Internal

Internal

Internal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

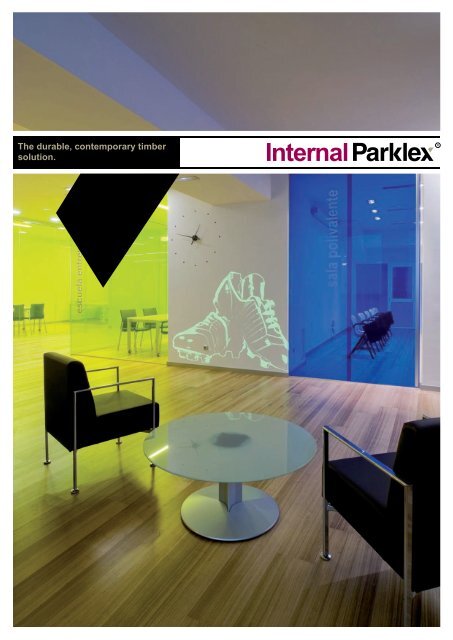

The durable, contemporary timber<br />

solution.<br />

<strong>Internal</strong>

Cover photo:<br />

Guipuzcoan Football Federation<br />

Project: Izaskun Larzábal<br />

Photography: Susana Aréchaga and Luis M. Ambrós<br />

Parklex 2000, Eucalyptus

Indoor wood<br />

coverings.<br />

The natural wood used to manufacture Parklex provides<br />

a look of quality and comfort for building interiors from<br />

the very first moment.<br />

With Parklex, ceilings, walls and floors, in addition to<br />

any other surface, such as counter tops, bathrooms<br />

and even showers take on a new leading role.<br />

If you’re looking for quality and comfort, Parklex has a<br />

wide range of natural wood finishes that achieve both<br />

purposes. In addition, its variety of finishes allows<br />

decorators and architects to be creative with combinations<br />

on any type of surface, allowing them to decorate the<br />

floors, walls or ceiling in the same wood, providing the<br />

degree of quality and comfort that only natural, highquality<br />

materials can convey.

Floor,<br />

walls and<br />

ceiling.<br />

The same colors and<br />

finishes throughout the<br />

interior.<br />

Parklex paneling may be installed on any surface:<br />

floors, walls and ceilings, combining aesthetic elements<br />

or keeping the same colors and finishes throughout<br />

the interior, converting rooms into authentic enclosures,<br />

completely lined with natural wood panels.<br />

Recommended products:<br />

· Floors:<br />

2000<br />

3000<br />

· Walls and ceiling:<br />

Dry areas:<br />

500<br />

Damp areas:<br />

700

Quality at<br />

your feet.<br />

Recommended products:<br />

· Floors:<br />

2000<br />

3000<br />

The quality of Parklex comes from the materials and<br />

processes used to manufacture them. This quality is<br />

demonstrated precisely where the product suffers the<br />

most wear: floors, transit spaces and areas of intensive<br />

use, where any material suffers a high level of wear.<br />

Parklex, however, performs at top levels in these areas,<br />

with its properties remaining unchanged. Simple<br />

maintenance is all that is needed to prolong the life of<br />

these coverings, which makes them immediately<br />

economical.<br />

It demonstrates its<br />

quality where it suffers<br />

the most wear.

Silence:<br />

another form<br />

of comfort.

Recommended products:<br />

· Walls and ceiling:<br />

500<br />

Noise and reverberation prevention is also a form of<br />

comfort. Parklex 500 is designed to be installed as an<br />

indoor wall and ceiling covering in locations with high<br />

acoustic absorption requirements: conference halls,<br />

presentation rooms, auditoriums, offices, etc., as well<br />

as furniture coverings.<br />

These panels insulate rooms from outside noise or that<br />

of nearby areas, providing an even greater feeling of<br />

comfort.<br />

Coverings for locations<br />

with high acoustic absorption<br />

requirements.

Excellent fire<br />

behavior. Parklex<br />

means peace of<br />

mind.

Recommended products:<br />

· Floors:<br />

2000<br />

· Walls and ceiling:<br />

Dry areas:<br />

500<br />

Damp areas:<br />

700<br />

In addition to being manufactured from natural wood,<br />

the entire Parklex line is tested according to the new<br />

European standard EN 13.501 regarding reaction to<br />

fire, obtaining the best results possible for organic<br />

materials.<br />

With Parklex, you are sure to make the right decision.<br />

Natural wood with the<br />

best results for reaction<br />

to fire.

