vertical assessment iso/iec 17025:2005 laboratories - Sanas

vertical assessment iso/iec 17025:2005 laboratories - Sanas

vertical assessment iso/iec 17025:2005 laboratories - Sanas

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

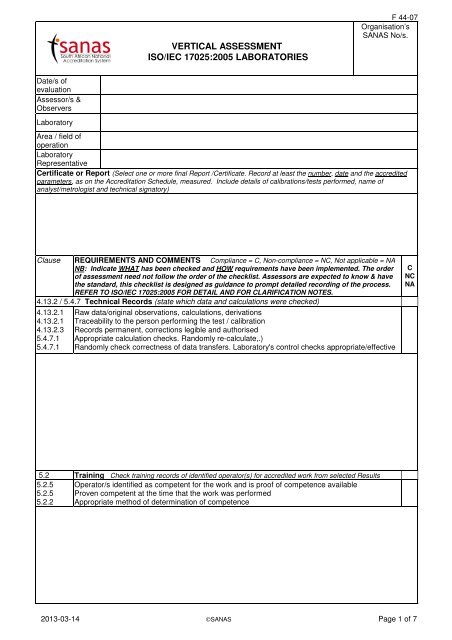

VERTICAL ASSESSMENT<br />

ISO/IEC <strong>17025</strong>:<strong>2005</strong> LABORATORIES<br />

F 44-07<br />

Organisation’s<br />

SANAS No/s.<br />

Date/s of<br />

evaluation<br />

Assessor/s &<br />

Observers<br />

Laboratory<br />

Area / field of<br />

operation<br />

Laboratory<br />

Representative<br />

Certificate or Report (Select one or more final Report /Certificate. Record at least the number, date and the accredited<br />

parameters, as on the Accreditation Schedule, measured. Include details of calibrations/tests performed, name of<br />

analyst/metrologist and technical signatory)<br />

Clause REQUIREMENTS AND COMMENTS Compliance = C, Non-compliance = NC, Not applicable = NA<br />

NB: Indicate WHAT has been checked and HOW requirements have been implemented. The order<br />

of <strong>assessment</strong> need not follow the order of the checklist. Assessors are expected to know & have<br />

the standard, this checklist is designed as guidance to prompt detailed recording of the process.<br />

REFER TO ISO/IEC <strong>17025</strong>:<strong>2005</strong> FOR DETAIL AND FOR CLARIFICATION NOTES.<br />

4.13.2 / 5.4.7 Technical Records (state which data and calculations were checked)<br />

4.13.2.1<br />

4.13.2.1<br />

4.13.2.3<br />

5.4.7.1<br />

5.4.7.1<br />

Raw data/original observations, calculations, derivations<br />

Traceability to the person performing the test / calibration<br />

Records permanent, corrections legible and authorised<br />

Appropriate calculation checks. Randomly re-calculate,.)<br />

Randomly check correctness of data transfers. Laboratory's control checks appropriate/effective<br />

C<br />

NC<br />

NA<br />

5.2 Training Check training records of identified operator(s) for accredited work from selected Results<br />

5.2.5 Operator/s identified as competent for the work and is proof of competence available<br />

5.2.5 Proven competent at the time that the work was performed<br />

5.2.2 Appropriate method of determination of competence<br />

2013-03-14 ©SANAS Page 1 of 7

F 44-07<br />

Additional Assessor Notes (This may be used for rough notes as well)<br />

2013-03-14 ©SANAS Page 2 of 7

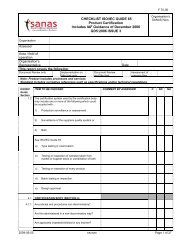

5.4.1-6 Performance capability of selected methods<br />

5.4.2<br />

5.4.3<br />

5.4.4<br />

5.4.5.2<br />

Proof of confirmation of proper operation of -standard methods,<br />

-laboratory developed methods<br />

-non-standard methods<br />

Methods validated and availability of performance capability<br />

5.4.5.3 Capability appropriate for use. Statistical application appropriate – (e.g. where relevant significant<br />

figure or rounding off policy for final results)<br />

5.4.6.2 Testing <strong>laboratories</strong> - Method uncertainty or specification tolerances<br />

5.4.6.1 Calibration <strong>laboratories</strong> - Results within MC and availability of supporting calculations<br />

F 44-07<br />

5.9 Assurance of validity of results<br />

eg a)-e) Indicate how the laboratory monitors results<br />

Appropriate and effective for ensuring the controlled performance of the accredited work<br />

