KM Bolt-On Weight Sensors - Kistler-Morse

KM Bolt-On Weight Sensors - Kistler-Morse

KM Bolt-On Weight Sensors - Kistler-Morse

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

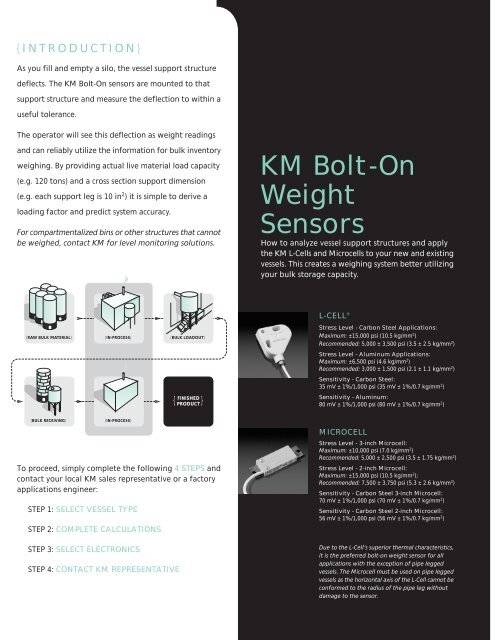

{INTRODUCTION}<br />

As you fill and empty a silo, the vessel support structure<br />

deflects. The <strong>KM</strong> <strong>Bolt</strong>-<strong>On</strong> sensors are mounted to that<br />

support structure and measure the deflection to within a<br />

useful tolerance.<br />

The operator will see this deflection as weight readings<br />

and can reliably utilize the information for bulk inventory<br />

weighing. By providing actual live material load capacity<br />

(e.g. 120 tons) and a cross section support dimension<br />

(e.g. each support leg is 10 in 2 ) it is simple to derive a<br />

loading factor and predict system accuracy.<br />

For compartmentalized bins or other structures that cannot<br />

be weighed, contact <strong>KM</strong> for level monitoring solutions.<br />

<strong>KM</strong> <strong>Bolt</strong>-<strong>On</strong><br />

<strong>Weight</strong><br />

<strong>Sensors</strong><br />

How to analyze vessel support structures and apply<br />

the <strong>KM</strong> L-Cells and Microcells to your new and existing<br />

vessels. This creates a weighing system better utilizing<br />

your bulk storage capacity.<br />

L-CELL ®<br />

{RAW BULK MATERIAL}<br />

{IN-PROCESS}<br />

{BULK LOADOUT}<br />

Stress Level - Carbon Steel Applications:<br />

Maximum: ±15,000 psi (10.5 kg/mm 2 )<br />

Recommended: 5,000 ± 3,500 psi (3.5 ± 2.5 kg/mm 2 )<br />

Stress Level - Aluminum Applications:<br />

Maximum: ±6,500 psi (4.6 kg/mm 2 )<br />

Recommended: 3,000 ± 1,500 psi (2.1 ± 1.1 kg/mm 2 )<br />

Sensitivity - Carbon Steel:<br />

35 mV ± 1%/1,000 psi (35 mV ± 1%/0.7 kg/mm 2 )<br />

FINISHED<br />

{ PRODUCT}<br />

Sensitivity - Aluminum:<br />

80 mV ± 1%/1,000 psi (80 mV ± 1%/0.7 kg/mm 2 )<br />

{BULK RECEIVING}<br />

{IN-PROCESS}<br />

To proceed, simply complete the following 4 STEPS and<br />

contact your local <strong>KM</strong> sales representative or a factory<br />

applications engineer:<br />

STEP 1: SELECT VESSEL TYPE<br />

STEP 2: COMPLETE CALCULATIONS<br />

STEP 3: SELECT ELECTRONICS<br />

STEP 4: CONTACT <strong>KM</strong> REPRESENTATIVE<br />

MICROCELL<br />

Stress Level - 3-inch Microcell:<br />

Maximum: ±10,000 psi (7.0 kg/mm 2 )<br />

Recommended: 5,000 ± 2,500 psi (3.5 ± 1.75 kg/mm 2 )<br />

Stress Level - 2-inch Microcell:<br />

Maximum: ±15,000 psi (10.5 kg/mm 2 );<br />

Recommended: 7,500 ± 3,750 psi (5.3 ± 2.6 kg/mm 2 )<br />

Sensitivity - Carbon Steel 3-inch Microcell:<br />

70 mV ± 1%/1,000 psi (70 mV ± 1%/0.7 kg/mm 2 )<br />

Sensitivity - Carbon Steel 2-inch Microcell:<br />

56 mV ± 1%/1,000 psi (56 mV ± 1%/0.7 kg/mm 2 )<br />

Due to the L-Cell’s superior thermal characteristics,<br />

it is the preferred bolt-on weight sensor for all<br />

applications with the exception of pipe legged<br />

vessels. The Microcell must be used on pipe legged<br />

vessels as the horizontal axis of the L-Cell cannot be<br />

conformed to the radius of the pipe leg without<br />

damage to the sensor.

