Catalog sheets of TGA and TGP servoamplifiers - TG Drives

Catalog sheets of TGA and TGP servoamplifiers - TG Drives

Catalog sheets of TGA and TGP servoamplifiers - TG Drives

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Servoamplifiers<br />

Digital <strong>servoamplifiers</strong> <strong><strong>TG</strong>A</strong>, <strong><strong>TG</strong>P</strong>

Digital <strong>servoamplifiers</strong> <strong><strong>TG</strong>A</strong>_300<br />

Digital <strong>servoamplifiers</strong> <strong><strong>TG</strong>A</strong>_300 are designed for driving rotary <strong>and</strong> linear<br />

synchronous servomotors. Servoamplifiers <strong><strong>TG</strong>A</strong>_300 are equipped with<br />

multiple inputs for communication with many types <strong>of</strong> positioning sensors.<br />

This gives us the possibility to find an optimum priced solution <strong>of</strong> used<br />

feedback sensors.<br />

Digital <strong>servoamplifiers</strong> <strong><strong>TG</strong>A</strong>_300 are designed to be easily connected to<br />

different control systems, because <strong>of</strong> this the <strong>servoamplifiers</strong> can be used in<br />

many applications. In relation to the application <strong>and</strong> control system used, it<br />

is possible to utilize the integrated motion functions or to use only the basic<br />

functions <strong>of</strong> control loops. A huge selection <strong>of</strong> expansion cards enable the<br />

<strong><strong>TG</strong>A</strong>_300 to connect to digital <strong>servoamplifiers</strong> with most available integrated<br />

interfaces (CANopen, PROFIBUS DP, SERCOS, EtherCat).<br />

Digital <strong>servoamplifiers</strong> <strong><strong>TG</strong>A</strong>_300 :<br />

analogue voltage +/-10V for<br />

speed or torque control<br />

Digital control inputs (4) <strong>and</strong> outputs<br />

(2) - activation <strong>of</strong> programmed<br />

position pr<strong>of</strong>iles.<br />

control signals for step motors<br />

„STEP“ <strong>and</strong> „DIRECTION“<br />

control in the form <strong>of</strong> an electronic<br />

gear-box<br />

control using the RS232 communication<br />

interface, CANopen<br />

control using expansion cards<br />

<strong><strong>TG</strong>A</strong>_300 can be connected to the<br />

following position sensors:<br />

Resolver-EnDAT<br />

(single-turn or multi-turn)<br />

Hiperface<br />

(single-turn or multi-turn)<br />

A sensor with sincos signals<br />

An Incremental sensor<br />

with commutative signals.<br />

The possibility to simultaneously<br />

connect two sensors<br />

(e.g. resolver <strong>and</strong> sincos)<br />

Other properties<br />

<strong>of</strong> servoamplifier:<br />

Digital current (32,25µs ..62,5µs),<br />

speed (62,5µs) <strong>and</strong> position loops<br />

(125µs) ensure high motion<br />

dynamics <strong>and</strong> recursion <strong>of</strong> set<br />

operation movements.<br />

The <strong><strong>TG</strong>A</strong>_300 <strong>servoamplifiers</strong> are<br />

equipped with an anti-interference<br />

network filter (class A).<br />

A built in internal brake resistor (with<br />

the ability to connect to external one).<br />

Control <strong>of</strong> the motor holding brake.<br />

Input (AS-enable) for the blocking <strong>of</strong><br />

repeated running.<br />

The versatility <strong>of</strong> use is increased by<br />

the wide spectrum <strong>of</strong> supply voltages<br />

1x115 – 3x230V for the 230V version<br />

<strong>and</strong> 3x208 – 3x480 V <strong>and</strong> CE, UL<br />

<strong>and</strong> cUL certification.<br />

The control s<strong>of</strong>tware that works under<br />

Windows allows: parameter controlling<br />

<strong>of</strong> the servoamplifier, tracking<br />

current values, oscilloscope function<br />

<strong>and</strong> service drive activation.<br />

2

Operating data<br />

Table <strong>of</strong> parameters for <strong><strong>TG</strong>A</strong>_300<br />

