Kvaerner corporate brochure

Kvaerner corporate brochure

Kvaerner corporate brochure

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2<br />

Gas export<br />

capacity:<br />

17M Sm 3 /day<br />

Oil export capacity:<br />

87 000 barrels/day<br />

Height:<br />

143m<br />

Width:<br />

110m<br />

Topside weight:<br />

22 000<br />

tonnes<br />

In Q4 2010, the Gjøa semisubmersible platform reached production start-up<br />

on schedule in the North Sea. <strong>Kvaerner</strong> provided the topside and assembly.

gjøa<br />

3<br />

ÒÒ<br />

ÒÒ<br />

Our scope: EPCH (Detail<br />

design of topside and hull,<br />

procurement, construction<br />

and hook-up of topside, and<br />

mating of topside and hull)<br />

Contract value:<br />

Approximately NOK 8 bn<br />

(2006)<br />

ÒÒ<br />

Peak manning: 3 000<br />

people at our in-house<br />

yard at Stord, Norway<br />

ÒÒ<br />

Electricity to Gjøa is<br />

provided from land, for the<br />

first time on the Norwegian<br />

Continental Shelf, saving<br />

annual CO2 emissions<br />

equivalent to those<br />

produced by 100 000 cars<br />

We create value by successfully<br />

planning and executing demanding<br />

EPC* projects<br />

ÒÒ<br />

ÒÒ<br />

Tie-in of remote field (Vega)<br />

Field development operator:<br />

Statoil<br />

ÒÒ<br />

Field operations operator:<br />

Gaz de France<br />

* Engineering, procurement and construction

Who we are<br />

<strong>Kvaerner</strong>: EPC specialist<br />

Common values<br />

4<br />

<strong>Kvaerner</strong> is a specialised engineering, procurement and<br />

construction (EPC) company focused on executing some<br />

of the world’s most demanding projects as the preferred<br />

partner for upstream and downstream oil and gas<br />

operators, industrial companies and other engineering<br />

and fabrication providers.<br />

A unique heritage<br />

The <strong>Kvaerner</strong> and Aker groups have decades of<br />

experience as EPC contractors for onshore and offshore<br />

facilities covering a wide range of technologies and<br />

solutions. The new <strong>Kvaerner</strong> further leverages the<br />

experience and expertise built up through the execution<br />

of demanding projects over the past 40 years.<br />

Tailored to meet client demands<br />

<strong>Kvaerner</strong> is tailored to meet the EPC market trends and<br />

client demands. We offer a safety focused and dedicated<br />

management and we have the mandate to enter into<br />

partnerships in order to establish reliable,<br />

flexible and competitive delivery models.<br />

Building trust through common values<br />

In any organisation, values are essential for building<br />

trust – in each other, with our partners, with our<br />

customers and with society. All the <strong>Kvaerner</strong> businesses<br />

share a common set of values – the compass that<br />

guides our policies, our operations and ultimately,<br />

our behaviour.<br />

Long-term ownership<br />

<strong>Kvaerner</strong> is headquartered in Oslo, Norway, and has<br />

more than 3 200 employees worldwide, in addition<br />

to a significant number of contract staff. Aker ASA,<br />

an investment company that exercises active<br />

ownership, is indirectly a significant shareholder<br />

in <strong>Kvaerner</strong>.<br />

Open and direct<br />

dialogue<br />

We encourage<br />

early and honest<br />

communication<br />

People and teams<br />

All our major<br />

achievements are<br />

teams efforts<br />

HSE mindset<br />

We take personal<br />

responsibility for<br />

HSE because<br />

we care<br />

Our mission:<br />

Successfully <br />

planning and<br />

executing <br />

demanding EPC<br />

projects, through:<br />

Hands-on<br />

management<br />

We know our<br />

business and get<br />

things done<br />

Customer drive<br />

Building customer<br />

trust is key to<br />

our business<br />

Delivering results<br />

We deliver<br />

consistently and<br />

strive to beat<br />

our goals<br />

1841 1853 EARLY 1900s 1960s<br />

Our history:<br />

Building strength<br />

through experience<br />

Aker founded in<br />

Oslo, Norway.<br />

<strong>Kvaerner</strong> founded in<br />

Oslo, Norway.<br />

Strong player in<br />

machinery, equipment,<br />

hydropower turbines,<br />

shipbuilding and other<br />

industries.<br />

Entered the offshore oil<br />

and gas industry. Shipyard<br />

modifications to cater<br />

for the coming<br />

offshore business.