Bulk<br />

Inventory<br />

<strong>Weight</strong><br />

Measurement<br />

Using:<br />

Product<br />

Selection<br />

and<br />

Application<br />

Guide<br />

{VESSEL TYPES}<br />

{VERTICAL LEG VESSELS}<br />

{HORIZONTAL BEAM VESSELS}<br />

STEP 1 STEP 1<br />

STEP 1<br />

{KISTLER-MORSE}<br />

{SKIRTED SILOS}

{LEG SUPPORTED VESSELS}<br />

Is this a stand-alone vessel supported on legs?<br />

If YES, find the best match for your vessel type from drawings 101 to 401. Proceed to STEP 2.<br />

If NO, go to section entitled HORIZONTAL BEAM SUPPORTED VESSELS.<br />

101<br />

N=0<br />

102<br />

N=0<br />

202<br />

N=1<br />

NOTE: Other L-Cell mounting locations for series 200 and up<br />

may be feasible for increased accuracy. Consult factory.<br />

502 502 502<br />

201<br />

N=1<br />

{HORIZONTAL BEAM SUPPORTED VESSELS}<br />

Is this vessel supported by horizontal beams and/or diagonals?<br />

If YES, find the best match for your vessel type from drawings 502 to 602. Proceed to STEP 2<br />

