CEAST SpA

CEAST SpA

CEAST SpA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

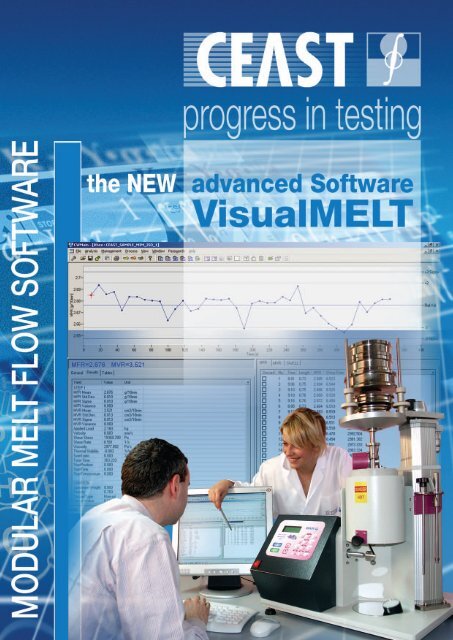

VisualMELT<br />

code 0710.650<br />

Modular Melt Flow software<br />

Modular Melt Flow 7027.000<br />

Fig. 1<br />

Instrument Configuration<br />

Working in the CeastVIEW platform, the VisualMELT<br />

software is designed to control all the functions of the<br />

Modular Melt Flow Family Fig. 1 , including the new<br />

multiweight tester (model 7027.000). From a library of<br />

international standards it is possible to select any test<br />

parameter Fig. 2 ; it is also possible to customise the<br />

test parameter in accordance with the customer needs.<br />

In fact, due to the new firmware the operator can choose:<br />

• the test starting point and the test ending point, defined<br />

by piston position or elapsed time<br />

• the step type, defined by length or elapsed time.<br />

Different criteria are available in the parameters definition<br />

for data selection and discarding in automatic or manual<br />

mode.<br />

Graphs and tables can be easily stored and recalled<br />

Fig. 3, 4, 5 . Test results include: Mass- and Volume- MFR,<br />

values and graph of single steps and whole test, test time,<br />

statistical data, velocity and variance, thermal stability,<br />

shear sensitivity, shear rate, shear stress and viscosity.<br />

When working with a multi-weight tester, it is possible to<br />

set up and control single-weight and multi-weigh tests, to<br />

select the order and number of weights to be applied, to<br />

manage all the optional equipment including the load cell<br />

for compaction and the automatic cutting device.<br />

The raw data received from the instrument are stored<br />

and further elaborations are allowed.<br />

Up to 40 data points can be acquired during one test<br />

(this corresponds to 0.75 mm steps over a 30 mm<br />

measuring length).<br />

Fig. 2<br />

Fig. 3<br />

Parameters Management<br />

Graphic Preview of 30 Data Points<br />

(up to 40 can be acquired and visualized)<br />

Compatible with Windows ® operating systems 95, 98, NT, 2000, ME and XP

Fig. 4 Display of Results Fig. 7 SQC Management: Raw Data<br />

Reference Test Management<br />

Complete management of planning of the Reference tests:<br />

different Reference Tests can be scheduled at the same time:<br />

• Each one refers to its own set of parameters and to an<br />

assessment table<br />

• Each one has its own planned mode: each day at a<br />

predefined time or every N number of Tests or hours or days<br />

• Programmable warning message system for immediate<br />

notification of test results fluctuations<br />

Fig. 5<br />

Full Screen Graph<br />

Additional <strong>CEAST</strong> software modules:<br />

OPERATOR Module - code 0710.651<br />

• Possibility to gain access to different functions of the software<br />

depending on the operator name, the access level and the password<br />

• Level of access hierarchically structured<br />

SQC Module - code 0710.657<br />

• Creating and managing the “SQC” (Statistical Quality Control) and<br />

the reference parameters Fig. 6<br />

• Selection of tests characterized by the same values of a selected<br />

set of parameters<br />

• Visualization of progress of test lots in graphic form (raw data or<br />

results) Fig. 7<br />

• Printing in numeric form of progress of test lots<br />

• Level of access hierarchically structured.<br />

Fig. 6<br />

Reference Test Management

VisualMELT<br />

code 0710.650<br />

Modular Melt Flow software<br />

Fig. 8<br />

Multi Instrument Management<br />

TRANSFER Module - code 0710.652<br />

• Possibility to manage and transfer data in Excel and Text<br />

files with format templates management.<br />

MULTI.n Module - code 0710.653.n<br />

• Concurrent management of n instruments at the same<br />

time for all enabled functions, including the complete<br />

handling of the process: parameters selection, test<br />

execution, realtime synoptic and data acquisition Fig. 8<br />

DIE SWELL Module – 0710.655<br />

• Supplied with the Die Swell option, records die swell<br />

data (measured by a laser detector on the sample being<br />

extruded) and calculates the swell ratio.<br />

WEIGHT Module - code 0710.658<br />

• Possibility to connect an electronic balance to evaluate<br />

the melt density.<br />

"Due to the continuous development policy of <strong>CEAST</strong>'s Research and Development Department, changes may be introduced without notice"<br />

<strong>CEAST</strong> S.p.A.<br />

www.ceast.com<br />

<strong>CEAST</strong> USA INC.<br />

www.ceast.com<br />

<strong>CEAST</strong> GmbH<br />

www.ceast.com<br />

These instruments are made<br />

in compliance with CE health<br />

and safety requirements<br />

Via Airauda, 12 • 10044 Pianezza (TO) Italy • Tel: (+39) 011.966.40.38 (10 lines) • Fax: (+39) 011.966.29.02<br />

e-mail: Int. Sales: InfoItaly@ceast.com • Int. after sales: aftersalestech@ceast.com<br />

4816 Sirus Lane • Charlotte - NC 28208 • Tel: 704-423-0042 • Fax: 704-423-0081<br />

e-mail: USA Sales: salesusa@ceast.com • USA Service: Keith@ceast.com<br />

Meylantstr. 89 B • D-44319 Dortmund • Germany • Tel: 0231 1389890 • Fax: 0231 1389891<br />

e-mail: info.germany@ceast.com<br />

AP0650-02 1004 - Pubblicità erremme2 - TORINO - Printed in Italy