Power Generation - Stewart & Stevenson

Power Generation - Stewart & Stevenson

Power Generation - Stewart & Stevenson

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Power</strong> <strong>Generation</strong><br />

1

<strong>Stewart</strong> & <strong>Stevenson</strong><br />

<strong>Power</strong> <strong>Generation</strong> for Global Markets<br />

<strong>Stewart</strong> & <strong>Stevenson</strong> has provided innovative power generation<br />

solutions for world markets since 1938. During World War II, our<br />

company was the second largest supplier of generators under the<br />

Lend-Lease program. After the war, <strong>Stewart</strong> & <strong>Stevenson</strong> developed<br />

increasingly advanced power generation equipment for military,<br />

municipal and industrial users around the globe.<br />

Today, <strong>Stewart</strong> & <strong>Stevenson</strong> is a major supplier of power<br />

generation packages utilized by the oil and gas, marine,<br />

mining, rail and agriculture industries. Our power generation<br />

solutions serve municipalities, universities, hospitals,<br />

data centers, chemical and power plants, manufacturing<br />

facilities and numerous other clients. Onsite continuous,<br />

emergency standby and peak-shaving power generator<br />

packages are available in stationary, mobile and containerized<br />

configurations. We are the power solutions<br />

source for emergency and disaster relief.<br />

Wherever they are put into service, on land or<br />

sea, our emissions certified power packages<br />

offer excellent reliability with high fuel efficiency,<br />

and come with unmatched aftermarket<br />

support. <strong>Stewart</strong> & <strong>Stevenson</strong>’s support<br />

centers, strategically located near major<br />

oil and gas fields in the United States and<br />

in a number of the world’s major energy<br />

producing countries, provide aftermarket<br />

support that includes OEM parts and service<br />

by well-trained technicians.<br />

www.stewartandstevenson.com<br />

Table of Contents<br />

<strong>Power</strong> <strong>Generation</strong> for Business and Industry. ........... 3<br />

<strong>Power</strong> <strong>Generation</strong> Packages for the Oilfield. ............ 4<br />

Offshore Packages. ............................... 5<br />

Onshore Packages. ............................... 6<br />

Auxiliary Products. ................................ 7<br />

Drive Systems, Micro Plus SCR and AC Drive ........... 8<br />

Swithgear, Codes & Standards and SmarkLInk 2000. ... 9<br />

Engineering, Advanced Control Systems. ............. 10<br />

Manufacturing and Added Value. .................... 11<br />

Locations Listing ................................ 12<br />

2

<strong>Power</strong> <strong>Generation</strong><br />

<strong>Power</strong> <strong>Generation</strong> for Business and Industry<br />

<strong>Stewart</strong> & <strong>Stevenson</strong> provides engines, prime movers and<br />

power generation packages from world-class manufacturers.<br />

Our business partner offerings include:<br />

<strong>Stewart</strong> & <strong>Stevenson</strong> Manufactured Generator Sets<br />

• MTU diesel-powered generator sets featuring digital engine<br />

and generator controls for superior performance and<br />

response time, proven reliability, reduced maintenance<br />

costs and the latest in emissions technology<br />

• EMD diesel-powered stationary power units and generators<br />

that provide 2000 to 5500 bhp. Heavy-duty units are<br />

applied as base load generating sets in remote locations,<br />

pipeline and dredge pump applications, nuclear power<br />

generating plants and medical emergency standby sets<br />

• Deutz diesel, air-cooled power generating solutions in<br />

power ranges from 27–120 kW<br />

Complete, Pre-packaged Generator Sets<br />

• MTU Onsite Energy diesel and natural gas generator sets<br />

for emergency, standby and prime power applications<br />

• MQ <strong>Power</strong> generator sets for rental<br />

3

<strong>Stewart</strong> & <strong>Stevenson</strong><br />

<strong>Power</strong> <strong>Generation</strong> Packages for the Oilfield<br />

