AquaFlex® Stainless Steel Sprinkler Fittings I-AQUAFLEX - Victaulic

AquaFlex® Stainless Steel Sprinkler Fittings I-AQUAFLEX - Victaulic

AquaFlex® Stainless Steel Sprinkler Fittings I-AQUAFLEX - Victaulic

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

INSTALLATION INSTRUCTIONS<br />

AquaFlex ® <strong>Stainless</strong> <strong>Steel</strong> <strong>Sprinkler</strong> <strong>Fittings</strong><br />

I-<strong>AQUAFLEX</strong><br />

• If construction is altered, refer to applicable standards to determine<br />

if additional sprinklers are required.<br />

• The owner is responsible for maintaining the fire protection system<br />

in proper operating condition.<br />

• For minimum maintenance and inspection requirements, refer<br />

to NFPA 25 and the NFPA pamphlet that describes the care<br />

and maintenance of sprinkler systems. In addition, the authority<br />

having jurisdiction may have additional maintenance, testing, and<br />

inspection requirements that must be followed.<br />

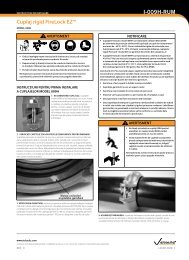

STAINLESS STEEL FLEXIBLE HOSE BEND<br />

CHARACTERISTICS<br />

Minimum<br />

bend radius<br />

90°<br />

2X<br />

Minimum<br />

bend radius<br />

Minimum<br />

bend radius<br />

WARNING<br />

• Re-location of AquaFlex products MUST be performed by<br />

qualified personnel familiar with the system’s original design<br />

criteria, sprinkler listings/approvals, and state and local codes<br />

(including NFPA 13 standards).<br />

Failure to re-locate this AquaFlex product properly could affect its<br />

performance during a fire, resulting in serious personal injury and<br />

property damage.<br />

2X<br />

Minimum<br />

bend radius<br />

OR<br />

Minimum<br />

bend radius<br />

OR<br />

Minimum<br />

bend radius<br />

Minimum<br />

bend radius<br />

Minimum<br />

bend radius<br />

Minimum<br />

bend radius<br />

FRICTION LOSS DATA<br />

Length of <strong>Stainless</strong> <strong>Steel</strong><br />

Flexible Hose<br />

Actual Length of <strong>Stainless</strong> <strong>Steel</strong> Flexible Hose<br />

inches/mm<br />

Outlet Size<br />

NOTE: For out-of-plane (three-dimensional) bends, care must be taken<br />

to avoid imparting torque on the flexible stainless steel hose.<br />

Equivalent Length of 1-inch/33.7-mm<br />

Schedule 40 Pipe<br />

feet/meters<br />

inches FM UL inches FM* UL‡<br />

24 N/A<br />

28<br />

1/2<br />

N/A<br />

18<br />

5.5<br />

700<br />

32<br />

3/4<br />

N/A<br />

9.8<br />

31<br />

31<br />

790<br />

31<br />

1/2<br />

9.6 27<br />

2.9 8.2<br />

780<br />

3/4<br />

8.2<br />

2.5<br />

33<br />

10.1<br />

36<br />

36<br />

915<br />

40<br />

1/2<br />

1000<br />

9.9 48<br />

3/4<br />

3.0 14.6<br />

11.0<br />

3.4<br />

44<br />

13.4<br />

48<br />

48<br />

1220<br />

17.1 53<br />

48<br />

1/2<br />

5.2 16.2<br />

1220<br />

16.5 55<br />

3/4<br />

5.0 16.8<br />

60<br />

21.4 68<br />

60<br />

61<br />

1/2<br />

6.5 20.7<br />

1525<br />

1540<br />

20.1 63<br />

3/4<br />

6.1 19.2<br />

72<br />

72<br />

1830<br />

27.3 73<br />

72<br />

1/2<br />

8.3 22.3<br />

1830<br />

26.2 76<br />

3/4<br />

7.9 23.2<br />

Maximum Number<br />

of 90° Bends at<br />

4-inch/102-mm<br />

Bend Radius §<br />

‡ Series AQU at 4-inch/102-mm minimum bend radius and straight reducers<br />

* Series AQB at 7-inch/178-mm minimum bend radius and straight reducers<br />

§ A higher number of bends may be permitted, provided the sum of degrees is equal to or less than the total maximum allowable degrees of bend (e.g. Two<br />

90° bends equal 180°. Three 90° bends equal 270°).<br />

For friction loss data for elbows, refer to <strong>Victaulic</strong> submittal 10.85.<br />

EXAMPLE: A 48-inch Series AQU hose installed with two 30° bends and two 90° bends at a 4-inch bend radius is permitted and considered equivalent to the<br />

data in the table shown above. In this example, the total number of degrees is 240°, which is less than the allowable 270°.<br />

NOTE: Differences in equivalent lengths are due to varying test methods, per UL 2443 and FM 1637 standards. Refer to these standards for additional<br />

information regarding friction loss test methods.<br />

2<br />

2<br />

3<br />

3<br />

3<br />

3<br />

www.victaulic.com<br />

VICTAULIC AND <strong>AQUAFLEX</strong> ARE REGISTERED TRADEMARKS OF VICTAULIC COMPANY. © 2010 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.<br />

I-<strong>AQUAFLEX</strong>_2<br />

REV_C