For Concrete and Masonry - Simpson Strong-Tie

For Concrete and Masonry - Simpson Strong-Tie

For Concrete and Masonry - Simpson Strong-Tie

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

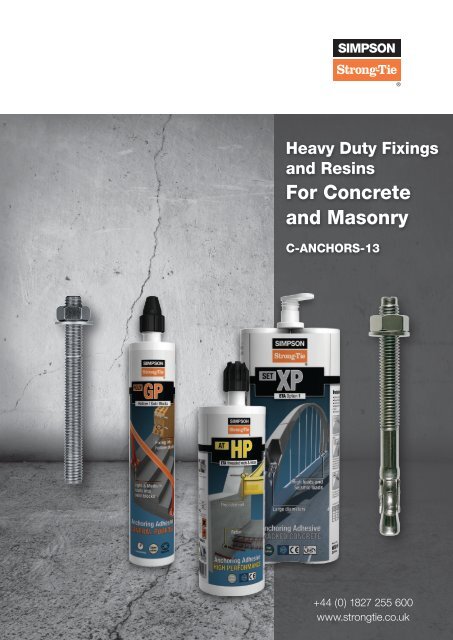

Heavy Duty Fixings<br />

<strong>and</strong> Resins<br />

BEFESTIGUNGSSYS-<br />

TEME<br />

<strong>For</strong> C-SL2008E <strong>Concrete</strong><br />

<strong>and</strong> <strong>Masonry</strong><br />

C-ANCHORS-13<br />

+44 (0) 1827 255 600<br />

www.strongtie.co.uk

We are pleased to present you with the 2013 Anchors for <strong>Masonry</strong><br />

<strong>and</strong> <strong>Concrete</strong> product catalogue.<br />

Testing Innovation <strong>and</strong> Performance<br />

<strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong>’s work has led to the creation of many anchor products<br />

that significantly improve the safety of homes, buildings, <strong>and</strong> other structures.<br />

Our state-of-the-art laboratory facilities are constantly testing new <strong>and</strong><br />

existing products to provide you with the best connecting <strong>and</strong> anchoring<br />

solutions <strong>and</strong> with the information you need in order to design with <strong>and</strong><br />

properly install our products.<br />

Technical Approvals<br />

Knowing that our products are extensively tested provides you with the<br />

reassurance that they will perform in the toughest conditions. Many of the<br />

products contained in this catalogue have been used in the most dem<strong>and</strong>ing<br />

safety-oriented applications such as nuclear power plants. We strive to<br />

ensure that our products are compliant with the highest European Technical<br />

Approvals for cracked <strong>and</strong> non cracked concrete.<br />

Customer Support<br />

The quality <strong>and</strong> variety of our product line provides engineers <strong>and</strong><br />

builders with design flexibility while offering reliable <strong>and</strong> proven performance.<br />

In addition, customers can count on our engineering technical support,<br />

experienced field representatives <strong>and</strong> training programs.<br />

www.strongtie.co.uk<br />

European Technical Approval<br />

Telephone: 01827 255600 | Visit: www.strongtie.co.uk<br />

2

CONTENTS<br />

Page<br />

Expansion <strong>and</strong> Undercut Anchor Systems<br />

WA, BOAX-II THROUGHBOLT 6-13<br />

Adhesive Anchor Systems<br />

POLY-GP 14-15<br />

AT-HP 16-18<br />

SET-XP 19-21<br />

KLS & KLP 22-25<br />

LMAS THREADED STUD 27<br />

C-ANCHORS-2013 © SIMPSON STRONG-TIE ®<br />

Accessories<br />

Applicator Guns, Brushes, Nozzles, Sleeves 26-27<br />

<strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong> ® reserves the right to change specifications, designs, <strong>and</strong> models without notice or liability for such changes.<br />

3

ANCHOR SELECTION GUIDE<br />

Page<br />

Anchoring<br />

Principle<br />

Cracked<br />

<strong>Concrete</strong><br />

Non-Cracked<br />

<strong>Concrete</strong><br />

Hollow<br />

<strong>Masonry</strong><br />

Type<br />

BOAX-II 8 • •<br />

WEDGE ANCHOR 6 •<br />

UNDERCUT ANCHOR 14 • •<br />

POLY-GP 18 •<br />

AT-HP 20 • •<br />

SET-XP 23 • •<br />

Expansion Anchor Systems Adhesive Anchor Systems Undercut Anchor Systems<br />

This type of anchor transfers load into<br />

the base material through friction grip<br />

that is established between the<br />

anchor’s expansion sleeve <strong>and</strong> the<br />

sidewalls of the drilled hole.<br />

This occurs when the anchor is set <strong>and</strong><br />

the cone is drawn into the expansion<br />

sleeve. Expansion anchors pro vide a<br />

reliable <strong>and</strong> economical fixing system.<br />

This type of anchor consists of a chemical<br />

mortar <strong>and</strong> a threaded metal stud. After<br />

installation a chemical reaction takes place<br />

that secures the stud in place <strong>and</strong> the<br />

chemical bonds to the sidewalls of the drilled<br />

hole.<br />

This system does not produce expansion<br />

forces, <strong>and</strong> therefore allows for smaller edge<br />

distances <strong>and</strong> spacings.<br />

This type of anchor transfers load into the base<br />

material through mechanical interlock with an<br />

undercut that is formed in the base material.<br />

The undercut can be formed before or during<br />

setting of the anchor.<br />

These systems have very high reliability <strong>and</strong><br />

performance.<br />

Tension Zone Anchor<br />

This anchor is suitable<br />

<strong>and</strong> approved for use<br />

in cracked (tension<br />

zone) <strong>and</strong> non-cracked<br />

(compression zone)<br />

concrete.<br />

Compression Zone<br />

Anchor<br />

This anchor is suitable<br />

<strong>and</strong> approved for<br />

use in non-cracked<br />

(compression zone)<br />

concrete.<br />

Hollow <strong>Masonry</strong><br />

This anchor is suitable<br />

<strong>and</strong> approved for use<br />

in solid masonry<br />

meet ing DIN 1053.<br />

Solid <strong>Masonry</strong><br />

This anchor is suitable<br />

<strong>and</strong> approved for use<br />

in solid masonry<br />

meet ing DIN 1053.<br />

European<br />

Technical Approval<br />

This anchor has<br />

been approved<br />

for construction<br />

applications in<br />

accordance with<br />

European Technical<br />

Approval Guidelines<br />

(ETAG).<br />

European<br />

Conformity Mark<br />

This product meets<br />

the requirements<br />

of the European<br />

Technical Approval <strong>and</strong><br />

can be used without<br />

restriction in the<br />

European Union.<br />

4

ANCHOR SELECTION GUIDE<br />

Solid<br />

<strong>Masonry</strong><br />

ETA-Approval<br />

Fire<br />

Resistance<br />

Sprinklers<br />

Steel,<br />

Zinc Plated<br />

Load Range<br />

Calculation<br />

Software<br />

Corrosion<br />

Resistance<br />

European Technical Approval<br />

Option 1 • • •<br />

Option 7<br />

Option 1 • • •<br />

• <strong>Masonry</strong> •<br />

•<br />

Option 8, <strong>Masonry</strong><br />

<strong>and</strong> Rebar<br />

Option 1<br />

•<br />

•<br />

•<br />

1.8–21.4<br />

kN<br />

3.4–26.7<br />

kN<br />

2.4–30.8<br />

kN<br />

0.3–0.7<br />

kN<br />

9.1–54.8<br />

kN<br />

5.4–57.4<br />

kN<br />

• •<br />

•<br />

•<br />

• •<br />

• •<br />

•<br />

Corrosion Resistance<br />

Approved Anchors<br />

C-ANCHORS-2013 © SIMPSON STRONG-TIE ®<br />

Corrosion is the destruction of metal through chemical or<br />

electrochemical attack by the environment. In most indoor<br />

conditions carbon steel anchors with zinc plating provide sufficient<br />

corrosion resistance. Stainless steel (A4) anchors are usually<br />

suitable for outdoor or damp indoor conditions. Stainless steel<br />

anchors with special corrosion resistant properties are necessary<br />

for aggressive conditions such as roadway tunnels or chloride<br />

atmospheres.<br />

To ensure that an anchor is capable of resisting the intended external<br />

loads, the anchor must be suitable for the intended application <strong>and</strong><br />

installed in accordance with the manufacturer’s recommended<br />

installation instructions.<br />

Anchors with independent technical approvals (such as DIBt or ETA)<br />

have demonstrated suitable behavior <strong>and</strong> performance<br />

for use in construction applications.<br />

Fire Resistance<br />

Suitable for use in fire<br />

protection applications.<br />

This anchor meets the<br />

requirements of VdS<br />

CEA 4001.<br />

Available in carbon steel,<br />

zinc plated <strong>and</strong> blue<br />

passivated.<br />

Permissible tension load.<br />

Calculation software.<br />

Corrosion Resistance.<br />

5

WA THROUGHBOLT<br />

ETA Option 7 Approved throughbolt for simple <strong>and</strong><br />

economical applications.<br />

The WA Throughbolt range. Providing an economical yet<br />

high performance fixing for installations with small space<br />

<strong>and</strong> edge distances in non-cracked concrete.<br />

Features <strong>and</strong> Benefits:<br />

• ETA Option 7 Approved (Non-Cracked <strong>Concrete</strong>)<br />

• Wide range of sizes from M6 to M20<br />

• M6 to M10 sizes require 100mm concrete thickness<br />

• High load capacity<br />

• Optimised design for fast installation<br />

• Suitable for small spacings between anchors<br />

• Suitable for small edge distances<br />

• Economical cost<br />

90°<br />

Drill hole Clean hole (blowing) Insert anchor through the<br />

fixture<br />

Apply recommended<br />

installation torque with a<br />

calibrated torque wrench<br />

6

Expansion Anchor Systems<br />

WA THROUGHBOLT<br />

ETA - 11/0080<br />

Material: Carbon Steel, Zinc Plated <strong>and</strong> Passivated<br />

Thread size M6 M8 M10 M12 M16 M20 (4)<br />

Effective embedment depth (h ef<br />

) [mm] 40 45 50 65 80 100<br />

Model WA 6/… WA 8/… WA 10/… WA 12/… WA 16/… WA 20/…<br />

Recommended tension loads for single anchors with no edge distances or spacings<br />

