SmartTimer II 2011.pdf - Pristine Water Solutions Inc.

SmartTimer II 2011.pdf - Pristine Water Solutions Inc.

SmartTimer II 2011.pdf - Pristine Water Solutions Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

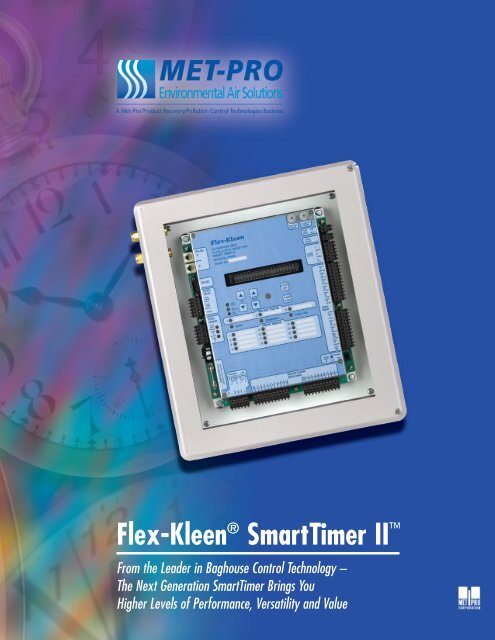

Flex-Kleen ® <strong>SmartTimer</strong> <strong>II</strong> <br />

From the Leader in Baghouse Control Technology –<br />

The Next Generation <strong>SmartTimer</strong> Brings You<br />

Higher Levels of Performance, Versatility and Value

Flex-Kleen’s <strong>SmartTimer</strong> <strong>II</strong> Sets a New<br />

Standard for Pulse-Jet Dust Collector<br />

System Control and Communications<br />

Today’s plant operations require higher levels of efficiency and reliability at even lower costs.<br />

The <strong>SmartTimer</strong> <strong>II</strong> will help you achieve these goals. From the industry leader known for<br />

providing innovation in baghouse control technology, the <strong>SmartTimer</strong> <strong>II</strong> has been designed<br />

and engineered to bring you outstanding programming flexibility, higher levels of control, the<br />

ability to handle larger collectors, extended data logging and the capability to consolidate<br />

multiple control devices into a single cost-effective package.<br />

The <strong>SmartTimer</strong> <strong>II</strong> is less costly than complex PLC’s with similar control capability. Features include:<br />

• Three cleaning modes: continuous operation, demand<br />

pulse, and self-adjusting<br />

• Compact, integrated alternative to separate pressure<br />

switch/timer assemblies<br />

• Remote monitoring and adjusting of dust collector<br />

operating conditions<br />

• Up to fifteen auxiliary alarms to monitor high hopper<br />

levels, broken bag detection, zero speed switch, low<br />

air header pressure, high temperature sensor, etc.<br />

• Ability to identify a faulty solenoid valve even when<br />

there is more than one solenoid wired to a single output<br />

• Warning when the differential pressure level reaches<br />

pre-programmed safety set points<br />

• Warning when the pre-programmed low differential<br />

set point is no longer attainable<br />

• Modular wiring buss for easier wiring<br />

• Dual voltage input (120/240)<br />

• 20 output sequencer capable of pulsing up to 120<br />

solenoid valves<br />

• RS 232/485 serial communications ports which<br />

deliver the most cost effective remote monitoring plus<br />

control and interconnectability<br />

• Timers which can be connected in series with each<br />

timer uniquely addressable<br />

• 20 character alpha-numeric display to provide users<br />

with more concise and informative visual output in<br />

three languages (English, French or Spanish) and user<br />

selectable units of measure (English or metric)<br />

• Up to 365 days data logging capability with data<br />

resolution options<br />

• Discrete alarms programmable for each input (variable<br />

alarm output)<br />

• Optional program password protection<br />

• Sensor and alarm inputs utilizing a tri-color status<br />

indicator to provide visual display of inputs<br />

• 24 hour, 7-event programmable timer for maximum<br />

flexibility to provide adjustable controls to meet your<br />

changing conditions<br />

• Differential pressure transourcer with calibration feature<br />

to help support Title V – clean air act required<br />

• Built-in connection for J-type thermocouple to allow<br />

temperature measurement/logging if needed<br />

• Ability to be retrofitted to any manufacturer’s pulse-jet<br />

dust collector, including cartridge-type collectors<br />

<strong>SmartTimer</strong> <strong>II</strong> is the biggest advancement in pulse-jet control technology in the last decade.<br />

