michele Guizzetti, Erling Ringgaard and Tomasz Zawada from<br />

Meggitt Sensing Systems presented their use of Lead Zirconate<br />

Titanate (PZT) piezoelectric thick <strong>film</strong>s for energy <strong>harvesting</strong><br />

through the conversion of kinetic energy into electrical energy.<br />

The conversion is done through the vibration of a cantilever<br />

beam covered with piezoelectric material.<br />

The stress induced by the vibrations (kinetic energy) creates<br />

the electrical charges which are harvested as a micro-current.<br />

After studying the optimal design of a piezoelectric bending<br />

structure where the neutral bending axis should be located at<br />

the interface between the PZT materials and the passive (Si)<br />

materials, the team established that for the typical device layer<br />

thickness of the Silicon on Insulator (SoI) wafer being used (20<br />

μm), a layer of 30 to 40 μm of active PZT material should be<br />

used.<br />

Meggitt Sensing System implements this through its proprietary<br />

thick <strong>film</strong> InSensor technology, screen-printing and<br />

integrating piezoelectric layers from 10 to 100 µm in thickness<br />

with a surface resolution of 100x100µm. Dispersed in an organic<br />

vehicle, the piezoelectric material can be screen-printed on a<br />

number of substrates that are compatible with MEMS manufacture<br />

for the design of the bending structures. Using silicon<br />

micromachining and screen-printing techniques, the researchers<br />

developed single clamped cantilever devices measuring<br />

10x10mm 2 , featuring a silicon proof mass at the free end of the<br />

cantilever – see figure 1 and 2.<br />

They tried various cantilever shapes and mass-beam length<br />

ratios (MBR) in both unimorph and bimorph configurations.<br />

Designed in cooperation with the department of micro and<br />

nanotechnology of the technical<br />

university of Denmark (DTU<br />

Nanotech), the devices yielded a<br />

charge sensitivity up to 37nC/g<br />

at 0.5 g peak, delivering up to<br />

4V at 0.5 g peak for the bimorph<br />

device, generating 15 to 20μW of<br />

power at moderate accelerations<br />

of about 0.5 g.<br />

The team demonstrated that<br />

the bandwidth of these microgenerators<br />

can be increased by<br />

introduction of non-linear effects<br />

such as magnetic coupling or<br />

mechanical non-linearity. These<br />

PZT thick-<strong>film</strong> micro-generators<br />

can be used to power sensor<br />

nodes for energy-autonomous,<br />

wireless measurement of acceleration<br />

and temperature.<br />

Fig. 1: Meggitt’s clamped cantilever device showing a silicon<br />

proof mass at the free end of the cantilever.<br />

Fig. 3: Algra’s Dynasim foils with a screen printable<br />

piezoelectric lacquer can be used in flexural mode.<br />

Fig. 2: A wafer showing<br />

several piezoelectric bending<br />

structures.<br />

Dr. Venkatesh Sivasubramaniam<br />

from swiss-based<br />

company Algra showcased a<br />

wireless piezoelectric switch<br />

for handheld or wall-mounted<br />

applications. Commercialized<br />

as Dynapic Wireless, the low<br />

actuation force (5N) switch<br />

relies on a simple piezoelectric<br />

membrane sandwiched between<br />

an overlaid electrode,<br />

a spacer defining the actuation<br />

displacement and a <strong>thin</strong> PCB on which the electronics is<br />

assembled.<br />

The circuitry includes a custom power management ASIC,<br />

a low power MCU and an RF transceiver capable of running<br />

standard low-power wireless protocols. The switches have been<br />

tested to over 10 million cycles, a longevity that is due to the<br />

low homogeneous stress level applied to the circular piezoelectric<br />

membrane, claims the company. As well as its noise-free<br />

switch, Algra discussed flexible<br />

piezoelectric polymer composite<br />

sensor foils – see figure 3. Instead<br />

of a sintered piezoelectric disc,<br />

Algra’s Dynasim foils feature a<br />

screen printable piezoelectric<br />

lacquer built up on electrode material<br />

using a roll-to-roll thick <strong>film</strong><br />

deposition technique. To be used<br />

in flexural mode, the foil could<br />