1) 5)<br />

N rec<br />

concrete 3) C40/50 [kN] 5.0 8.1 10.7 17.8 24.3 19.9<br />

C20/25 [kN] 4.3 5.7 7.6 12.6 17.2 19.9<br />

Non-cracked C30/37 [kN] 4.6 7.0 9.3 15.4 21.0 19.9<br />

C50/60 [kN] 5.3 8.9 11.8 19.5 26.7 19.9<br />

Recommended shear load for single anchors with no edge distances or spacings<br />

1) 2)<br />

V rec<br />

Non-cracked<br />

concrete 3)<br />

C20/25 [kN] 3.4 5.4 8.5 14.3 26.9 26.7<br />

C30/37 [kN] 3.4 5.4 9.7 14.3 26.9 26.7<br />

C40/50 [kN] 3.4 5.4 9.7 14.3 26.9 26.7<br />

C50/60 [kN] 3.4 5.4 9.7 14.3 26.9 26.7<br />

1. The recommended loads have been calculated using the partial safety factors for resistances stated in ETA-approval(s) <strong>and</strong> with a partial safety factor for actions of γᵧF=1.4. The loading figures<br />

are valid for unreinforced concrete <strong>and</strong> reinforced concrete with a rebar spacing s ≥ 15 cm (any diameter) or with a rebar spacing s ≥ 10 cm, if the rebar diameter is 10 mm or smaller.<br />

2. The figures for shear are based on a single anchor without influence of concrete edges. <strong>For</strong> anchorages close to edges (c ≤ max [10 hef; 60d]) the concrete edge failure shall be checked per<br />

ETAG 001, Annex C, design method A.<br />

3. <strong>Concrete</strong> is considered non-cracked when the tensile stress within the concrete is σσ L + σσ R ≤ 0. In the absence of detailed verification σσ R = 3 N/mm² can be assumed (σσ L equals the tensile<br />

stress within the concrete induced by external loads, anchors loads included).<br />

4. Not included in the approval ETA-11/0080 - Option 7.<br />

5. <strong>For</strong> combined tension <strong>and</strong> shear loads or anchor groups <strong>and</strong>/or in case of edge influence, a calculation per ETAG 001, Annex C, design method A shall be performed. <strong>For</strong> details see<br />

ETA - approval(s).<br />

With Hex Nut <strong>and</strong> Washer - Material: Carbon Steel, Zinc Plated <strong>and</strong> Blue Passivated<br />

C-ANCHORS-2013 © SIMPSON STRONG-TIE ®<br />

Type<br />

Item<br />

Code<br />

WA 6/5 (M6 x 60) WA06060 •<br />

ETA<br />

Thread Size<br />

Ø × Depth of<br />

Drilled Hole<br />

Max. Fixture<br />

Thickness<br />

Ø Fixture<br />

Hole<br />

Eff. Embedment<br />

Depth<br />

Length<br />

Thread<br />

Length<br />

d o<br />

x h 1<br />

t fix<br />

d f<br />

h ef<br />

L F<br />

mm mm mm mm mm mm<br />

WA 6/10 (M6 x 65) WA06065 • 10 65 30 100<br />

M6 6 x 55<br />

7 40<br />

WA 6/20 (M6 x 75) WA06075 • 20 75 35 100<br />

5<br />

Box<br />

Qty<br />

60 30 100<br />

WA 6/30 (M6 x 85) WA06085 • 30 85 40 100<br />

WA 8/5 (M8 x 68) WA08068 •<br />

WA 8/30 (M8 x 93) WA08093 • 30 93 50 50<br />

M8 8 x 65<br />

9 45<br />

WA 8/40 (M8 x 103) WA08103 • 40 103 50 50<br />

5<br />

68 40 50<br />

WA 8/10 (M8 x 73) WA08073 • 10 73 45 50<br />

WA 8/20 (M8 x 83) WA08083 • 20 83 45 50<br />

WA 8/50 (M8 x 113) WA08113 • 50 113 60 50<br />

WA 8/70 (M8 x 133) WA08133 • 70 133 85 50<br />

WA 8/100 (M8 x 163) WA08163 • 100 163 100 50<br />

WA 10/5 (M10 x 78) WA10078 •<br />

WA 10/30 (M10 x 103) WA10103 • 30 103 50 50<br />

M10 10 x 70<br />

12 50<br />

WA 10/40 (M10 x 113) WA10113 • 40 113 60 50<br />

5<br />

78 40 50<br />

WA 10/10 (M10 x 83) WA10083 • 10 83 40 50<br />

WA 10/20 (M10 x 93) WA10093 • 20 93 50 50<br />

WA 10/50 (M10 x 123) WA10123 • 50 123 60 50<br />

WA 10/70 (M10 x 143) WA10143 • 70 143 70 50<br />

WA 10/100 (M10 x 173) WA10173 • 100 173 80 50<br />

WA 12/5 (M12 x 104) WA12104 •<br />

WA 12/50 (M12 x 149) WA12149 • M12 12 x 90<br />

50 14 65<br />

149 100 25<br />

5<br />

104 60 25<br />

WA 12/10 (M12 x 109) WA12109 • 10 109 60 25<br />

WA 12/20 (M12 x 119) WA12119 • 20 119 70 25<br />

WA 12/30 (M12 x 129) WA12129 • 30 129 70 25<br />

WA 12/40 (M12 x 139) WA12139 • 40 139 80 25<br />

WA 12/80 (M12 x 179) WA12179 • 80 179 110 25<br />

WA 12/100 (M12 x 199) WA12199 • 100 199 110 25<br />

WA 12/120 (M12 x 219) WA12219 • 120 219 125 25<br />

WA 12/140 (M12 x 239) WA12239 • 140 239 125 25<br />

WA 12/160 (M12 x 259) WA12259 • 160 259 125 20<br />

WA 16/30 (M16 x 151) WA16151 •<br />

WA 16/80 (M16 x 201) WA16201 • M16 16 x 110<br />

80 18 80<br />

201 100 10<br />

30<br />

151 80 20<br />

WA 16/50 (M16 x 171) WA16171 • 50 171 80 20<br />

WA 16/100 (M16 x 221) WA16221 • 100 221 100 10<br />

WA 16/140 (M16 x 261) WA16261 • 140 261 110 10<br />

WA 20/30 (M20 x 173) WA20173 -<br />

WA 20/50 (M20 x 193) WA20193 - 50 193 100 10<br />

M20 20 x 130<br />

22 100<br />

WA 20/80 (M20 x 223) WA20223 - 80 223 125 10<br />

30<br />

173 100 10<br />

WA 20/120 (M20 x 263) WA20263 - 120 263 150 10<br />

Spacing, Edge Distance <strong>and</strong> Member Thickness<br />

M6 M8 M10 M12 M16 M20 (4)<br />

Effective Embedment Depth h ef mm 40 45 50 65 80 100<br />

Characteristic Spacing S cr,N mm 120 135 150 195 240 300<br />

Minimum Spacing S min mm 30 40 50 70 90 120<br />

Characteristic Edge Distance Ccr,N mm 60 67.5 75 97.5 120 150<br />

Minimum Edge Distance C min mm 40 40 50 70 90 120<br />

Minimum Member Thickness h min mm 100 100 120 140 170 180<br />

7

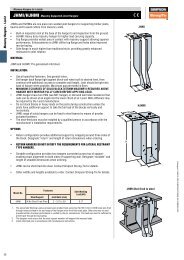

THROUGHBOLT BOAX-II<br />

<strong>For</strong> simple <strong>and</strong> economical applications. BOAX-II is<br />

ETA Option 1 approved.<br />

Function: Application of the installation torque draws the cone end of<br />

the stud into the expansion clip. The expansion clip exp<strong>and</strong>s <strong>and</strong><br />

develops a frictional grip with the sidewalls of the hole. This gives the<br />

anchor its resistance to tension loads.<br />

Benefits:<br />

• Economical anchor for medium-duty loads<br />

• Approved for use in cracked <strong>and</strong> non-cracked concrete<br />

8

Expansion Anchor Systems<br />

BOAX-II ETA - 08/0276<br />

CONSTRUCTION:<br />

BoAX-II<br />

with hex nut <strong>and</strong> washer<br />

MATERIAL:<br />

Carbon steel, zinc plated <strong>and</strong> blue passivated<br />

A4 stainless steel<br />

R 120<br />

BASE MATERIAL:<br />

Cracked <strong>and</strong> non-cracked concrete: C20/25 to C50/60 (B25 to B55)<br />

Also suitable for high density natural stones (σ D<br />

≥ 25 N/mm 2 )<br />

APPROVALS:<br />

ETA-08/0276 - Option 1: M8-M16, carbon steel, zinc plated<br />

ETA-08/0276 - Option 1: M8-M16, A4 stainless steel<br />

LOAD RANGE:<br />

Tension:<br />

Shear:<br />

N perm<br />

= 1.8 - 21.4 [kN]<br />

V perm<br />

= 1.8 - 22.4 [kN]<br />

PRODUCT RANGE:<br />

BoAX-II: M8 - M16, carbon steel, zinc plated <strong>and</strong> blue passivated<br />