<strong>Stewart</strong> & <strong>Stevenson</strong> offers the broadest line of oilfield power<br />

generation products available in the market. Included are new<br />

and refurbished engines, power units, generator packages and<br />

pump packages that increase productivity, improve efficiencies<br />

and reduce costs.<br />

<strong>Stewart</strong> & <strong>Stevenson</strong> provides essential, auxiliary and<br />

emergency power packages for workover and well servicing,<br />

onshore and offshore drilling and production facilities.<br />

We have in-house capabilities to design, engineer, build,<br />

install, commission, test and certify every package we sell.<br />

Designed using advanced three-dimensional computer<br />

modeling technology and built on our efficient, lean manufacturing<br />

flow lines, our power generation packages come<br />

with the assurance that:<br />

• Engine generator alignment is factory certified<br />

• Technical documentation package is comprehensive<br />

• Appropriate interface data is readily available<br />

• Technical manuals are interactive CD-ROM-based and<br />

are linked to the engineering documentation for accuracy<br />

and improved aftermarket support<br />

<strong>Stewart</strong> & <strong>Stevenson</strong>’s power generation packages are<br />

powered by the most reliable, high-performance engines<br />

available from MTU and Electro-Motive Diesel (EMD). These<br />

rugged offshore and onshore power generation units are the<br />

result of 75-plus years of generator set design experience.<br />

4

<strong>Power</strong> <strong>Generation</strong><br />

Offshore Packages<br />

Offshore power generation units, manufactured with MTU 2000,<br />

MTU 4000 and EMD 710 series engines, include:<br />

• 9 60 Hz models offering 932 to 5000 bhp (661 to 3581 kW)<br />

• 9 50 Hz models offering 771 to 4155 bhp (546 to 2976 kWe)<br />

• Essential vessel power packages<br />

■ Prime rig power<br />

■ SCR systems<br />

■ VFD systems<br />

■ Dredge power<br />

• Emergency and auxiliary<br />

power<br />

• Generators oversized to<br />

meet low power factor<br />

requirements<br />

• Latest emissions standards<br />

available on most applications<br />

• Generator sets certified to ABS, DNV and IMO/US<br />

EPA standards<br />

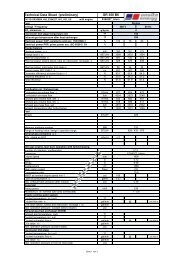

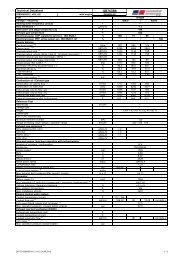

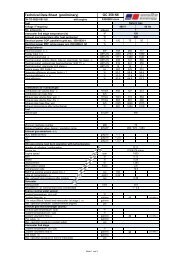

MODEL DM600M DM800M DM1500M DM2000M DM2500M<br />

Ratings 60 Hz 50 Hz 60 Hz 50 Hz 60 Hz 50 Hz 60 Hz 50 Hz 60 Hz 50 Hz<br />

Drilling (prime) kWe output 1 661 546 884 732 1520 1254 2129 1977 2661 2471<br />

Prime <strong>Power</strong> output (bhp) 932 771 1247 1033 2145 1770 3004 2789 3755 3487<br />

Speed, rated (rpm) 1800 1500 1800 1500 1800 1500 1800 1500 1800 1500<br />

Engine Manufacturer MTU MTU MTU MTU MTU<br />

Engine Model 12V2000 16V2000 12V4000 16V4000 20V4000<br />

MTU features: • High power to weight ratio • Increased variable deck load capabilities<br />

• Compact footprint<br />

• Series 4000 with common rail fuel system for enhanced performance and reduced emissions<br />

1 At rated voltage, frequency and PF according to ISO 3046/1 conditions. All data is subject to change without notice.<br />

MODEL DM1440E DM2150E DM2865E DM3580E<br />

Ratings 60 Hz 50 Hz 60 Hz 50 Hz 60 Hz 50 Hz 60 Hz 50 Hz<br />

Continuous kWe output 1 1432 1200 2148 1787 2865 2381 3581 2976<br />

Continuous <strong>Power</strong> output (bhp) 2000 1675 3000 2495 4000 3325 5000 4155<br />

