Product Data Sheet - Valspar Coil & Extrusion

Product Data Sheet - Valspar Coil & Extrusion

Product Data Sheet - Valspar Coil & Extrusion

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ALAMO WHITE TM<br />

<strong>Coil</strong> Coating System<br />

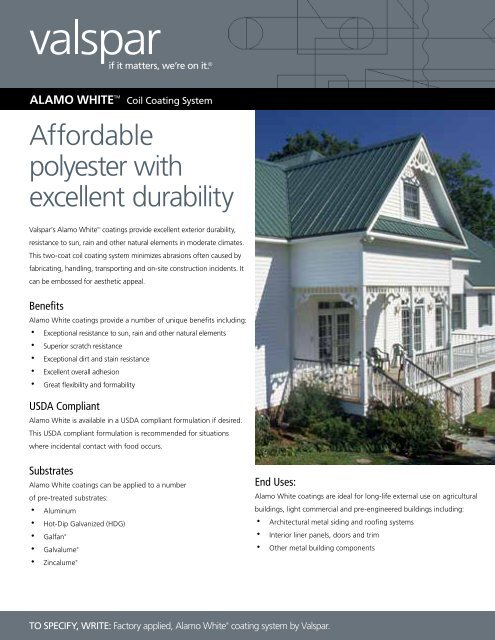

Affordable<br />

polyester with<br />

excellent durability<br />

<strong>Valspar</strong>’s Alamo White TM coatings provide excellent exterior durability,<br />

resistance to sun, rain and other natural elements in moderate climates.<br />

This two-coat coil coating system minimizes abrasions often caused by<br />

fabricating, handling, transporting and on-site construction incidents. It<br />

can be embossed for aesthetic appeal.<br />

Benefits<br />

Alamo White coatings provide a number of unique benefits including:<br />

h Exceptional resistance to sun, rain and other natural elements<br />

h Superior scratch resistance<br />

h Exceptional dirt and stain resistance<br />

h Excellent overall adhesion<br />

h Great flexibility and formability<br />

USDA Compliant<br />

Alamo White is available in a USDA compliant formulation if desired.<br />

This USDA compliant formulation is recommended for situations<br />

where incidental contact with food occurs.<br />

Substrates<br />

Alamo White coatings can be applied to a number<br />

of pre-treated substrates:<br />

h Aluminum<br />

h Hot-Dip Galvanized (HDG)<br />

h Galfan ®<br />

h Galvalume ®<br />

End Uses:<br />

Alamo White coatings are ideal for long-life external use on agricultural<br />

buildings, light commercial and pre-engineered buildings including:<br />

h Architectural metal siding and roofing systems<br />

h Interior liner panels, doors and trim<br />

h Other metal building components<br />

h Zincalume ®<br />

TO SPECIFY, WRITE: Factory applied, Alamo White ® coating system by <strong>Valspar</strong>.

ALAMO WHITE TM<br />

<strong>Coil</strong> Coating System<br />

DATA PERFORMANCE SPECIFICATIONS PRODUCT PERFORMANCE<br />

TECHNICAL DATA Specular Gloss at 60° ASTM D 523 2 20 to 35<br />

Pencil Hardness ASTM D 3363<br />

T-Bend ASTM D 4145 5<br />

Cross Hatch Adhesion ASTM D 3359<br />

F to 2H<br />

2T to 4T 3 , no loss of adhesion<br />

No loss of adhesion<br />

Reverse Impact ASTM D 2794 Aluminum: metal thickness inch-pounds, no loss of adhesion<br />

5 1.5x3<br />

Steel: 3x metal thickness inch-pounds, no loss of adhesion<br />

Humidity Resistance<br />

100% RH 1,000 Hours ASTM D 2247<br />

HDG and Galvalume ® : No field blisters<br />

Salt Spray Resistance<br />

1,000 Hours ASTM B 117<br />

HDG and Galvalume ® : Creep from scribe ≤ 1/8 inch (3mm), few no. 8 blisters<br />

Water Immersion: 168 hours 100° F ASTM D 870<br />

Dew Cycle Weatherometer<br />

200 Total Hours ASTM D 3361<br />

Abrasion Resistance: ASTM D 968<br />

Film Integrity:<br />

Vertical 90° Angle<br />

Non-Vertical Angle > 15° from vertical<br />

Chalk Resistance ASTM D 659 2<br />

Vertical 90° Angle<br />

Color Change: ASTM D 2244<br />

Vertical 90° Angle<br />

No field blisters with minimal color change<br />

Chalk: Rating no less than 6<br />

Color: No more than 3ΔE Hunter units maximum<br />

Total Sand = 35 ± 5 Liters<br />

20 Years: No blistering, peeling, or cracking<br />

20 Years: No blistering, peeling, or cracking<br />

5 Years: Rating no less than 6<br />

APPLICATION Application Method Reverse roll coat<br />

5 Years: No more than 3ΔE Hunter units<br />

Substrate 1 Aluminum, HDG, Galfan ® , Galvalume ® or Zincalume ®<br />

Primer<br />

Recommended: PMY0302, also acceptable: 623L144<br />

Viscosity ASTM D 4212 (No. 4 Zahn cup)<br />

Weight per Gallon: ASTM D 1475<br />

26 to 32 seconds<br />

Solids per Volume ASTM D 2697 58% to 61%<br />

Solids per Weight ASTM D 2369 73% to 76%<br />

Reducing Thinner<br />

VOC (Theoretical) ASTM D 3960<br />

Clean-Up Solvent<br />

Peak Metal Temperature<br />

11.4 to 12.5 pounds per gallon<br />

Aromatic<br />

Contains Lubricant<br />

Yes<br />

MEK Double Rubs ASTM D 5402 100<br />

3.0 pounds per gallon<br />

Aromatic<br />

435° to 465° F<br />

ALAMO WHITE TM COATING SYSTEM<br />

Alamo White is a two coat polyester resin system<br />

with a total Dry Film Thickness (DFT) of 0.8 to 1.2 mils<br />

(1) All substrates must be properly pretreated. (2) American Society for Testing and Materials. (3) Alamo<br />

White is not designed to bridge cracks in the substrate. (4) Varies by color. (5) Alamo White coatings will<br />

generally meet the requirements for most post-painted fabrication processes. However, variations in<br />

metal quality, thickness or cleaning/pretreatment applications can lead to diminished flexibility.<br />

For details and health, safety and handling information, Material Safety <strong>Data</strong> <strong>Sheet</strong>s (MSDS) are<br />

available at www.valsparcoilextrusion.com.<br />

Alamo White (TM) is a trademark of The <strong>Valspar</strong> Corporation. The <strong>Valspar</strong> logo is a registered trademark<br />

of The <strong>Valspar</strong> Corporation. Galfan® is a registered trademark of ILZRO. Galvalume® is a registered<br />

trademark of International Steel Group. Zincalume® is a registered trademark of Steelscape, Inc.<br />

VALSPAR MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND DISCLAIMS ALL IMPLIED WARRANTIES<br />

INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. VALSPAR WILL<br />

NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES.<br />

Top coat: 0.6 to 0.9 mils Primer: 0.2 to 0.3 mils<br />

Backer: 0.3 to 0.4 mils<br />

<strong>Valspar</strong> <strong>Coil</strong> and <strong>Extrusion</strong> Coating Division<br />

Phone: 888-306-2645<br />

Email: coilhelp@valspar.com<br />

www.valsparcoilextrusion.com<br />

VAL5201C 2012-09<br />

©The <strong>Valspar</strong> Corporation. All Rights Reserved