BoAX-II A4: M8 - M16, A4 stainless steel<br />

APPLICATIONS:<br />

Steel construction<br />

Railing<br />

Brackets<br />

Facades<br />

Cable trays<br />

Ladders<br />

BENEFITS:<br />

Economical anchor for medium duty loads<br />

Less drilling effort: Anchor diameter = Drill bit diameter<br />

PRODUCT DESCRIPTION:<br />

The throughbolt anchor is installed through the fixture<br />

Torquing draws the cone end of the stud into the expansion clip. The expansion clip exp<strong>and</strong>s <strong>and</strong><br />

develops a frictional grip with the sidewalls of the hole.<br />

C-ANCHORS-2013 © SIMPSON STRONG-TIE ®<br />

INSTALLATION:<br />

Through-fix installation<br />

90°<br />

Drill hole Clean hole (blowing) Insert anchor<br />

through fixture<br />

Apply recommended<br />

fastening torque with a<br />

calibrated torque-wrench<br />

9

Expansion Anchor Systems<br />

BOAX-II<br />

Carbon steel, zinc plated<br />

THROUGHBOLT BOAX-II<br />

With hex nut <strong>and</strong> washer<br />

Material: Carbon steel, zinc plated <strong>and</strong> blue passivated<br />

Approval: ETA-08/0276 (M8 - M16) - Option 1<br />

Type<br />

Order Code<br />

Thread<br />

Size<br />

Ø x<br />

Depth of<br />

Drilled Hole<br />

Max.<br />

Fixture<br />

Thickness<br />

Ø Fixture<br />

Hole<br />

Eff.<br />

Embedment<br />

Depth<br />

Total<br />

Length<br />

d o x h 1 t fix d f h ef L f<br />

Thread<br />

Length Weight Box<br />

Quantity<br />

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [kg/100 pcs] [pcs]<br />

BoAX-II 8/10 BOAXII08045010 M8 8 x 60 10 9 45 72 32 2.91 50<br />

BoAX-II 8/30 BOAXII08045030 M8 8 x 60 30 9 45 92 52 3.53 50<br />

BoAX-II 8/50 BOAXII08045050 M8 8 x 60 50 9 45 112 72 4.14 40<br />

BoAX-II 8/85 BOAXII08045085 M8 8 x 60 85 9 45 147 107 5.21 40<br />

BoAX-II 10/10 BOAXII10060010 M10 10 x 75 10 12 60 92 47 5.92 40<br />

BoAX-II 10/20 BOAXII10060020 M10 10 x 75 20 12 60 102 57 6.41 25<br />

BoAX-II 10/30 BOAXII10060030 M10 10 x 75 30 12 60 112 67 6.91 25<br />

BoAX-II 10/50 BOAXII10060050 M10 10 x 75 50 12 60 132 87 7.89 25<br />

BoAX-II 10/80 BOAXII10060080 M10 10 x 75 80 12 60 162 115 9.37 25<br />

BoAX-II 12/5 BOAXII12070005 M12 12 x 90 5 14 70 103 53 9.53 20<br />

BoAX-II 12/20 BOAXII12070020 M12 12 x 90 20 14 70 118 68 10.60 20<br />

BoAX-II 12/30 BOAXII12070030 M12 12 x 90 30 14 70 128 78 11.31 20<br />

BoAX-II 12/50 BOAXII12070050 M12 12 x 90 50 14 70 148 98 12.73 20<br />

BoAX-II 12/65 BOAXII12070065 M12 12 x 90 65 14 70 163 113 13.80 20<br />

BoAX-II 12/80 BOAXII12070080 M12 12 x 90 80 14 70 178 115 14.87 20<br />

BoAX-II 16/5 BOAXII16085005 M16 16 x 110 5 18 85 123 65 20.16 10<br />

BoAX-II 16/20 BOAXII16085020 M16 16 x 110 20 18 85 138 80 22.17 10<br />

BoAX-II 16/50 BOAXII16085050 M16 16 x 110 50 18 85 168 110 26.19 10<br />

BoAX-II 16/60 BOAXII16085060 M16 16 x 110 60 18 85 178 115 27.53 10<br />

10

Expansion Anchor Systems<br />

BOAX-II TECHNICAL DATA<br />

Carbon steel, zinc plated<br />

Permissible loads for single anchors with no influencing edge distances or spacings. Loads are calculated using partial safety<br />

factors from ETAG 001 <strong>and</strong> the characteristic anchor <strong>and</strong> installation data from this catalogue.<br />

Design calculations shall follow the requirements of ETA-08/0276.<br />

Material: Carbon steel, zinc plated <strong>and</strong> blue passivated<br />

Thread size M8 M10 M12 M16<br />

Effective embedment depth (h ef ) [mm] 45 60 70 85<br />

Type BoA-... BoAX-II 8/… BoAX-II 10/… BoAX-II 12/… BoAX-II 16/…<br />

1) 4)<br />

Permissible tension loads<br />

N perm<br />

Cracked<br />

<strong>Concrete</strong><br />

C20/25 [kN] 2.0 3.6 4.8 9.5<br />

C30/37 [kN] 2.2 4.0 5.3 10.5<br />

C40/50 [kN] 2.4 4.3 5.8 11.4<br />

C50/60 [kN] 2.6 4.6 6.1 12.2<br />

Non-cracked C20/25 [kN] 3.6 6.3 7.9 16.7<br />

concrete 3) C30/37 [kN] 3.9 6.9 8.7 18.4<br />

C40/50 [kN] 4.3 7.6 9.5 20.0<br />

C50/60 [kN] 4.6 8.1 10.1 21.4<br />

1) 2) 4)<br />

Permissible shear loads<br />

V perm<br />

Cracked<br />

<strong>Concrete</strong><br />

C20/25 [kN] 4.8 8.7 11.0 21.0<br />

C30/37 [kN] 4.8 8.7 11.0 21.0<br />

C40/50 [kN] 4.8 8.7 11.0 21.0<br />

C50/60 [kN] 4.8 8.7 11.0 21.0<br />

Non-cracked C20/25 [kN] 4.8 8.7 11.0 21.0<br />

concrete 3) C30/37 [kN] 4.8 8.7 11.0 21.0<br />

C40/50 [kN] 4.8 8.7 11.0 21.0<br />

C50/60 [kN] 4.8 8.7 11.0 21.0<br />

Permissible bending moments 1)<br />

4)<br />

M zul [Nm] 10.0 22.9 34.3 88.6<br />

Spacings, edge distances <strong>and</strong> member thicknesses<br />

Effective embedment depth h ef [mm] 45 60 70 85<br />

Characteristic spacing 4) s cr,N [mm] 135 180 210 255<br />

Minimum spacing s min [mm] 50 55 60 70<br />

Characteristic edge distance 4) c cr,N [mm] 68 90 105 128<br />

Minimum edge distance c min [mm] 50 50 55 85<br />

Minimum member thickness h min [mm] 100 120 140 170<br />

Installation data<br />

Drill hole diameter d 0 [mm] 8 10 12 16<br />

Drill hole depth h 1 [mm] 60 75 90 110<br />

Clearance hole in the fixture d f [mm] 9 12 14 18<br />

Width across flats sw [mm] 13 17 19 24<br />

Installation torque T inst [Nm] 20 35 50 120<br />

Installed anchor<br />

L<br />

f<br />

sw<br />

Tinst<br />

C-ANCHORS-2013 © SIMPSON STRONG-TIE ®<br />

d0<br />

1) The permissible loads have been calculated using the partial safety factors for resistances stated in the ETA-approval <strong>and</strong> a partial safety factor for<br />

actions of γ F = 1.4.<br />

The permissible loads are valid for unreinforced concrete <strong>and</strong> reinforced concrete with a rebar spacing s ≥ 15 cm <strong>and</strong> reinforced concrete with a rebar<br />

2) The permissible shear loads are based on a single anchor without influencing concrete edges. <strong>For</strong> shear loads applied close to an edge (c < 10 h ef or <<br />

60 d) concrete edge failure must be checked per ETAG 001, Annex C, design method A.<br />

3) <strong>Concrete</strong> is considered non-cracked when the tensile stress within the concrete is σ L + σ R ≤ 0. In the absence of detailed verification σ R = 3 N/mm 2 can<br />

be assumed (σ L equals the tensile stress within the concrete as a result of external loads, forces on anchors included).<br />

4) <strong>For</strong> combined tension <strong>and</strong> shear loads or anchor groups <strong>and</strong>/or in case of edge influence, a calculation per ETAG 001, Annex C, design method A<br />

shall be performed. <strong>For</strong> details see ETA - approval(s).<br />

h<br />

min<br />

h<br />

1<br />

h<br />

ef<br />

t fix<br />

df<br />

11

Expansion Anchor Systems<br />

BOAX-II<br />

A4 stainless steel<br />

THROUGHBOLT BOAX-II A4<br />

With hex nut <strong>and</strong> washer<br />

Material: A4 stainless steel<br />

Approval: ETA-08/0276 (M8 - M16) - Option 1<br />

Type<br />

Order Code<br />

Thread<br />

Size<br />

Ø x<br />

Depth of<br />

Drilled Hole<br />

Max.<br />

Fixture<br />

Thickness<br />

Ø Fixture<br />

Hole<br />

Eff.<br />

Embedment<br />

Depth<br />

Total<br />

Length<br />

Thread<br />

Length<br />

d o x h 1 t fix d f h ef L f<br />

Weight<br />

Box<br />

Quantity<br />

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [kg/100 pcs] [pcs]<br />

BoAX-II 8/10 A4 BOAXII08045010A4 M8 8 x 60 10 9 45 72 32 2.9 50<br />

BoAX-II 8/30 A4 BOAXII08045030A4 M8 8 x 60 30 9 45 92 52 3.5 50<br />

BoAX-II 8/50 A4 BOAXII08045050A4 M8 8 x 60 50 9 45 112 72 4.1 40<br />

BoAX-II 10/10 A4 BOAXII10060010A4 M10 10 x 75 10 12 60 92 47 5.9 40<br />

BoAX-II 10/20 A4 BOAXII10060020A4 M10 10 x 75 20 12 60 102 57 6.4 25<br />

BoAX-II 10/30 A4 BOAXII10060030A4 M10 10 x 75 30 12 60 112 67 6.9 25<br />

BoAX-II10/50 A4 BOAXII10060050A4 M10 10 x 75 50 12 60 132 87 7.9 25<br />

BoAX-II 12/5 A4 BOAXII12070005A4 M12 12 x 90 5 14 70 103 53 9.5 20<br />

BoAX-II 12/20 A4 BOAXII12070020A4 M12 12 x 90 20 14 70 118 68 10.6 20<br />

BoAX-II 12/30 A4 BOAXII12070030A4 M12 12 x 90 30 14 70 128 78 11.3 20<br />

BoAX-II 12/50 A4 BOAXII12070050A4 M12 12 x 90 50 14 70 148 98 12.7 20<br />

BoAX-II 12/65 A4 BOAXII12070065A4 M12 12 x 90 65 14 70 163 113 13.8 20<br />

BoAX-II 16/5 A4 BOAXII16085005A4 M16 16 x 110 5 18 85 123 65 20.2 10<br />

BoAX-II 16/20 A4 BOAXII16085020A4 M16 16 x 110 20 18 85 138 80 22.2 10<br />

BoAX-II 16/50 A4 BOAXII16085050A4 M16 16 x 110 50 18 85 168 110 26.2 10<br />

12

Expansion Anchor Systems<br />

BOAX-II TECHNICAL DATA<br />

A4 stainless steel<br />

Permissible loads for single anchors with no influencing edge distances or spacings. Loads are calculated using partial safety<br />

factors from ETAG 001 <strong>and</strong> the characteristic anchor <strong>and</strong> installation data from this catalogue.<br />