Speed, rated (rpm) 900 750 900 750 900 750 900 750<br />

Engine Manufacturer EMD EMD EMD EMD<br />

Engine Model 8-710 12-710 16-710 20-710<br />

EMD features:<br />

• Proven offshore reliability • EPA Tier 2 Certification for 60 Hz Ratings • Less maintenance = higher availability<br />

• Durable medium speed engines • Extended TBO intervals • <strong>Power</strong>ful, responsive two-cycle design<br />

1 According to ISO 3046/1 conditions and based on generator efficiencies 95-97%. All data is subject to change without notice.<br />

5

<strong>Stewart</strong> & <strong>Stevenson</strong><br />

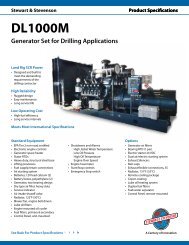

Onshore Packages<br />

Onshore power generation packages feature MTU Series 60,<br />

2000 and 4000 engines. We offer:<br />

• 7 models offering 685 to 2425 bhp (420 to 1633 kW)<br />

• 1800, 1500 and 1200 rpm<br />

• 60 Hz and 50 Hz applications<br />

• Latest emissions standards available on most applications<br />

• Essential rig power packages<br />

■ Prime rig power<br />

■ SCR systems<br />

■ VFD systems<br />

• Emergency and auxiliary power<br />

• Options that allow customer tailoring for each application<br />

• Additional <strong>Stewart</strong> & <strong>Stevenson</strong> units:<br />

■ Pump packages<br />

■ Pump drivers<br />

■ Natural gas power packs<br />

MODEL<br />

DX420M<br />

Ratings<br />

Prime kWe/kVA ratings 1 420/525<br />

Rated Voltage<br />

480/277 VAC<br />

Rated Frequency<br />

60 Hz<br />

Rated <strong>Power</strong> Factor (lagging) 0.8<br />

Engine manufacturer<br />

MTU<br />

Engine Model Series 60<br />

<strong>Power</strong> output (hp) 685<br />

Speed, rated (rpm) 1800<br />

1 At rated voltage, frequency and PF according to ISO 3046/1<br />

conditions. All data is subject to change without notice.<br />

MODEL DL700M DL900M DL1000M DL1200M DL1250M DL1600M<br />

Ratings 60 Hz 50 Hz 60 Hz 50 Hz 60 Hz 60 Hz 50 Hz 60 Hz 60 Hz 50 Hz<br />

Drilling (prime) kWe output 1 687 564 912 727 997 1223 1088 1254 1633 1445<br />

Prime <strong>Power</strong> output (bhp) 1020 838 1354 1080 1481 1817 1616 1863 2425 2146<br />

Speed, rated (rpm) 1800 1500 1800 1500 1200 1800 1500 1200 1800 1500<br />

Engine Manufacturer MTU MTU MTU MTU MTU MTU<br />

Engine Model 12V2000 16V2000 12V4000 12V4000 16V4000 16V4000<br />

1 At rated voltage, frequency and PF according to ISO 3046/1 conditions. All data is subject to change without notice.<br />

6

<strong>Power</strong> <strong>Generation</strong><br />

Auxiliary Products<br />

ERGPS—Engine Regulation (Speed / Load) Generator<br />

Protection / Control System<br />

The ERGPS is suitable for most engine generator applications<br />

whether land-based or offshore. <strong>Stewart</strong> & <strong>Stevenson</strong><br />