To learn more about the <strong>SmartTimer</strong> <strong>II</strong> or other Flex-Kleen pro<br />

call 1-800-621-0734, or visit ou

A new and unique blend of the latest control and communications technologies provides reduced<br />

air and maintenance costs, maximum bag life, expanded programmability similar to more<br />

complex PLC’s, long-term data logging and economical multi-system connectability/control...<br />

...all this high performance is delivered with outstanding cost effectiveness.<br />

• 20 CHARACTER ALPHANUMERIC<br />

DISPLAY – pre-programmed messages<br />

provide easy-to-read visual information<br />

on dust collector and auxiliary equipment<br />

operation<br />

• VACUUM FLUORESCENT DISPLAY – produces<br />

clear, glare-free, message displays<br />

• REMOTE MONITORING AND<br />

CONTROLS – Monitor and adjust dust<br />

collector operating conditions from a<br />

remote computer location via the<br />

RS-232 and RS-485 serial ports<br />

• CLEANING CYCLE LED INDICATORS –<br />

provides visual display of current<br />

cleaning mode<br />

• KEY PAD – simplified set-up/programming<br />

to suit individual applications<br />

• THREE SEPARATE OPERATION MODES<br />

(CONTINUOUS OPERATION, DEMAND<br />

PULSE, AND SELF ADJUSTING) – choose<br />

the most cost-effective dust collector<br />

operating mode for your process<br />

conditions<br />

• CYCLE DOWN FUNCTION – provides<br />

additional cleaning cycles of the dust<br />

collector after shutdown of fan<br />

• 120/240 VAC INPUT CAPABILITY<br />

• INTEGRATED PRESSURE SENSOR – compact, lowcost<br />

alternative to a separate pressure switch and<br />

gauge<br />

• PRESSURE CONNECTIONS – hose barbs allow<br />

quick connections<br />

• USER-FRIENDLY INTERFACE – provides easy visual<br />

reference for system status and alarm inputs<br />

• J-TYPE THERMOCOUPLE INPUT<br />

• 4-20 MILLIAMP TRANSMITTER –<br />

provides input for remote display of dust<br />

collector’s current operating pressure<br />

• 4-20 MILLIAMP INPUTS – 3 discrete<br />

channels allow additional sensors to be<br />

monitored<br />

• AUXILIARY ALARM INPUTS – provides<br />

up to 12 separate alarms for remote<br />

monitoring of dust collector auxiliaries<br />

(i.e., rotary valve, screw conveyor, compressed<br />

air pressure, Broken Bag<br />

Detector, high temperature sensor, etc.)<br />

• ADJUSTABLE PRESSURE ALARMS –<br />

provides alarm when pre-set safety<br />

pressure levels are reached or when<br />

low/off set point is unattainable<br />

• PROGRAM CLOCK/DATA LOGGER/7-<br />

EVENT TIMER – provides ability to<br />

retrieve historical data up to 365 days<br />

and gives user maximum flexibility to<br />

meet a variety of plant operating conditions<br />

• 20 SOLENOID OUTPUTS – connects up<br />

to 120 air solenoids<br />

FS Series Broken Filter Bag Detector<br />

Connecting your microprocessor-based <strong>SmartTimer</strong> <strong>II</strong> to Flex-Kleen’s FS Series Broken Bag<br />

