The system solution for conventional and mulch seeding

The system solution for conventional and mulch seeding

The system solution for conventional and mulch seeding

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

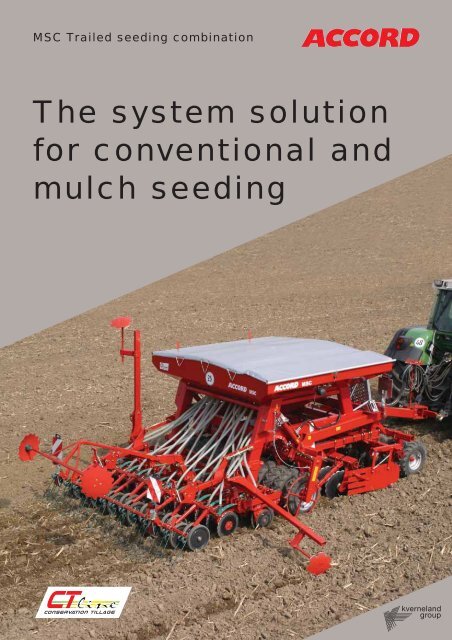

MSC Trailed <strong>seeding</strong> combination<br />

<strong>The</strong> <strong>system</strong> <strong>solution</strong><br />

<strong>for</strong> <strong>conventional</strong> <strong>and</strong><br />

<strong>mulch</strong> <strong>seeding</strong>

<strong>The</strong> MSC - Output of up to 5 ha/h<br />

High working speeds <strong>and</strong> precision <strong>for</strong> long-term profitability.<br />

With the new generation of MSC,<br />

Accord is responding to the requirements<br />

of cost-conscious <strong>and</strong><br />

successful farmers <strong>and</strong> contractors<br />

who need to combine high <strong>for</strong>ward<br />

speed output with quality<br />

crop establishment.<br />

<strong>The</strong> rapid trend of increasing farm<br />

sizes <strong>and</strong> lower "farm gate" prices<br />

necessitates changes in farming<br />

prices, which relates to reduced<br />

labour <strong>and</strong> machinery costs per<br />

hectare.

<strong>The</strong> MSC flexible <strong>system</strong><br />

Soil preparation <strong>and</strong> sowing in a single pass.<br />

<strong>The</strong> Accord MSC meets the criteria of<br />

the new cost-conscious farmer: This<br />

combination optimises soil preparation<br />

<strong>and</strong> sowing in one operation, helping to<br />

drive down both machine <strong>and</strong> labour<br />

costs. This cost-saving effect is further<br />

enhanced by the MSC's large hopper<br />

capacity (3700 l), reducing machine<br />

turn around time during filling.<br />

<strong>The</strong> machine's universal application<br />

makes it suitable <strong>for</strong> both <strong>conventional</strong><br />

<strong>and</strong> <strong>mulch</strong> <strong>seeding</strong>.<br />

<strong>The</strong> MSC is a modular design. <strong>The</strong><br />

machine can be fitted with an optional<br />

front levelling wheel packer consisting<br />

of either 4 or 8 wheels.<br />

<strong>The</strong> st<strong>and</strong>ard disc harrow facilitates the<br />

soil preparation. Each disc element is<br />

mounted on rubber suspension to protect<br />

the disc <strong>and</strong> supporting arm during work.<br />

<strong>The</strong> front section of the disc harrow<br />

can be adjusted <strong>for</strong> depth independently<br />

to that of the rear section. <strong>The</strong> depth of<br />

both disc harrows can then be adjusted<br />

in parallel either manually or hydraulically,<br />

making the <strong>system</strong> extremely versatile<br />

<strong>and</strong> enabling it to be easily adapted to<br />

different soil conditions. After the seedbed<br />

preparation, the soil is re-compacted<br />

by a wheel packer prior to sowing. For<br />

seed deposition, the <strong>system</strong> uses the<br />

"New" CX Mulch disc coulters, which<br />

are mounted on 2 separate toolbars.<br />

<strong>The</strong> seed coulters have a constant coulter<br />

pressure of 160 kg, thus ensuring<br />

that sowing depths of up to 10 cm can be<br />

easily achieved even at high working<br />

speeds (18 km/h). <strong>The</strong> CX Mulch seed<br />

coulters are fitted as st<strong>and</strong>ard with the<br />

well known <strong>and</strong> tried Kvernel<strong>and</strong> leafspring<br />

"auto reset" stone protection<br />

<strong>system</strong>.<br />

An S-type following harrow is fitted as<br />

st<strong>and</strong>ard.<br />

Optional press wheels can be used<br />

behind the CX Mulch seed coulters <strong>for</strong><br />

improved seed soil contact.<br />

<strong>The</strong> MSC is available in working widths<br />

of 3 <strong>and</strong> 4 m. <strong>The</strong> rear wheel packer also<br />

functions as a transport axle, the transport<br />

width is the same as the working<br />

width. In the st<strong>and</strong>ard version, the MSC<br />

is fitted with a hydraulic fan drive <strong>and</strong> the<br />

electronic tramlining controller (ESC).<br />

Electronic metering device drive ESA or<br />

TELLUS <strong>and</strong> a half-width shut-off are<br />

available as optional equipment.