provides custom designs to meet specific requirements.<br />

• Fully digital generator protective features<br />

■ Generator over/under voltage<br />

■ Generator frequency<br />

■ Generator load imbalance<br />

■ Generator over-current<br />

■ Generator reverse power<br />

■ kW load monitoring and control<br />

■ Adjustable load/unload ramp rates<br />

■ Isochronous load sharing<br />

■ Adjustable kW load sharing percentage<br />

• Engine controls<br />

■ Fully digital engine speed controller with load share<br />

■ Speed adjustment for synchronizing<br />

■ Engine control switch “shutdown-idle-run-load”<br />

• Excitation control system<br />

■ 0.5% or better voltage regulation<br />

■ Frequency compensation<br />

■ Overexcitation limiting<br />

■ Soft starting<br />

■ VAR sharing<br />

■ Loss of sensing<br />

■ <strong>Power</strong> input PMG 50–400 Hz<br />

• Metering built into ERGPS faceplate<br />

■ KVAR<br />

■ kW<br />

■ Volt–selectable<br />

■ AMP–phase selectable<br />

■ RS485 interface<br />

• Synchronizing<br />

■ Dead bus sensing<br />

■ Sync check relay prevents operator error<br />

• Indication<br />

■ Engine running light<br />

■ Engine shutdown light<br />

■ Generator protection trip light<br />

7

<strong>Stewart</strong> & <strong>Stevenson</strong><br />

Drive Systems<br />

<strong>Stewart</strong> & <strong>Stevenson</strong> is a world-class supplier of AC (Variable<br />

Frequency Devices, or VFD) and DC (SCR) systems to various<br />

industries including, but not limited to, land-based and<br />

offshore oilwell drilling and marine propulsion. Each system is<br />

custom designed to meet the client’s requirements. Additional<br />

subsystems, as required, are integrated to provide a complete<br />

trouble-free system:<br />

• Motor control centers<br />

• Driller and mud pump consoles<br />

• Engine generator switchgear<br />

• Distribution panels<br />

• Transformers<br />

• Air conditioning systems<br />

Each system undergoes a thorough factory production test<br />

to ensure any potential problems are resolved in our facility.<br />

Fault current, coordination and load analysis studies can also<br />

be provided. Combining <strong>Stewart</strong> & <strong>Stevenson</strong> power generation<br />

modules with the drive systems ensures a seamlessly<br />

integrated, trouble-free, “single source” electrical system.<br />

Micro Plus SCR<br />

The <strong>Stewart</strong> & <strong>Stevenson</strong> Micro Plus SCR meets compact size<br />

and simple operating requirements while providing up to 2000A<br />

DC power. Built to withstand harsh environments and maintain<br />

a high level of performance, Micro Plus SCR combines ease<br />

of maintenance with simple operation. The digital controls are<br />

not susceptible to “thermal drift” problems experienced by<br />

analog control systems. Each system incorporates a diagnostic<br />

display for information and trouble-shooting purposes.<br />

<strong>Stewart</strong> & <strong>Stevenson</strong>’s Micro Plus SCR systems are operating<br />

in some of the world’s most severe environments with<br />

exceptional results.<br />

Micro Plus AC Drive<br />

The <strong>Stewart</strong> & <strong>Stevenson</strong> Micro Plus AC Drive is an integral<br />

part of today’s oilwell drilling systems. When integrated with the<br />

<strong>Stewart</strong> & <strong>Stevenson</strong> digital engine/generator switchgear and<br />

engine generator power modules, unsurpassed trouble-free<br />

performance is the result.<br />

The Micro Plus AC Drive has many advantages over other<br />

systems. Drives rated 1200 to 3500 horsepower are available<br />

in very compact modules. All units undergo a full load test prior<br />

to shipment. A system stage test is also performed on every<br />

system prior to shipment from our factory.<br />

8

<strong>Power</strong> <strong>Generation</strong><br />

Switchgear<br />

<strong>Stewart</strong> & <strong>Stevenson</strong> brings more than 60 years of experience and capability<br />

to the low- and medium-voltage industry. We are a major supplier to the<br />

power generation market:<br />

• Frame turbines<br />

• Aero derivative turbines<br />

• Diesel and gas engines<br />

We also provide switchgear and support for the<br />

industrial, commercial, military and marine businesses.<br />

All <strong>Stewart</strong> & <strong>Stevenson</strong> switchgear is custom designed<br />