Detector, can provide visual information to allow detection and location of leaking filter bags.<br />

ducts & services, contact your local Flex-Kleen Representative,<br />

r web site at www.mpeas.com

Technical Data Sheet – <strong>SmartTimer</strong> <strong>II</strong> <br />

Factory Default Settings<br />

Lo Pressure Alarm<br />

0.5" water column<br />

Lo Pressure<br />

2" water column<br />

Hi Pressure<br />

4" water column<br />

Hi Pressure Alarm<br />

14" water column<br />

Output Quantity 20<br />

Off Time<br />

15 seconds<br />

On Time<br />

0.05 seconds<br />

Output configuration Manual<br />

Units<br />

<strong>Inc</strong>hes (metric optional)<br />

Unattainable Lo Pressure 15 cycles<br />

Display Language<br />

English (French or Spanish option)<br />

Cycle Down<br />

Not Selected<br />

Number of Cycles 2<br />

4-20 mA Input #1 Enabled as Diff. Press. Input-major alarm<br />

calibration/Alarm Setpts. = 0<br />

4-20 mA Input #2 Enabled as Manifold Input-minor alarm<br />

calibration/Alarm Setpts. = 0<br />

4-20 mA Input #3 Enabled as Emission Input-minor alarm<br />

calibration/Alarm Setpts. = 0<br />

Alarm Output #1<br />

Enabled (normally open relay logic)<br />

Alarm Output #2<br />

Enabled "MM"(Major & Minor Alarms)<br />

normally open relay logic<br />

Alarm Inputs #1-12<br />

Enabled (Y) Major Alarm<br />

All Alarm Delays<br />

000 seconds<br />

Temp. Sensor Input<br />

Disabled (Major Alarm-Fahrenheit scale)<br />

High Resolution Data 7 days<br />

24 Hour Clock Factory Set-Current Time (CST)<br />

7 Event Timer Day On, Day Off = SU<br />

all other parameters = 0<br />

Password Required<br />

No<br />

Password<br />

0000 for field settable password<br />

Factory Set Password 9876<br />

Factory Default Restore Yes (see manual)<br />

Input Operating Electrical<br />

Voltage<br />

Dual Selection (120-135 VAC 50/60Hz<br />

or 210-270 VAC 50/60Hz)<br />

Analog Inputs<br />

Three 4-20 mA current loop inputs:<br />

Input #1 – Programmable as Diff. Pressure Sensor or Aux. Analog Input<br />

Input #2 – Programmable as Manifold Sensor or Aux. Analog Input<br />

Input #3 – Programmable as Emissions Sensor or Aux. Analog Input<br />

(Accuracy of Current Loops: +/- 0.3 mA of Full Scale)<br />

Temperature Sensor: One J type Thermocouple<br />

(sensing range -40 to 700°F +/- 10°F<br />

Maximum Ratings at 135 or 270 VAC Input Voltage<br />

Power Consumption<br />

By-pass Switch Open circuit Voltage<br />

By-Pass Switch short circuit current<br />

Alarm Input Switch open Circuit Voltage<br />

Alarm Input Switch short circuit current<br />

Outputs<br />

Maximum Solenoid Output<br />

Solenoid Output Voltage Drop<br />

Solenoid Output Type<br />

Solenoid Output Short<br />

circuit protection<br />

Alarm Outputs (2) Type<br />

Cycle Down Output Type<br />

3 mA<br />

18 VDC<br />

3 mA<br />

18 VDC<br />

3 mA<br />

200VA or Watts at max. duty cycle<br />

2.5 VAC @ 200 VA Load<br />

Solid State TRIAC<br />

3AG Fast 3A/250 VAC Fuse<br />

FORM A Relay Contact rated 3A @ 250 VAC<br />

FORM A Relay Contact rated 3A @ 250 VAC Output<br />

Monitoring<br />

Pressure Transducer<br />

Current Sense Monitor<br />

Minimum Solenoid Load<br />

Detects up to 3 solenoids per<br />

Output, detects open solenoid<br />

w/33% current drop.<br />

4-20mA output tracks either<br />

on-board or ext. press. Sensor<br />

5 VA for auto output sense to<br />

detect load present<br />

Air Pressure Measurement<br />

Sensor Type<br />

Silicone Piezoresistive w/dual inlets<br />

Measurement Range 0.0 to 25.0 <strong>Inc</strong>hes of <strong>Water</strong> with +/- 5%<br />

