VERTICAL MACHINING CENTER - Compumachine

VERTICAL MACHINING CENTER - Compumachine

VERTICAL MACHINING CENTER - Compumachine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>VERTICAL</strong> <strong>MACHINING</strong> <strong>CENTER</strong>

Vertical Machining Center<br />

Column Traveling Type Compact Machining Center<br />

Fixed table and column traveling structure are suitable<br />

for a factory automation<br />

Coolant and chips were flushed into the rear of the machine<br />

for central chip collection.<br />

The width of the machine(1,460mm,57.5 ) is ideally<br />

suited for a factory automation

World Top Class Quality<br />

HYUNDAI-KIA Machine<br />

Milling, Tapping and Drilling Center<br />

TOOL CHANGE TIME<br />

RAPID TRAVERSE<br />

SPINDLE POWER<br />

Tool to Tool : 0.9sec<br />

Chip to Chip : 2.5sec<br />

X,Y Axis : 30m/min(1,181ipm)<br />

Z-Axis : 24m/min(945ipm)<br />

5.5/3.7kW(7.5/5HP)

Variety of Functions<br />

TABLE<br />

KV25<br />

Table Size(W L) 650 300(25.6 11.8 )<br />

Max. Load on table Unlimited<br />

T-Slot 18 3EA<br />

NC Rotary Table<br />

KV25P<br />

Table Size(W L) 2-560 320(2-22 12.6 )<br />

Max. Load on table 2-150kg(2-330lb)<br />

Tap Hole Type<br />

ATC (Automatic Tool Changer)<br />

Tool Capacity 16EA<br />

Tool Shank BT30<br />

Tool Size 80 x 200 (3kg)<br />

(Max. Weight) 3.1" x 7.9" (6.6 lb)<br />

Tool Change Time T-T (0.9 sec)<br />

C-C (2.5 sec)<br />

COOLANT SYSTEM<br />

Flood Coolant<br />

Jet Coolant (For Bed Flush)<br />

Gun Coolant<br />

Oil Mist<br />

SPINDLE<br />

5.5/3.7kW (7.5/5HP)<br />

(Fanuc 0iM)<br />

12,000 rpm<br />

APC (Automatic Pallet Changer)<br />

APC(V25P Only)<br />

CHIP DISPOSAL SYSTEM<br />

External Chip Conveyor<br />

Air Gun

KV25/25P<br />

TOTALLY ENCLOSED SPLASH GUARD<br />

Totally Enclosed Splash Guard (V25)<br />

APC Totally Enclosed Splash Guard (V25P)<br />

Automatic Door<br />

PROCESSING MANAGEMENT FUNCTION<br />

Rigid Tapping<br />

Tool Life Management<br />

Call Light (Yellow)<br />

Spindle Load Meter<br />

Spindle RPM Meter<br />

Spindle Override<br />

Broken Tool Detecting Device<br />

Work Counter<br />

Buzzer Alarm System<br />

Tool Presetter<br />

OPTION<br />

Run Hour Display (Screen)<br />

Electric Leakage Detecting Breaker<br />

Weekly Timer<br />

Automatic Power Cut / Off Device<br />

ACCURACY MANAGEMENT FUNCTION<br />

Semi - Closed Loop<br />

Closed Loop (MMS)<br />

MISCELLANEOUS<br />

Auto Oil Lubrication.<br />

Work LIight<br />

High Column

Speed & Power<br />

Superior Quality & Compactness<br />

Fixed table and column Traveling type<br />

bed construction are designed for an<br />

optimal factory automation and the<br />

superb performance.

KV25/25P<br />

Rapid Traverse<br />

- X, Y, Z 30 30 24 m/min (1,181 1,181 945 ipm)<br />

- Cutting Feed Rate 1~10,000 mm/min (394ipm)<br />

Tool Change Time<br />

- Tool to Tool : 0.9sec<br />

- Chip to Chip : 2.5sec<br />

Unlimited Load on Table (Standard Table Only)<br />

Rigid tapping(Standard)<br />

Double anchor type ball screw<br />

Pallet Change Time : 4.0sec<br />

Main Spindle in KV25 is Directly connected with the motor to<br />

accomplish high-accuracy while minimizing nosie and vibration<br />

Spindle Speed : 12,000rpm<br />

Spindle Power : 5.5/3.7kW(7.5/5HP)<br />

Max. Rigid Tapping Speed : 4,000rpm<br />

12,000rpm(standard)<br />

Table Size<br />

KV25 : 650mmx300mm(25.6 x11.8 )<br />

KV25P : 2x560mmx320mm(22 x12.6 )<br />

Travel(XxYx Z)<br />

500x 280x 380mm(19.7 x11 x15 )