Foundation for growth<br />

Focus on HSE performance<br />

ÒÒ<br />

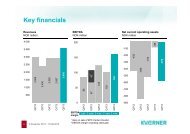

<strong>Kvaerner</strong> is a leading EPC company<br />

with a solid track record<br />

ÒÒ<br />

Operating revenues of more than<br />

NOK 13 billion (2011)<br />

In <strong>Kvaerner</strong>, concern for health, safety and the<br />

environment is a core value. This HSE Mindset,<br />

symbolised by Just Care, is founded on the belief<br />

that all incidents can be prevented. We work<br />

systematically to ensure continual improvement<br />

of our HSE culture and performance.<br />

5<br />

ÒÒ<br />

Long-term active ownership by Aker ASA<br />

ÒÒ<br />

We strive continuously for zero harm to personnel,<br />

material and non-material assets.<br />

ÒÒ<br />

Well positioned for long-term growth<br />

trends in key markets<br />

ÒÒ<br />

Ambition to maintain strong North Sea<br />

position and further grow international<br />

EPC deliveries<br />

ÒÒ<br />

We focus on employee health and on continuously<br />

improving the work environment.<br />

ÒÒ<br />

We require every employee to take personal<br />

responsibility for HSE by focusing on their<br />

own behaviour.<br />

1970s 1980s<br />

1990s 2000s 2010<br />

Yards in Stord and Verdal<br />

founded. Developed and<br />

delivered pioneering<br />

concepts like the<br />

Aker H-3 drilling rigs<br />

and the Condeep<br />

platforms.<br />

Key partner in North<br />

Sea field developments<br />

such as Gullfaks,<br />

Oseberg, Ekofisk.<br />

Key partner in<br />

world-class projects<br />

in the North Sea<br />

and international<br />

markets.<br />

Merger of Aker and <strong>Kvaerner</strong>. Key partner in some of<br />

the world’s most demanding field developments. Leading<br />

field development provider in Norway, both offshore<br />

and onshore. Global leader in deepwater developments<br />

and concrete GBS. Europe’s leading provider of big<br />

steel jackets. Strong position in North America within<br />

downstream oil & gas, energy & environmental<br />

and industrial construction.<br />

2011: <strong>Kvaerner</strong> established<br />

as a specialised EPC company<br />

in a demerger from Aker<br />

Solutions. Listing on the<br />

Oslo Stock Exchange.<br />

Clear growth ambition.

6<br />

We plan &<br />

execute<br />

demanding<br />

EPC<br />

projects<br />

Proven EPC project management<br />

We are an experienced main contractor for onshore and offshore facilities covering a wide range of<br />

technologies and solutions. We understand that good customer references build our reputation – and the<br />

only way to achieve this is through consistent and predictable performance. Our proprietary project execution<br />

model is based on best practice from many of the industry’s most challenging projects. This ensures safe<br />

and efficient project execution and risk management.<br />

Engineering<br />

Procurement<br />

Construction<br />

Our multi-discipline organisation covers all<br />

of the technical and administrative functions<br />

needed to execute demanding engineering<br />

tasks for upstream and downstream oil<br />

and gas operators, industrial companies<br />

and other engineering and fabrication<br />

providers. We tailor the delivery model<br />

to match our customers’ needs and<br />

business priorities.<br />

<strong>Kvaerner</strong> provides best value to our clients<br />

by proactively utilising global networks, market<br />

opportunities, market knowledge and global<br />

sourcing. Our supply management and<br />

procurement organisations support the<br />

businesses through a systematic proactive<br />

process of optimising the total costs,<br />

risk, quality, lead-time and HSE of all<br />

outsourced products and services.<br />

We combine the expertise built up over<br />

40 years at our specialised in-house yards<br />

in Norway with cost effective fabrication from<br />

our high quality partner yards. By using local<br />

partnerships and local value creation, we<br />

increase our capacity and contribute to<br />

significantly increasing the local content<br />

of a project. All our projects are overseen<br />

by <strong>Kvaerner</strong> project and construction<br />

management expertise.

7<br />

Topsides Floaters Concrete jackets Onshore CONSTRUCTION<br />

Offshore topside facilities<br />

Floating oil &<br />

gas facilities<br />

Concrete GBS for offshore<br />

platforms<br />

Steel jackets for offshore<br />

platforms<br />

Onshore facilities to oil<br />

and gas, power, steel and<br />

industrial markets.<br />

Construction and<br />

maintenance services

Designed and constructed for<br />

arctic environments<br />

with heavy ice loads<br />

8<br />

Two platform<br />

substructures<br />

developed with a total<br />

high-performance<br />

concrete weight of<br />

15 000 tonnes<br />

In 2007, the LUN-A and PA-B concrete gravity base structures delivered by <strong>Kvaerner</strong> were<br />

successfully installed offshore Russia on the far east coast as part of the Sakhalin-II project.