Bathrooms,<br />

gymnasiums, spas<br />

or pools: don’t<br />

relinquish comfort.<br />

Cozy, moisture resistant<br />

spaces.<br />

Moisture is a factor that generally determines the materials<br />

used in bathrooms. Thanks to the production and treatment<br />

processes Parklex uses on natural wood, it is now possible<br />

to use Parklex coverings in any area of the bathroom,<br />

even in the shower, transforming them into areas that are<br />

just as inviting as the rest of the interior.<br />

The Parklex line stands out for its moisture resistance,<br />

which also allows its problem-free use in gymnasiums,<br />

spas or pools, making these areas (and any other space<br />

where appearance, hygiene, resistance and cleanliness<br />

are important) exclusive places that are both pleasant and<br />

totally unique.<br />

Recommended products:<br />

· Walls and ceiling:<br />

Damp areas:<br />

700<br />

· Floors (bathrooms and<br />

gymnasiums):<br />

2000

Parklex<br />

Projects

Guggenheim<br />

Bilbao<br />

Bilbao, Spain.<br />

Architect: Frank O. Gehry<br />

Project manager: César Caicoya<br />

Parklex 2000, Museum Ash<br />

Bilbao, May 14, 2007<br />

Bilbao, 14 de mayo de 2007<br />

Dear Sirs:<br />

After ten years of intensive use, withstanding<br />

the regular heavy machinery<br />

traffic and the exposition of sculptures<br />

weighing many tons, we would like to<br />

express our satisfaction with the wood<br />

floors in the Guggenheim Museum galleries<br />

(Manufacturer: Composites Gurea,<br />

model Parklex 2000, lightened<br />

ash), with regards to both the ease of<br />

cleaning<br />

and their durability and strength.<br />

Estimados Señores:<br />

Tras diez años de funcionamiento intensivo de los suelos<br />

de madera en las Galerías del Museo Guggenheim<br />

(Fabricante Composites Gurea, modelo Parklex 2000,<br />

fresno clarificado), soportando el paso habitual de<br />

maquinaria pesada y la exposición de esculturas de gran<br />

tonelaje, comunicamos nuestra satisfacción con los<br />

mismos, tanto en su facilidad de limpieza como en su<br />

durabilidad y resistencia.<br />

Rogelio Diez<br />

Maintenance and Installations Supervisor

Navarran<br />

Government<br />

Press Room<br />

Pamplona, Spain.<br />

Architects: Javier Barcos Berruezo<br />

and Manolo Enríquez Jiménez<br />

Parklex 500, Walnut<br />

Parklex 2000, Walnut

Marqués de Riscal<br />

Hotel<br />

The Luxury Collection.<br />

Alava, Spain.<br />

Architect: Frank O. Gehry<br />

Project manager: César Caicoya<br />

Parklex 500, Maple<br />

Parklex 2000, Maple

Cepa 21 Wineries<br />

Valladolid, Spain.<br />

Architects: BSA Arquitectos<br />

Interior design: TGA+Asociados<br />

and Javier Machimbarrena<br />

Parklex 500, Maple<br />

Burlada Cultural<br />

Center<br />

Navarre, Spain.<br />

Architect: Miguel Ayate Bariain<br />

Parklex 500

Puerta de America<br />

Hotel<br />

Madrid, Spain.<br />

Architect: Jean Nouvel<br />

Parklex 2000

Zubieta XXI Sports<br />

Complex<br />

Guipuzcoa, Spain.<br />

Project: Izaskun Larzábal, Fernando<br />

Gárate and Agustín Oteiza<br />

Photography: Susana Aréchaga<br />

and Luis M. Ambrós<br />

Parklex 2000, Natural Beech

De la Peña Station<br />

Bilbao, Spain.<br />

Architect: GPD Studio<br />

Parklex 500

La Perla Hotel<br />

Pamplona, Spain.<br />

Architect: Javier Martínez Oroquieta<br />

Parklex 500, Walnut<br />

Parklex 2000, Walnut<br />

Thermae Bath Spa<br />

The Minerva Bath.<br />

Bath, United Kingdom.<br />

Architect: Nicholas Grimshaw & Partners<br />

Photography: Matt Cardy<br />

Parklex 700, Maple

Guipuzcoan<br />

Football<br />

Federation<br />

Guipuzcoa, Spain.<br />

Project: Izaskun Larzábal<br />

Photography: Susana Aréchaga<br />

and Luis M. Ambrós<br />

Parklex 2000, Eucalyptus

Attic in San<br />

Sebastian<br />

Guipuzcoa, Spain.<br />

Interior design: Verónica Conejos<br />

Parklex 2000, Museum Ash<br />

COEC, Catalonian<br />

Odontologist and<br />

Stomatologist<br />

Association<br />

Barcelona, Spain.<br />

Architect: Pere Fosch i Alvarez<br />

Parklex 3000, Maple

Beroa Bar<br />

Guipuzcoa, Spain.<br />

Design: Formak Studio<br />

Parklex 2000 (floor)<br />

Parklex 3000, Zebrano (bar)<br />

Home in<br />

Pamplona<br />

Navarre, Spain.<br />

Interior design: Héctor Elizaga<br />

Photography: Susana Aréchaga<br />

and Luis M. Ambrós<br />

Parklex 2000, Maple

Air France, VIP<br />

Lounge<br />

Narita International Airport.<br />

Tokyo, Japan.<br />

Architect: Noé Duchaufour-Lawrance<br />

Parklex 500, Reconstituted Oak<br />

Parklex 2000, Reconstituted Oak

Electronics Arts<br />

London, United Kingdom.<br />

Architect: Foster + Partners<br />

Photography: Nigel Young<br />

Parklex 2000, Natural Beech<br />

Amrey Hotel<br />

Barcelona, Spain.<br />

Architect: Ramón Domenech<br />

Parklex 2000, Maple

Home in San<br />

Sebastian<br />

Guipuzcoa, Spain.<br />

Interior design: Javier Machimbarrena<br />

Photography: Susana Aréchaga<br />

and Luis M. Ambrós<br />

Parklex 2000, Walnut<br />

Home in Puerto<br />

Pollença<br />

Majorca, Spain.<br />

Architect: Joan Riusech<br />

Photography: Susana Aréchaga<br />

and Luis M. Ambrós<br />

Parklex 2000, Maple

Technical<br />

characteristics

About Parklex<br />

Production process<br />

Natural wood<br />

Each type of Parklex is subjected to a different production<br />

process, depending on its final application: interiors, exteriors,<br />

