technical regulations - Red Line Oil Karting Championships

technical regulations - Red Line Oil Karting Championships

technical regulations - Red Line Oil Karting Championships

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

OFFICIAL RULES &<br />

REGULATIONS<br />

presented by<br />

2008<br />

SEASON<br />

U.S. Rotax Max Challenge 3101 Alejo Road, Palm Springs, CA 92262 www.rmaxchallenge.com

WELCOME<br />

2008 RULES AND CLASS STRUCTURE U.S. RMAX CHALLENGE<br />

Photo by Ken Johnson<br />

2007 U.S. GRAND FINALS TEAM SPONSORED BY<br />

Since it’s inception in 1998, the Rotax Series focus has been on<br />

the grass roots racer. It is this local weekend warrior that benefi ts from the<br />

concept of low maintenance, high performance motors. The Rotax Series has<br />

always been focused on the ability of the driver, and not the depth of the pocketbook.<br />

The FR125 was fi rst introduced in the United States. Since then we have made the local<br />

series the main focal point of our program. It is with this focus that the strength and growth<br />

of the Rotax Series in the United States continues. You, the club racer, can go to your local track,<br />

enjoy many laps with only minor mechanical maintenance and clean up. Your motor can run 50 hours<br />

without sending it to the engine shop. This can translate into 2-3 years of racing. You get to race with many<br />

who have become your friends and share a common bond of friendly competition. Everyone wants to win on<br />

the track, but in the pits it is everyone working to make sure all have a good time.<br />

This philosophy works. The proof is the continued growth of the program. The program is designed for a minimum<br />

of classes, which results in larger fi elds and more track time.<br />

In 2006 a unique opportunity was presented. Champ Car, looking for a fi rst rung on the ladder, sought out the<br />

Rotax Max Challenge to be a partner. While our main focus is on the weekend warrior, there are a number of national<br />

level racers who have chosen to compete in the Rotax series because it truly showcases their driving ability.<br />

This is the same reason Champ Car offi cials looked to Rotax as its karting affi liate. With this partnership we can<br />

now offer the young driver, looking to move into the professional ranks, a place to start. In the Rotax series the<br />

aspiring driver can hone his on track skills and earn the opportunity to showcase his talent in front of professional<br />

teams at the annual US Rotax Grand Nationals.<br />

2<br />

presented by

presented by<br />

3

YOUR SOURCE FOR ROTAX<br />

NEWS AND COVERAGE<br />

IT ALL STARTS HERE.<br />

800-942-0033<br />

www.nkn.com<br />

NATIONAL KART NEWS<br />

AMERICA’S LEADING KARTING MAGAZINE SINCE 1986

2008 RULE BOOK CONTENTS<br />

presented by<br />

SECTION 1 - U.S. RULES & CLASS STRUCTURE<br />

RULES PRIMER ................................................ 12<br />

CLASS STRUCTURE .......................................... 15<br />

LOGO PLACEMENT ............................................ 17<br />

POINTS STRUCTURE ......................................... 18<br />

SECTION 2 - NATIONAL EVENT PROCEDURES - 20<br />

SECTION 3 - SPORTING REGULATIONS<br />

ROTAX MOJO MAX CHALLENGE ..........................28<br />

GRAND FINALS ................................................33<br />

SECTION 4 - TECHNICAL REGULATIONS<br />

ROTAX MOJO MAX CHALLENGE ..........................48<br />

MICRO & MINI MAX ......................................... 51<br />

125 JUNIOR MAX & 125 MAX ...........................55<br />

125 MAX DD2 .................................................64<br />

SECTION 5 - INFORMATION & REFERENCES<br />

ROTAX MOJO MAX CHALLENGE ..........................48<br />

MICRO & MINI MAX ......................................... 51<br />

125 JUNIOR MAX & 125 MAX ...........................55<br />

125 MAX DD2 .................................................64<br />

HIERARCHY OF RULES<br />

• US-specifi c Sporting and Technical Regulations<br />

• Rotax Sporting and Technical Regulations<br />

• CIK Sporting and Technical Regulations<br />

Every effort has been made to ensure the accuracy of this rule<br />

book. In the event of a discrepency, fi nal ruling will be determined<br />

using the offi cial documents found on the following websites.<br />

Rotax US: www.rmaxchallenge.com<br />

Rotax World: www.maxchallenge-rotax.com<br />

CONTACT INFORMATION:<br />

SSC Racing<br />

3101 East Alejo Road<br />

Palm Springs, CA<br />

Program Director<br />

Jermie Meyer<br />

Jmeyer@SSCRacing.com<br />

National Race Director<br />

Marshall Martin<br />

RMaxNRD@sbcglobal.net<br />

East Service<br />

Center Certification<br />

Dave Davies<br />

RJV Enterprises/SSC East<br />

ddavies@rjventerprises.com<br />

National Tech Director<br />

Scott Evans<br />

tech@maxchallenge.com<br />

West Service<br />

Center Certification<br />

James Perez<br />

SSC Racing/KARBZ Inc.<br />

Rotax Power Center

GRAND NATIONALS IN SHAWANO, WI<br />

U.S. RMAX CHALLENGE<br />

GRAND NATIONAL GETS A MAKEOVER<br />

2008 U.S. Rotax Max Challenge Grand Nationals, Shawano, WI<br />

Organizers are giving the 2008<br />

Rotax Grand National a makeover<br />

this year, making it the most<br />

exciting and competitive event to<br />

date. From unique and memorable<br />

lodging options, to family friendly<br />

games and events, USAIR and<br />

Champ Car Rotax are pulling out<br />

all the stops to make this race<br />

an unforgettable experience for<br />

competitors, families, and fans<br />

alike.<br />

Several new and intriguing<br />

housing options will be available<br />

this year as well. Attendees will get<br />

to choose from a selection of hotel<br />

rooms, private lakeside vacation<br />

homes, RV rentals, and RV camping<br />

spaces in the competitors’ village.<br />

There are quite a few special<br />

extras, in the planning stages<br />

at this point, including: paintball<br />

team challenge, classic car show,<br />

movie night, event dance, live<br />

music, welcome banquet, awards<br />

barbeque, and more. Many of<br />

presented by<br />

these events will be held at a<br />

facility centered in the competitors’<br />

village. The planned layout and<br />

nature of activities at this year’s<br />

Grand Nationals are aimed at<br />

fostering a sense of community<br />

and fun among Rotax competitors.<br />

These events will be open to all<br />

ages and supported by local,<br />

regional, national, and international<br />

sponsors.<br />

Other amenities will include: a<br />

shuttle bus to transport attendees<br />

not staying in the competitors’<br />

village, to and from events, official<br />

race directory, pre-paid meal<br />

vouchers, and VIP viewing boxes.<br />

USA International Raceway offers<br />

bumper boats, arcade games,<br />

swimming pools, mini-golf, and a<br />

fun kart track. Passes will be made<br />

available to competitors and their<br />

families for use of these facilities.<br />

An official event calendar will be<br />

made available closer to race time<br />

and will include information on all<br />

of the exciting amenities available<br />

to competitors and spectators.<br />

Attendees are urged to book early<br />

and check in often in order to take<br />

advantage of all the housing and<br />

activity options available at the<br />

2008 U.S. Rotax Max Challenge<br />

Grand National.<br />

For more information on<br />

USA International Raceway, visit<br />

usainternationalraceway.com, or<br />

call (414) 234-8230.<br />

For more information on the<br />

U.S. Rotax Max Challenge, visit<br />

rmaxchallenge.com, or call (888)<br />

SSC-Kart.<br />

8<br />

presented by

125 MAX DD2<br />

FR 125 MAX

SECTION 1<br />

U.S. RULES<br />

AND CLASS<br />

STRUCTURE SECTION 1<br />

RULES PRIMER ............................. 12<br />

CLASS STRUCTURE ..................... 15<br />

LOGO PLACEMENT .........................17<br />

POINTS STRUCTURE ................... 18<br />

presented by

SECTION 1<br />

RULES AND CLASS STRUCTURE<br />

NATIONAL RULES PRIMER<br />

GENERAL<br />

ENGINE<br />

CHASSIS<br />

2008 USRMC National Rules Primer<br />

Rules contained within this primer apply equally to all classes unless otherwise specified.<br />

Data acquisition gauges must be mounted such that protrusion above the plane of the steering wheel is kept to a minimum; however<br />

specifi c control of this dimension per CIK Regulations is not applicable.<br />

Scoring transponder location on back of the seat with the following requirements:<br />