deliver enough energy to wake<br />

up a microprocessor from a deep<br />

sleep mode.<br />

A supplier of PMN-PT (lead<br />

magnesium niobium-lead titanate)<br />

single piezoelectric crystals,<br />

iBULe Photonics’ CEO Sang-Goo<br />

Lee presented his company’s<br />

<strong>approach</strong> to acoustic micro-gener-<br />

18 Electronic Engineering <strong>Times</strong> <strong>Europe</strong> September 2012 www.electronics-eetimes.com

TFTs<br />

Rugged TFT-LCD Modules<br />

viewing excellence<br />

semis.info@meg.mee.com · www.mitsubishichips.eu Stand 1-639

DESIGN & PRODUCTS<br />

<strong>Energy</strong> <strong>harvesting</strong><br />

ators. The company has the know-how to bond PMN-PT single<br />

crystals onto silicon wafers and then micro-machine them into<br />

resonating structures of appropriate thicknesses (down to 15<br />

microns), in effect, designing what it calls piezoelectric micromachined<br />

ultrasonic transducers (P-MUT).<br />

The efficiency of PMN-PT vibrational energy harvesters is<br />

about seven times that of PZT-based devices, highlighted Lee.<br />

iBULe Photonics has built<br />

up prototypes of monolayer<br />

acoustic generators arrays<br />

measuring 30x30mm,<br />

featuring arrangements of<br />

10x10 microgenerator cells<br />

each 2.5mm in diameter<br />

and only 0.01mm <strong>thin</strong> – see<br />

figure 4.<br />

With 15mWh delivered<br />

by each cell at a sound<br />

pressure of 1Pa at 12.5kHz,<br />

the whole array could yield<br />

up to 1500mWh of usable<br />

power. The company is also<br />

Fig. 4: One of iBULe Photonics’<br />

microgenerator cells, 2.5mm in<br />

diameter and only 0.01mm <strong>thin</strong>.<br />

looking at superposing several such arrays to increase power<br />

output. Future developments include the use of PMN-PT/epoxy<br />

piezocomposite materials to build up 3-dimensional energy <strong>harvesting</strong><br />

structures and the use of <strong>thin</strong>-<strong>film</strong> batteries for energy<br />

storage on the same device.<br />

Fig. 5: AIST’s thermoelectric conversion <strong>film</strong> devices fabricated<br />

by stencil printing yields a fully flexible prototype.<br />

A researcher at the National Institute of Advanced Industrial<br />

Science and Technology (AIST) from Japan, Kouji Suemori presented<br />

new materials printable into thermoelectric conversion<br />

devices. Unlike many competing thermoelectric materials, the<br />

carbon nanotube-polymer composite developed by the AIST<br />

does not contain rare metals such as Bi and Te.<br />

The composite is mixed mechanically at a nanometer-level<br />

with a resin matrix in an inking solvent and can then be printed<br />

onto flexible substrates such as plastic <strong>film</strong>s and papers. Adding<br />

drying and sintering steps, this process enables the manufacture<br />

of thermoelectric conversion devices onto 20µm-thick<br />

substrates that conform to any shape for optimum conversion<br />

efficiency.<br />

The thermoelectric energy harvester is obtained through<br />

stencil printing, patterning tiny material sections between top<br />

and bottom electrodes to form many thermoelectric cells that<br />

are connected in series – see figure 5.<br />

As shown in figure 5, the researchers prototyped a flexible<br />

thermoelectric conversion <strong>film</strong> featuring 1000 such devices in<br />

series, each cell measuring 0.5×0.8×0.3mm.<br />

This thermoelectric conversion<br />

<strong>film</strong> remained operational even<br />

when bent at 5mm of curvature.<br />

It has shown to be conformable<br />

to both curved and spherical surfaces<br />

while being able to generate<br />

power with small temperature<br />

differences.<br />

This could even be used in<br />

garments for wearable power<br />

generation. As a lab experiment,<br />

the temperature difference created<br />

by one’s hand placed on<br />

top of the <strong>film</strong> fixed to a 10°C<br />

plate generated 108.9mV - see<br />

figure 6.<br />

Fig. 7: Wibicom’s photovoltaic antennas for UWB<br />

transceivers. (a) Dipole antenna. (b) Loop antenna.<br />

Fig. 6: A flexible thermoelectric conversion <strong>film</strong> generating<br />