to meet the customer’s requirements. System engineering<br />

studies, including fault current, coordination and<br />

load analysis studies, can be provided if required.<br />

A thorough production system test is performed on<br />

every system before shipment.<br />

Codes & Standards<br />

<strong>Stewart</strong> & <strong>Stevenson</strong> has the capability to custom<br />

design systems in conformance with most<br />

national and international standards including:<br />

• ABS<br />

• ANSI<br />

• DNV<br />

• IEC<br />

• IEEE<br />

• Lloyd’s Register<br />

• NEC<br />

• NEMA<br />

SmartLink 2000<br />

<strong>Stewart</strong> & <strong>Stevenson</strong>’s SmartLink 2000<br />

system is a simplified way to save money while<br />

troubleshooting and maintaining oil rig operating<br />

systems. This unique system allows rig operators<br />

to solve problems by computer modem or<br />

broadband connection, reducing the demand<br />

for specialized rig-based technicians and onsite<br />

trouble-shooting procedures.<br />

The system also features new software programs<br />

that can be written and downloaded via the same<br />

high-speed connection, giving operators the flexibility<br />

to custom tailor their control systems for new situations.<br />

This feature is especially useful when on-board drilling<br />

systems must be modified from location to location<br />

around the world.<br />

The SmartLink 2000 is available either as an upgrade to an<br />

existing <strong>Stewart</strong> & <strong>Stevenson</strong> AC or DC Drilling system, or as<br />

an option installed on new systems from the factory.<br />

9

<strong>Stewart</strong> & <strong>Stevenson</strong><br />

Engineering<br />

At <strong>Stewart</strong> & <strong>Stevenson</strong>’s manufacturing facility in Houston,<br />

Texas, innovative product engineering and quality manufacturing<br />

processes result in reliable, high performance, durable<br />

power generation systems. Our dedicated power generation<br />

engineering team, composed of mechanical and electrical<br />

engineers, CAD designers and configuration administrators,<br />

applies more than 200 years of combined experience to the<br />

development of our power generation equipment. For every<br />

power generation unit we build, we provide comprehensive<br />

engineering that includes:<br />

• Full 3-D engineering documentation package<br />

• System schematics for all electrical and mechanical<br />

operating systems<br />

• General arrangement and interface control diagrams<br />

to assist with locating critical installation details<br />

• Interactive CD-ROM technical manuals to assist with<br />

operating, troubleshooting and training vessel crews<br />

Specialized engineering analysis and support ensures power<br />

generation solutions that meet customer needs.<br />

• In-house, finite element analysis ensures design integrity<br />

• Virtual prototyping allows for flexible and fast configuration<br />

changes<br />

• 3-D models (as solids or “shrink-wrap” surfaces) are<br />

available for use by naval architects<br />

• Design assistance with vessel arrangement ensures<br />

proper installation of all equipment subsystems<br />

Advanced Control Systems Design<br />

<strong>Stewart</strong> & <strong>Stevenson</strong>’s engineering and design team continues<br />

to increase the durability, efficiency and safety of our power<br />

generation products with advancements in control systems<br />

design.<br />

• PLC-based control systems are housed in stainless steel<br />

NEMA 4X enclosures<br />

• Color touch screen HMI panels provide clear and intuitive<br />

access to all genset control and monitoring functions<br />

• MODBUS and other protocols provide remote monitoring<br />

and diagnostics of all vital generator functions<br />

10

<strong>Power</strong> <strong>Generation</strong><br />

Manufacturing<br />

<strong>Stewart</strong> & <strong>Stevenson</strong>’s ISO 9001 certified manufacturing facility<br />