• The bottom of the transponder body must be located no closer than 15cm from ground level.<br />

• The transponder may not be mounted forward of the tangent point defi ned by the radius transitioning to the side of the seat and<br />

the seat back.<br />

Specific decals must be applied to the bodywork in the locations specified by the current release of the Official USRMC<br />

Logo Placement document on page 17.<br />

In conformance with latest revision release of Technical Regulations as released by ROTAX-BRP with the following<br />

exceptions and/or clarifications:<br />

Exhaust port height requirements:<br />

All engines sealed prior to April 1, 2008 are NOT subject to specifi c exhaust port height measuring criteria listed in the 2008 ROTAX<br />

Technical Regulations until August 1, 2008.<br />

Any engine sealed on or after April 1, 2008 IS subject to the port measuring criteria.<br />

From August 1, 2008 going forward, all engines are subject to 2008 port height measuring criteria.<br />

Dual seal requirements:<br />

All engines sealed on April 1, 2008 or later must carry a valid secondary crankcase seal and dual seal passport, with offi cial authorized<br />

service center stamp and signature, in accordance with USRMC dual seal directive listed at www.rmaxchallenge.com.<br />

Silicone or like substance may be applied to the exhaust springs for vibration dampening only.<br />

All classes except DD2, fuel pump must be mounted on original bracket, bottom location only.<br />

Spark plug NGK BR.EG of any heat range is acceptable for use.<br />

Any sit-up, sprint kart chassis constructed in conventional manner of round, tubular steel is permitted. Chassis must conform to the<br />

dimensional specifi cations of the current CIK Technical Regulations in all respects with the following exceptions:<br />

Rear axle wall thickness per CIK with the following exceptions: 40mm axle – 2.2 minimum, 50mm axle – 1.7mm<br />

Brake system homologation is NOT required for any class except for DD2. Functional front braking systems are prohibited in the<br />

MicroMax, MiniMax and Junior classes only. All braking systems must be operated simultaneously by a single foot pedal unless necessitated<br />

by physical handicap and approved by the event scrutineer.<br />

It is recommended to use the CIK-prescribed method (ref: two bolts minimum of 6mm diameter minimum with secure fasteners) to<br />

attach ballast. It is permitted to use the national-standard single fastener method for ballast under seven pounds provided the fastener<br />

diameter is 8mm or greater and positive safety retention methods are used. Acceptable retention methods when using a single fastener<br />

are drilled bolts and threaded fasteners used in conjunction with safety wiring or cotter pins only. Neither double-nutting nor wire<br />

“wrapping” is considered acceptable in this case. Ballast weights over seven pounds must use two fasteners with appropriate security<br />

as described in the CIK Technical Regulations.<br />

BUMPERS AND NERF BARS<br />

Senior, Masters and Junior Max classes only:<br />

• Front and rear bumpers and side nerf bars are required.<br />

• Functional quick fi xation nose cone mounting is not mandatory and fabricated hard mounting of design consistent with industry<br />

standards is permissible.<br />

• When Velocity bodywork is utilized, standard Velocity side nerf bars and front bumper is mandatory.<br />

• Standard steel tubing rear bumpers must conform to CIK specifi cations with the exception that the height of top bar must be no<br />

lower than the top of the rear axle or higher than the plane passing through the tops of front and rear tires.<br />

• Homologated rear protection systems are optional for use but must be utilized as-homologated with no substitutions or alterations.<br />

• CIK02 and later bumpers and nerf bars are both acceptable for National Challenge<br />

12 presented by

NATIONAL RULES PRIMER<br />

RULES AND CLASS STRUCTURE<br />

DD2 class only:<br />

• Front and side bumpers must be homologated from the CIK08 or CIK11periods only.<br />

SECTION 1<br />

BODYWORK<br />

TIRES<br />

Senior, Masters and Junior Max classes only:<br />

• Bodywork shall be defi ned as a nose cone, steering fairing and two side pods or contoured panels, constructed of highstrength<br />

plastic only. All of the components are required. Bodywork must conform to the following specifi cations:<br />

Must conform to specifi cations for CIK, Velocity-1 or Velocity-2 only. The only acceptable CIK bodywork will be from the<br />

CIK02, -08 or -11 homologation period. Mixing CIK02 with -08 or -11 bodywork is acceptable. ‘Matched set’ CIK08 or<br />

-11 bodywork is not required.<br />

Cutting or otherwise altering of bodywork components shall be for chassis or component clearance only and is permissible<br />

on CIK02, -08 and -11 bodywork. Cutting of CIK08 and -11 bodywork is limited to right side pods for radiator<br />

clearance only.<br />

Use of tape or similar material shall be limited to damage repair only. Covering the openings of the CIK02 side pods<br />

is permissible in wet race conditions only. Any use of tape or similar materials to provide a modifi ed air fl ow over the<br />

chassis is strictly prohibited with the exception of rain shields for brake discs in wet conditions.<br />

Specifi c side pod protrusion rule outboard of the quadrilateral formed by the four wheels is applicable. (Reference: CIK<br />

Technical Regulations, section 7.1.4, fi rst paragraph)<br />

DD2 class only:<br />

• Bodywork shall be defi ned as a nose cone, steering fairing and two side pods or contoured panels, constructed of highstrength<br />

plastic only. All of the components are required. Bodywork must conform to the following specifi cations:<br />

Bodywork must be utilized with front and side bumpers and homologated from the CIK08 or CIK11 period only.<br />

‘Matched set’ CIK08 or -11 bodywork is not required, however side bumpers and sidepods must match as well the<br />

front bumper and nose cone must match.<br />

No alteration of bodywork components is permissible.<br />

Specifi c side pod protrusion rule outboard of the quadrilateral formed by the four wheels is not applicable. (Reference:<br />

CIK Technical Regulations, section 7.1.4, fi rst paragraph)<br />

All classes except Mini and MicroMax, MOJO D2 (dry) 4.5x10-5 front, 7.10x11-5 rear and Bridgestone YKP or<br />

YJP (wet) 4.5x10-5 front, 6.0x11-5 rear. Wet tire compound for Grand National is YKP only.<br />

• (3) bead retention screws per CIK requirements in the outer wheel rims, front and rear, are mandatory for slick tires only<br />

for all classes except Mini and MicroMax. Bead locks are not required for wet tires in any class.<br />

• Maximum mounted front tire width is 140mm.<br />

• One set of tires (slick and wet) is allowed per event, plus one front and one rear spare (slick and wet).<br />

FUEL AND OIL<br />

98-octane (anti-knock index) maximum, commercial, unleaded gasoline in mixture between 33:1 and 50:1<br />

with high quality synthetic two cycle oil. For events where the fuel is not supplied as premix, the mixture ratio<br />

shall be verified by comparison with Digatron DT-15 or DT-47 to a controlled sample at 50:1. Competitors’ fuel<br />

must measure within +10/-5 points to the controlled sample.<br />

• The offi cial fuel and oil for the USRMC is VP Racing Fuels Motorsports 93 unleaded gasoline and Motul 800 2T Factory<br />

<strong>Line</strong> Off Road full synthetic two cycle oil.<br />

MINIMAX CLASS SPECIFIC REGULATIONS<br />

All <strong>regulations</strong> previously described apply equally to the MiniMax class unless specifically excepted in this<br />

section.<br />

• Original and unaltered exhaust header, ROTAX P/N 273 972, is required, inside diameter 22 +/-0,2mm.<br />

• One of the following inlet restrictors is required: Unaltered USRMC inlet restrictor shown at this link http://www.rmaxchallenge.com/page.cfmcontent=4&display=127<br />

with inside diameter of 19+0/0,2mm or unaltered BRP component part<br />

number 267 535. BRP component must show blue anodized coating all over.<br />

• Noise limit - per local limits or a maximum of 90dB (a) at 25 feet, measured perpendicular to the line of travel, engine<br />

under full load between 9,000rpm and 10,000rpm.<br />

• Wheelbase - 41 inches (1041.4mm) maximum.<br />

• The highest point at the center of the seat back shall be 12.0 inch minimum from ground level.<br />

• CIK axle wall thickness requirements are not applicable in MiniMax class.<br />

