SE LP10 - Access Control Solutions from ASSA ABLOY

SE LP10 - Access Control Solutions from ASSA ABLOY

SE LP10 - Access Control Solutions from ASSA ABLOY

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SE</strong> <strong>LP10</strong><br />

Mortise Lock<br />

Installation Instructions<br />

A8113C (M1)<br />

2/14<br />

Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company.<br />

All rights reserved. Reproduction in whole or in part without the express written<br />

permission of Sargent Manufacturing Company is prohibited.

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

Table of Contents<br />

Warning ....................................................................................3<br />

General Description..................................................................4<br />

Technical Specifications..........................................................4<br />

Electrical Specifications...........................................................4<br />

Parts Breakdown......................................................................5<br />

Installation Instructions...........................................................7<br />

Wiring Diagrams.....................................................................15<br />

UL294 Compliance..................................................................18<br />

Mechanical Operational Check..............................................19<br />

Electrical Operational Check..................................................19<br />

Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.<br />

02/15/14<br />

1<br />

Warning<br />

!!<br />

Changes or modifications to this unit not expressly approved by the party<br />

responsible for compliance could void the user’s authority to operate the equipment.<br />

FCC:<br />

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of<br />

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential<br />

installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used<br />

in accordance with the instructions, may cause harmful interference to radio communications. However, there is no<br />

guarantee that interference will not occur in a particular installation. If this equipment does cause harmful Interference<br />

to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged<br />

to try to correct the interference by one or more of the following measures:<br />

• Reorient or relocate the receiving antenna.<br />

• Increase the separation between the equipment and receiver.<br />

• Connect the equipment into an outlet on a circuit different <strong>from</strong> that to which the receiver is connected.<br />

• Consult the dealer or an experienced radio/TV technician for help.<br />

Industry Canada:<br />

This Class B digital apparatus meets all requirements of the Canadian Interference Causing Equipment Regulations.<br />

Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this<br />

device must accept any interference received, including interference that may cause undesired operation.<br />

Cet appareillage numérique de la classe B répond à toutes les exigences de l’interférence canadienne causant des<br />

règlements d’équipement. L’opération est sujette aux deux conditions suivantes: (1) ce dispositif peut ne pas causer<br />

l’interférence nocive, et (2) ce dispositif doit accepter n’importe quelle interférence reçue, y compris l’interférence qui<br />

peut causer l’opération peu désirée.<br />

“This equipment complies with FCC radiation exposure limits set forth for an uncontrolled environment. This equipment<br />

should be installed and operated with minimum distance 20cm between the radiator and your body. This transmitter<br />

must not be co-located or operating in conjunction with any other antenna or transmitter.”<br />

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a type and maximum<br />

(or lesser) gain approved for the transmitter by Industry Canada. To reduce potential radio interference to other users,<br />

the antenna type and its gain should be so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more<br />

than that necessary for successful communication.<br />

Observe precautions for handling electrostatic sensitive devices.<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com 3

<strong>SE</strong> <strong>LP10</strong> Mortise Lock<br />

2<br />

3<br />

General Description<br />

The SARGENT <strong>SE</strong> <strong>LP10</strong> mortise lock* is designed to interface with existing Wiegand Electronic <strong>Access</strong><br />

<strong>Control</strong> (EAC) panels. The reader requires 5-16 VDC for power and supports multiple high and low frequency<br />

credentials. <strong>SE</strong> <strong>LP10</strong> is backed by SARGENT’s Grade 1 hardware. The mortise lock comes with Request to<br />

Exit (RX) and Door Position (DPS) monitoring inside the lock body. It is available as 12-24 VDC. The <strong>SE</strong> <strong>LP10</strong><br />

reader provides visual (LED) and audible indicators of lock state (locked/unlocked).<br />

*Patent Pending<br />

Technical Specifications<br />

• Latch - Stainless steel 3⁄4” projection one-piece<br />

• Deadbolt - One-piece hardened stainless steel<br />

• Guardbolt - Stainless steel, non-handed<br />

• Handing - Easily field reversible without opening case<br />

• Case - 12 gauge heavy duty wrought steel<br />

• Outside lever controlled by compatible credential<br />

• Field-selectable to Fail Safe or Fail Secure<br />

• Door position switch (DPS) within lock body<br />

• Inside lever provides RX signal and retracts latch<br />

and deadbolt<br />

• Locks furnished for 1-3/4” doors. Other door<br />

thicknesses require confirmation with factory.<br />

• UL and CUL listed for use on Fire Doors<br />

• Listed to UL 294 (<strong>Access</strong> <strong>Control</strong> System Units)<br />