damp areas, etc.<br />

The base is always high-density laminated wood with a paper<br />

fiber core that has been treated with thermosetting resins and<br />

compressed at high pressure and temperature.<br />

The surface is always made from 100% natural wood, treated<br />

according to its application: to resist special weather conditions<br />

or to perfectly resist the intensive use it might receive in<br />

interiors.<br />

Finishes<br />

Range<br />

Perfect adaptation to the project design is an essential requirement.<br />

That’s why the technology used to manufacture Parklex<br />

allows us to apply different finishes, all in natural wood, to<br />

integrate them completely into the environment that is required<br />

for each project.<br />

The variety of finishes and colors in natural and dyed panels<br />

sets Parklex apart as a result of its versatility, making it the<br />

ideal covering from any type of project.<br />

International<br />

Architects<br />

Providing service on an international level has meant establishing<br />

an extensive network of Parklex distributors on all five<br />

continents. This allows us to work more closely with our clients<br />

and offer them better service in a way that is more accessible<br />

to them. It also lets us understand their needs perfectly and<br />

first hand.<br />

Guarantees / Quality Certificates<br />

The best architects in the world use Parklex in their most<br />

emblematic creations. Why is this so? Because they feel<br />

comfortable and at ease, and because the results do not<br />

disappoint them. Without a doubt, it is because at Parklex we<br />

have been working for over 15 years on a daily basis with<br />

architects from all over the world, including, for example,<br />

Santiago Calatrava, Frank Gehry, Norman Foster, Jean Nouvel<br />

and Nicholas Grimshaw, adapting our range to their requirements.<br />

This has made Parklex the natural wood covering of<br />

choice in many of the best quality and best-known projects in<br />

the world.<br />

This can only be achieved by a brand with an absolute<br />

guarantee, capable of offering the perfect product, totally<br />

adapted to their needs, with problem-free application.<br />

Rigorous testing guarantees Parklex’s excellent performance.

Parklex – The ideal solution<br />

Quality and performance are only the most visible results<br />

of Parklex. As if this weren’t enough, the advantages<br />

offered by Parklex are evident from the moment<br />

it is installed, up to its long-term maintenance.<br />

Characteristics<br />

Ease of installation.<br />

The floating flooring system is simple and low-cost. The rest<br />

of the products may be easily installed, following clear, professional<br />

instructions.<br />

Maintenance.<br />

Parklex does not require any sort of scraping or varnishing<br />

as part of its maintenance. It need only be lightly cleansed<br />

with a mop, using liquid ph-neutral soap and water.<br />

Acoustic absorption.<br />

Parklex 500 and Parklex 700 may be perforated, making them<br />

the ideal materials for acoustic absorption. They have been<br />

manufactured specifically for interiors where the acoustic<br />

factor is important.<br />

Service.<br />

Parklex has a technical support department to answer any<br />

questions regarding product assembly and to give advice on<br />

the most appropriate type of covering to meet every need.<br />

Strength.<br />

Material for intensive use indoor areas is made with the highest<br />

quality natural wood panels that have been impregnated using<br />

the Gureprex system, which provides a series of benefits with<br />

regards to abrasion, moisture resistance, hardness, scratch<br />

resistance and dimensional stability that are far superior to<br />

any of the varnish-treated products currently found on the<br />

market.<br />

Quality.<br />

Parklex means quality. All our products have earned the CE<br />

mark and carry an absolute guarantee. Exterior panels are<br />

manufactured according to the European standard EN 438,<br />

which applies to HPL (high pressure laminates). This is why<br />

Parklex is the covering preferred by the world’s most prestigious<br />

architects.<br />

Moisture resistance.<br />

The technology used by Parklex to manufacture the exterior<br />

coverings completely guarantees them against extreme weather<br />

conditions: rain, sun, humidity and heat. This same technology<br />

allows us to provide a material for interiors with identical<br />

resistance properties. Parklex therefore provides the ideal<br />

product for damp areas.<br />

Fire behavior.<br />

The entire Parklex line is classified according to the new<br />

European standard EN 13.501-1:2002 regarding reaction to<br />

fire, obtaining the best results possible for organic materials.

Parklex product guide<br />

Damp areas<br />

700<br />

Stratified timber panels for internal<br />

use, with high resistance<br />

to humidity.<br />

Walls and<br />

ceilings<br />

Dry areas<br />

500<br />

Natural timber ceiling and wall<br />

finishes.<br />

<strong>Internal</strong><br />

Floating<br />

parquet<br />

2000<br />

Natural timber floor for extreme<br />

wear environments.<br />

Floors<br />

Raised<br />

flooring<br />

3000<br />

Natural timber finish for full<br />

access raised floors.<br />

External<br />

Façades<br />

Facade<br />

High-density stratified timber<br />

panels for external use.