Our customers have selected <strong>Kvaerner</strong><br />

to play a key role in some of the<br />

world’s most demanding projects<br />

9<br />

SAKHALIN-I: ARKUTUN-DAGI GBS<br />

ÒÒ<br />

ÒÒ<br />

ÒÒ<br />

Our scope: Engineering, procurement,<br />

management and project services for<br />

a platform substructure<br />

Customer: Exxon Neftgas Ltd<br />

Execution: 44 months from FEED to offshore<br />

installation of a concrete GBS<br />

ÒÒ<br />

ÒÒ<br />

Site build-up in remote location: Dry-dock from<br />

Sakhalin II project was reinstated. Bund wall<br />

was rebuilt and dock emptied. A completely<br />

new infrastructure was built with permanent<br />

workshops for rebar, formwork and mechanical<br />

outfitting prefabrication.<br />

Strong local content performance: More than<br />

90% of material and workforce from Russia.<br />

More than 35 local subcontractors with up<br />

to 4 000 employees were used to perform<br />

the work. About 30% of the workforce had<br />

experience from the previous, Sakhalin II<br />

project.<br />

Designed and<br />

constructed<br />

to withstand<br />

seismic<br />

activity<br />

SAKHALIN-II: LUNSKOYE GBS & PILTUN-ASTOKHSKOYE-B GBS<br />

ÒÒ<br />

ÒÒ<br />

ÒÒ<br />

Our scope: Engineering, procurement,<br />

management and project services for<br />

two platform substructures<br />

Customer: Sakhalin Energy<br />

Execution: 30 months from FEED to offshore<br />

installation of two concrete GBSs<br />

ÒÒ<br />

ÒÒ<br />

Site build-up in remote location: Excavation and<br />

transportation of more than 2 000 000m 3 of<br />

soil. Road construction in winter conditions.<br />

Strong local content performance: More than<br />

90% Russian labour and materials utilised, with<br />

more than 600 Russian vendors who acquired<br />

unique experience in marine oil and gas<br />

construction.

10<br />

Delivering quality on time<br />

to our customers<br />

<strong>Kvaerner</strong> is a leading provider of project management, design, engineering, procurement, construction, installation<br />

and commissioning for demanding projects worldwide.<br />

Time and time again, our organisation has delivered the first, the largest, the deepest and the most cost-efficient<br />

installations addressing a wide range of challenges – always with an HSE focus.<br />

Our ambition is to stay at the forefront of technology as one of the world’s leading EPC contractors, and to ensure<br />

that innovation and development work is achieved in harmony with both people and the environment – and to the<br />

best advantage of our customers.<br />

We take pride in delivering quality on time to our customers.

Eldfisk 2/7 S: EPC for topside and bridges<br />

Kollsnes: EPC for modification and development<br />

of gas plant<br />

European CO2 Technology centre at Mongstad<br />

in Norway: EPC for construction<br />

Edvard Grieg: EPC for jacket and topside<br />

11<br />

Gudrun: EPC for platform jacket<br />

Ekofisk 2/4 L: EPC for platform and bridge<br />

support jackets<br />

Clair Ridge: EPC jackets for Drilling Production<br />

platform and Quarters Utility platform.<br />

Nordsee Ost: EPC for 49 steel jackets and piles<br />

for offshore wind project<br />

Sakhalin-1: EPC for Arkutun-Dagi GBS<br />

Ormen Lange/Nyhamna: EPCM for modifications<br />

and projects at the onshore facilities.<br />

Hebron: FEED and site preparation for GBS,<br />

with EPC option<br />

Gulf LNG: EPC for onshore LNG terminal<br />

V&M Star: Construction of pipe mill process<br />

building<br />

Kashagan: Contracts for hook-up work Browse: Competition FEED for two TLPs Skarv: Preparation of FPSO

EKOFISK 2/4L<br />

12<br />

We are a knowledge-based<br />

company with unique experience<br />

and know-how, and the drive<br />

to get things done<br />

ÒÒ<br />

ÒÒ<br />

ÒÒ<br />

Our scope: Engineering,<br />

procurement, construction,<br />

load-out and sea-fastening<br />

of two steel jackets<br />

(Accomodation jacket,<br />

bridge support jacket and<br />

associated piles)<br />

Customer: ConocoPhillips<br />

Number 36 and 37 in the<br />

series of jackets delivered<br />

by our yard in Verdal,<br />

Norway.