Design calculations shall follow the requirements of ETA-08/0276.<br />

Material: A4 stainless steel<br />

Thread size M8 M10 M12 M16<br />

Effective embedment depth (h ef ) [mm] 45 60 70 85<br />

Type BoA-... BoAX-II 8/… BoAX-II 10/… BoAX-II 12/… BoAX-II 16/…<br />

Permissible tension loads 1)<br />

N perm<br />

Cracked<br />

<strong>Concrete</strong><br />

C20/25 [kN] 2.0 3.6 4.8 9.5<br />

C30/37 [kN] 2.2 4.0 5.3 10.5<br />

C40/50 [kN] 2.4 4.3 5.8 11.4<br />

C50/60 [kN] 2.6 4.6 6.1 12.2<br />

Non-cracked C20/25 [kN] 3.6 6.3 7.9 16.7<br />

concrete 3) C30/37 [kN] 3.9 6.9 8.7 18.4<br />

C40/50 [kN] 4.3 7.6 9.5 20.0<br />

C50/60 [kN] 4.6 8.1 10.1 21.4<br />

1) 2)<br />

Permissible shear loads<br />

V perm<br />

Cracked<br />

<strong>Concrete</strong><br />

C20/25 [kN] 5.2 8.1 11.9 22.4<br />

C30/37 [kN] 5.2 8.1 11.9 22.4<br />

C40/50 [kN] 5.2 8.1 11.9 22.4<br />

C50/60 [kN] 5.2 8.1 11.9 22.4<br />

Non-cracked C20/25 [kN] 5.2 8.1 11.9 22.4<br />

concrete 3) C30/37 [kN] 5.2 8.1 11.9 22.4<br />

C40/50 [kN] 5.2 8.1 11.9 22.4<br />

C50/60 [kN] 5.2 8.1 11.9 22.4<br />

Permissible bending moments 1)<br />

4)<br />

M zul [Nm] 10.5 21.4 37.6 95.2<br />

Spacings, edge distances <strong>and</strong> member thicknesses<br />

Effective embedment depth h ef [mm] 45 60 70 85<br />

Characteristic spacing 4) s cr,N [mm] 135 180 210 255<br />

Minimum spacing s min [mm] 50 55 60 70<br />

Characteristic edge distance 4) c cr,N [mm] 68 90 105 128<br />

Minimum edge distance c min [mm] 50 50 55 85<br />

Minimum member thickness h min [mm] 100 120 140 170<br />

Installation data<br />

Drill hole diameter d 0 [mm] 8 10 12 16<br />

Drill hole depth h 1 [mm] 60 75 90 110<br />

Clearance hole in the fixture d f [mm] 9 12 14 18<br />

Width across flats sw [mm] 13 17 19 24<br />

Installation torque T inst [Nm] 20 35 50 120<br />

Installed anchor<br />

L<br />

f<br />

sw<br />

Tinst<br />

C-ANCHORS-2013 © SIMPSON STRONG-TIE ®<br />

d0<br />

1) The permissible loads have been calculated using the partial safety factors for resistances stated in the ETA-approval <strong>and</strong> a partial safety factor for<br />

actions of γ F = 1.4.<br />

The permissible loads are valid for unreinforced concrete <strong>and</strong> reinforced concrete with a rebar spacing s ≥ 15 cm <strong>and</strong> reinforced concrete with a rebar<br />

2) The permissible shear loads are based on a single anchor without influencing concrete edges. <strong>For</strong> shear loads applied close to an edge (c < 10 h ef or <<br />

60 d) concrete edge failure must be checked per ETAG 001, Annex C, design method A.<br />

3) <strong>Concrete</strong> is considered non-cracked when the tensile stress within the concrete is σ L + σ R ≤ 0. In the absence of detailed verification σ R = 3 N/mm 2 can<br />

be assumed (σ L equals the tensile stress within the concrete as a result of external loads, forces on anchors included).<br />

4) If spacings or edge distances become smaller than the characteristic values (i.e. s ≤ s cr,N<br />

<strong>and</strong>/or c ≤ c cr,N<br />

) a calculation per ETAG 001, Annex C, design<br />

method A must be performed.<br />

h<br />

min<br />

h<br />

1<br />

h<br />

ef<br />

t fix<br />

df<br />

13

POLY-GP<br />

CHEMICAL ANCHOR SYSTEM<br />

Styrene free general purpose resin.<br />

POLY-GP is a<br />

styrene-free<br />

polyester resin<br />

specially formulated<br />

for light or medium<br />

duty fixings in<br />

hollow or solid base<br />

materials.<br />

Easy to use <strong>and</strong> fast<br />

curing, it enables<br />

good performance<br />

when used in<br />

applications such as<br />

fixing architectural<br />

steelwork, cable<br />

trays, h<strong>and</strong> rails <strong>and</strong><br />

gates.<br />

• Styrene free.<br />

• Use in solid or<br />

hollow masonry<br />

products.<br />

• Non-flammable.<br />

14

Adhesive Systems<br />

POLY-GP<br />

POLY-GP is a styrene-free polyester resin specially formulated to light or medium duty fixings in hollow or<br />

solid base materials. It's easy to use <strong>and</strong> fast curing. It enables good performance when used in basic jobs<br />

such as fixing a shutter, a satelllite dish, a boiler, shelves or a gate.<br />

POLY-GP is non-flammable product.<br />

Cartridges available are adapted to the needs of anyone who has a universal manual dispensing tool (such as<br />

a silicone dispensing tool) with the 300 ml cartridge.<br />

DAZ 0816/1<br />

Reference<br />

Contents<br />

POLY-GP300-UK<br />

300 ml<br />

Two mixers are supplied with each cartridge.<br />

BENEFITS:<br />

• Fast curing<br />

• Low odour<br />

• Non-flammable product<br />

• Good performance in hollow <strong>and</strong> solid base material<br />

CERTIFICATION: SOCOTEC Hollow blocks DAZ 0816/1<br />

MATERIAL:<br />

Hollow or solid bricks<br />

APPLICATIONS:<br />

• Blinds<br />

• Hinges<br />

• Air-conditioners<br />

• Satellite dishes<br />

• Boilers<br />

POLY-GP<br />

300 ml<br />

Beige<br />

Colour<br />

CURING SCHEDULE:<br />

Let anchor fully cure without disturbing<br />

Temp. of Resin °c Temp. of Support °c Working Time Curing time<br />

+5°c -5°c 25 mins 4 h<br />

+5°c 0°c 15 mins 3 h<br />

+5°c +5°c 12 mins 2 h 30 mins<br />

+10°c +10°c 8 mins 1 h 15 mins<br />

+15°c +15°c 7 mins 55 mins<br />

+20°c +20°c 4 mins 30 mins<br />

+30°c +30°c 2 mins 20 mins<br />

Working Loads<br />

Working loads limit performance details have been determined from minimal values of tests carried out in<br />

Laboratories. Those minimal values take into account a minimal safety of 4 (SOCOTEC-DAZ 0816/1).<br />

Strength limits take into account the position of the anchors in the material <strong>and</strong> the respect of the installation<br />

instructions. <strong>For</strong> hollow materials of unknown resitance, tests on construction sites are necessary<br />

(according to BS 8539).<br />

Tension Hollow block (kN) Hollow concrete (kN)<br />

Threaded Rod (M8 - M10 - M12) 0.6 0.9<br />

Shear Hollow block (kN) Hollow concrete (kN)<br />

Threaded Rod (M8 - M10 - M12) 1.5 1.5<br />

LMAS<br />

Zinc-plated steel<br />

See page 31.<br />

Graduated mixer MN1<br />

Sleeve SH<br />

See Page 30<br />

Installation Data<br />

C-ANCHORS-2013 © SIMPSON STRONG-TIE ®<br />

Material<br />

Threaded Rod<br />

diam xL (mm)<br />

Drill diam<br />

(mm)<br />

Sleeve<br />

diam xL (mm)<br />

Drill depth<br />

(mm)<br />

Tightening<br />

torque (Nm)<br />

Number of<br />

pressure<br />

Hollow block M8x140 16 16x85 90 4 8<br />

Hollow block M10x140 16 16x85 90 6 8<br />

Hollow block M12x140 16 16x85 90 8 8<br />

Hollow concrete M8x160 16 16x130 135 4 13<br />

Hollow concrete M10x160 16 16x130 135 6 13<br />

Hollow concrete M12x160 16 16x130 135 8 13<br />

Safety <strong>and</strong> environment<br />

We care about developing products that are user-safe <strong>and</strong> environmentally respectful<br />

when properly h<strong>and</strong>led <strong>and</strong> disposed of. Once empty, dispose of this cartridge in a<br />

hazardous waste disposal skip.<br />

Xi irritant O Oxidising<br />

Observe these safety precautions (Contains dibenzoyl peroxide):<br />

R52/53 Harmful to aquatic organisms, may cause long-term adverse effects in the aquatic environment (A).<br />