within the U.S. only<br />

• Wire <strong>from</strong> EAC Panel to door must be shielded<br />

with drain terminated at EAC Panel controller<br />

4<br />

Electrical Specifications<br />

Wiegand <strong>Access</strong><br />

<strong>Control</strong> System<br />

Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.<br />

Total<br />

One-Way<br />

Length of<br />

Wire Run (ft)<br />

12/24VDC System<br />

• Reader Draw = .140 Amp @12V<br />

• Actuator Draw = .015 Amp continuous<br />

• Maximum (2) locks per 1 Amp power supply<br />

(1/2 Amp current draw)<br />

Load Current @ 12VDC<br />

1/4A 1/2A 3/4A 1A 1-1/4A 1-1/2A 2A 3A<br />

100 20 18 16 14 14 12 12 10<br />

150 18 16 14 12 12 12 10 —<br />

200 16 14 12 12 10 10 — —<br />

250 16 14 12 10 10 10 — —<br />

300 16 12 12 10 10 — — —<br />

400 14 12 10 — — — — —<br />

500 14 10 10 — — — — —<br />

750 12 10 — — — — — —<br />

1,000 10 — — — — — — —<br />

1,500 10 — — — — — — —<br />

Wire Gauge Charts<br />

Total<br />

One-Way<br />

Length of<br />

Wire Run (ft)<br />

McKinney<br />

Electric<br />

Hinge<br />

<strong>SE</strong> <strong>LP10</strong><br />

Load Current @ 24VDC<br />

1/4A 1/2A 3/4A 1A 1-1/4A 1-1/2A 2A 3A<br />

100 24 20 18 18 16 16 14 12<br />

150 22 18 16 16 14 14 12 10<br />

200 20 18 16 14 14 12 12 10<br />

250 18 16 14 14 12 12 12 10<br />

300 18 16 14 12 12 12 10 —<br />

400 18 14 12 12 10 10 — —<br />

500 16 14 12 10 10 — — —<br />

750 14 12 10 10 — — — —<br />

1,000 14 10 10 — — — — —<br />

1,500 12 10 — — — — — —<br />

02/15/14<br />

HID, the HID logo, iCLASS <strong>SE</strong>, iCLASS, and Edge are trademarks or registered trademarks of HID Global in the U.S. and/or other countries. All other trademarks,<br />

service marks, and product or service names are trademarks or registered trademarks of their repsective owners.<br />

4<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com

<strong>SE</strong> <strong>LP10</strong> Mortise Lock<br />

5<br />

Parts Breakdown<br />

Lever Hand Reverse Door<br />

6<br />

4 3 5<br />

3<br />

3<br />

2<br />

1A<br />

1* 2<br />

2<br />

2<br />

2<br />

10<br />

11<br />

9<br />

7<br />

Tools Required:<br />

• #2 Phillips screwdriver<br />

• Push pin (provided)<br />

• T10 Torx Driver<br />

• 3/32” drill bit<br />

12*<br />

• 3/4” drill bit<br />

• 5/16” drill bit<br />

• 3/8” drill bit<br />

• 7/16” drill bit<br />

• 1” bore<br />

• 2-1/8” bore<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com 5<br />

7<br />

15<br />

13<br />

*Patent Pending<br />

14<br />

8<br />

15<br />

14<br />

02/15/14 Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

<strong>SE</strong> <strong>LP10</strong> Mortise Lock<br />

Parts Breakdown (Continued)<br />

Lever Hand Reverse Door<br />

ITEM PART # Description Req.<br />

1* 52-4524 <strong>SE</strong> Reader Assembly- Black 1<br />

52-4525 <strong>SE</strong> Reader Assembly- Gray<br />

52-4528 FIPS <strong>SE</strong> Reader Assembly- Black (200 bit Wiegand output)<br />

52-4529 FIPS <strong>SE</strong> Reader Assembly- Gray (200 bit Wiegand output)<br />

52-4567 FIPS <strong>SE</strong> Reader Assembly- Black (75 bit Wiegand output)<br />

52-4568 FIPS <strong>SE</strong> Reader Assembly- Gray (75 bit Wiegand output)<br />

1A -- <strong>SE</strong> Mounting Plate 1<br />

2 52-4539 Screw Pack 1<br />

3 52-4542 Fire Block Kit 1<br />

Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.<br />

4 52-1359 Trim Bezel- Black 1<br />

52-1360 Trim Bezel- Gray<br />

5 52-5218 Inside Mounting Plate 1<br />

6 52-5196 Inside Escutcheon With Thumb Turn 1<br />

82-0706 Inside Escutcheon Without Thumb Turn<br />

7 -- Reference <strong>SE</strong> <strong>LP10</strong> Catalog For Available Lever Styles 1<br />

8 -- Reference <strong>SE</strong> <strong>LP10</strong> Catalog For Available Rose Styles 1<br />

9 82-3211 Trim Pack 1<br />

79-2162 DL Trim Pack 1<br />

10 -- Rosette Spring Assembly 1<br />

11 -- Cylinder (Size 41) 1<br />

12* Lock Body "M1-82270-12/24 VDC x Finish" w/out Deadbolt, Fail Safe 1<br />

"M1-82271-12/24 VDC x Finish" w/out Deadbolt, Fail Secure 1<br />

"M1-82272-12/24 VDC x Finish" w/out Deadbolt, Fail Safe, Both Levers Lock 1<br />