700<br />

Stratified timber panels for internal use,<br />

with high resistance to humidity.<br />

Parklex 700 is a high-density stratified natural timber panel,<br />

made from kraft paper that has been treated with thermoset<br />

resins compressed under high pressures and temperatures,<br />

finished with natural timber veneers.<br />

Finish range<br />

(1) Panels manufactured from joined timber<br />

veneers. There may be as many as 12 veneer<br />

pieces in each full panel (16 in the case of<br />

stained finishes).<br />

Ambar (2) Antra (2)<br />

Ayous Natural<br />

Black<br />

Cherry (1) Copper (2) Eucalyptus (1) Museum Ash (1)<br />

Gold (2) Grey Beech (1)<br />

Natural Beech (1)<br />

Green Beech (1)<br />

Maple (1)<br />

Walnut (1)<br />

Onix (2)<br />

Quartz (2)<br />

Natural Oak (1) Reconstituted Oak (1) Rubi (2) Sapelli (1)<br />

Silver (2)<br />

Wengue (1)<br />

Natural Zebrano (1)<br />

Surface characteristics<br />

Special finishes<br />

(2) Available only in a Smooth surface finish.<br />

Woodskin ® . A finish that allows you to<br />

feel the grain and subtlety of natural<br />

timber.<br />

Smooth. Traditional Parklex finish.<br />

Reveals the simple, natural beauty of the<br />

wood it is manufactured with.<br />

Assembly systems *<br />

Exposed fastening. The Parklex panels<br />

are fastened with stainless steel screws<br />

or rivets to the treated wood or metal<br />

substructure.<br />

Hidden fastening, with special hanging<br />

profiles. The Parklex panels are attached<br />

to the aluminum substructure, using guide<br />

profiles and hanging pins.<br />

Chequerplate Rubber Smooth Rubber<br />

Panel construction<br />

Chequerplate (3)<br />

Perforated<br />

Hidden fastening, using adhesive. The<br />

Parklex panels are fastened using adhesive<br />

to the treated wood or metal substructure.<br />

Hidden fastening, with caps. The Parklex<br />

panels are attached with screws hidden<br />

by caps with a diameter of 10,75mm and<br />

a section of 2mm, using the same material<br />

and finish as the panel.<br />

* For more information on installation, consult the <strong>Internal</strong> Parklex Assembly Catalogue<br />

or our web page (www.parklex.com).<br />

HPL core<br />

Moisture resistant overlay<br />

Natural timber veneer<br />

HPL core<br />

Natural timber veneer<br />

Balancing film<br />

Parklex is manufactured from fine timber veneers, therefore the colour and grain of different batches will exhibit natural variations. Due to the limitations of<br />

printed media, the finishes printed in this catalogue are merely an approximation of their real color. For this reason, before placing any order, Parklex<br />

recommends consulting our sales personnel to request actual samples.

Technical characteristics<br />

Tests Stand Property or attribute Measurement unit<br />

Parklex 700 CGS<br />

(Standard)<br />

Parklex 700 CGF<br />

(Fire Class)<br />

1. Inspection Rev: 03 (09.2009) Rev: 03 (09.2009)<br />

Result<br />

Thickness<br />

6mm<br />

Colour, pattern and surface finish EN 438-8 Part 5.2.2.3<br />

Due to the fact that wood is a natural product, each veneer may be considered as unique. Colour and structure differences<br />

are considered as normal. Singularities such as knots and resin inclusions are not considered as defects, but as a part of the<br />

décor. There are differences in light fastness performances depending on the wood species and the source of the wood.<br />

2. Dimensional tolerances<br />

Thickness (t) EN 438-2 Part 5 6,0 ≤ t < 8,0 mm<br />

8,0 ≤ t < 12,0<br />

12,0 ≤ t < 16,0<br />

16,0 ≤ t < 20,0<br />

20,0 ≤ t < 25,0<br />

Length and width EN 438-2 Part 6 – mm<br />

Edge straightness EN 438-2 Part 7 – mm/m<br />

Edge squareness EN 438-2 Part 8 – mm/m<br />

± 0,40<br />

± 0,50<br />

± 0,60<br />

± 0,70<br />

± 0,80<br />

+10 / - 0<br />

1,5<br />

1,5<br />

3. Physical properties<br />

Dimensional stability at elevated temperatures EN 438.-2 Part 17 Cumulative dimensional change<br />