R43 May cause sensitisation by skin contact (B). R7 May cause fire (B). S3/14 Keep in a cool place away<br />

from-combustible or reducing materials-acids-oxidation catalysts (B). S36/37/39 Wear suitable protective<br />

clothing, gloves <strong>and</strong> eye/face protection (B). S7 Keep container tightly closed (B). S60 This material <strong>and</strong> its<br />

container must be disposed of as hazardous waste (B).<br />

15

AT-HP<br />

HIGH PERFORMANCE<br />

Methacrylate resin for threaded rod <strong>and</strong> rebar.<br />

AT-HP is a styrene<br />

free methacrylate<br />

resin suitable for<br />

high performance<br />

fixing applications<br />

of threaded rod <strong>and</strong><br />

rebar into concrete<br />

(ETA approved for<br />

each application).<br />

Easy to dispense<br />

<strong>and</strong> fast curing,<br />

specially designed<br />

for structural fixings<br />

<strong>and</strong> construction<br />

uses.<br />

Applications for<br />

metallic racking or<br />

work in reinforced<br />

concrete.<br />

• ETA approve for<br />

masonry <strong>and</strong><br />

rebar.<br />

• Fast curing.<br />

• Low odour.<br />

• Non-flammable.<br />

• High<br />

performance<br />

in threaded<br />

rod <strong>and</strong> rebar<br />

connections.<br />

16

Adhesive Systems<br />

AT-HP TECHNICAL DATA<br />

ETA - 11/0139, ETA-13/0416, ETA-11/0150, ETA-11/0151<br />

AT-HP is a styrene free methacrylate resin suitable for high performance fixing applications of threaded rod<br />

<strong>and</strong> rebar into concrete (double ETA). Easy to dispense <strong>and</strong> fast curing, specially designed for structural<br />

fixings <strong>and</strong> very technical construction sites. Applications for metallic racking or for work in reinforced<br />

concrete.<br />

Cartridges available are adapted to the needs of a craftsman who uses from time to time chemical anchors<br />

(such as a peeler cartridge 160 ml with a silicone gun) or to the needs of a professional<br />

accustomed to chemical fixing <strong>and</strong> who uses a coaxial cartridge in 380 ml.<br />

ETA-13/0416<br />

ETA-11/0150<br />

ETA-11/0151<br />

ETA-11/0139<br />

Reference<br />

Contents<br />

AT-HP<br />

160 ml<br />

AT-HP<br />

280 ml<br />

AT-HP160-UK<br />

160 ml<br />

AT-HP280-UK<br />

280 ml<br />

AT-HP380-UK<br />

380 ml<br />

Two mixers are supplied with each cartridge.<br />

BENEFITS:<br />

• Fast curing<br />

• low odour<br />

• Non-flammable<br />

MATERIAL:<br />

Non-Cracked <strong>Concrete</strong><br />

Solid Bricks<br />

Hollow Blocks<br />

AAC Blocks<br />

AAC Blocks<br />

APPLICATIONS:<br />

• Threaded rod <strong>and</strong> rebar connections<br />

• Racking<br />

• Balconies<br />

• Facade<br />

CERTIFICATION:<br />

AT-HP<br />

380 ml<br />

Grey<br />

WRAS<br />

MA3404/E<br />

0706528<br />

CURING SCHEDULE:<br />

Let anchor fully cure without disturbing<br />

Temperature of Anchorage Base<br />

T anchorage base<br />

Working Time<br />

t gel<br />

Curing Time<br />

t cure<br />

Graduated mixer MN1<br />

C-ANCHORS-2013 © SIMPSON STRONG-TIE ®<br />

-5°C 45 min 9 h<br />

0°C 15 min 4 h<br />

+5°C 12 min 1 h 30 min<br />

+10°C 9 min 60 min<br />

+20°C 4 min 30 min<br />

+30°C 1 min 20 min<br />

Note: temperature of the resin ≥ 5°C.<br />

METHOD OF CLEANING HOLES IN<br />

SOLID BASE MATERIALS:<br />

Normal diameter<br />

Method of cleaning hole<br />

All diameter<br />

2 blow<br />

+ 2 brush<br />

+ 2 blow<br />

+ 2 brush<br />

+ 2 blow<br />

17

Adhesive Systems<br />

AT-HP TECHNICAL DATA<br />

Material: Carbon steel, Grade 5.8, zinc plated <strong>and</strong> blue passivated; A4-70 stainless steel / AT-HP TM<br />

TECHNICAL DATA FOR THREADED ROD FOR FIXINGS IN CONCRETE<br />

Installation parameters<br />

M8 M10 M12 M16 M20<br />

Drill hole diameter, d 0<br />

mm 10 12 14 18 22<br />

Drill hole depth, h 0<br />

mm 64 96 80 120 96 144 128 192 160 240<br />

Clearance hole in the fixture, d f<br />

mm 9 12 14 18 22<br />

Width across flats, sw mm 13 17 19 24 30<br />

Installation torque, T inst<br />

Nm 10 20 40 80 150<br />

Spacings, edge distances <strong>and</strong> member thicknesses<br />

M8 M10 M12 M16 M20<br />

Effective embedment depth, h ef<br />

mm 64 96 80 120 96 144 128 192 160 240<br />

Characteristic spacing 4) , s cr,N<br />

mm 128 192 160 240 192 288 256 384 320 480<br />

Minimum spacing, s min<br />

mm 35 48 40 60 48 72 64 96 80 120<br />

Characteristic edge distance 4) , c cr,N<br />

mm 64 96 80 120 96 144 128 192 160 240<br />

Minimum edge distance, c min<br />

mm 35 48 40 60 48 72 64 96 80 120<br />

Minimum member thickness, h min<br />

mm 100 130 110 150 130 175 160 225 200 280<br />

Recommended loads Steel<br />

C24/25<br />

C30/37<br />

C40/50<br />

C50/60<br />

C20/25<br />

C30/37<br />

C40/50<br />

C50/60<br />

Tension N rec<br />

kN<br />

1) 3)<br />

M8 8) M10 8) M12 M16 M20<br />

h ef 64 96 80 120 96 144 128 192 160 240<br />

9.1 9.1 14.3 14.4 19.0 19.0 28.6 38.8 35.7 54.8<br />

Shear 5) V rec 4.5 4.5 7.2 7.2 10.4 10.4 19.4 19.4 30.3 30.3<br />

BENDING MOMENT M rec Nm 9.0 9.0 18.6 18.6 32.4 32.4 82.4 82.4 160.5 160.5<br />

Recommended loads A4 1) 3) M8 8) M10 8) M12 M16 M20<br />

C24/25<br />

C30/37<br />

C40/50<br />

C50/60<br />

C20/25<br />

C30/37<br />

C40/50<br />

C50/60<br />

Tension N rec<br />

kN<br />

h ef 64 96 80 120 96 144 128 192 160 240<br />

9.8 9.8 14.3 15.4 19.0 22.2 28.6 41.4 35.7 54.8<br />

Shear 5) V rec 5.9 5.9 9.3 9.3 13.5 13.5 25.2 25.2 39.3 39.3<br />

BENDING MOMENT M rec Nm 11.9 11.9 23.8 23.8 42.1 42.1 106.7 106.7 207.9 207.9<br />

L<br />

sw<br />

inst<br />

T<br />

LMAS<br />

Zinc-plated steel<br />

See page 31<br />

0<br />

d<br />

f<br />

d<br />

0 ef fix<br />

h = h t<br />

min<br />

h<br />

NOTES :<br />

1. Steel failure decisive.<br />

2. The design resistances have been<br />

calculated using the partial safety<br />

factors for resistances stated in ETAapprovals(s).<br />

3. The recommended loads have been<br />

calculated using the partial safety factors<br />

for resistances stated in ETA-approval(s)<br />

<strong>and</strong> with a partial safety factor for actions<br />

of ᵧf=1.4.<br />

4. The load figures are valid for reinforced<br />

concrete with a rebar spacing ≥ 15cm<br />

(any diameter) or with a rebar spacing<br />

≥ 15cm if the rebar diameter is 10mm<br />

or smaller.<br />

5. The figures for shear are based on<br />

a single anchor without influence of<br />

concrete edges. <strong>For</strong> anchorages close<br />

to the edges (c ≤ hef 60d) the concrete<br />

edge failure shall be calculated per ETAG<br />

001, Annex C, design method A.<br />

6. <strong>Concrete</strong> is considered non-cracked<br />

when the tensile stress within the<br />

concrete is σ L +σ R ≤ 0. In the absence<br />

of detailed verification σ R = 3 N/mm 2 can<br />

be assumed (σ L equals the tensile stress<br />

within the concrete induced by external<br />

loads, anchors loads included).<br />

7. <strong>For</strong> combined tension <strong>and</strong> shear loads<br />

or anchor groups <strong>and</strong>/or in the case of<br />

edge influence, a calculation per ETAG<br />

001, Annex C, design method A shall<br />

be performed. <strong>For</strong> details see the ETAapproval(s).<br />

8. Load values for carbon steel hot dip<br />

galvanised for threaded studs with<br />

undersized threads acc EN ISO 10684:<br />

M8: N rk / N rd / N Rec = 16.5 / 11.1 / 7.9 kN V rk / V rd / V rec = 8.4 / 5.6 / 4.0 kN<br />

M10: N rk / N rd / N Rec = 26.7 / 17.9 / 12.8 kN V rk / V rd / V rec = 13.5 / 9.0 / 6.4 kN<br />