<strong>The</strong> MSC - Superb versatility<br />

Infinite adjustment possibilities <strong>for</strong> sowing directly<br />

into the furrow or under <strong>mulch</strong> conditions<br />

Optional working lights

Versatile equipment<br />

<strong>and</strong> adjustment variants<br />

<strong>The</strong> parallelogram<br />

mounted, height<br />

<strong>and</strong> angle adjustable<br />

side plates avoid<br />

ridge <strong>for</strong>mation when<br />

work matching. (std<br />

spec in UK)<br />

<strong>The</strong> central depth<br />

control is easily<br />

<strong>and</strong> safely adjusted<br />

via spacer<br />

wafers on the two<br />

major lifting cylinders.<br />

Safe <strong>and</strong> easy<br />

access to the<br />

seed hopper via<br />

folding steps.<br />

<strong>The</strong> especially<br />

user-friendly large<br />

hopper entry is<br />

closed via a selfroll<br />

hoper cover.<br />

Technical specifications: MSC 3 & 4 m rigid<br />

Working<br />

widths (m)<br />

Number of<br />

coulters<br />

Row width<br />

(cm)<br />

Tank<br />

capacity<br />

Unladen<br />

Weight, (kg)<br />

Max Coulter<br />

pressure<br />

(per coulter) (kg)<br />

Tractor power<br />

requirement (min)<br />

3.0<br />

24<br />

12.5<br />

3700 l<br />

4040 kg<br />

160<br />

150 PS / 110 KW<br />

4.0<br />

32<br />

12.5<br />

3700 l<br />

5310 kg<br />

160<br />

180 PS / 132 KW

Disc harrow section<br />

<strong>for</strong> plough <strong>and</strong><br />

<strong>mulch</strong> <strong>seeding</strong><br />

Wheel packer <strong>for</strong> a<br />

level consoilidated<br />

seed bed.<br />

Seed coulter with<br />

Kvernel<strong>and</strong> leafspring<br />

"auto reset"<br />

tone protection<br />

Press wheels<br />

<strong>for</strong> optimum<br />

emergence<br />

Each disc is individually mounted<br />

on rubber buffers <strong>The</strong> depth of<br />

the front section of the disc harrow<br />

can be independently adjusted<br />

to that of the rear section.<br />

Optional, hydraulic parallel depth<br />

adjustment of the entire disc harrows.<br />

Fixed cutting angle discs<br />

20" (508 mm), 2 x 18" outside<br />

hollow discs.<br />

Each pair of tyres are fixed with<br />

rubber mounting <strong>for</strong> overload protection<br />

scrapers <strong>and</strong> stone<br />

deflectors are fitted as st<strong>and</strong>ard.<br />

Tyre size 6.50/80x15.<br />

A wheel packer <strong>for</strong> re-compaction<br />

in the field <strong>and</strong> safe transport on<br />

the road. Pneumatic or hydraulic<br />

braking <strong>system</strong>s are available as<br />

an option.<br />

<strong>The</strong> new CX Mulch seed coulter<br />

from Accord operates at a constant<br />

coulter pressure of 160 kg,<br />

to ensure even depth seed<br />

placement even at high working<br />

speeds. <strong>The</strong> proven leaf-spring<br />

stone protection protects the<br />

coulters against overload. <strong>The</strong><br />

coulter consists of a serrated<br />

steel disc <strong>and</strong> a convex plastic<br />

disc. No adjustable scraper<br />

required!<br />

Rubber mounted press wheels<br />

behind the CX Mulch seed coulters<br />

feature infinitely variable<br />

pressure <strong>and</strong> depth adjustment<br />

<strong>for</strong> optimum re-compaction. In<br />

wet conditions, the press wheels<br />

can be fully raised to extend the<br />

machine's operational perameters.<br />

<strong>The</strong> S covering tines continue<br />

to work independently of this.