"M1-82273-12/24 VDC x Finish" w/out Deadbolt, Fail Secure, Both Levers Lock** 1<br />

"M1-82280-12/24 VDC x Finish" w/ Deadbolt, Fail Safe 1<br />

"M1-82281-12/24 VDC x Finish" w/ Deadbolt, Fail Secure 1<br />

"M1-82282-12/24 VDC x Finish" w/ Deadbolt, Fail Safe, Both Levers Lock 1<br />

"M1-82283-12/24 VDC x Finish" w/ Deadbolt, Fail Secure, Both Levers Lock** 1<br />

13 82-0579 Outside Faceplate w/ Deadbolt 1<br />

82-0578 Outside Faceplate w/out Deadbolt 1<br />

14 82-0110 Strike Plate 1<br />

15 77-4236 Lock Body and Strike Screw Pack 2<br />

16 A8123 Field Prep Template (not shown) 1<br />

17 4702 Door Manufacturer Template (not shown) 1<br />

18 A8113A Installation Instructions (not shown) 1<br />

19 A8129 Outside Field Prep Template (not shown) 1<br />

*Patent Pending<br />

**CAUTION: Not recommended for use on any door used for Life Safety Egress<br />

02/15/14<br />

6<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com

<strong>SE</strong> <strong>LP10</strong> Mortise Lock<br />

6<br />

Installation Instructions<br />

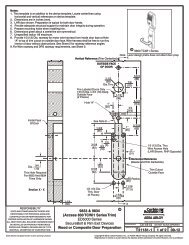

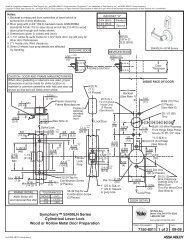

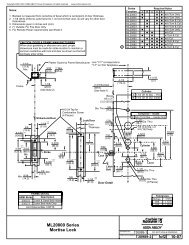

1 Door Preparation<br />

A. Verify Hand and Bevel of Door<br />

Stand on outside of locked door when determining door hand.<br />

Left Hand<br />

Hinges Left.<br />

Open Inward.<br />

“LH”<br />

Left Hand<br />

Reverse Bevel<br />

Hinges Left.<br />

Open Outward<br />

“LHRB”<br />

Fig. 1A<br />

Right Hand<br />

Hinges Right.<br />

Open Inward.<br />

“RH”<br />

Right Hand<br />

Reverse Bevel<br />

Hinges Right.<br />

Open Outward<br />

“RHRB”<br />

B. Door Preparation<br />

Prepare door according to appropriate template. If necessary, refer to website<br />

www.intelligentopenings.com.<br />

• Prior to installation, make sure all holes are free of burrs, debris, and sharp edges.<br />

• If doors are not properly reinforced per ANSI 115.2, commercially available reinforcements<br />

should be installed.<br />

• Templates:<br />

Pre-drill Holes (2 places)<br />

Outside Cylinder Hole<br />

(70/71, 72/73, 80/81,<br />

82/83 functions only)<br />

o Field Template: A8123 and A8129 (ships with product).<br />

o Door Manufacturer’s Template: 4702 metal and wood door.<br />

Lever Handle Hole<br />

Pre-drilled and/or<br />

Tapped Holes (2 Places)<br />

Outside of Door<br />

Mortise<br />

Area<br />

Fig. 1B<br />

(Wood Door Shown)<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com 7<br />