• Bumpers and bodywork, meeting industry standards must be employed at all times. For bodywork, CIK homologation<br />

presented by<br />

13

SECTION 1<br />

RULES AND CLASS STRUCTURE<br />

NATIONAL RULES PRIMER<br />

is not required, but construction must be similar in form and consistent with the size of the chassis. Quick fi xation mounting<br />

method for nose cone is not required.<br />

• Cadet nose cone may be of the full size design with maximum protrusion outboard of the front tires of 40mm per side.<br />

• Tire sizes MOJO D2(dry) 4.5x10-5 front and rear, Bridgestone YJP or YKP (wet) 4.5x10-5 front and rear. Wet tire compound<br />

for Grand National is YKP only. Maximum mounted tire width is 145mm. Maximum circumference at any time is 32.0 inches,<br />

all compounds.<br />

• Wide rear bumpers covering both rear wheels are mandatory. Bumpers must cover at minimum the inboard half of each tire,<br />

but may not protrude outboard of the edge of either tire except in wet conditions. Bumper construction must conform to the<br />

following requirements:<br />

The rear bumper must consist of at least an upper and lower bar, both of 16mm minimum outside diameter.<br />

Height of the top of the upper bar shall be no lower than the top of the rear axle or higher than the plane passing through<br />

the top of the front and rear tires.<br />

Height of the top of the lower bar shall be 80 +/- 20mm from ground level.<br />

The entire unit must be attached to the chassis frame in a minimum of two points to the main frame tubes, fl exible connection<br />

permitted.<br />

The upper and lower bars must be of continuous loop profi le with a minimum bar diameter of 16mm in all places except<br />

between the chassis rails. Area between the chassis rails must also be protected by a bar of 16mm minimum outside diameter<br />

but it is not required to be part of the continuous loop. A minimum of 80 percent of the opening between chassis rails<br />

must be protected if accomplished with a secondary loop extending downward from the top bar.<br />

The upper and lower bars must be - in general terms - inline and parallel to one another and connected on the outboard<br />

ends by a full radius bend of suffi cient dimension to prevent injury.<br />

Any possible adjustability of the bumper must not incorporate or expose sharp edges, protruding fasteners or other elements<br />

that present any danger of puncture-type injury.<br />

Final acceptance of any bumper’s acceptability with regards to safety lies with the event scrutineer.<br />

In an effort to encourage progressive designs in this arena, the USRMC and its designees reserve the right to evaluate for acceptance<br />

any rear bumper design presented. In this light, bumpers not meeting these exact criteria but satisfying the intent of<br />

application can be considered for acceptance with pre-event submission of design and specifi cations to the local scrutineers.<br />

Competitors/suppliers desiring evaluation of a non-conforming design are urged to consult local and/or national <strong>technical</strong> departments<br />

well in advance of the event in question. Commercial designs approved by the national <strong>technical</strong> department will be listed<br />

and posted on the website.<br />

MICROMAX CLASS SPECIFIC REGULATIONS<br />

All <strong>regulations</strong> previously described apply equally to the MicroMax class unless specifically excepted in this section.<br />

• Engine <strong>regulations</strong> per US Primer engine section and MicroMax specifi c rules from BRP-ROTAX at website http://www.maxchallenge-rotax.com/download/RMC-RMCGF_Technical_Regulations_2008_10012008_Mini_Micro.pdf<br />

• Carburetor jet selection limited to 112 to 132.<br />

• Chassis: Per US Primer MiniMax rules except maximum wheelbase is 950mm.<br />

14 presented by

CLASS STRUCTURE<br />

RULES AND CLASS STRUCTURE<br />

2008 USRMC Class Structure<br />

SECTION 1<br />

MICRO MAX Age 7-10 235 lbs. minimum<br />

Mandatory use of Rotax Micro Max package. Spec gear 14 x 73. 95cm chassis maximum. SFI Chest Protectors required,<br />

shoulder and rib protection recommended. This is a new class for 2008 and will not be included as a Grand Nationals class.<br />

Once a competitor moves up to Mini Max they cannot move back down unless mandated by a local race director.<br />

MINIMAX Age: 9-12 265 lbs. minimum<br />

Mandatory use of junior cylinder and restrictors as specifi ed by ROTAX, or other restrictors that may be required by the<br />

2008 USRMC Rules Primer. Spec gear would be optional at Race Director’s discretion. Chassis per 2008 USRMC Rules Primer.<br />

SFI, Chest Protectors mandatory, shoulder and rib protection recommended.<br />

JUNIOR* Age: 13-16 320 lbs. minimum<br />

Mandatory use of a junior cylinder without exhaust valve. Competitor must reach the age of 13 by October 31, 2008 (see<br />

note_1 below). No Junior class competitor may attain the actual age of 17-years-old prior to October 31, 2008. SFI approved<br />

Chest Protectors recommended.<br />

SENIOR MAX Age: 15 & up 365 lbs. minimum<br />

Competitor must reach the age of 15 by October 31, 2008.<br />

MASTER Age: 16 & up 405 lbs. minimum<br />

Offi cial Masters class age is 32 (32nd birthday must fall during 2008).<br />

Competitors of competition age less than 32-years-old (competition age) must reach the age of 16 by October 31, 2008<br />

and have a minimum driver weight of 190 pounds including all race apparel except helmet.<br />

DD-2 Age: 15 & up 385 lbs. minimum<br />

Competitor must reach the age of 15 by October 31, 2008<br />

Waivers to allow a competitor to move up in class (Mini Max to Junior only) will only be granted with proof of need and<br />

driver ability to compete at the higher level. Drivers granted waivers to move up will not be allowed to compete in the higher<br />

class at USRMC national level events. Once a competitor moves up in class he/she will no longer be eligible to compete in the<br />

lower class at any offi cial RMax event.<br />

It is recommended that all competitors participating in an OFFICIAL RMAX CHALLENGE SERIES EVENT be a<br />

current member of the US RMax Club. To compete at any USRMC National level event membership in the RMax Club is required.<br />

A driver can use his license to race and gain punches/Points at an Offi cial RMax Challenge race. It is the responsibility<br />

of the RMax Challenge Series Administrator to insure all competitors are encouraged to hold a valid RMax Club Membership.<br />

RMax Club Membership provides constant communication between members and Rotax offi cials.<br />

All competitors under the age of 18 must submit a copy of Birth Certifi cate or Passport with membership application. All<br />

ages are subject to verifi cation by public records and any discrepancies will be corrected before membership is granted.<br />

Membership application will not be approved until birth certifi cate, and/or, passport is received.<br />

2008 AGE REQUIREMENTS FOR USRMC CLASSES:<br />

MICRO MAX*<br />

MINI MAX*<br />

Participant must be 7 years old before competing in a offi cial RMax event.<br />

Participant must be have reached 8th birthday before competing in a local RMC event. To compete in<br />

2008 USRMC Grand Nationals 9th birthday must be prior to Sept 1, 2008 (DOB prior to 9-1-1999).<br />

JUNIOR** Participant must have his/her 13th birthday before October 31, 2008. He/she must have his/her 17th<br />

birthday after October 31, 2008. (See Note)<br />

NOTE: Rotax rules now state to be eligible for Junior class 13th birthday must be prior to October 31, 2007. This is the<br />

eligibility date for inclusion to the Rotax World Finals. We will follow past guideline of age as Dec 31, 2008 for inclusion in<br />

USRMC Junior Class. It must be understood that for those whose 13th birthday fall between October 31 and Dec 31 2008 there<br />

is no eligibility to be awarded a spot at the Rotax Grand Finals.<br />

SENIOR Participant must have his/her 15th birthday before October 31, 2008.<br />

MASTERS 32nd birthday must be prior to October 31, 2007 “or” 16th birth date must be prior to Oct 31, 2008 and<br />

Driver must be a minimum of 190lbs.<br />

* Micro Max and Mini Max competitors starting the season within the age guidelines may compete thru the date of<br />

the Grand Nationals in the respective class. Following the date of the Grand Nationals the Micro Max competitor must<br />

presented by<br />

15

SECTION 1<br />

RULES AND CLASS STRUCTURE<br />

move up to the Mini Max Class and the Mini Max competitor must move to the Junior class.<br />

CLASS STRUCTURE<br />

**Junior class age represents an overlap of eligible participation. Participants between the age of 15 and 16 have a choice<br />

of competing in Junior or Senior classes but once participation in the senior class is established competitor will no longer be<br />

able to compete as a Junior.<br />

Competition Age<br />

Competition age is defi ned as the age of the competitor on October 31, 20XX.<br />