(t≥6_mm)<br />

Resistance to impact with large diameter ball EN 438-2 Part 21 Maximum height for which no visible surface mm<br />

cracking or imprint greater than 10mm<br />

(t≥ 6mm)<br />

Tensile strength EN ISO 527-2 Longrain<br />

Crossgrain<br />

% max Longrain<br />

% max Crossgrain<br />

MPa<br />

0,3<br />

0,6<br />

≥ 1.800<br />

≥ 60<br />

4. CE Safety requirements<br />

Water vapour permeability EN 438-7 Part 4.4 Wet cup method µ<br />

Dry cup method<br />

Resistance to fixings EN 438-7 Part 4.5 Screw holding value t ≥ 6_mm N<br />

FScrew holding value t ≥ 8_mm<br />

Screw holding value t ≥ 10_mm<br />

Release of formaldehyde EN 438-7 Part 4.11 Classification Rating<br />

110<br />

250<br />

> 2.000<br />

> 3.000<br />

> 4.000<br />

E1<br />

Flexural strength EN ISO 178 Longrain MPa<br />

≥ 80<br />

Crossgrain<br />

≥ 80<br />

Flexural Modulus EN ISO 178 Longrain MPa<br />

≥ 9.000<br />

Crossgrain<br />

≥ 9.000<br />

Resistance to inmersion in boiling water EN 438-2 Part 12 Moisture absorbed % 2 3<br />

Moisture absorbed % ≤ 2 ≤ 6<br />

Appear<br />

Degree<br />

≥ 4<br />

Density EN ISO 1.183 Density g/cm 3<br />

≥ 1,35<br />

5. CE Safety requirements - Reaction to fire<br />

Reaction to fire EN 13.501-1 Euroclass t ≥ 6_mm Classification C-s2,d0 B-s2,d0<br />

Panel dimensions<br />

Length (grain direction) x width 2440 x 1220 mm Thickness* - Smooth finish<br />

Thickness* - Chequerplate finish<br />

* 3 and 6 mm can only be used for special applications. Other thicknesses may be available upon request.<br />

3, 6, 8, 10, 12,14, 18 & 22 mm<br />

10, 12,14, 18 & 22 mm

500<br />

Natural timber ceiling and wall finishes.<br />

Parklex 500 is a timber panel manufactured from 100% natural<br />

timber fibres, pressed under high temperatures and impregnated<br />

with thermoset resins using our exclusive Gureprex<br />

system.<br />

Finish range<br />

(1) Panels manufactured from joined timber<br />

veneers. There may be as many as 12 veneer<br />

pieces in each full panel (16 in the case of<br />

stained finishes).<br />

Ambar<br />

Antra<br />

Ayous Natural<br />

Bamboo (1)<br />

Black<br />

Cherry (1) Eucalyptus (1) Museum Ash (1)<br />

Grey Beech (1) Natural Beech (1) Green Beech (1)<br />

Maple (1)<br />

Walnut (1)<br />

Onix Natural Oak (1) Reconstituted Oak (1)<br />

Rubi<br />

Sapelli (1) Wengue (1) Natural Zebrano (1)<br />

Surface characteristics<br />

Panel construction<br />

Woodskin ® . A finish that allows you to<br />

feel the grain and subtlety of natural<br />

timber.<br />

Gureprex wear resistant overlay<br />

Natural timber veneer<br />

Resin bonded WBP plywood core<br />

HPL balancer<br />

Wood<br />

Acoustics<br />

Assembly systems *<br />

Slots<br />

Perforated<br />

Parklex 500 acoustic is designed for<br />

interior wall and ceiling finishes requiring<br />

high levels of acoustic absorption.<br />

It is machined in different forms and<br />

dimensions allowing for the desired level<br />

of acoustic performance.<br />

Exposed fastening. The Parklex panels<br />

are fastened with stainless steel screws<br />

or rivets to the treated wood or metal<br />

substructure.<br />

Hidden fastening, using adhesive. The<br />

Parklex panels are fastened using adhesive<br />

to the treated wood or metal substructure.<br />

Hidden fastening, with special hanging<br />

profiles. The Parklex panels are attached<br />

to the aluminum substructure, using guide<br />

profiles and hanging pins.<br />

Hidden fastening, with caps. The Parklex<br />

panels are attached with screws hidden<br />

by caps with a diameter of 10,75mm and<br />

a section of 2mm, using the same material<br />

and finish as the panel.<br />

* For more information on installation, consult the <strong>Internal</strong> Parklex Assembly Catalogue<br />

or our web page (www.parklex.com).<br />

Parklex is manufactured from fine timber veneers, therefore the colour and grain of different batches will exhibit natural variations. Due to the limitations of<br />

printed media, the finishes printed in this catalogue are merely an approximation of their real color. For this reason, before placing any order, Parklex<br />

recommends consulting our sales personnel to request actual samples.

Technical characteristics<br />

Tests Standard Property or attribute Measurement unit<br />

Result<br />

Thickness<br />

8mm<br />

Parklex 500 VDS<br />

(Standard)<br />

Parklex 500 VDF<br />

(Fire Class)<br />

1. Inspection requirements Rev: 03 (09.2009) Rev: 03 (09.2009)<br />

Colour, pattern and surface finish EN 438-8 Part 5.2.2.3<br />

Due to the fact that wood is a natural product, each veneer may be considered as unique. Colour and structure<br />

differences are considered as normal. Singularities such as knots and resin inclusions are not considered as<br />

defects, but as a part of the décor. There are differences in light fastness performances depending on the wood<br />

species and the source of the wood<br />

2. Dimensional tolerances<br />

Thickness (t) EN 438-2 Part 5 t = 6,0 mm +1,0 / -0,6<br />

t = 8,0 +1,6 / -1 +1,0 / -0,7<br />

t = 11,0 +1,4 / -1,1 +1,2 / -0,8<br />

t = 14,0 +1,6 / -1,1 +1,3 / -0,9<br />

t = 17,0 +1,3 / -1,3 +1,4 / -1,0<br />

t = 20,0 +1,3 / -1,1 +1,6 / -1,2<br />

t = 40,0 +2,0 / -1,6<br />

Tolerance for thickness variations inside a panel EN 315:1993 t (nominal thickness) mm<br />