If NO, go to section entitled SKIRTED SILOS.<br />

551<br />

553<br />

203<br />

N=2<br />

553 553<br />

301<br />

N=2<br />

302<br />

N=2<br />

303<br />

N=2<br />

601 601 601<br />

304<br />

N=2<br />

401<br />

N=2<br />

LEGEND<br />

Mounting Location for L-Cell<br />

N Cross-Brace Effect<br />

STEP 2 STEP 2<br />

602 602<br />

651 651 651 701<br />

LEGEND<br />

Vertical Leg<br />

Vessel Support Point<br />

Ring Supported Vessel<br />

Mounting Location for L-Cell<br />

{SKIRTED SILOS}<br />

Does only the skirt support this vessel?<br />

If YES, find the best match for your Vessels Diameter. Proceed to STEP 2<br />

If NO, consult with the factory.<br />

4 5 3<br />

6<br />

4 5 6<br />

3 7<br />

2<br />

1<br />

8<br />

5 6 7<br />

4 8<br />

3 9<br />

2 10<br />

1<br />

45 6 7 8<br />

9<br />

10<br />

3 11<br />

2 12<br />

1<br />

5<br />

6 7 8 9<br />

10<br />

11<br />

4<br />

3<br />

2<br />

1<br />

12<br />

13<br />

14<br />

7 8 9 10<br />

11<br />

6<br />

12<br />

5<br />

4<br />

3<br />

2<br />

1<br />

13<br />

14<br />

15<br />

16<br />

8 9 10 11<br />

7<br />

12<br />

6<br />

5<br />

13<br />

14<br />

4<br />

3<br />

2<br />

1<br />

15<br />

16<br />

17<br />

8<br />

7<br />

6<br />

5<br />

4<br />

9 10 11 12 13<br />

14<br />

15<br />

16<br />

17<br />

3<br />

2<br />

1<br />

18<br />

19<br />

20<br />

STEP 2<br />

9’ (2.7m) Dia.<br />

9’- 5” (2.9m)<br />

L-Cell Spacing<br />

12’ (3.7m) Dia.<br />

9’- 5” (2.9m)<br />

L-Cell Spacing<br />

15’ (4.6m) Dia.<br />

9’- 5” (2.9m)<br />

L-Cell Spacing<br />

2 1<br />

LEGEND<br />

18’ (5.5m) Dia.<br />

9’- 5” (2.9m)<br />

L-Cell Spacing<br />

21’ (6.4m) Dia.<br />

9’- 5” (2.9m)<br />

L-Cell Spacing<br />

24’ (7.3m) Dia.<br />

9’- 5” (2.9m)<br />

L-Cell Spacing<br />

26’ (7.9m) Dia.<br />

9’- 5” (2.9m)<br />

L-Cell Spacing<br />

28’ (8.5m) Dia.<br />

8’-10” (2.7m)<br />

L-Cell Spacing<br />

L-Cell Set<br />

Junction Box<br />

Door

Number of Similar Vessels<br />

Vessel Type (Select closest type 101-104)<br />

Leg Type<br />

(If pipe leg - use Microcells in same configuration as L-Cells)<br />

LEG TYPES<br />

A<br />

C<br />

B<br />

I-BEAM<br />

Area = (A x 2B) x C<br />

A<br />

C<br />

B<br />

ANGLE<br />

Area = (A + B) x C<br />

Live Load (Working capacity)<br />

lbs<br />

Number of Legs<br />

Live Load per Leg (See formula)<br />

Steel Area Calculation (See Leg Type formula)<br />

Load Factor (See formulas)<br />

Percentage ±Error (From chart at right) ±<br />

Accuracy (In pounds)<br />

±<br />

Proceed to STEP 3<br />

lbs<br />

in 2<br />

psi<br />

%<br />

lbs<br />

FORMULAS<br />

A T T D<br />

B<br />

TUBULAR<br />

Area = (2A + 2B) x T<br />

PIPE<br />

Area = 3.14 x D x T<br />

Live Load per Leg = Live Load (Working capacity) ÷ Number of Legs<br />

Load Factor (psi) = Live Load per Leg ÷ Steel Area Calculation<br />

Accuracy in Pounds = Live Load x ±Error% (From chart at right)<br />

Number of Similar Vessels<br />

Vessel Type (Select closest type 502-602)<br />

LEG TYPE<br />

A<br />

D<br />

Live Load (Working capacity)<br />

Number of Support Beams<br />

lbs<br />

I-BEAM<br />

Shear Area = A x D<br />

Live Load per Support Point Beam (See formula)<br />

Steel Area Calculation (See Shear Area formula)<br />

lbs<br />

in 2<br />

FORMULA<br />

Load factor (See formula)<br />

psi<br />

Percentage ±Error (From chart at right)<br />

±<br />

%<br />

Accuracy (In pounds)<br />

±<br />

lbs<br />

Proceed to STEP 3<br />

Number of Similar Silos<br />

Silo Type (<strong>Bolt</strong>ed or Welded)<br />

SILO<br />

TYPE<br />

Live Load (Working capacity)<br />

lbs<br />

Vessel (D)iameter (In inches)<br />

in<br />

Skirt (T)hickness (In inches)<br />

in<br />

T<br />

Load Factor (See formula)<br />

psi<br />

D<br />

Percentage ±Error (From chart at right)<br />

Accuracy (In pounds)<br />

±<br />

±<br />

%<br />

lbs<br />

FORMULA<br />

Load Factor (psi) = Live Load (Working capacity) ÷ (3.14 x D x T)<br />

Proceed to STEP 3<br />

Accuracy in Pounds = Live Load x ±Error% (From chart at right)

LEG ACCURACY CHART<br />

{± ERROR %}<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

CONSULT FACTORY<br />

{3089 psi}<br />

{example}<br />

Outside N=0<br />

Outside N=1<br />

Outside N=2<br />

Inside N=0<br />

Inside N=1<br />

Inside N=2<br />

EXAMPLE {see example to the left}<br />

Storage silo located outside with a capacity of 120,000 lbs. It is supported<br />

by four 10” I-Beam legs (that are type W10X33). There are no braces.<br />

Vessel Type 101<br />

Leg Type I-Beam W10X33 (10” x 8”)<br />

Live Load<br />

120,000 lbs<br />

Number of Legs 4<br />

Live Load per Leg 120,000 ÷ 4 = 30,000 lbs per Leg<br />

Steel Area Calc. 9.71 in 2<br />

Load Factor<br />

3,089 psi<br />

Accuracy<br />

±2.5% of 120,000 lbs = ±3,000 lbs<br />

2 L-Cells per leg with appropriate electronics.<br />

0<br />

0 1000 2000 3000 4000 5000 6000 7000 8000 9000<br />

{STRESS IN PSI}<br />

See Vessel Drawing for N value.<br />

HORIZONTAL ACCURACY CHART<br />

{± ERROR %}<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

0<br />

CONSULT FACTORY<br />

{example}<br />

{3600 psi}<br />

1000 2000 3000 4000 5000 6000 7000 8000 9000<br />

{STRESS IN PSI}<br />

4 Cells/Beam<br />

2 Cells/Beam<br />

1 Cell/Beam<br />

EXAMPLE {see example to the left}<br />

Load out vessel located outside with a capacity of 120,000 lbs. It is beam<br />

supported by four diagonal 12” I-Beams (that are type W12X53). There<br />

are no other support points. NOTE: In load out applications, batch<br />

accuracy is typically greater than inventory accuracy as stated.<br />

Vessel Type 551<br />

Leg Type I-Beam W12X53 (12” x 10”)<br />

Live Load<br />

120,000 lbs<br />

Number of Beams 4<br />

Live Load per Beam 120,000 ÷ 4 = 30,000 lbs per support Beam<br />

Shear Load per Beam 30,000 ÷ 2 = 15,000<br />

Steel Area Calc. 4.161 in 2<br />

Load Factor<br />

3,605 psi<br />

Accuracy<br />

±1.75% of 120,000 lbs = ±2,100 lbs<br />

2 L-Cells per support beam with appropriate electronics.<br />

STEP 3<br />

SKIRT ACCURACY CHART<br />

{± ERROR %}<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

CONSULT FACTORY<br />

{2123 psi}<br />

{example}<br />

Best Case<br />

Worst Case<br />

Working Area<br />

EXAMPLE {see example to the left}<br />

Receiving silo for flour is a Peabody bolted TecTank ® that is 12’ in<br />

diameter by 56’ tall and located outside. It has a skirt thickness of 3/16”<br />