Rated data DIM 303 306* 310* 341 343* 346* 312* 324*<br />

1x110V-10% ... 1x230V+10%<br />

Rated supply voltage<br />

3x187–528 V / 50-60 Hz<br />

V~ 3x110V-10% ... 3x230V+10%<br />

(grounded supply, phase to phase)<br />

50 / 60 Hz 50 / 60 Hz<br />

Rated installed power for S1 operation kVA 1.1 2 3.5 1.1 2 3.5 8.5 16.8<br />

Rated DC bus link voltage V= 135–450 300–675<br />

Rated output current (rms value, ± 3%)<br />

Peak output current (max. approx. 5s, +/-3%)<br />

– at 1 x 110V rated voltage Aef 3 / 5 3 / 5 3 / 5 – – – – –<br />

– at 1 x 230 / 240V rated voltage Aef 3 / 9 4 / 9 4 / 9 – – – – –<br />

– at 3 x 115V mains voltage Aef 3,5 / 9 8 / 15 10 / 20 – – – – –<br />

– at 3 x 230V mains voltage Aef 3 / 9 6 / 15 10 / 20 2 / 4,5 5 / 7,5 6 / 12 12 / 24 24 / 48<br />

– at 3 x 400V mains voltage Aef – – – 1,5 / 4,5 4 / 7,5 6 / 12 12 / 24 24 / 48<br />

– at 3 x 480V mains voltage Aef – – – 1,5 / 4,5 3 / 7,5 6 / 12 12 / 24 24 / 48<br />

Continuous power regen circuit (RBint) W 20 50 50 50 50 50 200 200<br />

Continuous power regen circuit (RBext) max. kW 0,3 1 1 0,3 1 1 2 2<br />

Peak power regen circuit (RBext) max. kW 0,75–3 0,75–3 0,75–3 2,1–9 2,1–9 2,1–9 5–21 5–21<br />

* with fan<br />

Dimensions <strong><strong>TG</strong>A</strong>_300<br />

Model 303 306/310 341 343/346 312 324<br />

Height (with fan) (mm) 246 279 246 279 280 280<br />

Width (mm) 70 70 70 70 70 100<br />

Depth (mm) 171 171 171 171 245 245<br />

Depth with connectors (mm) < 200 < 200 < 235 < 235 < 275 < 275<br />

Additional Interfaces<br />

PROFIBUS-DP – expansion card<br />

The servoamplifier can be operated<br />

through a PROFIBUS DP interface.<br />

This expansion card makes it possible<br />

to transmit setpoint <strong>and</strong> to read actual<br />

values <strong>of</strong> the <strong><strong>TG</strong>A</strong>_300 servoamplifier.<br />

Transmission baud rates are from 187.5 k<br />

Baud to 12 M baud.<br />

SERCOS- expansion card<br />

This expansion card makes it possible to<br />

connect <strong>servoamplifiers</strong> <strong><strong>TG</strong>A</strong>_300 with<br />

the data bus through optical fibers. The<br />

pre-selectable baud rate is 2 or 4 Mbaud.<br />

This expansion card makes it possible<br />

to transmit setpoint <strong>and</strong> to read actual<br />

values with different cycle times (1 to 65<br />

ms) with an additional interpolation <strong>of</strong><br />

the setpoints within the drive.<br />

This enables a synchronization that is<br />

exact to the µs, for fast, precise multi-axis<br />

controling.<br />

EtherCat – Ethernet expansion card<br />

This expansion card connects your<br />

servoamplifier <strong><strong>TG</strong>A</strong>_300 through LAN<br />

to the protocol EtherCat.<br />

DeviceNet- expansion card<br />

A DeviceNet Interface expansion card<br />

can be used as an option to connect<br />

<strong>servoamplifiers</strong> <strong><strong>TG</strong>A</strong>_300 to the data bus.<br />

I/O expansion card<br />

The I/O-expansion card is an extremely<br />

economical way <strong>of</strong> operating servo<br />

controllers under position control for<br />

simple automation tasks.<br />

14 additional digital inputs permit<br />

the selection <strong>and</strong> start <strong>of</strong> the motion<br />

tasks that are stored in the motion-task<br />

memory <strong>of</strong> the Digital <strong>servoamplifiers</strong><br />

<strong><strong>TG</strong>A</strong>_300.<br />

8 digital outputs report the status <strong>of</strong> the<br />

drive to the higher-level control.<br />

Single Axis Controller – The motion<br />

controller option card is the solution for<br />

complex motion controlling.<br />

Enables the <strong><strong>TG</strong>A</strong>_300 digital servoamplifier<br />