Length and width EN 438-2 Part 6 – mm<br />

Edge straightness EN 438-2 Part 7 – mm/m<br />

Edge squareness EN 438-2 Part 8 – mm/m<br />

≤0,6<br />

+10 / - 0<br />

1,5<br />

1,5<br />

3. Physical properties<br />

Revolutions<br />

Resistance to surface wear EN 438-2 Part 10 Resistance to surface wear<br />

Initial wear point<br />

Wear resistance<br />

Resistance to inmersion in boiling water EN 438-2 Part 12 Aspect Rating<br />

Resistance to scratching EN 438-2 Part 25 Force Rating<br />

Lightfastness (xenon arc) EN 438-2 Part27 Contrast Grey scale rating<br />

Flexural strength EN 310<br />

Longitudinal direction<br />

MPa<br />

Flexural modulus EN 310<br />

Transversal direction<br />

Longitudinal direction<br />

MPa<br />

Transversal direction<br />

Perpendicular tensile strength ASTM C 297 Adhesion force MPa<br />

≥ 50<br />

≥ 150<br />

≥ 4<br />

≥ 2<br />

≥ 4<br />

< 4 (A)<br />

≥ 70<br />

≥ 60<br />

≥ 7000<br />

≥ 6000<br />

≥ 2<br />

Density - Density g/cm3 ≥ 0,75 ≥ 0,80<br />

4. CE Safety requirements<br />

Resistance to fixings EN 438-7 Part 4.5 Force N/mm ≥ 200 ≥ 130<br />

Bonding strength EN 438-7 Part 4.7 Bond strength MPa ≥ 1,42 ≥ 2,64<br />

Flexural tensile strength EN 438-7 Part 4.8 Bond strength MPa ≥ 1,42 ≥ 2,64<br />

Content of pentachlorophenol EN 438-7 Part 4.10 Content pentachlorophenol ppm<br />

≤ 5<br />

Release of formaldehyde EN 717-2 Release of formaldehyde Rating<br />

E1<br />

Glue-line quality EN 438-7 Part 4.13.3 Expression of results Rating 5 3<br />

Resistance to elevated temperature EN 438-7 Part 4.13.3 Aspect Result<br />

No damage<br />

Water resistance EN 438-7 Part 4.13.3 Thickness increase % ≤ 7 ≤ 2,5<br />

(A) Maple; Bryna; Ayous Natural; Cherry; Natural Beech; Reconstituted Oak<br />

5. CE Safety requirements - Reaction to fire<br />

Reaction to fire EN 13.501-1 Euroclass t ≥ 8mm Classification D-s3,d0 –<br />

Euroclass t ≥ 14mm Classification – B-s2,d0<br />

Panel dimensions<br />

Length (grain direction) x width 2440 x 1220 mm Thickness*<br />

* Other thicknesses may be available upon request.<br />

8, 11, 14, 17, 20 & 26 mm

2000<br />

Natural timber floor for extreme wear<br />

environments.<br />

Parklex 2000 is a natural timber floating floor made from the<br />

highest quality veneers, impregnated using our exclusive<br />

Gureprex system. This provides extraordinary qualities of<br />

dimensional stability and resistance to both abrasion and<br />

humidity.<br />

Finish range<br />

(1) Panels manufactured from joined timber<br />

veneers. There may be as many as 12 veneer<br />

pieces in each full panel (16 in the case of<br />

stained finishes).<br />

Ambar<br />

Antra<br />

Ayous Natural<br />

Bamboo (1)<br />

Black<br />

Cherry (1) Eucalyptus (1) Museum Ash (1)<br />

Grey Beech (1) Natural Beech (1) Green Beech (1)<br />

Maple (1)<br />

Walnut (1)<br />

Onix Natural Oak (1) Reconstituted Oak (1)<br />

Rubi<br />

Sapelli (1) Wengue (1) Natural Zebrano (1)<br />

Surface characteristics<br />

Matt. A finish that provides a high quality,<br />

comfortable surface appearance that only<br />

authentic natural timber can provide.<br />

Maintenance and cleaning<br />

Maintenance. The non-porous nature of<br />

the surface prevents the penetration of<br />

dirt. Parklex 2000 requires no specific<br />

stripping or re-finishing.<br />

Cleaning. Mop with water and (neutral)<br />

gel soap.<br />

Resistance to abrasion<br />

Assembly systems *<br />

Resistance to abrasion<br />

AC4<br />

Floating parquet. Floating installation of<br />

boards glued tongue-in-groove over a<br />

layer of insulation.<br />

Glued. Installation of tongue-in-groove<br />

boards that are adhered to waterproof<br />

DM, using lines of adhesive.<br />

Panel construction<br />

Gureprex wear resistant overlay<br />

Natural timber veneer<br />

Resin bonded WBP plywood core<br />

HPL balancer<br />

Parquet over underfloor heating. Installation<br />

as floating parquet over underfloor<br />

heating.<br />

* For more information on installation, consult the <strong>Internal</strong> Parklex Assembly Catalogue<br />