and holds 180,000 lbs. The fill method is pneumatic and the use of the<br />

system will be for inventory purposes.<br />

Vessel Type<br />

Skirted Silo (<strong>Bolt</strong>ed)<br />

Live Load<br />

180,000 lbs<br />

Vessel Diameter 144 in (12 Feet)<br />

Skirt Thickness 3/16 in (0.1875)<br />

Load Factor<br />

2,123 psi<br />

Accuracy<br />

±3.0 to 5.0% of 180,000 lbs = ±5,400 to 9,000 lbs<br />

4 sets of L-Cells per silo with appropriate electronics.<br />

0<br />

0 1000 2000 3000 4000 5000 6000 7000 8000 9000<br />

{SKIRT STRESS IN PSI}

STEP 3 STEP 4<br />

Select the electronics<br />

and options that meet<br />

your requirements.<br />

SVS2000<br />

A single-vessel weight indicator featuring easy to read<br />

LCD display, menu driven “quick-config” and net/tare/gross<br />

functions with modular output options. NEMA 4X plastic.<br />

WEIGH ll<br />

A 1-4 vessel weight indicator featuring easy to read LCD<br />

display, menu driven “quick-config” and net/tare/gross<br />

functions with modular output options. NEMA 4X plastic.<br />

MVS 4D (MULTI-VESSEL SYSTEM)<br />

A controller for measuring and monitoring bulk material<br />

inventories. By combining simple plug-in input and<br />

output cards to match your specific needs this multivessel<br />

system will monitor and provide control for up<br />

to 32 vessels.<br />

MVS 8D (MULTI-VESSEL SYSTEM)<br />

A vessel controller (19” rack configuration) for<br />

measuring and monitoring bulk material inventories.<br />

By combining simple plug-in input and output cards<br />

to match your specific needs this multi-vessel, rack<br />

mount system will monitor and provide control for<br />

up to 120 vessels.<br />

{FAX TO<br />

FACTORY}<br />

425.402.1500<br />

VESSEL INFORMATION<br />

Type<br />

Capacity<br />

PSI<br />

Accuracy<br />

ELECTRONIC INFORMATION<br />

Type<br />

Options<br />

Date<br />

1<br />

1-4<br />

1-32<br />

Number of Vessels<br />

1-120<br />

SITE INFORMATION<br />

Company Name<br />

Address<br />

City, State, Zip<br />

Phone<br />

( )<br />

Monitored<br />

Opt<br />

Opt<br />

Opt<br />

Opt<br />

Analog (4-20 mA)<br />

CONTACT INFORMATION<br />

Name<br />

Title<br />

Std<br />

Opt<br />

Opt<br />

Opt<br />

Relay Setpoints<br />

Opt<br />

Std<br />

Std<br />

Std<br />

Serial Communications<br />

RS422/485<br />

Opt<br />

N/A<br />

N/A<br />

N/A<br />

Fax<br />

DeviceNet<br />

Allen-Bradley<br />

Remote I/O(RIO)<br />

Opt<br />

Opt<br />

Opt<br />

Opt<br />

( )<br />

Phone ( )<br />

Fax ( )<br />

Std<br />

Std<br />

Std<br />

Opt<br />

Nema 4X Enclosure<br />

Stainless Steel<br />

Enclosure<br />

Opt Std<br />

Opt Std<br />

Opt Std<br />

N/A Std<br />

CE Approval<br />

UL Approval<br />

Std<br />

N/A<br />

N/A<br />

N/A

NOTES:<br />

P/N 97-5092<br />

<strong>KM</strong> is represented in your area by:<br />

WORLD HEADQUARTERS<br />

19021 120th Ave. NE<br />

Bothell, WA 98011 USA<br />

1.800.426.9010<br />

tel: 425.486.6600<br />

fax: 425.402.1500<br />

kistlermorse.com<br />

EUROPE<br />

Rucaplein 531<br />

B-2610 Wilrijk-Belgium<br />

+32.3.218.99.99<br />

fax: +32.3.230.78.76<br />

kistler.morse@skynet.be