to be connected with a PROFIBUS-DP.<br />

This expansion card makes it possible<br />

to transmit setpoint <strong>and</strong> to read actual<br />

values on servoamplifier <strong><strong>TG</strong>A</strong>_300.<br />

Transmission baud rate is up to 2Mbauds.<br />

3

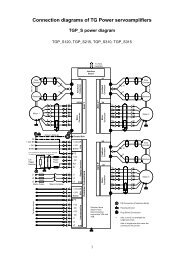

Digital <strong>servoamplifiers</strong><br />

The <strong><strong>TG</strong>P</strong>ower is a servo_drive designed as an intelligent<br />

power module with integrated positioning (62,5µs), velocity<br />

(62,5µs) <strong>and</strong> current (62,5µs) control loop.<br />

The servodrive is optimally designed to be easily connected<br />

to control systems with digital communication. Optimal<br />

price solutions can be met by choosing one, two or three<br />

axes module.<br />

Properties <strong>of</strong> <strong><strong>TG</strong>P</strong>ower<br />

Direct connection to an ordinary<br />

power supply (3x230V to 3x480V)<br />

Direct connection to a special power<br />

supply (3x48-85 V, 3x115-230V)<br />

Built in anti-interference filter<br />

Control <strong>of</strong> the motor holding brake<br />

A built in internal brake resistor (with<br />

the ability to connect an external one)<br />

Interpolation (linear or spline)<br />

in a positioning controller<br />

Communicates via CAN bus-protocol<br />

CANopen<br />

Communicates via network bus with<br />

EtherCAT protocol<br />

Digital inputs for capturing fast actions<br />

occurring at the same time point<br />

Reduced losses due to new space<br />

vector modulation (SVM)<br />

CE, UL, <strong>and</strong> cUL certificate<br />

Input for blocking <strong>of</strong> repeated running<br />

to insure personnel safety, category 4<br />

according to EN 954-1<br />

<strong>and</strong> EN 61508<br />

Feedback<br />

Resolver<br />

EnDAT (single-turn or multi-turn)<br />

Hiperface (single-turn or multi-turn)<br />

A sensor with sincos signals<br />

An incremental sensor with<br />

commutative signals (comcoder)<br />

The possibility to simultaneously<br />

connect two sensors (e.g. resolver<br />

<strong>and</strong> sincos)<br />

Control<br />

Current control – applied current<br />

controller only<br />

Speed control – applied current<br />

<strong>and</strong> speed controller<br />

Position control – applied current,<br />

speed <strong>and</strong> position controller<br />

<strong><strong>TG</strong>P</strong> control (same for all models)<br />

Digital inputs:<br />

Enable (blocking <strong>of</strong>f control circuits)<br />

Lock (blocking <strong>of</strong>f the power supply for IGBT modules rousers)<br />

EN-Brake releasing <strong>of</strong> elmag. brake (release elmag. brake)<br />

5 programmable digital inputs (e.g. position lock)<br />

Digital outputs:<br />

Relay READY<br />

Relay for locking <strong>of</strong> the power supply<br />

2 programmable outputs<br />

Communication:<br />

RS232 Service channel for adjusting all parameters<br />

(applicable in all models)<br />

USB Service channel for adjusting all parameters<br />

(applicable in all models)<br />

CAN Real time motion control through the CANbus<br />

EtherCat Real time motion control through the network bus EtherCat<br />

SSI Real time motion control through serial channel SSI<br />

Modules <strong><strong>TG</strong>P</strong> can be<br />

ordered with these<br />

communication cards:<br />

CAN Communication<br />

through CAN bus<br />

ETH Communication<br />

through EtherCat<br />

UNI Communication<br />

through CAN bus<br />

or EtherCat<br />

SSI Communication<br />

through a fast serial<br />

interface with SSI<br />

protocol<br />

4

Technical data for models 3x48-230V<br />

Description <strong><strong>TG</strong>P</strong>_A310 <strong><strong>TG</strong>P</strong>_E305<br />