LICENSE REQUIREMENTS<br />

All permanent and temporary residents of the US are eligible to hold US Rotax License/Membership. For participation in<br />

National Level events, i.e. US Grand Nationals, only US Citizens and Permanent Residents.<br />

Definition of permanent resident by the United States government;<br />

A non-U.S. citizen who has been given permission to make his or her permanent home in the United States. If you acquire<br />

permanent residence, you will be issued a green card to prove it. The terms permanent resident and “green card holder” mean<br />

exactly the same thing. You cannot be a permanent resident without a green card and you cannot have a green card without<br />

being a permanent resident. As a permanent resident, you may travel as much as you like, but your place of residence must<br />

be the United States and you must keep that residence on a permanent basis. If you leave the United States and stay away for<br />

more than a year, you risk losing your green card. A link to the website with the above defi nition can be found below.<br />

http://www.nolo.com/defi nition.cfm/term/3FC4D406-1B07-4120-B4B09A6824005E0E<br />

It is our goal to welcome everyone into the Rotax program. The spots available to the World Finals will be open to US Citizens<br />

and permanent residents only. We encourage all local and regional series to allow visitors working in our country to participate<br />

in their series whenever possible.<br />

ADDITIONAL REQUIREMENTS<br />

Kart Numbering: For any event the fi rst competitor to enter has the choice of numbers. Local and regional series may set<br />

up a system for securing numbers by competitors for their respective series. Approved numbers are 2 or 3 digits, letters are<br />

not recognized. USRMC reserves the right to assign numbers to competitors that do not provide acceptable numbers for their<br />

entry thru the normal registration process. It is not the responsibility of event organizers to supply the required numbers for<br />

any entry.<br />

Transponders: Each competitor is required to bring a transponder to each event. Transponder presentation will be considered<br />

part of Scrutineering. Transponder renting to racers will not be a responsibility of event organizers or the host track/club.<br />

It is the responsibility of the racer and his crew to insure the competitor’s transponder is charged and on the kart each time it<br />

enters the track during any offi cial portion of the event.<br />

Spec Gear Mini Max class: At events under the control of local or regional series directors, local offi cials will have the<br />

option of choosing a spec gear for their respective tracks. The recognized spec gear nationally is 13 x 82 with a local option<br />

of 12 x 76 (new for 2007). The offi cial National Spec Gear will remain 13 x 82 and this is the gear that will be assigned for the<br />

USRMC Grand Nationals.<br />

Spec Gear Micro Max class: At events under the control of local or regional series directors, local offi cials will have the<br />

option of choosing a spec gear for their respective tracks. The recognized spec gear nationally is 14 x 73<br />

2008 USRMC GRAND NATIONAL<br />

Each series will elect the procedure to qualify their members for participation in the 2008 U.S. Rotax Max Challenge Grand<br />

Nationals. All competitors qualifying thru their respective series will be given 5 days to register to secure their spots. Following<br />

this cutoff date registration will be opened to all competitors who have competed in a minimum of 3 local series races prior to<br />

August 10, 2008. Registration will remain open until the class cap is reached or the cutoff date occurs.<br />

Member selection for the Mazda 2009 US Grand Finals Team will be announced once allocations are received from Rotax-<br />

Austria.<br />

The Official 2009 Rotax Season will start October 1, 2008.<br />

Local series may elect to schedule races following this date to start the qualifying procedure for the 2009 USRMC Grand<br />

Nationals.<br />

16 presented by

LOGO PLACEMENT<br />

RULES AND CLASS STRUCTURE<br />

2008 USRMC Logo Placement<br />

SECTION 1<br />

A total of 6 logos will be required for placement on all competitors’ karts competing as a 2008 Rotax License holder in all<br />

offi cial Champ Car Rotax Kart Challenge events during the 2008 competition year.<br />

• Official US Rotax Kart Challenge Presented by Mazda Logo (1) placed near the meeting of the front steering fairing<br />

and the nose cone.<br />

• Official NKN logo placed above the location for the National Class Sponsor Logo.<br />

• When there is a class sponsor the US Rotax Kart Challenge logo will be required on the nose cone with the class sponsor<br />

logo on the steering fairing above.<br />

* 2007-2008 Senior Max Class sponsor is Mazda. This logo will be forwarded to all Senior Max Class members.<br />

NKN logo<br />

National Class Sponsor<br />

ROTAX MAX CHALLENGE<br />

presented by<br />

The Rotax and MoJo logos are to be placed 1 on each side pod; Location is free<br />

• Rotax Logo<br />

(Side Pod)<br />

• Mojo Tire Logo<br />

(Side Pod)<br />

• National Kart News Logo<br />

(Front Fairing)<br />

Additional national class sponsor logos may be required at some time during the year. Each competitor will receive 1 set<br />

of required decals as part of the membership package. Additional decals needed by competitors will be provided at a nominal<br />

cost.<br />

presented by<br />

17

SECTION 1<br />

RULES AND CLASS STRUCTURE<br />

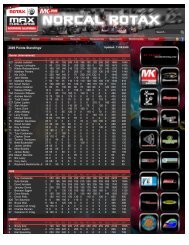

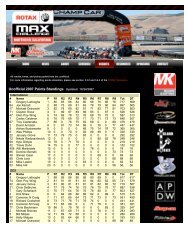

FINAL POINTS<br />

Final points are based<br />

on chart below and class<br />

participation weighting<br />

chart to the right<br />

Finishing<br />

Position<br />

Points<br />

1 200<br />

2 175<br />

3 155<br />

4 140<br />

5 130<br />

6 120<br />

7 110<br />

8 100<br />

9 90<br />

10 80<br />

11 75<br />

12 70<br />

13 65<br />

14 60<br />

15 55<br />

16 50<br />

17 45<br />

18 40<br />

19 35<br />

20 30<br />

21 27<br />

22 24<br />

23 21<br />

24 18<br />

25 15<br />

26 12<br />

27 10<br />

28 9<br />

29 8<br />

30 7<br />

31 6<br />

32 5<br />

33 4<br />

34 3<br />

35 2<br />

36 1<br />

USRMC National Points Structure<br />

EXAMPLE:<br />

Points Finish<br />

1 226 1<br />

2 201 2<br />

3 181 3<br />

4 166 4<br />

5 156 5<br />

6 DQ DQ<br />

7 146 6<br />

8 136 7<br />

9 126 8<br />

10 116 9<br />

11 106 10<br />

12 101 11<br />

13 96 12<br />

14 91 13<br />

15 86 14<br />

16 81 15<br />

17 76 16<br />

18 71 17<br />

19 46 DNS<br />

20 46 DNS<br />

21 DQ DQ<br />

Points are assigned for the finishing order of<br />

the feature only.<br />

National Points will be awarded based on a system weighted for<br />

number of registered members participating in a class. Points<br />

will be awarded using the Points Chart and the points weighting<br />

chart. No points will be awarded for Pre-Final. Final race is only<br />

points earned.<br />

Class Size Multiplier Plus Pts Bonus Pts<br />

1-4 0.75 0 0<br />

5 0.8 Class # 0<br />

6 0.85 Class # 0<br />

7 0.9 Class # 0<br />

8 0.95 Class # 0<br />

9 0.975 Class # 0<br />

10-19 1 Class # 0<br />

20-36 1 Class # 5<br />

EXAMPLES:<br />

POINTS STRUCTURE<br />

Revised Sept 4, 2007<br />

Class Size: 5 racers<br />

1st 200<br />

165<br />

2nd 175 x .8 145<br />

plus 5”<br />

3rd 155 129<br />

Class Size: 13 racers<br />

1st 200 213<br />

2nd 175 plus 13 188<br />

10th 80 93<br />

DNF<br />

Class Size: 21 racers<br />

1st 200 226<br />

A DNF will receive credit for the number<br />

plus 21<br />

of laps completed.<br />

2nd 175 plus 5 201<br />

10th 80<br />

106<br />

DNS<br />

A DNS will receive last place points. If<br />

more than one entry is a DNS then each<br />

21st 26 52<br />

will receive the same last place points. No bonus points will be added.<br />

DQ<br />

All DQs will receive 0 points. A DQ may be used as a drop except for Non Sportsmanlike conduct<br />

Dis-qualifi cation. This is at the descretion of the event Race Director or Tech Director.<br />