Accuracy<br />

High-Precision, High-Rigidity<br />

Each axes are designed with a large<br />

diameter ballscrew, fixed by pre-tensioned<br />

ballscrews, to provide high-rigidity and<br />

minimize thermal<br />

distortion<br />

Quick-APC<br />

Minimizing non-cutting time and the highest<br />

productivity can be provided.<br />

Space-saving design minimizes floor space to make<br />

the KV25 suitable for the factory automation.<br />

Maximizing operator's convenient.<br />

The unique ATC system has the fastest tool<br />

change time in its class.<br />

- Tool to Tool 0.9 sec.<br />

- Chip to Chip 2.5 sec.<br />

High speed travel each axes can greatly reduce<br />

the none cutting time.<br />

- X,Y : 30m/min (1,181 ipm)<br />

- Z : 24m/min (945 ipm)

KV25/25P<br />

High Power and Heavy Duty Cutting<br />

135<br />

The flood coolant system is standard.<br />

1,605mm (63.2")<br />

The rotatable(135 ) control panel is designed to<br />

increase a productivity and to provide a<br />

convenience by eliminating unnecessary<br />

operator’s movement.<br />

FANUC 0iM<br />

1rev.<br />

1pitch<br />

Fast and accurate tapping by rigid tapping<br />

can maximize productivity<br />

Rigid Tap function improves an accuracy<br />

and efficiency of the top cutting.<br />

No hydraulics.<br />

Easy maintenance.<br />

1 pitch 1 rev.<br />

4,000 rpm<br />

Chips are flushed through the slanted bed by a<br />

flush coolant toward the rear side of machine for<br />

a clean work environment and a minimum<br />

thermal distortion.<br />

Easy to attach various options. A large capacity<br />

coolant tank 85gal, which can be the great<br />

advantage to minimize thermal growth.