Jacket height:<br />

110 meters<br />

Topside weight<br />

for jacket design:<br />

19 000 tonnes<br />

Jacket weight:<br />

Approximately<br />

5 700 tonnes<br />

13<br />

Water depth:<br />

80 meters

Setting the standard<br />

14<br />

KRISTIN HPHT GAS PLATFORM<br />

GJØA SEMI-SUBMERSIBLE<br />

ADRIATIC LNG TERMINAL<br />

The first HPHT (high pressure, high temperature) gas floater.<br />

Delivered by <strong>Kvaerner</strong> on schedule in 2005.<br />

The first floating platform to be supplied with electric power from<br />

shore. Delivered by <strong>Kvaerner</strong>.<br />

The world’s first offshore LNG regasifier, a strategic component<br />

of the Italian gas system. Delivered by <strong>Kvaerner</strong>.<br />

Offshore topside facilities<br />

40 years of experience on all types of facilities that<br />

may be required on an offshore facility.<br />

Floating oil & gas facilities<br />

More than 30 floating oil and gas exploration and<br />

production facilities delivered by <strong>Kvaerner</strong> worldwide.<br />

Concrete GBS for offshore oil & gas facilities<br />

World leader in marine concrete structures for oil<br />

and gas field developments, as the lead contractor<br />

in more than 20 major concrete projects worldwide.

GRANE PLATFORM JACKET SNØHVIT LNG PRODUCTION PLANT 15 POWER PLANTS SINCE 2002<br />

15<br />

17 500 tonne fixed steel substructure for drilling, production,<br />

processing and accommodation facilities. Delivered by <strong>Kvaerner</strong>.<br />

The first plant of its kind in Europe and the world’s northernmost<br />

liquefied natural gas facility. Delivered by <strong>Kvaerner</strong>.<br />

New plants, as well as retrofits, environmental modifications,<br />

maintenance and upgrades to existing facilities<br />

Steel jackets for offshore platforms<br />

37 jackets for oil and gas field developments delivered<br />

since 1975, at a total of more than 250 000 tonnes.<br />

Onshore oil, gas and petrochemical facilities<br />

A leading developer of onshore oil and gas facilities<br />

in Norway, with a strong position in North America<br />

within downstream oil and gas projects, including LNG,<br />

refineries and petrochemical facilities, as well as power<br />

plants, utilities and infrastructure.<br />

Construction and maintenance services<br />

A premier provider to the U.S. and Canadian steel,<br />

energy and industrial construction market.

Edvard Grieg<br />

16<br />

ÒÒ<br />

Our scope: Engineering,<br />

procurement and<br />

construction (EPC) of the<br />

steel jacket and the topside<br />

module.<br />

ÒÒ<br />

ÒÒ<br />

ÒÒ<br />

ÒÒ<br />

Contract value:<br />

Topside NOK 8 billion<br />

Steel jacket NOK 1.1 billion<br />

The topside has a total<br />

weight of 21 000 tonnes<br />

and consists of a main<br />

topside model, a combined<br />

living quarter and utility<br />

module, a process module<br />

and a flare tower.<br />

Delivery set to April 2015.<br />

Most of the scope will be<br />

performed in Norway.<br />

The steel jacket<br />

with a total weight of<br />

14 500 tonnes, will be<br />

delivered from <strong>Kvaerner</strong>’s<br />

specialized jacket yard<br />

in Verdal in the spring of<br />

2014.<br />

Customer:<br />

Lundin Norway AS

We address the global market<br />

and tailor our delivery models<br />

to match customers’ needs<br />

and business priorities<br />

17

Our competence covers<br />

all key disciplines<br />

19<br />

<strong>Kvaerner</strong> offers more than 3 200 HSE-focused and experienced in-house resources<br />

in the fields of engineering, procurement and project management, in addition to a<br />

significant number of contract staff.<br />

This is a solid foundation, and ensures that we in cooperation with engineering partners<br />

and sub-contractors are able to plan and execute our projects effectively, and control<br />

quality and risk.<br />

However, our ambitions go even further. We aim for continued growth, and are actively<br />

recruiting additional in-house personnel and seeking new global partnerships.<br />

<strong>Kvaerner</strong> strives to attract and develop talented people and teams who understand our<br />

customers’ needs and requirements and who can produce and deliver the best solutions.<br />