National points standings will be based on the best 6 races for each competitor. It is the responsibility of series administrators to submit<br />

all results on the offi cial report form within 5 days fo the event. Racers may elect to count 1 race from another series or multiple series<br />

race in their national points totals. They must be listed on the race report for this race to count.<br />

Questions concerning the reporting and recording of USRMC National Points should be directed to the Marshall Martin, National Race<br />

Director and Membership/Series administrator.<br />

Multiple Series Race<br />

In races where more than one series is competing each racer should receive fi nishing position in relation to other members of their<br />

series. Bonus points for each racer should be awarded based on total of racers from all series.<br />

18 presented by

SECTION 2<br />

NATIONAL<br />

EVENT<br />

PROCEDURES SECTION 2<br />

presented by<br />

presented by<br />

19

SECTION 2<br />

NATIONAL EVENT PROCEDURES<br />

REGISTRATION<br />

Items you will receive at registration;<br />

• Registration packet, including tire, fuel and oil vouchers.<br />

• Event information and schedules. Each day will have a set schedule. Your packet will include the schedule for practice and<br />

qualifying. Schedules for the heats, LCQs, Pre-Finals and Finals may not be available until the day of each of these sessions.<br />

If this is the case they will be available at the gate when you arrive or at the registration area each day.<br />

• Additional items each competitor is to receive as part of the event package.<br />

SCRUTINEERING PROCESS DEFINED<br />

Note: Those of you familiar with my rules writing style will note the profuse usage of words in this document like ‘should’,<br />

‘may’, ‘sometimes’, ‘generally’ and similar “soft” words. This should be the fi rst clue that this document is not an offi cial rules<br />

document, rather an informal explanation for the benefi t of our constituents.<br />

–Scott G Evans - National Technical Director<br />

U.S. Rotax Max Challenge<br />

The scrutineering (<strong>technical</strong> inspection) process at a kart race can vary widely depending on the organizer but they always<br />

have the following similarities: Before the event starts - You must get the kart, engine and safety gear inspected and/or recorded<br />

and during the event - Your kart is subject to some level of scrutineering requirements every time you enter or leave<br />

the track.<br />

Before the event, you must have your kart and gear inspected by the event scrutineer(s). This element is also known as<br />

“pre-tech”. The inspectors will check for safety and eligibility of your kart and gear, possibly recording seal numbers or serial<br />

numbers depending on the requirements. You should be very familiar with all of the rules before you bring your kart up for<br />

inspection. Your kart should be well-maintained and clean, bolts and nuts checked for security and weight ballast securely<br />

mounted per the series’ rules. Numbers should be on the kart, scoring transponder charged and installed in case operation<br />

or location will be verifi ed.<br />

Bring your safety gear to pre-tech. Requirements vary with respect to validity of helmets ratings, suits, neck collars, boots<br />

and gloves. Know the series requirements and make sure any certifi cation tags are visible and in good shape. An inspector<br />

accepts some - at minimum, moral - liability when knowingly allowing a sub-standard, i.e. expired, piece of safety gear, so<br />

don’t put him in that position.<br />

Many times, the inspectors may have some comments about your kart and its condition. Sometimes, the problem is serious<br />

enough to require your immediate attention before proceeding. Remember that any issues found at this time in this process<br />

are better than fi nding them later, so try to keep a positive attitude and cooperate with the scrutes.<br />

The inspectors may “tag” your kart with an identifying band or label to make it apparent that you have passed inspection,<br />

assigned to a group, or to provide traceability. Sometimes, the process of pre-event scrutineering signifi es your status of being<br />

under offi cial race control and has implications on chassis, tire and engine usage or other elements of protocol you should be<br />

aware of. Most of the time, it means - having passed this phase - you are ready to take the track.<br />

During the event, there is usually a session of “free practice” where you are allowed on track to test and make adjustments.<br />

As the name implies, you have the freedom from scrutiny here to the extent that weighing in at scales is not normally required,<br />

your engine will not generally be inspected during this time and the control of tires and fuel is not likely. You do have the obligation<br />

to keep your kart safe and use the prescribed safety gear, but if you see a scrutineer during free practice it is probably<br />

for reasons other than inspection. He will be around for that later.<br />

Nevertheless, many times the inspectors will “cruise” the grid or otherwise monitor activities during free practice. Do not<br />

despair however, if a grim-looking man is holding his chin and staring at your kart. Most likely he has discovered an anomaly<br />

on your kart that requires some attention. This is proactive inspection and you should be very glad to see him at this time.<br />

Again, it is much better to catch issues at this early stage. You may however complain that if your kart passed inspection<br />

earlier, why the problem now<br />

Please understand the daunting job it is to inspect the dozens, even hundreds of karts during a pre-event inspection process.<br />

It is impossible to catch every anomaly and besides, pre-tech is focused on safety and data recording and the scrute may<br />

want to discuss some other performance-related area or even offer advice on some rule that you need to know. Again, keep<br />

a positive attitude and cooperate with the scrutes.<br />

Once qualifying begins, your attention to the scrutineering process will be greater and remain so throughout the event. Once<br />

you enter the gate to the grid you are under scrutineering control and must submit to their requests to dismount, disassemble<br />

or otherwise undergo testing to determine your continued eligibility. Most testing done prior to taking the track is non-invasive<br />

such as quick fuel tests, clutch testing or overall width of your chassis. These pre-element tests are done to ensure fair play<br />

and avoid post-event exclusions.<br />

Upon exit from the track, you are generally required to scale yourself and your kart to make sure your minimum weight is<br />

as prescribed. This usually involves proceeding through a queue with your other competitors while the weight is checked and<br />

recorded on every kart. In this line, you will likely see another (!) scrutineer, visually making verifi cations while you wait for<br />

scales. He may ask you to remove your fuel cap or submit to some other test. He may mark or seal key components of your<br />

engine, requiring this component to remain in use and with all results subject to a possible later inspection of the component.<br />

But wait, your inspection experience may not yet be done!<br />

20 presented by

NATIONAL EVENT PROCEDURES SECTION 2<br />

After you clear the scales, you must be “invited” to leave the scrutineering area. Usually, the top fi nishers of that<br />

session are invited to stay for post-element inspections, above and beyond what may have already transpired. Make<br />

sure you know what your status is with the scrutes before you leave. Random choices are sometimes made so be<br />

sure before you leave. The best person to ask is usually the scale attendant. Almost without exception, leaving the<br />

controlled area without permission exposes you to penalty.<br />

If you are lucky enough to be invited to stay, most likely you will be required to dismount the kart, put it up on your<br />

stand and undergo further testing or measuring with the inspectors. You are required to disassemble anything at<br />

their request. Refusal usually results in exclusion or disqualifi cation from that element and is generally viewed as an<br />

admission of guilt.<br />

So, you ask, if I am disassembling my kart during the event, how do I get it back together Short and sweet, this is<br />

your responsibility and the scrutes have no liability here. The standard operating procedure is to keep daily inspections<br />

to an acceptable level without causing undue inconvenience on the competitor. Except in extreme cases, you should<br />

not expect to have to remove your crankshaft fi rst thing in the morning. You should expect to remove and disassemble<br />

your carburetor, exhaust, ignition, intake silencers, spark plugs, wheel hubs, brakes amongst others. You may have<br />

to undergo further fuel or tire testing. It is your responsibility for all disassembly and your readiness to do so speeds<br />

the process. A simple tool bag carried on your kart stand will suffi ce most of the time in post-tech. Lack of any tools<br />

causes delays, frustration and congestion. Be prepared. Karts are pretty easy to work on and the scrute will often offer<br />

his help or advice if you get stuck.<br />

When the inspections are completed, you will hopefully get the news that all is conforming. You will then be invited to<br />

leave the controlled area and proceed to the next step of exit, whether it be checking in of your tires or fuel or simply<br />

exit to the paddock. Either way, you have passed inspections and you should be smiling.<br />

If the news is something more negative, it means that the scrutes have found something that is not conforming<br />

to the rules. They will explain to you the concerns they have, show you the rule as required and inform you of their<br />

intent. Most times, this involves some sort of penalty assessed to you for that particular session. Technical violations<br />

are usually dealt exclusions or disqualifi cations wherein you would be assessed that penalty in offi cial results. The<br />

implications for your event success can vary with event structure and depending on the session when the violation<br />

was discovered.<br />

You are subject to this inspection process every time you enter and exit the track. Your results may vary, but with<br />

good preparation and rules knowledge, your scrutineering experience will be fi lled with handshakes and smiling<br />

congratulations. Without that prep, well, that grim-looking man may have something else to say…<br />

