SPRING 2012

Distributor's Link Magazine Spring Issue 2012 / VOL 35 / NO.2

Distributor's Link Magazine Spring Issue 2012 / VOL 35 / NO.2

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

34 THE DISTRIBUTOR’S LINK<br />

Guy Avellon<br />

Guy Avellon has been in the MRO and fastener distribution industry for over 30 years. He began his metallurgical<br />

engineering career at Republic Steel Research Center in metal coatings and has since held positions as sales<br />

engineer; Chief Engineer; Manager of Product Marketing, Product Engineering and Quality and Director of Quality and<br />

Engineering. He founded GT Technical Consultants where he performs failure analysis, presents lectures on fastener<br />

safety, worked for law firms and designs and audits Quality systems.<br />

He is a member of SAE and is Vice Chairman of the ASTM F16 Fastener Committee and Chairman of the F16.01 Test<br />

Methods Committee, since 1988. He also received the ASTM Award of Merit in 2005.<br />

Guy and his wife, Linda currently reside in Lake Zurich, IL and may be reached at 847-477-5057 or visit his website<br />

at http://www.BoltDoc.com.<br />

TORQUE VARIABLES AND LIABILITY<br />

When is it safe to recommend torque values<br />

Earlier articles have cited how to calculate torque<br />

values, how variables can affect the pre load and<br />

different techniques employed for installing the fastener.<br />

We spoke of material grades and components and a few<br />

applications.<br />

But what does this mean<br />

to a distributor Of course they<br />

should be knowledgeable<br />

about fasteners; however<br />

when it comes to<br />

recommending torque values,<br />

how great is your liability<br />

Many times the customer does<br />

not reveal all of the details of<br />

the application. It takes a<br />

trained individual to be able to<br />

dig into what the customer is<br />

using and how. This is<br />

because there are many<br />

variables to consider when<br />

tightening a simple fastener.<br />

The incorrect answer could<br />

cause a great failure and it still<br />

boils down to “the man with<br />

the wrench.”<br />

First, let’s list some of<br />

those variables:<br />

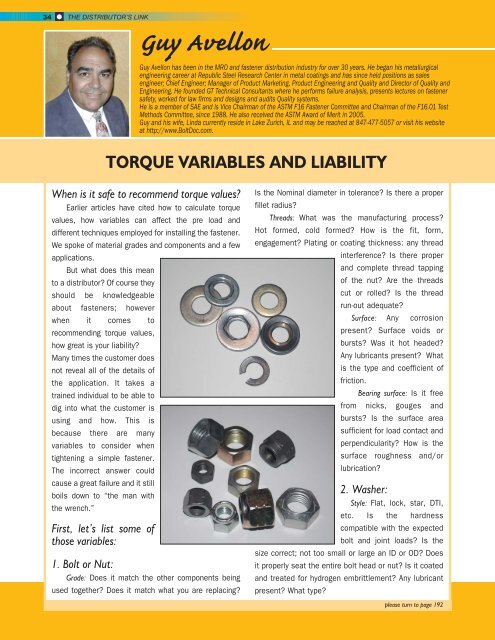

1. Bolt or Nut:<br />

Grade: Does it match the other components being<br />

used together Does it match what you are replacing<br />

Is the Nominal diameter in tolerance Is there a proper<br />

fillet radius<br />

Threads: What was the manufacturing process<br />

Hot formed, cold formed How is the fit, form,<br />

engagement Plating or coating thickness: any thread<br />

interference Is there proper<br />

and complete thread tapping<br />

of the nut Are the threads<br />

cut or rolled Is the thread<br />

run-out adequate<br />

Surface: Any corrosion<br />

present Surface voids or<br />

bursts Was it hot headed<br />

Any lubricants present What<br />

is the type and coefficient of<br />

friction.<br />

Bearing surface: Is it free<br />

from nicks, gouges and<br />

bursts Is the surface area<br />

sufficient for load contact and<br />

perpendicularity How is the<br />

surface roughness and/or<br />

lubrication<br />

2. Washer:<br />

Style: Flat, lock, star, DTI,<br />

etc. Is the hardness<br />

compatible with the expected<br />

bolt and joint loads Is the<br />

size correct; not too small or large an ID or OD Does<br />

it properly seat the entire bolt head or nut Is it coated<br />

and treated for hydrogen embrittlement Any lubricant<br />

present What type<br />

please turn to page 192