DIM 10A/10A/10A 5A/5A/5A<br />

Number <strong>of</strong> axis 3 3<br />

Rated supply voltage V AC<br />

3(1)×44–100 V/45–65 Hz 3(1)×104–276 V/45–65 Hz<br />

Rated installed load for S1 operation kVA 3 6<br />

Rated DC link voltage VDC 60–130 150–360<br />

Rated output <strong>of</strong> current axis 1 (+/- 3%) A rms<br />

10 5<br />

Rated output <strong>of</strong> current axis 2 (+/- 3%) A rms<br />

10 5<br />

Rated output <strong>of</strong> current axis 3 (+/- 3%) A rms<br />

10 5<br />

Peak output <strong>of</strong> current axis 1 (+/- 3%) A rms<br />

20 10<br />

Peak output <strong>of</strong> current axis 2 (+/- 3%) A rms<br />

20 10<br />

Peak output <strong>of</strong> current axis 3 (+/- 3%) A rms<br />

20 10<br />

Max. continuous sum current (cooling) A rms<br />

20 15<br />

Rated load <strong>of</strong> internal regen circuit W 66 66<br />

Peak power regen circuit (ext) W 200 400<br />

Peak power regen circuit W 800 1500<br />

Width mm 114<br />

Height mm 241<br />

Depth (with connectors) mm 255 (300)<br />

Technical data for models 3x230-480V<br />

Description <strong><strong>TG</strong>P</strong>_S120 <strong><strong>TG</strong>P</strong>_S315 <strong><strong>TG</strong>P</strong>_S310 <strong><strong>TG</strong>P</strong>_S315<br />

DIM 20A 10A/15A 10A/10A/10A 10A/10A/15A<br />

Number <strong>of</strong> axis 1 2 3 3<br />

Rated supply voltage V AC<br />

3×207–528 V/45–65 Hz<br />

Rated installed load for S1 operation kVA 14 14 14 14<br />

Rated DC link voltage VDC 290–690<br />

Rated output <strong>of</strong> current axis 1 (+/- 3%) A rms<br />

20 10 10 10<br />

Rated output <strong>of</strong> current axis 2 (+/- 3%) A rms<br />

– 15 10 10<br />

Rated output <strong>of</strong> current axis 3 (+/- 3%) A rms<br />

– – 10 15<br />

Peak output <strong>of</strong> current axis 1 (+/- 3%) A rms<br />

40 20 20 20<br />

Peak output <strong>of</strong> current axis 2 (+/- 3%) A rms<br />

– 30 20 20<br />

Peak output <strong>of</strong> current axis 3 (+/- 3%) A rms<br />

– – 20 30<br />

Max. continuous sum current (cooling) A rms<br />

20 20 20 20<br />

Rated load <strong>of</strong> internal regen circuit W 200 200 200 200<br />

Peak power regen circuit (ext) W 1500 1500 1500 1500<br />

Peak power regen circuit kW 6,5–27<br />

Width mm 158<br />

Height (with connectors) mm 378 (472)<br />

Depth mm 235<br />

5

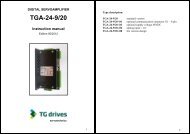

DIGITAL SERVOAMPLIFIERS <strong><strong>TG</strong>A</strong>-24-9/20<br />

<strong><strong>TG</strong>A</strong>-24-9/20 controllers are designed to operate AC synchronous servomotors<br />

<strong>of</strong> up to 150W. A power supply <strong>of</strong> 24VDC allows the <strong>servoamplifiers</strong> to be<br />

used in applications, where it is not possible to supply a voltage <strong>of</strong> 230 / 400V<br />

AC e.g. in mobile equipment or in environments that require safe voltages to<br />

be used.<br />

A high-performance processor ensures not only high quality, accuracy, control<br />

<strong>and</strong> dynamics <strong>of</strong> the servomotor but also ensures a selection <strong>of</strong> user functions<br />

that allow the universal utilization <strong>of</strong> the servomotor.<br />

A digital current loop (current measuring, vector control, position measuring<br />

from a resolver) is calculated every 62,5µs, speed loop is calculated every<br />