power through the temperature difference created by a hand<br />

on the <strong>film</strong> installed on a 10 °C plate generated 108.9mV.<br />

Taking a look at every<strong>thin</strong>g <strong>thin</strong>, Wibicom should be cited<br />

for its innovative <strong>approach</strong> to antenna design, directly powered<br />

by dye sensitised cells fabricated on top of an antenna foil.<br />

The small technical consulting company from the Netherlands<br />

presented its WibiSol concept antenna capable of <strong>harvesting</strong><br />

energy from ambient light or the sun and simultaneously transmitting<br />

and receiving RF signals – see figure 7.<br />

In previous papers, the company founder & CEO Mina<br />

Danesh detailed the implementation of dipole and loop antennas<br />

designed for 3.1 to 10.6GHz ultrawideband communications,<br />

covered with amorphous-silicon PV cells based on<br />

hydrogenated amorphous silicon (aSi:H). The dipole antenna<br />

uses two separate PV cells measuring 20×20mm 2 , each having<br />

its own DC connections,<br />

connected in parallel.<br />

The loop antenna has<br />

five-series DC-connected<br />

cells. In this case the PV<br />

module is 25mm wide<br />

and 110mm long with a<br />

loop diameter of 36mm.<br />

Here again for the continuous<br />

operation of sensor<br />

nodes, the photovoltaic<br />

energy would have to be<br />

stored in supercapacitors<br />

or in <strong>thin</strong>-<strong>film</strong> rechargeable<br />

batteries.<br />

20 Electronic Engineering <strong>Times</strong> <strong>Europe</strong> September 2012 www.electronics-eetimes.com

Turning waste heat from industrial piping<br />

into electrical energy<br />

By Josh Moczygemba<br />

Marlow Industries’ EverGen PowerStrap is a thermoelectric-based<br />

energy <strong>harvesting</strong> solution that produces multiple<br />

watts of power by conversion of waste heat from industrial piping<br />

directly into electrical energy. This product provides remote<br />

power for wireless sensors, wireless transmitters, actuators,<br />

and controls in large industrial, chemical, oil and gas infrastructures.<br />

This energy <strong>harvesting</strong> solution can be customized to fit<br />

any pipe diameter and pipe orientation, without modification to<br />

existing pipeline infrastructure.<br />

Power output is proportional to the temperature difference<br />

from the pipe surface to ambient, and the number of straps<br />

employed in the application. The EverGen PowerStrap is<br />

composed of three main components: Bi2Te3 thermoelectric<br />

generators (TEGs), anodized aluminium clamping straps and<br />

natural convection heat sinks.<br />

The TEG modules produce power from the temperature<br />

difference between the pipe wall and ambient air. They have a<br />

maximum operating temperature of 230°C and are sealed for<br />

environmental protection. The clamping straps provide a geometrical<br />

transition from the round exterior pipe wall to the flat<br />

TEG surface. The clamp attaches with a compression technique<br />

that requires no modifications to the pipe wall. Straps are<br />

custom sized based on pipe diameter. The heat sinks dissipate<br />

heat to the ambient environment, they are typically made of<br />

aluminium with anodized coatings.<br />

Design methodology<br />

Maximizing power in the EverGen P owerStrap system requires<br />

a balance between the thermal and electrical system design.<br />

Thermal optimization starts by defining a thermal load resistance<br />

ratio (m).<br />

CircularConnectorsAd-<strong>EE</strong><strong>Times</strong>_Layout 1 8/22/12 2:25 PM Page 1<br />