features six-station flowline assembly that ensures product<br />

design integrity and quality unit after unit. Manufacturing<br />

capability is enhanced with:<br />

• Kanban Pull Scheduling, which improves production efficiency<br />

• Non-Conformance Reporting system, which tracks and<br />

corrects design, manufacturing and supplier quality issues<br />

• Certified Project Management (PMP) staff who ensure<br />

performance to contractual elements and act as<br />

customer’s liaison during and after project execution<br />

Generators are produced according to the following<br />

manufacturing standards:<br />

• All fluid handling lines smaller than 2 inches are constructed<br />

of stainless steel ASTM 304 piping and tubing to ensure<br />

long service life for vital systems<br />

• All carbon steel piping is designed and manufactured in<br />

accordance with ASME B31.1 and B31.3, as applicable<br />

• Structural welding is performed in accordance with<br />

ANSI/AWS D1.1/D1.1M:2006<br />

• Critical structural welds receive NDE magnetic particle testing<br />

• Marine grade three-coat paint system (S&S specification<br />

ES-502) maintains the highest level of corrosion protection<br />

throughout equipment lifetime<br />

• Mechanical gauges provide redundant instrumentation<br />

of critical operating parameters<br />

• Electrical control interfaces are conveniently located in<br />

stainless steel NEMA 4X junction boxes<br />

Added Value…<br />

Every power generation unit is thoroughly tested before<br />

shipping to the customer. Our two-bay indoor test facility<br />

allows for uninterrupted testing year-round. It features:<br />

• Full load test capacity via PC-controlled resistive/reactive<br />

load bank<br />

• Generator output voltages from 480 V to +15 kV<br />

• Data Acquisition System records all vital operating<br />

parameters during the Factory Acceptance Test<br />

• Data records are archived for future reference and<br />

comparison with shipboard performance<br />

Worldwide Service<br />

For every product that we manufacture,<br />

<strong>Stewart</strong> & <strong>Stevenson</strong> offers Equipment<br />

Commissioning, Operator Training, and<br />

Aftermarket Service and Parts that are<br />

available for the life of the equipment.<br />

11

STEWART & STEVENSON<br />

Arizona<br />

Phoenix<br />

7028 West Van Buren St.<br />

Phoenix, AZ 85043<br />

+1 602-462-1636<br />

Arkansas<br />

Stuttgart<br />

1111 Park Avenue<br />

Stuttgart, AR 72160<br />

+1 870-673-3575<br />

Colorado<br />

Denver<br />

5840 Dahlia St.<br />

Commerce City, CO 80022<br />

+1 303-287-7441<br />

Grand Junction<br />

2380 US Highway 6 & 50<br />

Grand Junction, CO 81505<br />

+1 970-248-4100<br />

Pueblo<br />

1313 Quartz Road<br />

Pueblo, CO 81008<br />

+1 719-543-7056<br />

Kansas<br />

Great Bend<br />

6115 West 10th Street<br />

Great Bend, KS 67530<br />

+1 620-793-3552<br />

Liberal<br />

210 Country Estates Rd.<br />

Liberal, KS 67901<br />

+1 620-624-5672<br />

Louisiana<br />

Lafayette<br />

401 Commercial Pkwy.<br />

Broussard, LA 70518<br />

+1 337-837-9001<br />

New Orleans<br />

1400 Destrehan Ave.<br />

Harvey, LA 70058<br />

+1 504-347-4326<br />

<strong>Stewart</strong> & <strong>Stevenson</strong> LLC<br />

Company Headquarters • 1000 Louisiana, Suite 5900 • Houston, TX 77002<br />

+1 713-751-2700 • www.stewartandstevenson.com • Headquarters@ssss.com<br />

<strong>Stewart</strong> & <strong>Stevenson</strong> <strong>Power</strong> Products LLC<br />