250µs, position is calculated every 1ms.<br />

Operating modes<br />

The <strong><strong>TG</strong>A</strong> servoamplifier can operate<br />

in the following modes:<br />

Torque control<br />

Speed control<br />

Absolute positioning<br />

Relative positioning<br />

Pulse <strong>and</strong> direction signals control<br />

(stepper-motor control)<br />

Electronic gearing<br />

Continuous control via CAN-BUS<br />

Communication<br />

The <strong><strong>TG</strong>A</strong> servoamplifier is able to communicate<br />

via the RS 232 serial interface,<br />

RS 485 (422) - protocol MODBUS<br />

<strong>and</strong> via CAN BUS.<br />

Inputs / outputs<br />

The <strong><strong>TG</strong>A</strong> is equipped with 8 digital<br />

inputs, 4 digital outputs, 1 analogue<br />

input (+/-10V or 0-5V or 0-10V), 2 fast<br />

configurable count inputs/outputs.<br />

Parameter settings,<br />

status monitoring<br />

The SETUP program (included in the<br />

delivery) allowing parameter settings<br />

<strong>and</strong> status monitoring using a PC.<br />

The program SETUP is executable under<br />

Windows operating systems <strong>and</strong> communicates<br />

with the <strong><strong>TG</strong>A</strong> servoamplifier via<br />

the RS 232 serial interface.<br />

Operation<br />

The <strong><strong>TG</strong>A</strong> servoamplifier can be operated<br />

using:<br />

Analog voltage – torque or speed<br />

Stepper-motor signals (pulse <strong>and</strong><br />

direction)<br />

Digital inputs – start <strong>of</strong> programmable<br />

position or speed pr<strong>of</strong>iles<br />

Digital control by serial interface<br />

RS 232 (422 / 485) or by CAN-BUS<br />

(torque, speed, position pr<strong>of</strong>iles etc.)<br />

Firmware - customized<br />

We <strong>of</strong>fer customized firmware made<br />

for special applications. The <strong><strong>TG</strong>A</strong><br />

Firmware Loader is a program that allows<br />

new firmware to be uploaded to the<br />

<strong><strong>TG</strong>A</strong> servoamplifier via the RS 232 serial<br />

interface. The firmware upload takes<br />

several seconds.<br />

Mechanical design:<br />

The L-section allows variable mounting<br />

<strong>of</strong> the servoamplifier to the switchboard<br />

or directly to the machine.<br />

6

Technical data <strong>of</strong> <strong>servoamplifiers</strong> <strong><strong>TG</strong>A</strong>-24-9/20<br />

<strong><strong>TG</strong>A</strong>-24-9/20<br />

Parameters Unit Data<br />

Rated supply voltage V = 24 (15–42)<br />

Rated installed load for S1 operation W 230<br />

Rated output current A rms<br />

9<br />

Peak output current (max. ca 5 s) A rms<br />

18,5<br />

Overvoltage protection threshold (transil) V 47<br />

Loss at rated load W 20<br />

Fusing<br />

Supply 24 VDC<br />

Inputs / outputs<br />

Analog input, resolution 12 bit<br />

Input resistance<br />

Digital inputs with adjustable function<br />

24 VDC<br />

Digital outputs with adjustable function,<br />

24 VDC, PNP<br />

– internal – T 10 A<br />

– external – C 8 A<br />

V 0–5 / 0–10/ ±10 V<br />

kΩ 6.6<br />

qty 8<br />

V low 0–5/high 7–30<br />

mA 6<br />

qty 4<br />

V max. 36<br />

mA 25<br />

Counter inputs for IRC<br />

or stepper-motor signals<br />

– 5V (RS422)<br />

Connectors<br />

Control signals – Interhart 3.81, 1.5 mm 2<br />

Power – Interhart 5.08, 2.5 mm 2<br />

Resolver input – Interhart 3.81, 1.5 mm 2<br />

Communication – SubD 9-pole plug<br />

Mechanical data<br />

Weight kg 0.6<br />

Dimensions without connectors mm 157×86×40<br />

Environment<br />

Operating temperature °C 0–40<br />

Relative humidity % max. 85<br />

7

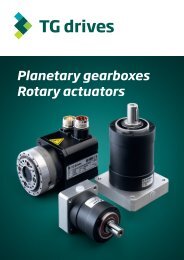

Digital <strong>servoamplifiers</strong><br />

AC brushless servomotors<br />

Universal PC based control system<br />

This project shall be co-financedby the European Fund<br />

for Regional Development<strong>and</strong> by the Ministry <strong>of</strong> Trade <strong>and</strong> Industry.<br />

8<br />

<strong>TG</strong> <strong>Drives</strong> s. r. o., Jeneweinova 37, CZ-617 00 Brno,<br />

tel. (+420) 545 234 935, fax (+420) 545 234 735<br />

info@tgdrives.cz<br />

www.tgdrives.cz