Inside of Door<br />

Pre-drill Holes (4 places)<br />

Inside Wire Hole<br />

Thumb Turn Hole<br />

Lever Handle Hole<br />

02/15/14 Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

<strong>SE</strong> <strong>LP10</strong> Mortise Lock<br />

2 How to Change Hand of Lock body<br />

A. Reverse Lock Hand<br />

Red surface of locking piece must face the<br />

outside/locked side of door. To rotate locking<br />

piece (Fig. 2A):<br />

1. Position lock body with red surface of<br />

locking piece visible.<br />

2. Insert blade type screwdriver into locking<br />

piece slot to rotate locking piece toward<br />

back of lock body.<br />

3. Rotate the locking piece 180° until RED<br />

surface is on opposite side.<br />

Note: Red indicates locked side (outside).<br />

Locking Guide Slot:<br />

Red color indicates<br />

locked side.<br />

Fig. 2A<br />

Push In<br />

Right Hand<br />

Lock Shown<br />

B. Reverse Latch Hand<br />

Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.<br />

02/15/14<br />

Beveled surface of latch must face strike (Fig. 2B).<br />

The deadlatch is self adjusting.<br />

To change hand of latchbolt:<br />

1. Insert screwdriver into the spade<br />

shaped slot.<br />

2. Rotate screwdriver 90º to push latch out<br />

until back of latch clears lock front; then<br />

rotate latch 180º.<br />

Latch will then re-enter lock body.<br />

Note: Latch cannot be unscrewed.<br />

3 Configure the DIP Switch Settings<br />

IMPORTANT: The 3-position DIP-switch settings<br />

located at the bottom of the mortise lock body<br />

must be set prior to lock installation.<br />

1 2 3<br />

DIP Switch<br />

RH & RHR<br />

8<br />

Handing<br />

Triangular Slot<br />

LH & LHR<br />

Check Polarity:<br />

Verify + (red wire)<br />

Normally<br />

Open<br />

RX Output<br />

Normally<br />

Closed<br />

Fig. 2B<br />

Actuator Operation<br />

Fail Safe<br />

Latchbolt<br />

Fail Secure<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com

<strong>SE</strong> <strong>LP10</strong> Mortise Lock<br />

4 Install Lock body<br />

1. Wires and connectors go into the mortised area and out of the inside cylinder hole.<br />

2. Insert mortise lock body into mortise door preparation.<br />

3. Carefully feed wires <strong>from</strong> mortise lock through the non-cylinder side hole of the door preparation.<br />

4. Hold lock body loosely in place with (2) lock body screws (wood or metal depending on type of door).<br />

Note: Do not completely tighten screws at this time.<br />

Inside of Door<br />

(2) #12-24 x 1/2”<br />

Flat Head Philips<br />

Screws (Metal Doors)<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com 9<br />

(2)#12 x 1-1/4” Flat<br />

Head Wood Screws<br />

(Wood Doors)<br />

Fig. 4<br />

02/15/14 Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

<strong>SE</strong> <strong>LP10</strong> Mortise Lock<br />

5 Installation of Card Reader and Inside Mounting Plate<br />

NOTE: Feed mortise connectors through the corresponding hole on the<br />

mounting plate.<br />

1. Attach the mounting plate using the two lower screws ONLY (Fig. 5A).<br />

2. For fire-rated doors only, install fire shield (Fig. 5B).<br />

3. Attach reader backplate to the fire shield using two #8 x 1/2” Phillips flat<br />

head self drill screws (Fig. 5B).<br />

4. Fit trim bezel around the reader. Ensure access hole in the bezel aligns<br />

with screw hole on reader. The reader should be mounted so the holes<br />

face the bottom of door.<br />

5. Align top of reader with top of backplate. Pivot reader down until seated.<br />

Guide wires as needed to avoid pinching.<br />

6. Secure the reader with (1) #6-32 x 3/8” Phillips or anti-tamper security torx<br />

screw to the mounting plate (Fig. 5C).<br />

Inside of Door<br />

(2) 8-32 x 3/8”<br />

Phillips Flat<br />

Head Self-<br />

Drilling Screw<br />

Outside of Door<br />

Fig. 5A<br />

Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.<br />

Reader<br />

Backplate<br />

Fig. 5B<br />

Fire Shield<br />

Reader Cable<br />

Fig. 5C<br />

Trim Bezel<br />

02/15/14<br />

10<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com

<strong>SE</strong> <strong>LP10</strong> Mortise Lock<br />

6 Wire Connections<br />

1. Connect ElectroLynx (4 and 8 pin) <strong>from</strong> the door harness to<br />

P1 and P2 on the reader assembly. See Figure 6A.<br />

Note: Connectors only go on one way.<br />

2. Connect 2-pin connector <strong>from</strong> lock body to P4 (2-pin) on<br />

reader harness.<br />

3. Connect 6-pin connector <strong>from</strong> lock body to P3 (6-pin) on<br />

reader harness.<br />

4. Carefully tuck ElectroLynx connectors into 1 inch hole in<br />

door. See photo in Figure 6B.<br />

Notes: Neatly fold the wires into the remaining space to<br />

prevent pinching wires when mounting escutcheon. Do<br />

not tuck extra mortise lock body wires back inside the lock<br />

body cylinder hole. Do not offset connectors and be sure<br />

they are completely seated.<br />

Fig. 6B<br />

Fig. 6A<br />

7 Fire Plate Installation and Earth Ground Connection<br />

1. Remove lower right screw <strong>from</strong> mounting plate. Feed screw through green/yellow<br />

ground wire ring terminal. Reinstall screw. Ensure that green/yellow wire points toward top of<br />

door in order to avoid interference with escutcheon<br />

2. Install the fire plate to the mounting plate. Use caution not to trap wires between pad and<br />

mounting plate. Fasten plate with two #8 x 1 1/4” Phillips pan head self-drilling screws.<br />

Note: For non-fire rated doors, omit fire plate.<br />

Inside of Door<br />

Fig. 7A<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com 11<br />

Fig. 7B<br />

02/15/14 Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

<strong>SE</strong> <strong>LP10</strong> Mortise Lock<br />

8 Outside Cylinder Installation<br />

NOTE: Verify that the lock body wires do not contact any moving parts as cylinder and deadbolt move.<br />