18

SET-XP<br />

PURE EPOXY<br />

Seismically approved, pure epoxy adhesive.<br />

Set-XP is a high<br />

strength epoxy<br />

injection adhesive<br />

for fastening heavy<br />

structural fixings in<br />

cracked <strong>and</strong> noncracked<br />

concrete.<br />

It's high bond<br />

strength <strong>and</strong> nonshrinking<br />

formula<br />

are suitable for use<br />

in oversized or wet<br />

holes.<br />

• ICC-ES approved<br />

for cracked<br />

concrete.<br />

• ETA option 1<br />

approved.<br />

• Extended<br />

working time.<br />

• High bond<br />

strength.<br />

• Non-shrinking<br />

formula.<br />

• Seismically<br />

approved.<br />

19

Adhesive Systems<br />

SET-XP TECHNICAL DATA<br />

ETA - 11/0360<br />

SET-XP is a pure epoxy resin suitable for heavy threaded rod fixing applications in both cracked <strong>and</strong> noncracked<br />

concrete (ETA Option 1). It's specially designed for highly technical <strong>and</strong> structural fixings. This<br />

solution is perfect for large diameters <strong>and</strong> applications in hot weather countries. SET-XP is tested in seismic<br />

conditions.<br />

Cartridges available (650 ml) perfectly adapted for big job sides.<br />

Reference Contents Weight Qty. Box Qty. Outer-box Unit Bar Code<br />

SET-XP650-UK 650 ml 1,1 kg 10 10 3523140538402<br />

Two mixers are supplied with each cartridge.<br />

BENEFITS:<br />

• ETA <strong>and</strong> ICC-ES for cracked concrete (option 1)<br />

• Extended working time<br />

• High-bond strength<br />

• Non-shrinking<br />

• Suitable for wet holes<br />

• Easy storage in hot weather countries<br />

MATERIAL:<br />

Cracked or non-cracked concrete<br />

APPLICATIONS:<br />

• Heavy structural fixings into cracked or noncracked<br />

concrete<br />

• Oversized holes<br />

CERTIFICATION:<br />

• ICC-ES for cracked concrete<br />

• ETA 11-0360 (Option 1)<br />

SET-XP<br />

650 ml<br />

Teal<br />

colour<br />

Tested according to<br />

ACI 355.2.<br />

ICC-ES ESR-2508<br />

NSF/ANSI Std. 61<br />

LMAS<br />

Zinc-plated steel<br />

See page 31.<br />

CURING SCHEDULE:<br />

Let anchor fully cure without disturbing<br />

T °C Working time Curing time 6)<br />

10 60 min 72 h<br />

21 45 min 24 h<br />

32 25 min 24 h<br />

43 12 min 24 h<br />

METHOD OF CLEANING HOLES:<br />

Normal diameter<br />

Method of cleaning hole<br />

All diameter<br />

Clean hole by brushing <strong>and</strong><br />

blowing alternately with<br />

oil-free compressed air at<br />

minimum 5.5 bar: 2x blow,<br />

4x brush, 2x blow.<br />

Mixer MN2<br />

20

Adhesive Systems<br />

SET-XP TECHNICAL DATA<br />

Material: Carbon steel, Grade 5.8, zinc plated <strong>and</strong> blue passivated; A4-70 (≤M24) <strong>and</strong> A4-50 (>M24) stainless steel / SET-XP TM<br />

Installation parameters<br />

Spacings, edge distances <strong>and</strong> member thicknesses<br />

M12 M16 M20 M24 M27<br />

Drill hole diameter, d 0<br />

mm 14 18 24 28 30<br />

Drill hole depth, h 0<br />

mm 70 240 80 320 90 400 100 480 110 540<br />

Clearance hole in the fixture, d f<br />

mm 14 18 22 26 30<br />

Width across flats, sw mm 19 24 30 36 41<br />

Installation torque, T inst<br />

Nm 40 60 80 100 120<br />

M12 M16 M20 M24 M27<br />

Effective embedment depth, h ef<br />

mm 70 240 80 320 90 400 100 480 110 540<br />

Characteristic spacing 4) , s cr,N<br />

mm 210 720 240 960 270 1200 300 1440 330 1620<br />

Minimum spacing, s min<br />

mm 45 60 70 80 90<br />

Characteristic edge distance 4) , c cr,N<br />

mm 105 360 120 480 135 600 150 720 165 810<br />

Minimum edge distance, c min<br />

mm 80 100 115 135 155<br />

Minimum member thickness, h min<br />

mm 100 270 116 356 138 448 156 536 170 600<br />

Recommended values for resistance to tension <strong>and</strong> shear loads<br />

M12 M16 M20 M24 M27<br />

h ef 70 240 80 320 90 400 100 480 110 540<br />

Steel A4 Steel A4 Steel A4 Steel A4 Steel A4 Steel A4 Steel A4 Steel A4 Steel A4 Steel A4<br />

Permissible tension loads 1) , for Temperature range: I 5) in Cracked concrete 3) ≥ C20/25, N perm<br />

kN 5.4 5.4 18.4 18.4 6.1 6.1 24.6 24.6 5.7 5.7 25.6 25.6 7.6 7.6 36.9 36.9 9.5 9.5 46.7 46.7<br />

Permissible tension loads 1) , for Temperature range: I 5) in Non-cracked concrete 3) ≥ C20/25, N perm<br />

kN 10.0 10.0 20.0 22.5 12.3 12.3 37.6 42.0 14.6 14.6 58.5 65.6 17.1 17.1 84.2 94.3 19.8 19.8 109.0 57.4<br />

Permissible shear loads 1)2) for Temperature range: I 5) in Cracked concrete 3) ≥ C20/25, V perm<br />

kN 12.0 13.7 12.0 13.7 17.2 17.2 22.2 25.1 16.1 16.1 34.8 39.3 21.6 21.6 50.2 56.7 26.6 26.6 65.7 34.5<br />

NOTES :<br />

1)<br />

The permissible loads have been calculated<br />

using the partial safety factors for<br />

resistances stated in the ETA-approvals<br />

<strong>and</strong> a partial safety factor for actions of<br />

γ F<br />

= 1.4. The permissible loads are valid<br />

for unreinforced concrete <strong>and</strong> reinforced<br />

concrete with a rebar spacing s ≥ 15<br />

cm <strong>and</strong> reinforced concrete with a rebar<br />

spacing s ≥ 10 cm if the rebar is 10 mm<br />

or smaller.<br />

2)<br />

The permissible shear loads are based<br />

on a single anchor without influencing<br />

concrete edges. <strong>For</strong> shear loads applied<br />

close to an edge (c ≤ 10 h ef<br />

<strong>and</strong> 60d)<br />

concrete edge failure must be checked<br />

per ETAG 001, Annex C, design method<br />

A.<br />

3)<br />

<strong>Concrete</strong> is considered non-cracked<br />

when the tensile stress within the<br />

concrete is σ L + σ R ≤ 0. In the absence<br />

of detailed verification σ R = 3 N/mm² can<br />

be assumed (σ L equals the tensile stress<br />

within the concrete as a result of external<br />

loads, forces on anchors included).<br />

4)<br />

<strong>For</strong> combined tension <strong>and</strong> shear loads or<br />

anchor groups <strong>and</strong>/or in case of edge influence,<br />

a calculation per TR 029 shall be performed.<br />

<strong>For</strong> details see ETA - approval(s).<br />

5)<br />

Temperature range I: -40°C to +43°C<br />

(max long term temperature: +24°C; max<br />

short term temperature: 43°C).<br />

6)<br />

<strong>For</strong> installation in wet concrete the<br />

curing times shall be doubled (installation<br />

in water-filled drill holes is not<br />

allowed).<br />

Permissible shear loads 1)2) for Temperature range: I 5) in Non-cracked concrete 3) ≥ C20/25, V perm<br />

kN 12.0 13.7 12.0 13.7 22.2 25.1 22.2 25.1 34.8 39.3 34.8 39.3 48.0 48.0 50.2 56.7 55.4 34.5 65.7 34.5<br />

Permissible bending moments 1) , M perm<br />

Nm 37.7 42.1 37.7 42.1 94.8 106.6 94.8 106.6 185.7 207.9 185.7 207.9 320.5 359.9 320.5 359.9 475.4 249.7 475.4 249.7<br />

C-ANCHORS-2013 © SIMPSON STRONG-TIE ®<br />

21

CHEMICAL ANCHOR PLUS<br />

Polyester anchoring system for secure fixing<br />

into non-cracked concrete.<br />

Function: After drilling <strong>and</strong> cleaning the hole, the capsule is inserted into<br />

the hole <strong>and</strong> the anchor stud is driven with a rotating/hammering action.<br />

This breaks the capsule <strong>and</strong> mixes the contents. The resulting chemical<br />

reaction creates a durable expansion pressure free bond between the<br />

anchor stud, the reacted resin, <strong>and</strong> the concrete.<br />

Benefits:<br />

• Expansion pressure free<br />

• Reduced permissible edge distances <strong>and</strong> spacings<br />

• Completely seals drilled hole<br />

22

Adhesive Systems<br />

CHEMICAL ANCHOR PLUS<br />

CONSTRUCTION:<br />

KLS Threaded stud<br />

KLP Capsule<br />

Setting tool<br />

C-ANCHORS-2013 © SIMPSON STRONG-TIE ®<br />

MATERIAL:<br />

KLS: Carbon steel, zinc plated <strong>and</strong> blue passivated<br />

KLS A4: A4-70 stainless steel<br />

KLP: Glass capsule with polyester resin, hardener <strong>and</strong> mineral aggregates<br />

BASE MATERIAL:<br />

Non-cracked concrete C20/25 to C50/60 (B25 to B55)<br />

LOAD RANGE:<br />

Tension:<br />

Shear:<br />

TEMPERATURE RANGE:<br />

N perm<br />

= 4.0 - 60.0 [kN]<br />

V perm<br />

= 4.0 - 60.0 [kN]<br />

Maximum long-term service temperature = +50°C; Maximum short-term service temperature = +80 °C<br />

RANGE SUPPLIED:<br />

KLS: M8 – M30, carbon steel, zinc plated <strong>and</strong> blue passivated / A4 stainless steel<br />