TECHNICAL NEWSFLASH ENGINE SEAL/CHASSIS PROCEDURE NATIONAL EVENT March 16, 2006<br />

It has come to our attention that some clarity needs to be applied to the issue of chassis and engine use protocol at<br />

offi cial Challenge events. The following newsfl ash is designed to provide that clarity.<br />

Regarding the amount of equipment allowed for any Challenge event, each competitor is limited to one chassis and<br />

two engines. In initial scrutineering, a tamper-evident designation shall be placed on the chassis and it is only this<br />

chassis that is permissible for use beginning with practice through the end of the race event. The identifi cation of the<br />

chassis is recorded and associated with the competitor.<br />

In case of irreparable chassis damage due to accident, the chassis may be replaced with permission of the event<br />

scrutineer and/or race director providing the damage is assessed and determined to be indeed irreparable. For local<br />

Challenge events, the chassis may be replaced with any legal chassis.<br />

For Grand Regional and Grand National events, the damaged chassis may be replaced ONLY with models of the same<br />

manufacturer as the originally scrutineered chassis.<br />

Regarding engines, in initial scrutineering it is required that the USA-origin engine passport be presented for each<br />

engine desired. The engine(s) must be sealed at the time of presentation and the seal numbers and serial numbers<br />

of the engines must match the entries on the engine passport. The engine sealing must have been performed by an<br />

authorized USA sealing agent. Non-United States sourced engines or seals are not to be accepted without prior approval<br />

from ROTAX National Administration.<br />

Engine seal numbers are recorded and associated with the competitor in initial scrutineering.<br />

All engines are to remain sealed for the entirety of the event. Should internal engine service be required, necessitating<br />

the destruction of the seal, the engine must be submitted to the event scrutineer for any possible <strong>technical</strong><br />

checks that he deems necessary prior to or after breaking of the seal. As a minimum, squish gap conformity must be<br />

inspected. The scrutineer has the right to be witness to the engine service and is responsible to record the newly-applied<br />

seal number after service is complete.<br />

Should any non-conformances be identifi ed during the servicing process, the competitor is subject to exclusion from<br />

all previous results up to that point in the event.<br />

It is recommended that if two engines are to be declared for the event, that this declaration occur during the initial<br />

scrutineering process. It is however permissible for a competitor that has declared a single engine only in initial<br />

scrutineering to introduce a second engine during the event with notifi cation to the scrutineer. It is never possible to<br />

introduce a third engine regardless of circumstances.<br />

It is permissible for multiple competitors to declare a single engine as a backup engine. In this case however, once<br />

the engine is used by any one of the multiple competitors, it is no longer available to the others. This multiple-use<br />

presented by<br />

21

SECTION 2<br />

NATIONAL EVENT PROCEDURES<br />

notifi cation must be made to the scrutineer at the time of engine declaration. Notifi cation that the backup engine is in use must<br />

be made to the scrutineer by the competitor that is using it. At that time the engine number will be removed from the other<br />

competitors’ documentation. If any of the multiple competitors declaring the backup engine is found to be in use of it prior to<br />

this notifi cation, he is subject to penalty up to and including exclusion from prior results.<br />

Random verifi cations that engines and chassis matching the scrutineering documents shall be performed during the course<br />

of the event. Should any non-conformances be identifi ed during this process, the competitor is subject to exclusion from all<br />

previous results up to that point in the event.<br />

–Scott G Evans - National Technical Director<br />

U.S. Rotax Max Challenge<br />

PARC FERME PROCEDURES<br />

RULES FOR PARC FERME CHECK IN<br />

The following is a set of rules to help introduce you to the ins and outs of Parc Ferme, though it may contain some rules within,<br />

this is merely a summary of such rules an will not be referred to as part of the U.S. Rotax Max Challenge rule book.<br />

Parc Ferme, loosely translated to English, means closed area, which is exactly what it is. Parc Ferme is a servicing and storage<br />

area for your offi cial event fuel and tires, with limited access only to approved or invited competitors. Parc Ferme, also<br />

referred to as a servicing compound, servicing parks, impound area, or assembly/disassembly area, is composed of a fenced<br />

in area, a building, or combination of both which will store and protect the integrity of the competitor’s fuel and tires. Once<br />

introduced to Parc Ferme, a competitor’s fuel and tires may not leave the designated area. Should a competitor’s fuel or tires<br />

leave the area they would not be able to reintroduce said equipment. It will save you money and a fair amount of aggravation<br />

if you commit this to memory and ask yourself each time you head toward the exit of Parc Ferme “Did I return everything I<br />

need to Parc Ferme”<br />

Parc Ferme preparation starts at home. To make you life simpler, make sure you have a spare fuel jug and tank for your kart.<br />

The fuel and tank will be stored within Parc Ferme for the duration of the weekend. You will need a separate practice fuel jug<br />

and tank.<br />

LABEL EVERYTING!!!!! This cannot be stressed enough. Label everything you introduce to Parc Ferme. Your fuel jugs, fuel<br />

tank, wheels, mixing containers and rain tires. Label your gear permanently and as large as possible. the offi cials and Parc<br />

Ferme attendants are there to house and secure your race equipment, but it is ultimately the competitor’s responsibility to<br />

make sure his/her equipment is labeled properly. Never leave anything unattended in Parc Ferme. Though your day may be<br />

hectic and chaotic and you think you have more important things to be doing, always wait until you watch the Parc Ferme<br />

attendant place your equipment back in its proper place. Each competitor has a specifi c storage space that will not change<br />

during the course of the weekend. When you fi rst check in your equipment, watch where the attendants place your tires and<br />

fuel. It is the attendant’s job to store your equipment, but it is your responsibility to make sure that it is labeled and accessible<br />

for each segment of the race weekend. Again, LABEL EVERYTHING!!!!<br />

A day will be designated as the equipment introduction day. This day is usually the day of practice, before qualifying starts.<br />

The times for this process will be offi cially posted on the schedule for the race weekend. Don not fret, checking in is simple.<br />

Bring an empty fuel jug, tickets for tires, oil and fuel, and ALL of the rain tires you wish to use for the entire race event, to the<br />

offi cials at the Parc Ferme check-in entrance. You also must have your credentials for the corresponding driver you wish to<br />

check-in. At all times, no access will be granted to anyone who does not have proper identifi cation and equipment will only<br />

be issued through a visual inspection of credentials by attendants. With credentials, tickets, empty inspected fuel jug and rain<br />

tires for the weekend in hand, you will head to Parc Ferme to procure your oil, fuel, and slick tires. The attendants will log in<br />

your fuel, oil, and tires and store it. As per the Rotax Kart Challenge rule book, your rain tires must be in wrappers or have the<br />

nubs to indicate they are new. Wrapped rain tires will then be logged in with the attendants and stored. You have no successfully<br />

fulfi lled all of your Parc Ferme requirements. Mounting of tires and mixing of fuel is performed at you’re discretion and is<br />

not part of the scheduled time constraints of Parc Ferme. Parc Ferme is open from scheduled opening time to the designated<br />

deadline and the attendants and offi cials will help log in any competitor in nay class during this window. It would be to your<br />

advantage to take care of it early in the day so that it is done and you are not standing in line with the rest of the competitors<br />

that put it off until the last minute.<br />

This is just a summary of what is required for your Parc Ferme check-in and hopefully answers all of your questions about<br />

how the check-in process works. If you have nay further questions or concerns, offi cials at the track will gladly help.<br />

PARC FERME RULES FOR RACE EVENTS<br />

Now that you have labeled, checked-in and stored your equipment it is time to retrieve your gear and for racing. The following<br />

rules allow you to properly enter and exit Parc Ferme during the race event. Again a simple disclaimer, this is a summarize<br />

guideline. It is the competitor’s responsibility to acquire any additional documents made available to Rotax participants. These<br />

additional documents may contain supplements to the rules and clarifi cations.<br />

Kart Presentation to Parc Ferme Entrance<br />

• Both the driver and mechanic must have proper credentials corresponding with the kart number being introduced.<br />

• Fuel <strong>Line</strong>s must be drained. If reporting with the tank on the kart the tank must be completely empty.<br />