1. Verify orientation of cylinder so that SARGENT logo is right-side up (Fig. 8A).<br />

2. Withdraw the key about 25% out of the cylinder before inserting into the escutcheon (Fig. 8B).<br />

3. Rotate cylinder until it is nearly flush with the edge of rosette and the SARGENT<br />

logo is positioned correctly (Fig. 8A).<br />

Note: Do not attempt to tighten all the way.<br />

4. Tighten the cylinder clamp set screw to prevent<br />

unscrewing of the cylinder (Fig. 8C).<br />

5. Test cylinder function:<br />

• 70/71/72/73 Function:<br />

Key retracts latch.<br />

• 80/81/82/83 Function:<br />

Key retracts latch and projects<br />

and retracts deadbolt.<br />

• Ensure smooth operation of<br />

latchbolt and deadbolt.<br />

NOTE: Use lever handle holes<br />

to manipulate mortise to ease<br />

thread engagement of cylinder.<br />

Outside of Door<br />

Cylinder Set Screw<br />

Phillips<br />

Screwdriver<br />

Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.<br />

IMPORTANT: Position cylinder so that the<br />

SARGENT logo is positioned correctly.<br />

Correct<br />

Fig. 8A<br />

Incorrect<br />

Fig. 8B<br />

Fig. 8C<br />

02/15/14<br />

12<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com

<strong>SE</strong> <strong>LP10</strong> Mortise Lock<br />

9 Inside Outside Lever and Inside Adapter Plate Assembly<br />

1. With outside lever horizontal, insert the mounting post through outside of door and lock body.<br />

Make certain the lever spindle is properly engaged inside the lock body (Fig. 9A).<br />

2. On the inside of the door, insert spindle into square hole of mortise lock (Fig. 9B).<br />

3. Slide inside adapter and plate<br />

assembly over spindle and<br />

loosely secure with (2) 8-32 X 5/8”<br />

Phillips oval head and lock washer<br />

machine screws.<br />

Be sure to rotate the set screw hole<br />

so the hole (Studio Collection only)<br />

faces the hinge side and seat inside<br />

spindle fully into the lock body.<br />

4. Securely tighten the<br />

lock body screws.<br />

Outside of Door<br />

Lock Body<br />

Screw<br />

Inside of Door<br />

8-32 X 5/8”<br />

Phillips Oval<br />

Head and<br />

Lock Washer<br />

Machine<br />

Screw<br />

Fig. 9A<br />

Fig. 9B<br />

10 Install Inside Escutcheon Assembly<br />

1. Carefully and neatly fold back lock body wires.<br />

2. For locks equipped with deadbolts, align inside escutcheon<br />

turn lever with slot in lock body. Adjust wires as necessary<br />

to ensure they are clear of inside escutcheon. Seat inside<br />

escutcheon against door.<br />

3. Tighten the inside escutcheon securely to the mounting<br />

plate with the Phillips flat head machine screws provided.<br />

Use 8- 32 x 5/8” for the top of the escutcheon and the 8-<br />

32 x 1/4” screws for the bottom of the escutcheon located<br />

under the turn lever.<br />

4. Be sure the turn assembly and the deadbolt function<br />

properly.<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com 13<br />

Fig. 10<br />

Inside of Door<br />

8-32 X 5/8”<br />

Phillips<br />

Flat Head<br />

Undercut<br />

Machine<br />

Screw<br />

8-32 X 1/4”<br />

Phillips<br />

Flat Head<br />

Undercut<br />

Machine<br />

Screw<br />

02/15/14 Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

<strong>SE</strong> <strong>LP10</strong> Mortise Lock<br />

11 Install Inside Rose and Inside Lever Assembly<br />

1. Rotate the inside rose first counter clockwise<br />

to seat the threads then clockwise to<br />

securely tighten.<br />

2. Slide lever handle onto spindle until fully<br />

seated. Be sure handle is horizontal and<br />

facing the hinge side of the door. Push lever<br />

onto spindle so minimum gap is visible.<br />

3. Tighten the set screw securely with<br />

a 1/8” hex wrench.<br />

4. Before closing the door, test that the<br />

lever is functional and ensure<br />

smooth operation of the<br />

latchbolt and deadbolt.<br />

Spindle<br />

Rose<br />

Set Screw<br />

Inside of Door<br />

Fig. 11A<br />

Inside Lever<br />

Fig. 11B<br />

12 Attach Front Plate<br />

Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.<br />

1. Attach front plate with (2) 8-32x1/4” flat head screws<br />

and tighten securely.<br />

Fig. 12<br />

Outside of Door<br />

(2) 8-32x1/4”<br />

Flat Head Screws<br />

02/15/14<br />

14<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com

<strong>SE</strong> <strong>LP10</strong> Mortise Lock<br />

7<br />

Wiring Diagrams<br />

Product 8 PIN CONNECTOR 4 PIN CONNECTOR<br />

1-Black 2-Red 3-White 4-Green 5-Orange 6-Blue 7-Brown 8-Yellow 9-Violet 10-Gray 11-Pink 12-Tan<br />