APPLICATIONS:<br />

Brackets<br />

Base plates<br />

Railings<br />

BENEFITS:<br />

Causes no expansion pressure<br />

Reduced edge distances <strong>and</strong> spacings<br />

High capacity in non-cracked concrete<br />

PRODUCT DESCRIPTION:<br />

Steel construction<br />

Storage racks<br />

Machines<br />

Stud with hex head for easy installation<br />

with setting tool<br />

Completely seals drilled hole<br />

The Chemical Anchor Plus adhesive fixing system consists of a threaded stud <strong>and</strong> chemical-filled<br />

glass capsule.<br />

During installation, the capsule is crushed <strong>and</strong> the rotating <strong>and</strong> hammering action mixes the contents.<br />

After the recommended cure time, the fixture can be installed <strong>and</strong> the fixing can be loaded.<br />

Capsule have shelf life of 2 years when stored correctly. Don’t use if capsule is damaged or if the<br />

contents do not flow in a honey-like fashion of room temperature.<br />

The bond strength between the cured chemical <strong>and</strong> the drilled hole is dependent on the thorough<br />

cleaning of the drilled hole. Follow the installation instructions carefully.<br />

STORAGE OF KLP:<br />

Dry, dark, at a temperature between +5°C <strong>and</strong> +25°C. Avoid direct sunlight.<br />

SHELF LIFE:<br />

18 months after manufacturing date when stored according to the above recommendations.<br />

Information from Koelner Stahl.<br />

INSTALLATION:<br />

Pre-fix installation shown<br />

90°<br />

Photo: Lödige<br />

Drill hole <strong>and</strong> thoroughly<br />

clean (brushing <strong>and</strong> blowing)<br />

Insert KLP capsule into<br />

drilled hole<br />

Spin in KLS stud to the<br />

em bedment depth marking<br />

using a rotary hammer drill<br />

After the specified cure time,<br />

install the fixture <strong>and</strong> apply<br />

the recommended fastening<br />

torque with a calibrated<br />

torque-wrench<br />

23

Adhesive Systems<br />

CHEMICAL ANCHOR PLUS<br />

Carbon steel, zinc plated / A4 stainless steel<br />

KLS, CARBON STEEL, ZINC PLATED<br />

Threaded stud with hex head, hex nut <strong>and</strong> washer<br />

Material: Grade 5.8 steel, zinc plated <strong>and</strong> blue passivated<br />

Type<br />

Order Code<br />

Thread<br />

Size<br />

Ø x<br />

Depth of<br />

Drilled Hole<br />

Max.<br />

Fixture<br />

Thickness<br />

Ø Fixture<br />

Hole<br />

Eff.<br />

Embedment<br />

Depth<br />

Total<br />

Length<br />

Weight<br />

Box<br />

Quantity*<br />

Compatible<br />

Capsule<br />

d o x h 1 t fix d f h ef L<br />

[mm] [mm] [mm] [mm] [mm] [mm] [kg/100 pcs] [pcs] [Type]<br />

KLS 8/110 KLS0810080016 M8 10 x 80 16 9 80 110 4.0 10 KLP 8<br />

KLS 10/130 KLS1012090022 M10 12 x 90 22 12 90 130 9.0 10 KLP 10<br />

KLS 10/165 KLS1012090057 M10 12 x 90 57 12 90 165 10.6 10 KLP 10<br />

KLS 10/190 KLS1012090082 M10 12 x 90 82 12 90 190 11.7 10 KLP 10<br />

KLS 12/160 KLS1214110030 M12 14 x 110 30 14 110 160 14.5 10 KLP 12<br />

KLS 12/220 KLS1214110090 M12 14 x 110 90 14 110 220 18.6 10 KLP 12<br />

KLS 12/250 KLS1214110120 M12 14 x 110 120 14 110 250 20.7 10 KLP 12<br />

KLS 12/300 KLS1214110170 M12 14 x 110 170 14 110 300 24.1 10 KLP 12<br />

KLS 16/165 KLS1618125013 M16 18 x 125 13 18 125 165 26.0 10 KLP 16<br />

KLS 16/190 KLS1618125038 M16 18 x 125 38 18 125 190 29.0 10 KLP 16<br />

KLS 16/250 KLS1618125098 M16 18 x 125 98 18 125 250 36.3 10 KLP 16<br />

KLS 16/300 KLS1618125148 M16 18 x 125 148 18 125 300 42.3 10 KLP 16<br />

KLS 20/220 KLS2025170020 M20 25 x 170 20 22 170 220 50.1 6 KLP 20<br />

KLS 20/260 KLS2025170060 M20 25 x 170 60 22 170 260 58.0 6 KLP 20<br />

KLS 24/300 KLS2428210055 M24 28 x 210 55 26 210 300 98.5 6 KLP 24<br />

KLS 30/380 KLS3035280055 M30 35 x 280 55 33 280 380 196.0 4 KLP 30<br />

*Each box of KLS contains one setting tool.<br />

Custom lengths available on request.<br />

KLS, A4 STAINLESS STEEL<br />

Threaded stud with hex head, hex nut <strong>and</strong> washer<br />

Material: A4-70 stainless steel<br />

Type<br />

Order Code<br />

Thread<br />

Size<br />

Ø x<br />

Depth of<br />

Drilled Hole<br />

Max.<br />

Fixture<br />

Thickness<br />

Ø Fixture<br />

Hole<br />

Eff.<br />

Embedment<br />

Depth<br />

Total<br />

Length<br />

Weight<br />

Box<br />

Quantity*<br />

Compatible<br />

Capsule<br />

d o x h 1 t fix d f h ef L<br />

[mm] [mm] [mm] [mm] [mm] [mm] [kg/100 pcs] [pcs] [Type]<br />

KLS 8/110A4 KLS0810080016A4 M8 10 x 80 16 9 80 110 4.0 10 KLP 8<br />

KLS 10/130A4 KLS1012090022A4 M10 12 x 90 22 12 90 130 9.0 10 KLP 10<br />

KLS 10/165A4 KLS1012090057A4 M10 12 x 90 57 12 90 165 10.6 10 KLP 10<br />

KLS 10/190A4 KLS1012090082A4 M10 12 x 90 82 12 90 190 11.7 10 KLP 10<br />

KLS 12/160A4 KLS1214110030A4 M12 14 x 110 30 14 110 160 14.5 10 KLP 12<br />

KLS 12/220A4 KLS1214110090A4 M12 14 x 110 90 14 110 220 18.6 10 KLP 12<br />

KLS 12/250A4 KLS1214110120A4 M12 14 x 110 120 14 110 250 20.7 10 KLP 12<br />

KLS 12/300A4 KLS1214110170A4 M12 14 x 110 170 14 110 300 24.1 10 KLP 12<br />

KLS 16/165A4 KLS1618125013A4 M16 18 x 125 13 18 125 165 26.0 10 KLP 16<br />

KLS 16/190A4 KLS1618125038A4 M16 18 x 125 38 18 125 190 29.0 10 KLP 16<br />

KLS 16/250A4 KLS1618125098A4 M16 18 x 125 98 18 125 250 36.3 10 KLP 16<br />

KLS 16/300A4 KLS1618125148A4 M16 18 x 125 148 18 125 300 42.3 10 KLP 16<br />

KLS 20/220A4 KLS2025170020A4 M20 25 x 170 20 22 170 220 50.1 6 KLP 20<br />

KLS 20/260A4 KLS2025170060A4 M20 25 x 170 60 22 170 260 58.0 6 KLP 20<br />

KLS 24/300A4 KLS2428210055A4 M24 28 x 210 55 26 210 300 98.5 6 KLP 24<br />

KLS 30/380A4 KLS3035280055A4 M30 35 x 280 55 33 280 380 196.0 4 KLP 30<br />

*Each box of KLS contains one setting tool.<br />

Custom lengths available on request.<br />

KLP CAPSULE<br />

Glass capsule<br />

24<br />

Type<br />

Order Code<br />

Diameter Length Weight Box Quantity<br />

Ø<br />

L<br />

[mm] [mm] [kg/100 pcs] [pcs]<br />

KLP 8 KLP08 9 80 2.0 10<br />

KLP 10 KLP10 11 80 2.0 10<br />

KLP 12 KLP12 13 95 2.5 10<br />

KLP 16 KLP16 17 95 4.0 10<br />

KLP 20 KLP20 22 170 11.0 6<br />

KLP 24 KLP24 24 210 13.0 6<br />

KLP 30 KLP30 33 265 36.5 2

Adhesive Systems<br />

CHEMICAL ANCHOR PLUS TECHNICAL DATA<br />

Carbon steel, zinc plated / A4 stainless steel<br />

Permissible loads for single anchors without influence from edge <strong>and</strong> spacing distances.<br />

Material: Carbon steel, zinc plated <strong>and</strong> blue passivated; A4 stainless steel<br />

Thread size M8 M10 M12 M16 M20 M24 M30<br />

Effective embedment depth [mm] 80 90 110 125 170 210 280<br />

Type KLS... 8/... 10/... 12/... 16/... 20/... 24/... 30/...<br />

Permissible loads at any angle 1) Steel A4 Steel A4 Steel A4 Steel A4 Steel A4 Steel A4 Steel A4<br />

F perm<br />

Non-cracked concrete 2)<br />

C20/25 - C50/60<br />

[kN] 4.0 4.0 7.0 7.0 10.0 10.0 15.0 15.0 27.0 27.0 37.0 37.0 60.0 60.0<br />

Permissible bending moments<br />

M perm [Nm] 10.7 12.1 21.4 24.1 37.4 42.7 94.9 107.0 186.0 209.0 321.0 360.8 642.0 723.2<br />

Spacings, edge distances <strong>and</strong> member thicknesses<br />

Effective embedment depth h ef [mm] 80 80 90 90 110 110 125 125 170 170 210 210 280 280<br />

Characteristic spacing 3) a [mm] 200 200 220 220 270 270 310 310 420 420 520 520 700 700<br />

Minimum spacing a min [mm] 80 80 90 90 110 110 125 125 170 170 210 210 280 280<br />

Characteristic edge distance 3) a r [mm] 100 100 110 110 135 135 155 155 210 210 260 260 350 350<br />

Minimum edge distance a r,min [mm] 40 40 45 45 55 55 65 65 85 85 105 105 140 140<br />