- Parc Ferme Offi cials will inspect driver/mechanic credentials, kart, and toll boxes prior to admittance to assembly area. No<br />

22 presented by

PRACTICE<br />

BRIEFING<br />

NATIONAL EVENT PROCEDURES SECTION 2<br />

fl uids or loose weights are permitted within the confi nes of Parc Ferme, with the exception of beverages which<br />

we make you prove by drinking in out witness. Any allowed beverages MUST be consumed or disposed of prior to<br />

release from Parc Ferme to pre-grid.<br />

After inspection, you will be directed to an area to place your kart in order to assemble for racing. With credentials in<br />

hand for visual inspection by attendants, you will head for the issuing table. The attendant will inspect your credentials<br />

and retrieve the equipment you request. Once you have assembled and fueled your kart, return your fuel jug to the<br />

issuing table for storage. Next, wait until an offi cial release you to the pre-grid. During this time you should make sure<br />

that you have everything you will need to compete in the on track race segment. Once released from the assembly<br />

area of the Parc Ferme to the pre-grid, there is no way to exit the area and return. If a driver or mechanic leaves the<br />

pre-grid area, he/she will not be allowed to return. No additional parts or tools may be introduced to the pre-grid area,<br />

so before you leave the assembly area of Parc Ferme, make sure you have everything you need.<br />

Having completed the on track segment, crossed the scales, and fulfi lled any post race <strong>technical</strong> inspection you<br />

will immediately proceed to the disassembly area. In the disassembly area you will remove tires and fuel tank and<br />

return them to the Return Table. DO not just drop your equipment and walk away, stay with your tires and fuel until<br />

the attendant picks them up to place them in the storage area. You should also check your tires and fuel tank to make<br />

sure that all are still properly marked before handing them over to the attendant. If a mark or marks are missing the<br />

attendant will remark or label equipment under your supervision. With all competition tires and fuel properly stored<br />

with Parc Ferme attendants, you may now return to your paddock and get ready for the next segment. This procedure<br />

will repeat itself for each race session.<br />

Practice sessions are not under Parc Ferme requirements and therefore no fuel or tires will be issue for use during<br />

morning warm ups on race days.<br />

At Scrutineering a sticker was placed on the steering fairing of your kart. This sticker indicates your class and practice<br />

group. Practice times for your group are listed on the offi cial schedule for the day.<br />

You may only practice with your designated group. If for any reason you feel a change to another group is needed<br />

this request must be made to the Grid Marshall, the Grid Marshall is the only person that may grant a change to your<br />

practice group.<br />

While on the track, all fl ags will be obeyed, the same as under race conditions. No driver may cut the track or drive in<br />

the reverse direction of normal traffi c fl ow unless directed by a track offi cial. Failure to comply will mean forfeiture of<br />

this practice session and possible forfeiture of additional practice sessions as dictated by Event Offi cials.<br />

Hot pitting will only be allowed during practice sessions specifi cally designated as hot pit practice sessions. If the<br />

driver exits the track for any reason his practice session is considered to be fi nished. A driver may pull into a safe area<br />

to inspect his kart but no mechanic is allowed. If a mechanic touches the kart for any reason the driver’s session is<br />

done.<br />

The last practice session will be considered a Hot Pit session and a Hot Pit area will be designated. All hot pit practice<br />

sessions are under the same controls as offi cial qualifying sessions. Make sure the driver and mechanic have all parts<br />

and tools needed before entering the Hot Pit area. Once the mechanic has entered this area he may not leave until<br />

he considers his driver fi nished. The mechanic may not leave and re-enter the Hot Pit area nor may tools or parts be<br />

entered by other persons. A driver may pull in and with the help of his mechanic make changes to his kart or engine.<br />

All parts taken into the hot pit area, removed from the engine or kart are subject to inspection and/or impound at any<br />

time.<br />

Once qualifying has started no additional practice sessions will be offered. There may be a morning warm up prior<br />

to each day’s offi cial sessions. These are conducted under practice rules. Offi cial tires and fuel from Parc Ferme may<br />

not be used for these sessions. If you do not have other tires and rims you will not be allowed to participate. If you do<br />

not have an extra fuel tank check with Parc Ferme Director for the procedure you will need to follow allowing you to<br />

use your fuel tank for morning warm-ups and then re-enter the fuel tank into Parc Ferme.<br />

The last offi cial practice session will be used to determine qualifying groups. Once this practice session has completed<br />

you should remove your practice sticker because morning warm up groups will be determined by the days<br />

scheduled events. See the daily schedule to determine your morning warm up time if it is offered.<br />

A) Defi nition: The Entrants’ and Drivers’ Briefi ng is a meeting organised by the Race DIrector for all Mechanics and<br />

Drivers entered in the Event.<br />

B) Aim of the Briefi ng: to remind Entrants and Drivers of the specifi c points of the Supplementary Regulations concerning<br />

the organisation of the Event; to remind them of the safety notions, either general, or specifi c to the circuit<br />

used; to give any clarifi cation concerning the interpretation of the Regulations.<br />

C) The time of the Briefi ng is mentioned in the program of the Event. The time is considered as that of the beginning<br />

of the Briefi ng and the entrance door and access to the Briefi ng will be closed. The meeting shall always be held before<br />

Qualifying Practice or the fi rst Qualifying Heat. Extra meetings may be organised if this is deemed necessary.<br />

D) The presence of all concerned Mechanics and Drivers is mandatory throughout the Briefi ng under pain of a sanction<br />

or even of a possible exclusion from the Event. Two Attendance Sheets shall be signed, one by Drivers and the<br />

presented by<br />

23

SECTION 2<br />

NATIONAL EVENT PROCEDURES<br />

other by Mechanics.<br />

E) Before they can be allowed to continue the event, a mandatory fi ne of US $50.00 which must be paid to the Event Organizer<br />

(USRMC) hosting the event via the Race Offi cials will be infl icted on any Mechanic and Driver who do not attend the Briefi ng.<br />

QUALIFYING-LAST CHANCE RACE<br />

Following the last offi cial practice qualifying groups will be set. Classes will be divided into equal sizes and the slowest qualifying<br />

group will compete fi rst during each classes qualifying period.<br />

Following qualifying drivers will be listed per qualifying times with the fastest at the top. Starting grids for heat races will be<br />

determined based on class size;<br />

For classes with 36 or less the starting grid will be set for each of the 3 heats based on qualifying times. The Starting grid for<br />

each of the 3 heats will be the same.<br />

For classes with 37-72 entries, 4 grids will be set with a maximum of 18 in each grid. From the qualifying order the grids will<br />

be set using the qualifying positions as outlined below;<br />

Grid A B C D<br />

Qualifying Position 1 2 3 4<br />

5 6 7 8<br />

9 10 11 12<br />

13 14 15 16<br />

17 18 19 20<br />

21 22 23 24<br />

25 26 27 28<br />

29 30 31 32<br />

33 34 35 36<br />

37 38 39 40<br />

41 42 43 44<br />

45 46 47 48<br />

49 50 51 52<br />

53 54 55 56<br />

57 58 59 60<br />

61 62 63 64<br />

65 66 67 68<br />

69 70 71 72<br />

For classes with more than 72 entries a procedure outlined by CIK will be set.<br />

1st 0 6th 6 11th 11 16th 16<br />

2nd 2 7th 7 12th 12 17th 17<br />

3rd 3 8th 8 13th 13 18th 18<br />

4th 4 9th 9 14th 14<br />

5th 5 10th 10 15th 15<br />

The points are totaled for each competitor, the lowest 28 in points will transfer directly to the Pre-Final. Those fi nishing in<br />

point total positions 29-64 will compete in a 20km Last Chance Race with the top 6 fi nishers transferring to the Pre-Final in<br />

positions 29-34 based on their fi nishing positions in the LCR. Those fi nishing with points totals from 65th and lower will have<br />

completed their competition.<br />

In the event of ties for points qualifying times will be the tie breaker. In the case where qualifying times are equal best fi nishes<br />

will then become the tie breaker.<br />

STARTING PROCEDURE<br />

Each grid/class will be lined up in order on the grid. IF A COMPETITOR DOES NOT ARRIVE IN TIME OR DROPS OUT, THIS SPOT<br />

MUST BE LEFT OPEN ON THE FORMATION LAP UNTIL THE FORMATION FLAGS HAVE BEEN PASSED. Once past the formation<br />

fl ags open spots should be fi lled by each competitor in the line moving up. Each group will leave the grid for 2 warm up laps.<br />