or our web page (www.parklex.com).<br />

Wood<br />

Parklex is manufactured from fine timber veneers, therefore the colour and grain of different batches will exhibit natural variations. Due to the limitations of<br />

printed media, the finishes printed in this catalogue are merely an approximation of their real color. For this reason, before placing any order, Parklex<br />

recommends consulting our sales personnel to request actual samples.

Technical characteristics<br />

Tests Standard Property or attribute Measurement unit Result<br />

Thickness<br />

11 mm<br />

Parklex 2000 HDS (Standard)<br />

1. Inspection requirements Rev: 04 (09.2009)<br />

Colour, pattern and surface finish EN 438-8 Part 5.2.2.3<br />

Due to the fact that wood is a natural product, each veneer may be considered as unique. Colour and structure<br />

differences are considered as normal. Singularities such as knots and resin inclusions are not considered as defects,<br />

but as a part of the décor. There are differences in light fastness performances depending on the wood species and<br />

the source of the wood<br />

2. Dimensional tolerances<br />

Gap between pieces EN 13.329 – mm ≤ 0,2<br />

Leap between pieces EN 13.329 – mm ≤ 0,15<br />

3. Physical properties<br />

Resistance to surface wear EN 438-2 Part10 Initial point (PI) Revolutions<br />

≥ AC4<br />

≥ 4.000<br />

Resistance to inmersion in boiling water EN 438-2 Part 12 Aspect Rating ≥ 4<br />

Impact resistance (small diameter ball) EN 438-2 Part 20 Force resort N ≥ 10<br />

Resistance to scratching EN 438-2 Part 25 Force Rating ≥ 3<br />

Resistance to stain EN 438-2 Part26 Aspect<br />

Lightfastness (xenon arc) EN 438-2 Part27 Contrast<br />

Rating (Group 1 & 2) ≥ 5<br />

Rating (Group 3) ≥ 4<br />

≥ 4<br />

Grey scale rating<br />

< 4 (B)<br />

Resistance to cigarettes burn EN 438-2 Part 20 Aspect Rating ≥ 4<br />

Longrain ≥ 70<br />

Flexural strength EN 310 MPa<br />

Crossgrain ≥ 60<br />

Longrain ≥ 7000<br />

Flexural modulus EN 310 MPa<br />

Crossgrain ≥ 6000<br />

Density - Density g/cm3 ≥ 0,75<br />

4. CE Safety requirements<br />

Pentachlorophenol content EN 438-7 Part 4.10 Content pentachlorophenol ppm ≤ 5<br />

Release of formaldehyde EN 717-2 Release of formaldehyde Rating E1<br />

Electric resistance EN 1.081 Vertical resistance M_ 825 (antiestático)<br />

Tendency to accumulation electrostratic charges EN 1.815 Potential difference KV

3000<br />

Natural timber finish for full access raised<br />

floors.<br />

Parklex 3000 is a high-density stratified timber panel, impregnated<br />

using our exclusive Gureprex system. It may be adhered<br />

to any type of support material (fibreboard, MDF, fibre cement,<br />

galvanised steel etc.) normally used to construct full access<br />

floors.<br />

Finish range<br />

(1) Panels manufactured from joined timber<br />

veneers. There may be as many as 12 veneer<br />

pieces in each full panel (16 in the case of<br />

stained finishes).<br />

Ambar<br />

Antra<br />

Ayous Natural<br />

Bamboo (1)<br />

Black<br />

Cherry (1) Eucalyptus (1) Museum Ash (1)<br />

Grey Beech (1) Natural Beech (1) Green Beech (1)<br />

Maple (1)<br />

Walnut (1)<br />

Onix Natural Oak (1) Reconstituted Oak (1)<br />

Rubi<br />

Sapelli (1) Wengue (1) Natural Zebrano (1)<br />

Surface characteristics<br />

Matt. A finish that provides a high quality,<br />

comfortable surface appearance that only<br />

authentic natural timber can provide.<br />

Assembly systems *<br />

Hidden fastening, using adhesive. The<br />

Parklex panels are attached to different<br />

types of supports, using adhesive.<br />

Panel construction<br />

* For more information on installation, consult the <strong>Internal</strong> Parklex Assembly Catalogue<br />

or our web page (www.parklex.com).<br />

Gureprex wear resistant overlay<br />

Natural timber veneer<br />

HPL balancer<br />

Wood<br />

Parklex is manufactured from fine timber veneers, therefore the colour and grain of different batches will exhibit natural variations. Due to the limitations of<br />

printed media, the finishes printed in this catalogue are merely an approximation of their real color. For this reason, before placing any order, Parklex<br />

recommends consulting our sales personnel to request actual samples.