Josh Moczygemba is Power Generation Product Engineering<br />

Manager at Marlow Industries - www.marlow.com<br />

Circular Connectors<br />

Our vertical integration gives you custom<br />

MIL & Hi-Rel connectors FAST!<br />

• Custom EMI filtered and unfiltered connectors<br />

• We make our own planar and tubular capacitors,<br />

shells, shields, seals and grommets<br />

• Vertical integration means higher quality and the<br />

industry's shortest lead times (8-10 weeks, std)<br />

• Filtered connector styles include MIL-DTL-38999,<br />

MIL-DTL-83723, MIL-DTL-26482, MIL-DTL-55116<br />

and MIL-DTL-24308<br />

• Our EMI expertise gives you a better filtered connector<br />

• 100% testing for critical electrical parameters<br />

• Harnessing products to IPC-A-610 and J-STD-001<br />

Check out our new<br />

Specialty Connector Video @<br />

SpecEMC.com/specvid<br />

Call +49-9122-7950 or visit apitech.com/eis<br />

www.electronics-eetimes.com Electronic Engineering <strong>Times</strong> <strong>Europe</strong> September 2012 21

DESIGN & PRODUCTS<br />

ENERGY HARVESTING<br />

Where R TEG<br />

,thermal is the thermal<br />

resistance of the thermoelectric elements,<br />

HSR is the thermal resistance from the hot<br />

source to the hot side of the thermoelectric<br />

elements and CSR is the thermal resistance<br />

from the cold source to the cold side of the<br />

thermoelectric elements.<br />

Figure 2 represents the impact on<br />

performance that different thermal load<br />

ratios have on the power output. For most<br />

thermoelectric applications, designing<br />

for a thermal load resistance ratio of one<br />

ensures the best performance possible. In<br />

the case of the EverGen PowerStrap, the<br />

best performing natural convection heat<br />

sink was chosen, based on orientation, size, cost<br />

and manufacturing constraints. Computational fluid<br />

dynamics (CFD) software was used to aid in the heat<br />

sink design optimization. Next, the TEG devices were<br />

designed using Marlow’s proprietary TEG software to<br />

match the thermal resistivity of the natural convection<br />

Fig. 1: A 10-inch diameter<br />

implementation of the EverGen<br />

PowerStrap energy harvester from<br />

Marlow.<br />

generator module was held in compression between<br />

the heat sink and the strap base with two<br />

stainless steel bolts fitted with insulating phenolic<br />

washers. Thermal pads on both sides of the TEG<br />

were used to improve thermal resistance at the<br />

hot (strap) and cold (heat sink) interfaces. The<br />

clamping strap base was divided into three identical<br />

sections that form a compression fit around<br />

the pipe when bolted together. A series of lab<br />

tests were conducted with this design that mimicked<br />

varying operating conditions throughout the<br />

year. The test assembly was made from a section<br />

of 10” diameter steel pipe that was capped at<br />

one end and filled with oil. Submersible heaters,<br />

heat sinks under pure natural convection conditions.<br />

The electrical system optimization is analogous to<br />

the thermal system. For maximum power transfer, the<br />

internal electrical resistance of the power source must match<br />

the electrical resistance of the load being powered. In this case,<br />

the electrical load ratio (n) is defined as<br />

Where R load<br />

is the electrical resistance of the load being powered<br />

and R TEG<br />

,electrical is the electrical resistance of the TEG<br />

module under operating conditions.<br />

Figure 3 highlights why this is a particularly important consideration<br />

when designing thermoelectric power generation<br />

systems. In reality, both electrical and thermal characteristics of<br />

the TEG are interrelated with the thermal resistance of the TEG<br />

being affected by the electrical load connected to the TEG. In<br />

real world applications, where operating conditions and loads<br />

vary, it would be very difficult to always ensure proper load<br />

matching across all operating points due<br />

to temperature dependant properties<br />

of the TEG. Fortunately, commercially<br />

available maximum power point tracking<br />

(MPPT) controllers originally designed for<br />

the solar industry can also perform this<br />

function for thermoelectric systems. In<br />

cases where hybrid solar/thermoelectric<br />

systems are employed, a single MPPT<br />

controller accommodates both. The only<br />

design requirements are that the TEG<br />

system voltage and current outputs for<br />

the operating range meet the input requirements<br />

of the MPPT controller.<br />

Test setup<br />

Figure 1 shows a photograph of a 10-<br />

inch diameter EverGen PowerStrap. The<br />