of full scale over Temp. and Voltage Range<br />

Maximum Continuous Pressure 10 PSI (276.8 inches of water)<br />

Burst Pressure<br />

100 PSI (2768 inches of water)<br />

Zero Offset & Gain<br />

Compensates for long-term drift<br />

Calibration<br />

of sensor up to +/- 1.2" water<br />

NOTE: All pressure settings need to be verified after changing<br />

units selection from English to Metric.<br />

Timing<br />

Solenoid On Time Range<br />

Solenoid Off Time Range<br />

Timing Accuracy<br />

Solenoid On Time Synchronized<br />

to the AC Line Cycle<br />

Down Power Cycle Delay<br />

Display<br />

Type<br />

18x Tri-Color LED’s<br />

(R/G/Y)<br />

1x Bi-Color(R/Y) LED<br />

2x Green LED’s<br />

3x Red LED’s<br />

STD .05 - .20 seconds<br />

EXT .05 - 3.00 seconds<br />

3 – 999 seconds<br />

-2ms / +20ms or +/-1% whichever is greater<br />

1 – 60 seconds programmable<br />

20-Character Dot Matrix (0.25" high char.)<br />

Vacuum Fluorescent<br />

12x Alarm Inputs, 3x Analog Input Alarms,<br />

1x Temp. Alarm, 1x System Alarm, 1x Comm. Alarm<br />

On Demand Mode<br />

Continuous Clean & Self-Adjust Mode<br />

Major & Minor Alarms, Cycle Down Relay<br />

Current Loop<br />

Type 4-20 mA is sourced by this controller; signal represents<br />

0 - 25" diff. pressure with +/- 1% accuracy<br />

Serial Communications<br />

Type:<br />

RS-232<br />

Terminal: ANSI OR ANSI Terminal Emulation Program<br />

Mode:<br />

9600 Baud, 8 Data Bits, 1 Start Bit, 1 Stop Bit, No Parity<br />

Connector Type: 9 Pin Male HD Style<br />

Interface Cable: Null Modern Serial Cable when interfaced to IBM<br />

compatible computer<br />

Type:<br />

RS-485<br />

Terminal: ANSI OR ANSI Terminal Emulation Program<br />

Connector Type: Duplex RJ-11 Modular Jacks<br />

Data Logging<br />

7 days of high resolution data and 365 days of low resolution data.<br />

14 days of high resolution data and 340 days of low resolution data.<br />

21 days of high resolution data and 325 days of low resolution data.<br />

28 days of high resolution data and 300 days of low resolution data.<br />

Environmental<br />

Operating Temperature Range<br />

Warm-up Delay Temperature<br />

Protection<br />

-40 to 149°F, (-40 to 65°C)<br />

Less than 50°F (10°C)<br />

RTV Conformal Coating (for<br />

Humidity and Vibration)<br />

Important Notice to Users: Our timers are capable of use in a wide array of devices and in various applications. Any device or system incorporating a timer should be so designed<br />

that, in the event of failure, malfunction or normal wear-out of the timer, the system will become inoperative in a manner which will prevent property damage or bodily injury.<br />

CAUTION:<br />

1. Do not mount controls in high vibration areas without shock mounts.<br />

2. Do not mount controls in areas of high dust or corrosive atmospheres without a protective enclosure.<br />

3. Do not use a converter or inverter for the power source.<br />

4. Do not mount control in high transient voltage areas without an isolation transformer.<br />

5. Do not leave control box open.<br />

6. Do not allow a local repair shop to repair the controls, as we employ some very sophisticated components that could be further damaged. For service, call us directly at:<br />

800-621-0734.<br />

Flex-Kleen offers NEMA 4X-FPR enclosures with full view cover as a standard for mounting our controller. These enclosures are made of polyester and have a continuous hinge<br />

cover. The finish is gray. Other NEMA classified enclosures available.<br />

NOTE: In order to keep abreast of the latest technology, Flex-Kleen reserves the right to change components and/or design of controls without notice.<br />

45 North Bradon Drive, Glendale Heights, IL 60139 • Tel: 1-800-621-0734 • Email: info@mpeas.com • Website: www.mpeas.com<br />

©2012 Flex-Kleen. All rights reserved. 15-5003 911