The fi rst lap is to done at 75% of race speed. Once each competitor crosses the start fi nish line the group should form up. If<br />

a pace car is used it will pickup the grid at some point passed the start fi nish line on the formation lap. At approximately the<br />

3/4 point of the formation lap yellow fl ags (formation fl ags) on each side of the track will indicate the end of formation line. If<br />

anything occurs causing the competitor to fall behind the fi eld, competitor has until they reach the formation fl ags to regain<br />

their position. If not into their starting position by the formation fl ags competitor should move into a position corresponding to<br />

24 presented by

NATIONAL EVENT PROCEDURES SECTION 2<br />

their location in the fi eld at the point of the formation fl ags. At no time may a competitor use a short cut to catch up to<br />

the fi eld. Using a short cut will result in a time penalty equal to 1 lap.<br />

The fi eld will proceed at a speed dictated by a pace vehicle if one is on track. If no pace vehicle is used the speed<br />

should be slightly less than half speed, the leaders should use their Tachometer to determine this with 6,000 RPM<br />

being the ideal speed.<br />

If a Driver stops for any reason during the Formation Lap, he will not be allowed to try and start again before he has<br />

been passed by the whole fi eld. He shall start again from the back of the formation. Should he try to start ahead of<br />

the fi eld in the hope that the leading drivers overtake him, he would be shown the black fl ag and be excluded from<br />

that race.<br />

Driver who is delayed will have the possibility of regaining his grid position only if this manoeuvre does not impede<br />

other Drivers and in all cases before having reached the End of Formation Cones on the formation lap which will is<br />

indicated by 2 cones with Yellow Flags on each side of the track and location shown by the Race Director at the<br />

Briefi ng.<br />

The difference in the 2 paragraphs above are 1. “If a driver stops” i.e. chain falls off and driver stops to put chain<br />

back on. 2. “Driver is delayed” driver(s) spin or go off track during the hot lap.<br />

If he (Race Director) considers that a Driver has been immobilized as a result of another Driver’s mistake, the Race<br />

Director may stop the formation lap and start again the starting procedure on the basis of the original grid or allow the<br />

impeded Driver to regain his position.<br />

In the case of repeated false starts or incidents during the Formation Lap(s), the Race Offi cials may issue penalties to<br />

offending drivers that will be added to drivers total time at the end of the race. This penalty may be a time or position<br />

penalty.<br />

Any attempts to jump the start or delay it shall be sanctioned. Penalty(s) will be assessed by time upon the fi nish of<br />

the Heat/Race.<br />

As soon as the start has been given, racing conditions are applied and, irrelevant of the position of a kart on the track,<br />

it is forbidden to give it any assistance, except for moving it to a safe location. This restriction does not apply to the<br />

Mini Max class. Race Offi cials may help a Mini Max driver move his/her vehicle into a position to allow safe entrance<br />

back onto the racing surface.<br />

ACCELERATION ON STARTS<br />

Cones will be placed on each side of the track at a point approximately 25 meters before the start fi nish line. Cones<br />

will also be placed in the center of the track separating the two starting lines. This is the acceleration point for the<br />

competitors. It is the responsibility of the Pole position to set the pace and the responsibility of the off pole to remain<br />

with the pole driver without lagging or jumping. Both front row drivers should accelerate at the same time with drivers<br />

in rows following the front row accelerating at the same time. The green fl ag will be displayed by the Head Flag Man at<br />

some point after the acceleration cones. If the Race Director or the Head Flag Man calls for an aborted start the Head<br />

Flag Man will turn away from the starting fi eld and walk away from the track, at which time all competitors should<br />

raise their hand indicating a waved off start. All Corner Marshals will immediately display yellow fl ags. At this time<br />

the group needs to re form into the starting grid. Any driver who did not get into their starting position by the formation<br />

cones must remain where they are at, they may not attempt to move into their original starting position. If there<br />

has been an aborted start one more opportunity will be given for a correct start. If the start is aborted a second time<br />

offending drivers will be penalized on the fi nish of the race. Drivers found to be ahead of scheduled starting position<br />

will be penalized the number of positions gained plus 3. This does not apply if the line advances to fi ll a missing spot<br />

once passed the formation cones on the formation lap.<br />

No competitor may break formation until the green fl ag is displayed by the Head Flag Man, and the last cone placed<br />

in the center of the track is passed. A move out of formation prior to the Green Flag being given or passing the last<br />

cone in the center of the track will result in a minimum 15 second penalty for each offending driver(s). This penalty<br />

will be assessed at the end of the race.<br />

DRIVING INFRACTIONS<br />

HEATS<br />

A rolled black fl ag with an accompanying driver’s number on a display board will be a warning for a driving infraction.<br />

Penalties for driving infractions may be assessed with or without warning. Penalties will be assessed as a time penalty<br />

or a position penalty and applied at the end of the race. There is no maximum as to the amount of time a competitor<br />

may be assessed for a penalty.<br />

A waved Black Flag indicates the driver needs to exit the track, in a safe manner, the next time the driver comes to<br />

the track exit. The kart number will also be displayed at the start/fi nish line on a display board. Failure to exit the track,<br />

in a safe manner, may result in additional penalties.<br />

Each class will compete in 3 heats based on the qualifying positions. Heats will be 8-12 laps determined by Race Offi<br />

cials, based on the length of the track. Starting grids and points assignments for fi nishing positions will be assigned<br />

as outlined below. (Three heats will be for classes with 80 competitors or less. For classes with 81 or more competitors<br />

the number of heats will change based on the heat system used per CIK rules.<br />

presented by<br />

25

SECTION 2<br />

NATIONAL EVENT PROCEDURES<br />

Each competitor will be given points based on their fi nishing position in each of the heats. Points are assigned as follows;<br />

1st 0 6th 6 11th 11 16th 16<br />

2nd 2 7th 7 12th 12 17th 17<br />

3rd 3 8th 8 13th 13 18th 18<br />

4th 4 9th 9 14th 14<br />

5th 5 10th 10 15th 15<br />

PRE-FINALS<br />

FINALS<br />

The points are totaled for each competitor; the lowest 28 in points will transfer directly to the Pre-Final. Those fi nishing in<br />

point total positions 29-64 will compete in a 20km Last Chance Race with the top 6 fi nishers transferring to the Pre-Final in<br />

positions 29-34 based on their fi nishing positions in the LCR. Those fi nishing with points totals from 65th and lower will have<br />

completed their competition.<br />

In the event of ties for points qualifying times will be the tie breaker. In the case where qualifying times are equal best fi nishes<br />

will then become the tie breaker.<br />

Pre-Finals will be 20km in length as specifi ed in the CIK Specifi c Prescriptions. This will apply to all classes except Mini Max<br />

which will be 15km. The starting line up for the Pre-Final will be as outlined in the section on Heats above. The fi nishing order<br />

of the Pr-Final will determine the starting order of the Final.<br />

The starting order of the Final will be set as the fi nishing order of the Pre-Final. The length will be 30km for all classes except<br />

Mini Max which will be 20km. The winner of the Final will be awarded the title of U.S. Rotax Max Challenge Champion for the<br />

specifi c class for the year.<br />

All fi nishes of each qualifying, heat, LCR, Pre-Final and Final are unoffi cial until post race <strong>technical</strong> inspections are completed.<br />

RED FLAGS AND RESTARTS<br />

PROTESTS:<br />

When <strong>Red</strong> Flags are displayed by Corner Marshals and Race Offi cials all competitors should slow down and raise their hand<br />

high indicating they have seen the <strong>Red</strong> Flag signals. Competitors should proceed to a point on the track indicated during the<br />

Driver’s Briefi ng and wait for instructions from Race Offi cials.<br />

If a heat/race is red fl agged due to apparent driver injury, the driver requiring medical attention will not be allowed to re-start.<br />

Race offi cials may mandate a driver be evaluated by medical personnel. This will apply to “complete and single fi le restarts”<br />

If a race is red fl agged because of unsafe track conditions all drivers directly involved in the incident requiring the red fl ag<br />

will start at the back of the grid on the restart (single fi le restart only). Only drivers that were listed as crossing the start fi nish<br />

line on the lap preceding the red fl ag will be allowed to restart. Drivers retiring prior to the lap on which the red fl ag occurred<br />

will not be allowed to reenter the race.<br />