ACCESS CONTROL DEVICES: <strong>SE</strong> <strong>LP10</strong> Mortise, ElectroLynx wire Color / Function assignments<br />

SARGENT -<br />

<strong>SE</strong> <strong>LP10</strong>,<br />

Mortise<br />

12VDC<br />

(Reader)<br />

WIE-<br />

GAND<br />

WIE-<br />

GAND<br />

NEG POS DATA_1 DATA_0 NO COM REF.<br />

*DIA-<br />

GRAMS<br />

RX RX EGND OPTION 12/24 VDC<br />

(LOCK RELAY)<br />

REF.<br />

*DIA-<br />

GRAMS<br />

DPS<br />

(NC)<br />

DPS<br />

(COM)<br />

NEG POS DPS DPS<br />

*Diagrams on following pages<br />

The <strong>SE</strong> <strong>LP10</strong> reader can be configured for various modes of LED and beeper operation. HID programming<br />

cards are supported to configure the behavior for LED and beeper activity. (Call 1-800-<br />

810-WIRE (9473) for details.) Along with the programming cards, the OPTION wire can be connected<br />

within the panel and the lock in order to enable some of the listed features. See chart below:<br />

Default Operation Mode:<br />

• Red LED ‘ON’ when powered.<br />

• Presenting a 13.56MHz or 125 kHz credential causes LED to briefly<br />

turn green and then return to red state.<br />

• Presenting a FIPS 201 PIV credential causes LED to turn amber as<br />

credential is authenticated. Reader emits a short beep when credential<br />

is successfully read.<br />

• Reference *Diagram #1 as a function of power requirement (12VDC<br />

or 24VDC).<br />

Note: OPTION wire is unconnected.<br />

PIN 8 (Yellow – OPTION)<br />

PIN 6 (Blue – RX COM)<br />

PIN 4 (Green – Data 0)<br />

PIN 1 (Black – Reader NEG)<br />

PIN 3 (White – Data 1)<br />

PIN 5 (Orange – RX NO)<br />

PIN 7 (Brown - EGND)<br />

Optional Operation Mode:<br />

• Connect selected option wire <strong>from</strong> reader to ElectroLynx cable pin 8<br />

Note: For fire rated doors solder sleeve (P/N 52-1373) to be applied<br />

to desired lead 2.5” <strong>from</strong> base of reader. See diagram for application.<br />

• Connect Yellow OPTION wire <strong>from</strong> ElectroLynx cable to desired EAC<br />

panel control line.<br />

Reference Diagram #2<br />

• As appropriate, use configuration card to activate desired mode on<br />

reader.<br />

Reader Wire Color<br />

YELLOW<br />

BLUE<br />

ORANGE<br />

BROWN<br />

VIOLET<br />

Optional Function Chart<br />

Contact Factory For Reader Configuration Card Requirements<br />

Functional Assignment<br />

Beeper <strong>Control</strong><br />

Hold <strong>Control</strong><br />

GREEN LED <strong>Control</strong><br />

RED LED <strong>Control</strong><br />

Tamper Detect (open collector output <strong>from</strong> reader)<br />

ElectroLynx P1-8. Use appropriate configuration card to activate function on reader.<br />

Note: When Yellow OPTION wire is tied directly into EAC panel relay, no<br />

AC signals should be applied on wire or door reader performance will be<br />

impacted.<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com 15<br />

PIN 4 (Tan –DPS NC )<br />

PIN 2 (Gray – Lock POS)<br />

PIN 1 (Violet – Lock NEG)<br />

PIN 3 (Pink – DPS)<br />

Note: NC= Normally Closed<br />

NO= Normally Open<br />

Wire<br />

Strip 1/4”<br />

Solder Sleeve<br />

Overlap wires as shown. Use heat gun to set wires.<br />

02/15/14 Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

<strong>SE</strong> <strong>LP10</strong> Mortise Lock<br />

Typical <strong>SE</strong> <strong>LP10</strong> Mortise Application Diagram (12/24VDC Lock)<br />

DIAGRAM #1 – MODE 1: OPTION WIRE NOT U<strong>SE</strong>D = RED LED ON WHEN POWERED<br />

Standard Application Shown - For Alternative Applications Contact 1-800-810-WIRE (9473)<br />