New Mexico<br />

Albuquerque<br />

6565 Hanover Rd. NW<br />

Albuquerque, NM 87121<br />

+1 505-881-3511<br />

Farmington<br />

1515 West Murray Dr.<br />

Farmington, NM 87401<br />

+1 505-325-5071<br />

Texas<br />

Amarillo<br />

11403 I-40 West<br />

Amarillo, TX 79124<br />

+1 806-335-1688<br />

Cleburne<br />

1117 E. Kilpatrick Rd.<br />

Cleburne, TX 76031<br />

+1 817-645-8106<br />

Corpus Christi<br />

6530 Agnes St.<br />

Corpus Christi, TX 78406<br />

+1 361-289-5350<br />

Dallas<br />

1631 Chalk Hill Road<br />

Dallas, TX 75212<br />

+1 214-631-5370<br />

El Paso<br />

1377 N. Horizon Blvd.<br />

El Paso, TX 79928<br />

+1 915-790-1848<br />

Houston<br />

8631 East Freeway<br />

Houston, TX 77029<br />

+1 713-671-6220<br />

Houston Training Center<br />

581 Garden Oaks Blvd.<br />

Houston, TX 77018<br />

+1 713-803-0700<br />

Longview<br />

4935 Whitehurst Drive<br />

Longview, TX 75602<br />

+1 903-758-5562<br />

Lubbock<br />

2000 E. Slaton Hwy.<br />

Lubbock, TX 79404<br />

+1 806-745-4224<br />

Odessa<br />

11120 W. Highway 80 East<br />

Odessa, TX 79765<br />

+1 432-563-4800<br />

Pharr<br />

2701 North Cage Blvd.<br />

Pharr, TX 78577<br />

+1 956-787-6880<br />

San Antonio<br />

5717 IH-10 East<br />

San Antonio, TX 78219<br />

+1 210-662-1000<br />

Waco<br />

1247 Sun Valley Road Ste B<br />

Waco, TX 76706<br />

+1 254-857-4351<br />

Wichita Falls<br />

2301 Central Freeway East<br />

Wichita Falls, TX 76302<br />

+1 940-322-5227<br />

Utah<br />

Vernal<br />

1218 East Hwy. 40<br />

Vernal, UT 84078<br />

+1 435-789-3383<br />

Wyoming<br />

Casper<br />

1850 East F Street<br />

Casper, WY 82601<br />

+1 307-234-6975<br />

Gillette<br />

1607 East Energy Street<br />

Gillette, WY 82716<br />

+1 307-685-6413<br />

Bogota<br />

Avenida Calle 23<br />

No. 32 A 51<br />

Santa Fe De Bogota D.C.<br />

Colombia<br />

+57-1-369-4444<br />

Barranquilla<br />

Via 40 No 73-06<br />

Barranquilla, Colombia<br />

+57-5-370-0103<br />

Louisiana<br />

New Orleans<br />

1400 Destrehan Ave.<br />

Harvey, LA 70058<br />

+1 504-347-4326<br />

<strong>Stewart</strong> & <strong>Stevenson</strong> De Las Americas Colombia LTDA<br />

Bucaramanga<br />

Kilometro 7 Via Giron<br />

No. 16-04<br />

Bucaramanga, Colombia<br />

+57-7-646-0606<br />

Cali<br />

Carrera 1 No. 49-35<br />

Santiago De Cali, Colombia<br />

+57-2-447-8136<br />

<strong>Stewart</strong> & <strong>Stevenson</strong> De Venezuela S.A.<br />

Maracaibo<br />

Av. 48 No. 149-886 (Km. 4½ carretera vía La Cañada)<br />

Municipio San Francisco<br />

Apartado Postal 1087<br />

Venezuela<br />

+58 261 717-2350<br />

<strong>Stewart</strong> & <strong>Stevenson</strong> EMDSI<br />

Singapore<br />

7 Joo Koon Crescent<br />

#02-01 Maintech<br />

Engr. Building<br />

Singapore 629024<br />

+65 -6-863-9137<br />

Medellin<br />

Carrera 48 A<br />

No 61 Sur 142<br />

Medellin, Colombia<br />

+57-4-448-4008<br />

Argentina<br />

Esmeralda 847, 7th Floor<br />

Office J<br />

C1007AB1 -<br />

Buenos Aires, Argentina<br />

+54 -11-4313-6399<br />

www.stewartandstevenson.com<br />

Copyright © 2011 <strong>Stewart</strong> & <strong>Stevenson</strong><br />

11-07-011P