Monitoring data suitably recorded (e.g. control charts), evaluated reviewed.<br />

Effective control limits or tolerances been established<br />

Evidence of actions implemented when breaches have occurred.<br />

5.9<br />

Proficiency testing/Interlaboratory compar<strong>iso</strong>ns / Calibration measurement audit sample<br />

(refer to F176 for detailed evaluation)<br />

Appropriateness for the work performed<br />

Evaluate results - action on anomalies or outliers.<br />

2013-03-14 ©SANAS Page 3 of 7

F 44-07<br />

Additional Assessor Notes (This may be used for rough notes as well)<br />

2013-03-14 ©SANAS Page 4 of 7

F 44-07<br />

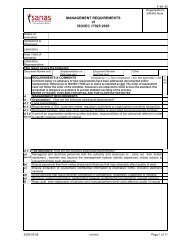

5.5 / 5.6 Calibration of equipment and/or standards used (Indicate which equipment/standards)<br />

5.5.2 Appropriateness of calibration and verification programmes, cover operating range<br />

5.5.8 Calibration status<br />

5.5.5 f) Records of calibration and verification complete, tolerances appropriate<br />

5.5.10 In-house verification techniques sufficient to ensure validity of calibration<br />

5.5.11 Suitable application of correction factors<br />

5.6.2.1<br />

5.6.2.2<br />

5.6.2.1.1<br />

5.6.3.1<br />

5.6.3.2<br />

5.6.3.3<br />

Traceability to national standards<br />

Traceability to appropriate measurement standards<br />

External calibration services used - demonstrated competence, measurement capability and<br />

traceability, certificates contain measurement results, measurement uncertainty<br />

Reference standards traceable calibration, not invalidate performance when used<br />

Reference materials -traceable, SI, CRMs. Internal reference materials - checked<br />

Intermediated checks - reference, primary, transfer and working standards<br />

5.5 / 5.6 Equipment maintenance and operation<br />

5.5.3 Instructions on use and maintenance<br />

5.5.5 a-h Records complete<br />

5.5.6 Handling/transport/storage/use to prevent contamination/deterioration of - equipment and<br />

5.6.3.4 - std/reference materials<br />

2013-03-14 ©SANAS Page 5 of 7

F 44-07<br />

Additional Assessor Notes (This may be used for rough notes as well)<br />

2013-03-14 ©SANAS Page 6 of 7

5.3 Accommodation and environmental conditions<br />

5.3.1 Critical areas of accommodation/environmental control which would affect the performance of the<br />

accredited work. (eg. Special room, Dust filtration, Positive pressure, Lighting, Static, Electric<br />

screening, Air lock entrance, Cleanliness, Vibration level, EMI, Dedicated Earth, etc.)<br />

5.3.2 Monitored, controlled and actioned when required<br />

5.3.3 Effective segregation of tests / equipment / standards and consumables<br />

5.8.4 Adequate storage areas<br />

F 44-07<br />

4.6 Purchasing of supplies (eg. Reference materials, critical consumables, etc.)<br />

4.6.2 Supplies verified prior to use to meet the quality criteria as required for the methods accredited<br />

4.6 System ensure supplies for the uninterrupted performance of work documented and effective -<br />

e.g. stock control, requisitioning, ordering and storage<br />

5.8 Handling of calibration or test items<br />

5.8.2 Uniquely identified, ensure that there can be no confusion regarding the identify at any time<br />

5.8.3 Condition of the item noted, where applicable<br />

5.8.4 System avoid deterioration/damage during storage, handling, preparation, and calibration or test<br />

5.10<br />

Reporting of the results (See detailed requirements in 5.10 of ISO/IEC <strong>17025</strong>:<strong>2005</strong> or SANAS<br />

F49)<br />

If not full report, written agreement and all data available in laboratory<br />

Signed:<br />

Technical Assessor<br />

Signed :<br />

Lead Assessor<br />

Date<br />

2013-03-14 ©SANAS Page 7 of 7