Reader Electronics Requires 5 to 16VDC Filtered and Regulated<br />

12/24VDC System<br />

• Reader Draw = .140 Amp<br />

• Actuator Draw = .015 Amp continuous<br />

• Maximum (2) locks per 1 Amp power supply (1/2 Amp current draw)<br />

120 VAC<br />

Input<br />

Black (Hot)<br />

H N G<br />

12/24VDC<br />

- +<br />

White (Neutral)<br />

Green (Gnd)<br />

Lock body<br />

Power Supply<br />

(By Others)<br />

Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.<br />

12 Conductor<br />

ElectroLynx Harness<br />

From McKinney<br />

<strong>SE</strong> <strong>LP10</strong><br />

QC12 Electric<br />

Hinge From<br />

McKinney<br />

READER NEG - Black, 1<br />

READER POS - Red, 2<br />

DATA 1 - White, 3<br />

DATA 0 - Green, 4<br />

RX (NO/NC) - Orange, 5<br />

RX (COM) - Blue, 6<br />

*EGND- Brown, 7<br />

OPTION - Yellow, 8<br />

LOCK NEG - Violet, 9<br />

LOCK POS - Gray, 10<br />

DPS (NC) - Pink, 11<br />

DPS (COM) - Tan, 12<br />

Not Used<br />

*IMPORTANT: Pin 7 must be tied to earth ground in the access control panel.<br />

Failure to follow proper ESD safe grounding procedures could lead to equipment failure.<br />

(-)<br />

(+)<br />

DATA 1<br />

DATA 0<br />

RX<br />

RX<br />

DPS<br />

DPS<br />

12VDC<br />

Use (NC) for<br />

Fail Safe<br />

Operation<br />

(NO) Fail<br />

Secure<br />

Operation<br />

Electronic<br />

<strong>Access</strong><br />

<strong>Control</strong><br />

Panel<br />

(By Others)<br />

Lock Relay<br />

02/15/14<br />

16<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com

<strong>SE</strong> <strong>LP10</strong> Mortise Lock<br />

Typical <strong>SE</strong> <strong>LP10</strong> Mortise Application Diagram (12/24VDC Lock)<br />

DIAGRAM #2 – MODE 2: OPTION WIRE TO EAC PANEL = EAC PANEL CONFIGURABLE<br />

Standard Application Shown - For Alternative Applications Contact 1-800-810-WIRE (9473)<br />

Reader Electronics Requires 5 to 16VDC Filtered and Regulated<br />

12/24VDC System<br />

• Reader Draw = .140 Amp<br />

• Actuator Draw = .015 Amp continuous<br />

• Maximum (2) locks per 1 Amp power supply<br />

(1/2 Amp v current draw)<br />

120 VAC<br />

Input<br />

Black (Hot)<br />

H N G<br />

12/24VDC<br />

- +<br />

White (Neutral)<br />

Green (Gnd)<br />

Lock body<br />

Power Supply<br />

(By Others)<br />

12 Conductor<br />

ElectroLynx Harness<br />

From McKinney<br />

<strong>SE</strong> <strong>LP10</strong><br />

QC12 Electric<br />

Hinge From<br />

McKinney<br />

READER NEG - Black, 1<br />

READER POS - Red, 2<br />

DATA 1 - White, 3<br />

DATA 0 - Green, 4<br />

RX (NO/NC) - Orange, 5<br />

RX (COM) - Blue, 6<br />

*EGND- Brown, 7<br />

OPTION - Yellow, 8<br />

LOCK NEG - Violet, 9<br />

LOCK POS - Gray, 10<br />

DPS (NC) - Pink, 11<br />

DPS (COM) - Tan, 12<br />

*IMPORTANT: Pin 7 must be tied to earth ground in the access control panel.<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com 17<br />

Failure to follow proper ESD safe grounding procedures could lead to equipment failure.<br />

