Case study - Veolia Water Solutions & Technologies

Case study - Veolia Water Solutions & Technologies

Case study - Veolia Water Solutions & Technologies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

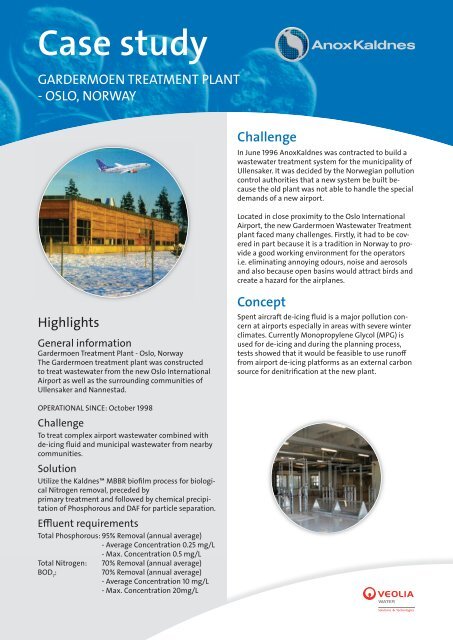

<strong>Case</strong> <strong>study</strong><br />

GARDERMOEN TREATMENT PLANT<br />

- OSLO, NORWAY<br />

Challenge<br />

In June 1996 AnoxKaldnes was contracted to build a<br />

wastewater treatment system for the municipality of<br />

Ullensaker. It was decided by the Norwegian pollution<br />

control authorities that a new system be built because<br />

the old plant was not able to handle the special<br />

demands of a new airport.<br />

Located in close proximity to the Oslo International<br />

Airport, the new Gardermoen Wastewater Treatment<br />

plant faced many challenges. Firstly, it had to be covered<br />

in part because it is a tradition in Norway to provide<br />

a good working environment for the operators<br />

i.e. eliminating annoying odours, noise and aerosols<br />

and also because open basins would attract birds and<br />

create a hazard for the airplanes.<br />

Highlights<br />

General information<br />

Gardermoen Treatment Plant - Oslo, Norway<br />

The Gardermoen treatment plant was constructed<br />

to treat wastewater from the new Oslo International<br />

Airport as well as the surrounding communities of<br />

Ullensaker and Nannestad.<br />

Concept<br />

Spent aircraft de-icing fluid is a major pollution concern<br />

at airports especially in areas with severe winter<br />

climates. Currently Monopropylene Glycol (MPG) is<br />

used for de-icing and during the planning process,<br />

tests showed that it would be feasible to use runoff<br />

from airport de-icing platforms as an external carbon<br />

source for denitrification at the new plant.<br />

OPERATIONAL SINCE: October 1998<br />

Challenge<br />

To treat complex airport wastewater combined with<br />

de-icing fluid and municipal wastewater from nearby<br />

communities.<br />

Solution<br />

Utilize the Kaldnes MBBR biofilm process for biological<br />

Nitrogen removal, preceded by<br />

primary treatment and followed by chemical precipitation<br />

of Phosphorous and DAF for particle separation.<br />

Effluent requirements<br />

Total Phosphorous: 95% Removal (annual average)<br />

- Average Concentration 0.25 mg/L<br />

Total Nitrogen:<br />

BOD 7<br />

:<br />

- Max. Concentration 0.5 mg/L<br />

70% Removal (annual average)<br />

70% Removal (annual average)<br />

- Average Concentration 10 mg/L<br />

- Max. Concentration 20mg/L

Design<br />

The plant is constructed and designed for pre- and<br />

post-denitrification. The external carbon source, the<br />

MPG from the airport, is hence used for post-denitrification.<br />

The biological treatment is followed by flocculation<br />

and flotation for separation of sludge.<br />

DESIGN LOAD<br />

Dimensioning Flow: 920 m/h<br />

Maximum Flow: 1,300 m/h<br />

TBOD7 : 2,680 kg/d<br />

TCOD: 5,480 kg/d<br />

SS: 3,290 kg/d<br />

TN: 704 kg/d<br />

TP: 101 kg/d<br />

Temperature Range: 4 o C - 14 o C<br />

Results<br />

Excellent plant performance since start-up.<br />

Total nitrogen removal efficiency in 2001 was more<br />

than 80% annual average.<br />

y<br />

c<br />

c<br />

Performance Year 2000<br />

In Out Removal<br />

BOD 7<br />

210 6.6 97%<br />

COD 559 34 94%<br />

TN 46 3 93%<br />

TP 7.05 0.18 97%<br />

SS 307 9 97%<br />

y<br />

c<br />

c<br />

info@anoxkaldnes.com<br />

www.anoxkaldnes.com<br />

AnoxKaldnes<br />

Klosterängsvägen 11A<br />

SE-226 47 Lund, Sweden<br />

Tel. +46 46-18 22 00<br />

Fax. +46 46-13 32 01