Easy filling ...<br />

... due to low filling height <strong>and</strong> large hopper openning.<br />

Original Spare Parts<br />

<strong>The</strong> Kvernel<strong>and</strong> Group regards the sale of each machine as the start of<br />

a long-term <strong>and</strong> valuable relationship. To support the relationship, we<br />

provide the vital high quality spare part <strong>and</strong> an efficient spare part service.<br />

Our parts are designed to ensure reliability, safety <strong>and</strong> an optimal per<strong>for</strong>mance of<br />

the machines. <strong>The</strong> quality lies in the innovative construction work <strong>and</strong> in the production<br />

processes at our production sites.<br />

You can depend on the Kvernel<strong>and</strong> Group to offer a premium service.<br />

It’s vital <strong>for</strong> us!

Please ask <strong>for</strong> other Accord<br />

brochures.<br />

Kvernel<strong>and</strong> Group is the<br />

largest specialised producer<br />

<strong>and</strong> distributor of farming<br />

implements in the world.<br />

<strong>The</strong> Group is a family<br />

of strong br<strong>and</strong>s enabling<br />

us to provide both the farmer<br />

<strong>and</strong> dealer with a unique <strong>and</strong><br />

complete range of high quality<br />

products <strong>for</strong> soil preparation,<br />

grass treatment, <strong>seeding</strong>,<br />

spreading, spraying, potato<br />

cultivation <strong>and</strong> grape harvesting.<br />

www.kvernel<strong>and</strong>group.com<br />

DA-X pneumatic seed<br />

drill<br />

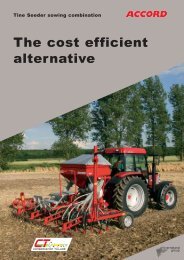

Tine Seeder (T-S)<br />

Seeding Combination<br />

Optima<br />

Pneumatic drills<br />

Semi-mounted, modular or tractormounted<br />

seed drills. Working widths range<br />

from 2.50m to 9.00m. Suffolk, B<strong>and</strong>, CX<br />

<strong>and</strong> CX-Plus disc coulters are available<br />

<strong>for</strong> use when using <strong>conventional</strong> <strong>and</strong><br />

conservation sowing methods. For grass,<br />

rape, wheat, barley, beans <strong>and</strong> many<br />

other types of seed.<br />

Kvernel<strong>and</strong> Accord Tine Seeder<br />

<strong>The</strong> Tine Seeder (T-S) is the low cost<br />

alternative built in combination with the<br />

well-proven Accord drill <strong>system</strong>. Three<br />

rows of auto-reset <strong>seeding</strong> tines are<br />

controlled by 4 depth wheels. S-type<br />

following harrow. Working widths of<br />

4.0m, 4,5m, 4,8m <strong>and</strong> 5.0m.<br />

Pneumatic Precision Seed Drills<br />

<strong>The</strong> Optima vacuum precision seed drill<br />

is suitable <strong>for</strong> <strong>conventional</strong> or <strong>mulch</strong><br />

<strong>seeding</strong> of natural, calibrated or pelleted<br />

seeds. Maize, beet, rape, sunflowers<br />

<strong>and</strong> many more. Available with row fertiliser<br />

applicators, micro granular applicators<br />

<strong>and</strong> opto electronic control <strong>system</strong>s.<br />

4-32 Rows.<br />

Producer:<br />

Kvernel<strong>and</strong> Soest GmbH<br />

Coesterweg 42<br />

D-59494 Soest, Germany<br />

Importers:<br />

Kvernel<strong>and</strong> Group UK Ltd.<br />

Walkers Lane, Lea Green, St. Helens<br />

Merseyside WA9 4AF, UK<br />

Phone: +44 17 44 853 200, Fax +44 17 44 853 400<br />

Kvernel<strong>and</strong> International BV<br />

Hoofdweg 1278, NL-2153 LR Nieuw-Vennep<br />

P.O. Box 1000, NL-2150 BA Nieuw-Vennep<br />

<strong>The</strong> Netherl<strong>and</strong>s<br />

Phone: +31 252 662 244, Fax: +31 252 687 325<br />

E-mail: accord-uk.kvernel<strong>and</strong>group.com<br />

www.kvernel<strong>and</strong>group.co.uk<br />

<strong>The</strong> in<strong>for</strong>mation <strong>and</strong> illustrations shown may include additional<br />

equipment that does not <strong>for</strong>m part of the st<strong>and</strong>ard range of<br />

equipment. <strong>The</strong> right to technical revision is reserved.<br />

Dealer:<br />

AC753182-GB-01/05