(-)<br />

(+)<br />

DATA 1<br />

DATA 0<br />

RX<br />

RX<br />

12VDC<br />

OPTION<br />

DPS<br />

DPS<br />

Use (NC) for<br />

Fail Safe<br />

Operation<br />

(NO) Fail<br />

Secure<br />

Operation<br />

Electronic<br />

<strong>Access</strong><br />

<strong>Control</strong><br />

Panel<br />

(By Others)<br />

Lock Relay<br />

02/15/14 Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

<strong>SE</strong> <strong>LP10</strong> Mortise Lock<br />

8<br />

UL294 Compliance<br />

<strong>SE</strong> <strong>LP10</strong> 8200 UL294 Application Diagram<br />

UL294 Requirements<br />

• HID EDGE E400 or ES400<br />

• POE Injector Altronix Netway1<br />

• SARGENT 3540 / Securitron BPS-24-2<br />

• HES 2001M MOV / Bridge (Optional)<br />

• OPTION Wire Use as Required<br />

Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.<br />

12 Conductor<br />

ElectroLynx Harness<br />

From McKinney<br />

<strong>SE</strong> <strong>LP10</strong><br />

QC12 Electric<br />

Hinge From<br />

McKinney<br />

READER NEG - Black, 1<br />

READER POS - Red, 2<br />

DATA 1 - White, 3<br />

DATA 0 - Green, 4<br />

RX (NO) - Orange, 5<br />

RX (COM) - Blue, 6<br />

EGND- Brown, 7<br />

OPTION - Yellow, 8<br />

Use as Required<br />

LOCK NEG - Violet, 9<br />

Red<br />

LOCK POS - Gray, 10<br />

Red/Green<br />

Tape Purple/Black<br />

DPS (NC) - Pink, 11<br />

Wires (Unused)<br />

DPS (COM) - Tan, 12<br />

120 VAC<br />

To NC Fire Alarm Contacts<br />

H<br />

F2<br />

FA<br />

F1<br />

H<br />

N<br />

G<br />

120 VAC Input Fire Alarm Contacts<br />

HES<br />

24 VDC Positive Outputs<br />

24 VDC Negative Outputs<br />

2001M<br />

P1<br />

P2<br />

P3<br />

P4<br />

R1<br />

R2<br />

R3<br />

R4<br />

Black<br />

Black<br />

*IMPORTANT: Pin 7 must be tied to earth ground in the access control panel.<br />

Wiring in accordance with the NEC, ANSI/NFPA 70<br />

Fail secure installations are subject to approval of local AHJ<br />

P22 GND<br />

P23 PWR<br />

P23 DATA 1<br />

P23 DATA 0<br />

P106 REX (+)<br />

P106 REX (-)<br />

P105 DS COM<br />

P105 DS NO<br />

ALTRONIX NETWAY1<br />

ALTRONIX<br />

POWER INPUTS<br />

NON-POLAR<br />

P106 DOOR MON (+)<br />

P106 DOOR MON (-)<br />

Fail secure installations shall permit use of Listed panic hardware to allow emergancy<br />

exit <strong>from</strong> the protected area.<br />

Failure to follow proper ESD safe grounding procedures could lead to equipment failure.<br />

*UL294 is a United States based standard.<br />

ALTRONIX<br />

RJ45 PORTS<br />

IN<br />

IN used for<br />

Networking/<br />

Monitoring<br />

Connection<br />

CAT5e OR<br />

GREATER<br />

CABLE<br />

RJ45<br />

PORT<br />

HID EDGE E400/<br />

ES400<br />

OUT<br />

02/15/14<br />

18<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com

<strong>SE</strong> <strong>LP10</strong> Mortise Lock<br />

9<br />

Mechanical Operational Check<br />

For 82280-82283 & 82270-82273 Function mortise locks with cylinders:<br />

1. Insert key into cylinder and rotate: There should be no friction against<br />

lock case, wire harness or any other obstructions.<br />

2. The key will retract the latch: Key should rotate freely.<br />

3. When the deadbolt is thrown: Ensure that the key retracts both the<br />

deadbolt and the latch.<br />

4. Inside lever: When used, ensure it retracts both the latch<br />

and deadbolt (if provided).<br />

5. Close door: Ensure latch and deadbolt fully extend<br />

and do not bind.<br />

10<br />

Electrical Operational Check<br />

Note: Once electrical wiring has been successfully<br />

completed according to proper application, perform<br />

the following steps:<br />

1. Ensure lock is interfaced with Wiegand Test Box (WT1)<br />

to verify installation & wiring up to the point of hinge (frame side)<br />

2. Turn power ON.<br />

3. Present compatible credential and verify LED and<br />

sounder activity.<br />

4. Verify valid card read on WT1 or at the EAC panel.<br />

5. Verify system operation functions; i.e., when credential<br />

is presented to reader, the door should unlock.<br />

If the lock fails to operate when DC voltage is applied:<br />

1. Remove power.<br />

2. Confirm the polarity of the supply (i.e., ‘+’ is positive).<br />

If the lock is functioning opposite to the desired fail-safe or fail-secure<br />

operation:<br />

1. Remove power and check the “Fail” condition by attempting<br />

to rotate the outside lever (e.g. if fail-secure, the outside lever should be<br />

rigid with power removed).<br />

2. If the function is incorrect, remove the lock and repeat section 6, step 3<br />

(Dip Switch configuration).<br />

A8113C • 800-810-WIRE (9473) • www.sargentlock.com 19<br />

02/15/14 Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

SARGENT Manufacturing<br />

100 Sargent Drive<br />

New Haven, CT 06511 USA<br />

800-727-5477 • www.sargentlock.com<br />

Founded in the early 1800s, SARGENT ® is a market leader in locksets, cylinders, door closers, exit devices,<br />

electro-mechanical products and access control systems for new construction, renovation, and replacement applications.<br />

The company’s customer base includes commercial construction, institutional, and industrial markets.<br />

Copyright © 2014, Sargent Manufacturing Company, an <strong>ASSA</strong> <strong>ABLOY</strong> Group company. All rights reserved.<br />

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.<br />

<strong>ASSA</strong> <strong>ABLOY</strong> is the global leader in door opening solutions, dedicated to<br />

satisfying end-user needs for security, safety and convenience.<br />

A8113C - 2/14