Minimum member width b min [mm] 80 80 90 90 110 110 125 125 170 170 210 210 280 280<br />

Minimum member thickness h min [mm] 130 130 140 140 160 160 175 175 220 220 260 260 330 330<br />

Installation data<br />

Drill hole diameter d 0 [mm] 10 12 14 18 25 28 35<br />

Drill hole depth h 1 [mm] 80 90 110 125 170 210 280<br />

Clearance hole in the fixture d f [mm] 9 12 14 18 22 26 33<br />

Width across flats hex nut sw [mm] 13 17 19 24 30 36 46<br />

Installation torque T inst [Nm] 10 20 40 80 150 200 400<br />

Installed anchor<br />

L<br />

sw<br />

Tinst<br />

Curing schedule<br />

d0<br />

h 0 = hef<br />

t fix<br />

hmin<br />

df<br />

Drill hole temperature Curing time<br />

[°C]<br />

[min]<br />

> 20 10<br />

10 - 20 20<br />

0 - 10 60<br />

1) Permitted loads per anchor in non-cracked concrete of strength C20/25 to C50/60 (B25 to B55) for axial tension, shear, <strong>and</strong> oblique loads.<br />

2) <strong>Concrete</strong> is considered non-cracked when the tensile stress within the concrete σ L<br />

+ σ R<br />

≤ 0. In the absence of a detailed analysis σ R = 3 N/mm2 can be assumed (σ L<br />

equals the tensile stress within the<br />

concrete resulting from external loads, including forces on the anchor).<br />

3) If spacings or edge distances are smaller than the characteristic values, the permissible loads shall be reduced based on the Kappa method.<br />

Complete your designs more easily by downloading our anchor software from our home-page: www.simpson-liebig.com<br />

C-ANCHORS-2013 © SIMPSON STRONG-TIE ®<br />

Quick-Set Drive Unit<br />

Use this setting tool with a st<strong>and</strong>ard drill to provide problem-free setting of M8-M20 threaded studs with the Chemical Anchor Plus<br />

(KLP) system (see page 50). The Quick-Drive setting tool also has a hexagonal recess that allow it to set threaded studs with hex<br />

heads.<br />

Type BE<br />

Type Order Code Size<br />

Weight<br />

[kg/100 pcs]<br />

Quick-Set Drive Unit M8 BE08 M8 11<br />

Quick-Set Drive Unit M10 BE10 M10 14<br />

Quick-Set Drive Unit M12 BE12 M12 14<br />

Quick-Set Drive Unit M16 BE16 M16 20<br />

Quick-Set Drive Unit M20 BE20 M20 34<br />

25

ACCESSORIES<br />

Dispensing Tools<br />

Equipped with a comfortable h<strong>and</strong>le they release a perfectly adapted pressure during dispensing. We striclty<br />

control the quality of the steel rods. Their hexagonal form makes them keep their shape. The reinforced<br />

cradle has been designed for an optimal positioning of the cartridge. Its anti-corrosive steel coating makes<br />

it a solid tool. <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong> ® has developed a line of professional manual applicator guns that are<br />

powerful, strong <strong>and</strong> pefectly matched to our products.<br />

Name Code Qty. Box Qty. Outer-box Cartridges<br />

Extrusion tool DT300 DT300 1 12 160/280/300 ml<br />

Extrusion tool DT380 DT380 1 6 380 ml<br />

Extrusion tool DT650 DT650 1 6 400/650 ml<br />

DT300<br />

DT380<br />

High quality steel rod<br />

Reinforced cradle<br />

DT650<br />

Adequate number of<br />

pressure<br />

Comfortable h<strong>and</strong>le<br />

Sleeves<br />

Sleeves are required for fixings in hollow bricks. Various sizes are available depending on the product to be<br />

fixed.<br />

Name Code Qty. Box Qty. Large Box Dimensions<br />

Sleeve SH 12x50 SH12050-RP10 10 160 12x50 mm<br />

Sleeve SH 16x85 SH16085-RP6 6 96 16x85 mm<br />

Sleeve SH 16x130 SH16130-RP6 6 96 16x130 mm<br />

Sleeve SH 20x85 SH20085-RP4 4 64 20x85 mm<br />

Sleeve SH<br />

Mixing Nozzles<br />

Always use the proper <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong>® mixing nozzle. Always inject the resin starting from the bottom<br />

of the hole <strong>and</strong> withdrawing gradually as the hole is filled. Ensure that the mixing nozzle reaches the bottom<br />

of the hole before starting injection. Use extension tubing if needed.<br />

Name Code Qty. Box Qty. Large Box Products<br />

Mixing nozzle MN1 MN1-RP10 10 60 POLY-GP/AT-HP<br />

Mixing nozzle MN2 MN2 20 20 SET-XP<br />

Extension Tubes<br />

In case of deep embedments it may be necessary to extend the mixer by attaching an extension tubes which<br />

enables to reach the bottom of the hole.<br />

Name Code Qty. Box Qty. Large Box Notes<br />

Extension MNE MNE-RP10 10 130 <strong>For</strong> MN1<br />

MN1<br />

MN2<br />

MNE<br />

26

ACCESSORIES<br />

Dust Pump<br />

Dust pumps are «a must» for proper hole cleaning.<br />

Name Code Qty. Box Qty. Large Box Notes<br />

Dust pump PUMP 1 4 Solid blocks<br />

Brushes<br />

Wire brushes with nylon bristles are available in two diameters <strong>and</strong> lengths. Always brush holes to loosen<br />

dust as per the installation instructions.<br />

Name Code Qty. Box Qty. Large Box Notes<br />

Brushes BR BR17-30 1 15<br />

One pack =<br />

1 BR17 + 1 BR30<br />

(Solid/Hollow blocks)<br />

PUMP<br />

BR17<br />

BR30<br />

Rods<br />

LMAS - Zinc-plated steel Grade 5.8<br />

Reference<br />

Threaded<br />

Rod<br />

Total<br />

length<br />

(mm)<br />

L<br />

Max<br />

thickness<br />

of the item<br />

to be fixed<br />

(mm)<br />

t fix<br />

Max Ø of the<br />

hole for the<br />

item to fix<br />

(mm)<br />

d f<br />

Embedment<br />

depth (mm)<br />

h ef<br />

Ø x min drill<br />

depth (mm)<br />

d 0<br />

x h 1<br />

LMAS0810064020 M8 95 20 9 64 10 x 64 30<br />

LMAS1012080025 M10 120 25 12 80 12 x 80 30<br />

LMAS1012080060 M10 155 60 12 80 12 x 80 30<br />

LMAS1214096035 M12 150 35 14 96 14 x 96 30<br />

LMAS1214096070 M12 185 70 14 96 14 x 96 30<br />

LMAS1618128020 M16 170 20 18 128 18 x 128 10<br />

LMAS1618128050 M16 200 50 18 128 18 x 128 10<br />

LMAS2022160050 M20 240 50 22 160 22 x 160 5<br />

LMAS A4 - Stainless Steel A4-70<br />

Box<br />

Qty<br />

LMAS<br />

Reference<br />

Threaded<br />

Rod<br />

Total<br />

length<br />

(mm)<br />

L<br />

Max<br />

thickness<br />

of the item<br />

to be fixed<br />

(mm)<br />

t fix<br />

Max Ø of the<br />

hole for the<br />

item to fix<br />

(mm)<br />

d f<br />

Embedment<br />

depth (mm)<br />

h ef<br />

Ø x min drill<br />

depth (mm)<br />

d 0<br />

x h 1<br />

LMAS0810064020A4 M8 95 20 9 64 10 x 64 20<br />

LMAS1012080025A4 M10 120 25 12 80 12 x 80 20<br />

LMAS1012080060A4 M10 155 60 12 80 12 x 80 20<br />

LMAS1214096035A4 M12 150 35 14 96 14 x 96 20<br />

LMAS1214096070A4 M12 185 70 14 96 14 x 96 20<br />

LMAS1618128020A4 M16 170 20 18 128 18 x 128 10<br />

LMAS1618128050A4 M16 200 50 18 128 18 x 128 10<br />

LMAS2022160050A4 M20 240 50 22 160 22 x 160 5<br />

Metal Sieve SHM<br />

Steel sieve (cut to length required)<br />

Box<br />

Qty<br />

C-ANCHORS-2013 © SIMPSON STRONG-TIE ®<br />

Compatible<br />

LMAS<br />

Ø Sieve<br />

Sieve<br />

Length<br />

Ø x<br />

Depth of<br />

Drilled Hole<br />

Weight<br />

Box<br />

Quantity<br />

Type<br />

Order Code<br />

d 0<br />

[mm] [mm] [mm] [mm] [kg/100 pcs] [pc]<br />

SHM 16/1000* SHM161000 LMAS M10 + M12 16 1000 16 7.6 1<br />

*Not included in approval.<br />

Internally Threaded Sleeve IGH<br />

Steel internally threaded sleeve<br />

Ø x<br />

Compatible<br />

Sieve<br />

Ø Sieve<br />

Depth of Drilled Hole<br />

Box<br />

Weight<br />

Type<br />

Order Code LMAS<br />

Length<br />

Quantity<br />

d 0 x h 1<br />

[mm] [mm] [mm] [mm] [kg/100 pcs] [pcs]<br />

IGH M8x80* IGH08080 LMAS M8 12 80 14 x 90 3.5 12<br />

IGH M10x80* IGH10080 LMAS M10 14 80 16 x 90 4.8 12<br />

IGH M12x80* IGH12080 LMAS M12 16 80 18 x 90 5.6 12<br />

*Not included in approval.<br />

27

SIMPSON STRONG-TIE ®<br />

Winchester Road<br />

Cardinal Point<br />

Tamworth<br />

Staffordshire<br />

B78 3HG<br />

United Kingdom<br />

Tel: +44 1827 255 600<br />

Fax: +44 1827 255 616<br />

www.strongtie.co.uk<br />

Telephone: 01827 255600 | Visit: www.strongtie.co.uk