Technical characteristics<br />

Thickness 1 mm<br />

Tests Standard Property or attribute Measurement unit Result<br />

Parklex 3000 HGS<br />

1. Inspection requirements Rev: 03 (09.2009)<br />

Colour, pattern and surface finish EN 438-8 Part 5.2.2.3<br />

Due to the fact that wood is a natural product, each veneer may be considered as unique. Colour and structure<br />

differences are considered as normal. Singularities such as knots and resin inclusions are not considered as<br />

defects, but as a part of the décor. There are differences in light fastness performances depending on the<br />

wood species and the source of the wood<br />

2. Dimensional tolerances<br />

Thickness (t) EN 438-2 Part 5 t = 1 mm mm ± 0,15<br />

Length and width EN 438-2 Part 6 – mm +10 / - 0<br />

Edge straightness EN 438-2 Part 7 – mm/m 1,5<br />

Edge squareness EN 438-2 Part 8 – mm/m 1,5<br />

Planimetry EN 438-2 Part 9 – mm/m 120<br />

3. Physical properties<br />

Revolutions 0<br />

Resistance to surface wear EN 438-2 Part 10 Resistance to surface wear<br />

Abrasion class<br />

AC4<br />

Initial point ≥ 4.000<br />

Resistance to inmersion in boiling water EN 438-2 Part 12 Delamination Pass/ No pass Pass<br />

Dimensional stability at high temperatures<br />

EN 438-2 Part17<br />

Longitudinal % max 0,75<br />

Transversal % max 1,25<br />

Impact resistance (small diameter ball) EN 438-2 Part 20 Force ressort N ≥ 10<br />

Resistance to scratching EN 438-2 Part 25 Force Rating ≥ 3<br />

Grupos 1 & 2 ≥ 5<br />

Resistance to stain EN 438-2 Part26 Aspect<br />

Lightfastness (xenon arc) EN 438-2 Part27 Contrast<br />

Grupo 3<br />

Grey scale rating<br />

≥ 4<br />

≥ 4<br />

< 4 (A)<br />

Resistance to cigarette burns EN 438-2 Part 30 Aspect Rating ≥ 2<br />

Density EN ISO 1.183 Density Classification ≥ 1,1<br />

(A) Maple; Bryna; Ayous Natural; Cherry; Natural Beech; Reconstituted Oak<br />

4. Reaction to fire<br />

Reaction to fire EN 13.501-1 Euroclass Classification D-s2,d0 (B)<br />

(B) Composite panels made by a non FIRE RETARDANT HPL adhered to a non fireproof wood substrate.<br />

Panel dimensions *<br />

Standard - Length (grain direction) x width<br />

Maximum - Length (grain direction) x width<br />

* Special dimensions available for other applications, upon request.<br />

610 x 610 mm Thickness 1 mm<br />

2440 x 1220 mm

Other Parklex products<br />

Facade<br />

High-density stratified timber panels for<br />

external use.<br />

External<br />

Parklex Facade is a high-density stratified timber panel<br />

manufactured from kraft paper treated with resins thermoset<br />

under high pressure and temperature, finished with natural<br />

timber veneers highly resistant to UV radiation and atmospheric<br />

agents.<br />

Parklex Facade includes Everlook ® , a special overlay that<br />

dramatically increases the normal life of the panel, improving<br />

UV resistance and colour stability. It also allows for the development<br />

of new panels with an extensive range of finishes.<br />

Finish range<br />

Ambar Antra Copper Gold Onix Quartz Rubi Silver<br />

Surface characteristics<br />

Smooth. Traditional Parklex finish.<br />

Reveals the simple, natural beauty of the<br />

wood it is manufactured with.<br />

Panel construction<br />

HPL core<br />

PVDF Antigraffiti overlay<br />

Everlook<br />

Natural timber veneer<br />

HPL core<br />

Natural timber veneer<br />

Balancing film<br />

NOTE. For more information about this product, consult the<br />

External Parklex Catalogue, the External Parklex Assembly<br />

Catalogue or our web page (www.parklex.com).<br />

Parklex is manufactured from fine timber veneers, therefore the colour and grain of different batches will exhibit natural variations. Due to the limitations of<br />

printed media, the finishes printed in this catalogue are merely an approximation of their real color. For this reason, before placing any order, Parklex<br />

recommends consulting our sales personnel to request actual samples.

Applications<br />

1.<br />

2. 3.<br />

1. Semilcos head office<br />

Vicenza, Italy.<br />

Architect: Pollini+Smania<br />

2. Hospital<br />

Korea.<br />

Architect: Seo hae-cheon<br />

3. Children Museum<br />

Ireland.<br />

Architect: Traynor O’Toole<br />

4.<br />

4. Alhambra Information points<br />

Granada, Spain.<br />

Architect: Francisco Martínez Manso, Rafael<br />

Soler Márquez

Facade<br />

700<br />

500<br />

2000<br />

3000<br />

EN/v04/0912<br />

ER-0370/2003<br />

www.parklex.com<br />

COMPOSITES GUREA, S.A.<br />

Zalain auzoa, 13<br />

31780 Vera de Bidasoa<br />

Navarra (Spain)<br />

[t] +34 948 625 045<br />

[f] +34 948 625 015<br />

parklex@parklex.com