Specification<br />

Unit:mm(in)<br />

KV25<br />

Table<br />

KV25P<br />

Pallet<br />

Unit:mm(in)<br />

KV25P<br />

KV25

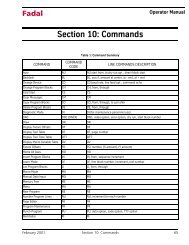

KV25/25P<br />

TABLE<br />

TRAVEL<br />

SPINDLE<br />

TRAVEL<br />

SPEED<br />

ATC<br />

LENGTH<br />

WIDTH<br />

mm(in)<br />

MAX. LOAD<br />

X-AXIS,TABLE LONGITUDINAL<br />

Y-AXIS, COLUMN CROSS<br />

Z-AXIS, SPINDLE HEAD <strong>VERTICAL</strong><br />

COLUMN-TO-SPINDLE <strong>CENTER</strong><br />

TABLE-TO-SPINDLE NOSE(UP-DOWN)<br />

kg(lb)<br />

mm(in)<br />

mm(in)<br />

mm(in)<br />

mm(in)<br />

mm(in)<br />

TAPER<br />

RPM<br />

RIGID TAPPING SPEED<br />

POWER<br />

SPEED CHANGE<br />

CUTTING<br />

RAPID TRAVERSE (X/Y/Z)<br />

TOOL CAPACITY<br />

rpm<br />

rpm<br />

kW (HP)<br />

Step<br />

mm/min(ipm)<br />

m/min(ipm)<br />

EA<br />

MAX. DIA LENGTH<br />

mm<br />

MAX. TOOL WEIGHT<br />

TOOL to TOOL<br />

CHIP to CHIP<br />

kg(lb)<br />

sec.<br />

sec.<br />

FLOOR SPACE (L W H)<br />

WEIGHT<br />

CONTROLLER<br />

mm(in)<br />

kg(lb)<br />

650 300 560 320<br />

(25.6 11.8 ) (22 12.6 )<br />

- 2-150(4-330)<br />

500(19.7 )<br />

280(11.02 )<br />

380(14.96 )<br />

368(14.5 )<br />

200~580 (7.9 ~22.8 )<br />

NT30<br />

12,000<br />

4,000<br />

5.5/3.7(7.5/5)<br />

STEPLESS<br />

1~10,000 (0.04~393.7)<br />

30/30/24 (1,181/1,181/945)<br />

16<br />

80 200 ( 3.15 7.9)<br />

3 (6.6)<br />

0.9<br />

2.5<br />

2,625 1,605 2,305 2,810 1,605 2,305<br />

(103.3 63.2 90.7 ) (110.6 63.2 90.7 )<br />

2,500 (5,511) 3,000 (6,614)<br />

FANUC OiMB<br />

FLOOD COOLANT<br />

1SET<br />

COOLANT TANK<br />

1SET<br />

TOTALLY ENCLOSED SPLASH GUARD 1SET<br />

TOOL BOX AND HAND TOOLS 1SET<br />

LEVELING BOLTS & PADS<br />

1SET<br />

RIGID TAPPING SYSTEM (4,000rpm) 1SET<br />

WORK LIGHT<br />

1SET<br />

CALL LIGHT(YELLOW)<br />

1SET<br />

APC (V25P ONLY)<br />

1SET<br />

BED FLUSHING<br />

1SET<br />

SPINDLE RPM METER<br />

1SET<br />

SPINDLE OVERRIDE<br />

1SET<br />

SPINDLE LOAD METER<br />

1SET<br />

GUN COOLANT<br />

BROKEN TOOL DETECTING DEVICE<br />

OIL MIST<br />

ELECTRIC LEAKAGE DETECTING<br />

BREAKER<br />

WEEKLY TIMER<br />

HIGH-COLUMN<br />

CALL LIGHT(3 COLOR)<br />

BUZZER ALARM SYSTEM<br />

AUTOMATIC POWER CUT-OFF<br />

DEVICE<br />

CHIP CONVEYOR WITH CHIP WAGON<br />

NC ROTARY TABLE<br />

AUTO DOOR<br />

DOOR INTERLOCK<br />

TOOL PRESETTER<br />

FIXTURE & TOOL<br />

WORK COUNTER<br />

Unit:mm(in)<br />

<br />

<br />

BT30 TOOL<br />

P30T-1

Specification<br />

Controller<br />

FANUC 0iMB<br />

Controls<br />

Spindle functions<br />

Feed functions<br />

Tool functions<br />

Programming functions<br />

Tape functions<br />

Other functions<br />

Options<br />

Controlled axes<br />

3(X,Y,Z) axes<br />

Simultaneous controllable axes<br />

Positioning(G00)/linear interpolation(G01)3axes<br />

Circular interpolation (G02, G03) 2axes<br />

Least command increment 0.001mm (0.0001 )<br />

Least input increment 0.001mm (0.0001 )<br />

Spindle speed command<br />

S5 digits, binary output<br />

Spindle speed override(10% increment) 10-150%<br />

Spindle orientation<br />

Spindle orientation<br />

Feedrate override(10% increment) 0-200%<br />

Dwell<br />

G04<br />

Reference point return<br />

G27, G28, G29, G30<br />

Manual pulse generator<br />

0.001/0.01/0.1mm(0.0001/0.001/0.01inch)<br />

Dry run<br />

Dry run<br />

Rapid traverse override F0 (fine feed), 25/50/100%<br />

Tool number command<br />

T2 digits<br />

Tool length compensation<br />

G43, G44<br />

Cutter compensation-type C<br />

G41, G42<br />

Number of tool offsets<br />

400EA<br />

Absolute/incremental programming G90/G91<br />

Canned cycle<br />

G70~G72, G74~G76, G80, G83~G88<br />

Decimal point input<br />

Input values with decimal point<br />

Circular interpolation by radius programming Radius programming by R value instead of I,J,K<br />

Sub program<br />

Nesting to 4 levels<br />

Work coordinate system<br />

G54-G59<br />

Local/Machine coordinate system G52/G53<br />

Maximum commandable value 99999.999mm( 9999.9999inch)<br />

M function<br />

M3 digits<br />

Input code<br />

ISO/EIA Auto recognition<br />

I/O interface<br />

RS232C<br />

Part program storage<br />

640M(2,100FT)<br />

Stored programs<br />

200 EA<br />

CRT unit / MDI<br />

8.4 Color LCD / soft key input for MDI<br />

Synchronized tapping<br />

Rigid tapping function<br />

Background editing<br />

Part program storage and editing during automatic operation<br />

Backlash compensation<br />

Pitch error offset compensation for each axis<br />

Stored pitch error compensation<br />

Backlash compensation<br />

Safety function<br />

Emergency stop / overtravel<br />

Program test functions<br />

Machine lock(all / Z axis) / single block<br />

Operation functions<br />

Tape / Memory / MDI/Manual<br />

Mirror image<br />

Reverse axis movement (Setting screen and M-function)<br />

Run hour and part count display<br />

Run time and part count display<br />

Self-diagnosis function<br />

Self-diagnosis test<br />

Custom Macro B #100 ~ #199, #500 ~ #999<br />

Program restart<br />

program restart<br />

Display of PMC alarm message<br />

Message display when PMC alarm occurred<br />

Stored stroke check 1<br />

Overtravel controlled by software<br />

Graphic Display<br />

PC connection through HSSB<br />

4-aixs function<br />

Handle interrupt function(add swithoh)<br />

Optional Blockskip(9EA)<br />

Figures in inch are converted from metric values.<br />

Design and specifications subject to change without notice.

Head Office<br />

<br />

<br />

<br />

Head Office & Factory<br />

<br />

<br />

<br />

<br />

Seoul Office<br />

<br />

<br />

<br />

HYUNDAI - KIA MACHINE AMERICA CORP. (New Jersey Office)<br />

<br />

<br />

<br />

HYUNDAI - KIA MACHINE AMERICA CORP. (Chicago Office)<br />

<br />

<br />

<br />

HYUNDAI - KIA MACHINE AMERICA CORP. (Argentina Office)<br />

<br />

<br />

<br />

HYUNDAI - KIA MACHINE EUROPE GmbH (Oberursel Office)<br />

<br />

<br />

HYUNDAI - KIA MACHINE EUROPE GmbH (Raunheim Service Center)<br />

<br />

<br />

HYUNDAI - KIA MACHINE SHANGHAI<br />

<br />

<br />

HYUNDAI - KIA MACHINE BEIJING<br />

<br />

<br />

HYUNDAI - KIA MACHINE GUANGZHOU<br />

<br />

<br />

HYUNDAI - KIA MACHINE INDIA OFFICE

3. (06. 08)