In-house<br />

resources,<br />

subcontractors and<br />

contract staff:<br />

one team<br />

delivering consistently<br />

for our<br />

customers

20<br />

Safe delivery on time,<br />

with agreed quality, on budget<br />

World-class studies and design<br />

We deliver technology, products, front-end, system<br />

definition and project execution through our strong<br />

in-house engineering staff and global engineering<br />

partners, including our long-term engineering partner<br />

Aker Solutions.<br />

We offer full field development understanding<br />

– from concept selection to completion – covering<br />

all key products and technologies within field<br />

development.<br />

Best value engineering<br />

For detail engineering, we secure cost-effective project<br />

execution for our customers through in-house resources<br />

and global engineering partners.<br />

Local partnerships, local value creation<br />

Using local partnerships and local value creation,<br />

<strong>Kvaerner</strong> can contribute to significantly increasing the<br />

local content of a project. This may include the labour<br />

workforce, suppliers and required materials. All of our<br />

EPC projects are overseen by <strong>Kvaerner</strong> project and<br />

construction management expertise.<br />

Cost-effective, high quality fabrication capacity<br />

Working with our in-house and partner yards, we offer<br />

cost-effective fabrication of hulls for floating facilities.<br />

For topside facilities, we offer cost-effective, flexible<br />

options tailored to our customers’ needs.<br />

We combine the expertise built up over 40 years<br />

at our specialised yards with cost effective fabrication<br />

from our high quality partner yard; the China Offshore<br />

Oil Engineering Corporation (COOEC) yard in Qingdao.<br />

Proven Project Execution Model<br />

We understand that good customer references build<br />

our reputation – and the only way to achieve this is<br />

by consistent and predictable performance. Our Project<br />

Execution Model (PEM) is based on best practice from<br />

many of the industry’s most challenging projects.<br />

PEM ensures efficient project execution and risk<br />

management.<br />

We have experienced project managers and project<br />

services personnel to ensure that all projects, large<br />

or small, are executed in accordance with the PEM<br />

and project specific execution philosophies.

Our<br />

proven<br />

Project<br />

Execution<br />

Model<br />

21<br />

Feasibility &<br />

concept<br />

System<br />

definition<br />

Detailing &<br />

fabrication<br />

Assembly<br />

& erection<br />

System<br />

completion<br />

ÒÒ<br />

Opportunity appraisal<br />

ÒÒ<br />

System definition<br />

ÒÒ<br />

Detailed design<br />

ÒÒ<br />

Transport & positioning<br />

ÒÒ<br />

Commissioning<br />

ÒÒ<br />

ÒÒ<br />

ÒÒ<br />

Feasibility studies<br />

Concept selection<br />

Concept definition<br />

ÒÒ<br />

ÒÒ<br />

System design<br />

& layout development<br />

Global design<br />

ÒÒ<br />

ÒÒ<br />

ÒÒ<br />

Work preparation<br />

Prefabrication<br />

Fabrication<br />

ÒÒ<br />

ÒÒ<br />

Assembly<br />

Mechanical completion<br />

ÒÒ<br />

ÒÒ<br />

ÒÒ<br />

Transport & installation<br />

Take-over<br />

Close-out

22<br />

We are ready to take on<br />

the world’s most demanding<br />

projects with you<br />

Aker H-6e drilling rigs<br />

ÒÒ<br />

Our scope: Turn-key contract for the delivery of two<br />

sixth-generation deepwater drilling semi-submersibles<br />

ÒÒ<br />

Contract value: NOK 7.6 billion (2005)<br />

ÒÒ<br />

ÒÒ<br />

Peak construction labour force:<br />

Approximately 4 000 people from 40 nations<br />

Customer: Aker Drilling

Aker Barents and Aker Spitsbergen: Two highly sophisticated<br />

6th generation semi-submersible drilling rigs for ultra deep<br />

water and harsh environments.<br />

Excellent<br />

performance<br />

and operator<br />

feedback<br />

23<br />

Developed to meet stringent<br />

environmental standards<br />

and operate in<br />

harsh environments,<br />

extreme temperatures<br />

and at long distances<br />

from supply infrastructure<br />

Designed and built to<br />

drill 10 000<br />

metre-long wells<br />

in water depths of<br />

up to 3 000 metres

www.kvaerner.com<br />

www.facebook.com/kvaernerasa Photos: Statoil, Sakhalin Energy, BP, ConocoPhillips, Adriatic LNG Terminal, Gulf LNG, Aker Solutions, Rolf Estensen (v-082012)