Download pdf - Marabu

Download pdf - Marabu

Download pdf - Marabu

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2.2 Production – Focus on Environmental Awareness Contents<br />

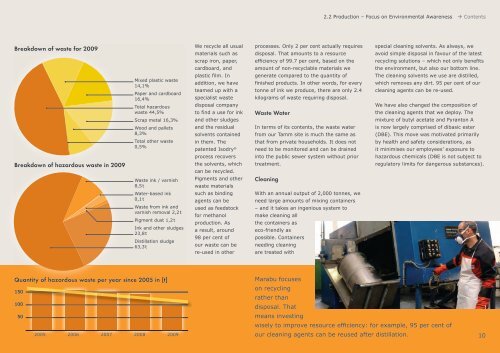

Breakdown of waste for 2009<br />

We recycle all usual<br />

materials such as<br />

processes. Only 2 per cent actually requires<br />

disposal. That amounts to a resource<br />

special cleaning solvents. As always, we<br />

avoid simple disposal in favour of the latest<br />

scrap iron, paper,<br />

efficiency of 99.7 per cent, based on the<br />

recycling solutions – which not only benefits<br />

cardboard, and<br />

amount of non-recyclable materials we<br />

the environment, but also our bottom line.<br />

Mixed plastic waste<br />

14,1%<br />

Paper and cardboard<br />

16,4%<br />

Total hazardous<br />

waste 44,5%<br />

Scrap metal 16,3%<br />

Wood and pallets<br />

8,3%<br />

Total other waste<br />

0,5%<br />

plastic film. In<br />

addition, we have<br />

teamed up with a<br />

specialist waste<br />

disposal company<br />

to find a use for ink<br />

and other sludges<br />

and the residual<br />

solvents contained<br />

in them. The<br />

patented Isodry ®<br />

generate compared to the quantity of<br />

finished products. In other words, for every<br />

tonne of ink we produce, there are only 2.4<br />

kilograms of waste requiring disposal.<br />

Waste Water<br />

In terms of its contents, the waste water<br />

from our Tamm site is much the same as<br />

that from private households. It does not<br />

need to be monitored and can be drained<br />

The cleaning solvents we use are distilled,<br />

which removes any dirt. 95 per cent of our<br />

cleaning agents can be re-used.<br />

We have also changed the composition of<br />

the cleaning agents that we deploy. The<br />

mixture of butyl acetate and Pyranton A<br />

is now largely comprised of dibasic ester<br />

(DBE). This move was motivated primarily<br />

by health and safety considerations, as<br />

it minimises our employees’ exposure to<br />

process recovers<br />

into the public sewer system without prior<br />

hazardous chemicals (DBE is not subject to<br />

Breakdown of hazardous waste in 2009<br />

the solvents, which<br />

can be recycled.<br />

treatment.<br />

regulatory limits for dangerous substances).<br />

Waste ink / varnish<br />

8,5 t<br />

Pigments and other<br />

waste materials<br />

Cleaning<br />

Water-based ink<br />

0,1 t<br />

Waste from ink and<br />

varnish removal 2,2 t<br />

Pigment dust 1,2 t<br />

Ink and other sludges<br />

23,8 t<br />

Distillation sludge<br />

63,3 t<br />

such as binding<br />

agents can be<br />

used as feedstock<br />

for methanol<br />

production. As<br />

a result, around<br />

98 per cent of<br />

our waste can be<br />

re-used in other<br />

With an annual output of 2,000 tonnes, we<br />

need large amounts of mixing containers<br />

– and it takes an ingenious system to<br />

make cleaning all<br />

the containers as<br />

eco-friendly as<br />

possible. Containers<br />

needing cleaning<br />

are treated with<br />

Quantity of hazardous waste per year since 2005 in [t]<br />

150<br />

100<br />

50<br />

2005 2006 2007 2008 2009<br />

<strong>Marabu</strong> focuses<br />

on recycling<br />

rather than<br />

disposal. That<br />

means investing<br />

wisely to improve resource efficiency: for example, 95 per cent of<br />

our cleaning agents can be reused after distillation.<br />

10